oil always results in carbonized motors, burned-out bearings, overheating and loss of power, or other serious

troubles. Like every other commodity, the payment of a fair price secures the best article.

In winter, a thinner grade of oil may be used than in summer. A tendency to overheat, which is indicated by

a rapid evaporation of the water from the radiator, may often be eliminated by using a medium grade, rather than

a thin grade, of motor oil of good quality.

Diagnosis of Common Trouble

IF MOTOR STOPS.

1. Out of gasoline.

2. Disconnected spark plug cables or other loose electrical connections.

3. Dirty contact points in the distributor or accumulation of oil or dirt on the

underside of the distributor cover.

4. Out of motor oil, indicated usually by knocking in the motor, followed by an abrupt stop. If this occurs,

do not attempt to use either the electric starter or hand crank until the motor has been allowed to cool off.

Kerosene should be applied to the pet cocks while the motor is still warm. This usually is a serious matter, and

the motor should have the attention of a good mechanic before attempting to put the car into service again.

5. Cannot crank motor. Frozen water pump. Seized motor bearings, due to lack of oil. Transmission

engaged.

REASONS FOR MOTOR MISSING.

1. Short circuited spark plug. Points not adjusted to .025".

2. Partially short circuited or broken secondary terminals.

3. Poor contact between the various ends and clips of wiring.

4. Loss of compression in one or more cylinders. Valves may be stuck. Valves may need regrinding or

reseating. Valve springs may be weak or broken.

5. Water in gasoline—the motor runs spasmodically. (This is the most difficult to separate from other

causes, and should be one of the last things looked for.)

6. When motor misses, you may locate the missing cylinder by opening the priming cock on top of the

cylinders, one at a time. After replacing with a new one the spark plug in the missing cylinder, or with one from

another cylinder, you will have to determine whether missing is caused by defective plugs or wires leading to

same. If the trouble is still continuing, turn over the motor slowly by hand in an endeavor to detect a defect in the

compression in the different cylinders.

7. If missing is not due to any of the items mentioned above, there may be an air leak between the carburetor

and intake manifold, or between the manifold and cylinder block.

8. If any wires in the entire electrical system have been tampered with at any time, refer to the wiring

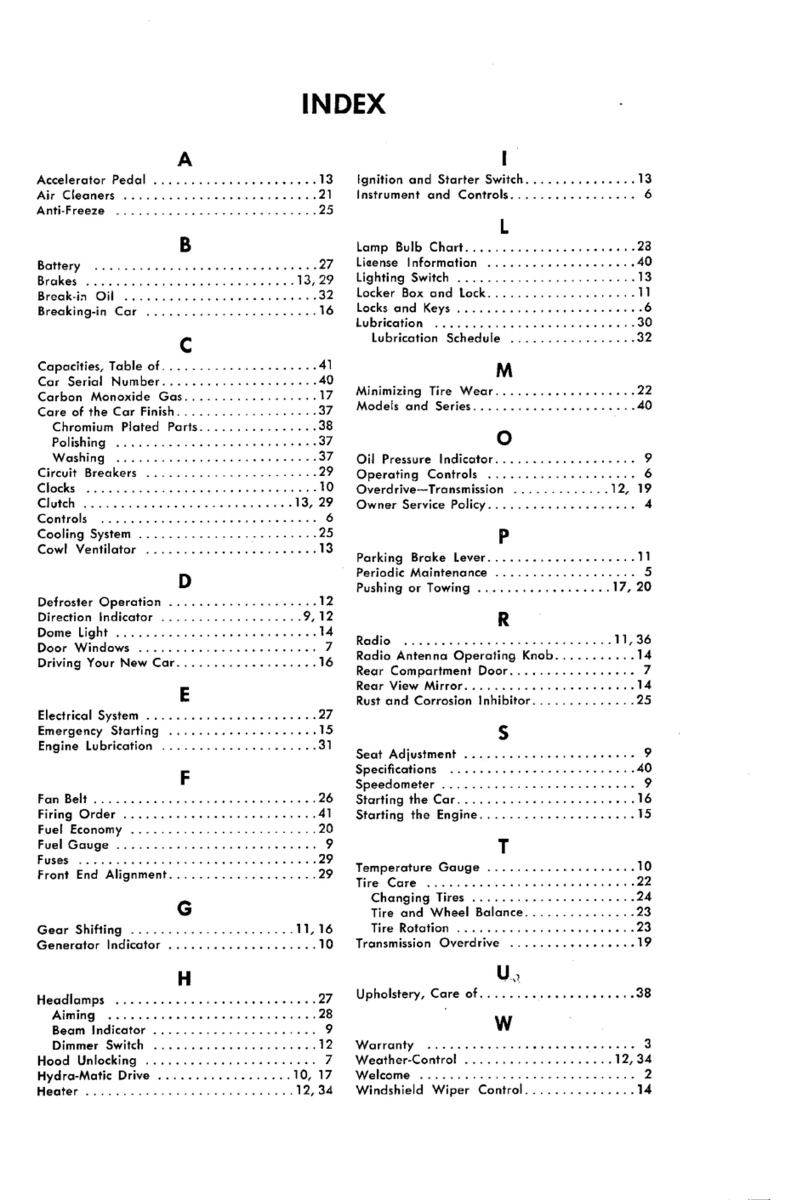

diagram in this Instruction Book. Page 40.

IF MOTOR LACKS POWER.

The motor will run but not pull on grades or under heavy loads.

1. Loss of compression due to leaky valves.

2. Too rich a mixture through some defect in carburetor, probably flooding due to grit under float valve.

3. Late Ignition. (See directions for timing of the distributor, page 42, retarded spark.)

4. Lack of water in radiator or oil in motor causing the motor to run hot.

5. Lack of gasoline. If lack of gasoline through stoppage of pipe, the motor will spit back through

carburetor when throttle is opened.

6. Poor grade of gasoline, in cold weather, causing too weak a mixture.

7. Dragging brakes. See that the car can be rolled by hand easily or that it will coast down hill when clutch

is released and not slow down. Feel the brake drum with your hand to determine over-heating.

8. Flat tires.

9. Stoppage of the jets in carburetor due to dirt or sediment.

6