ElectroVapRTH

Steam Output

Installation

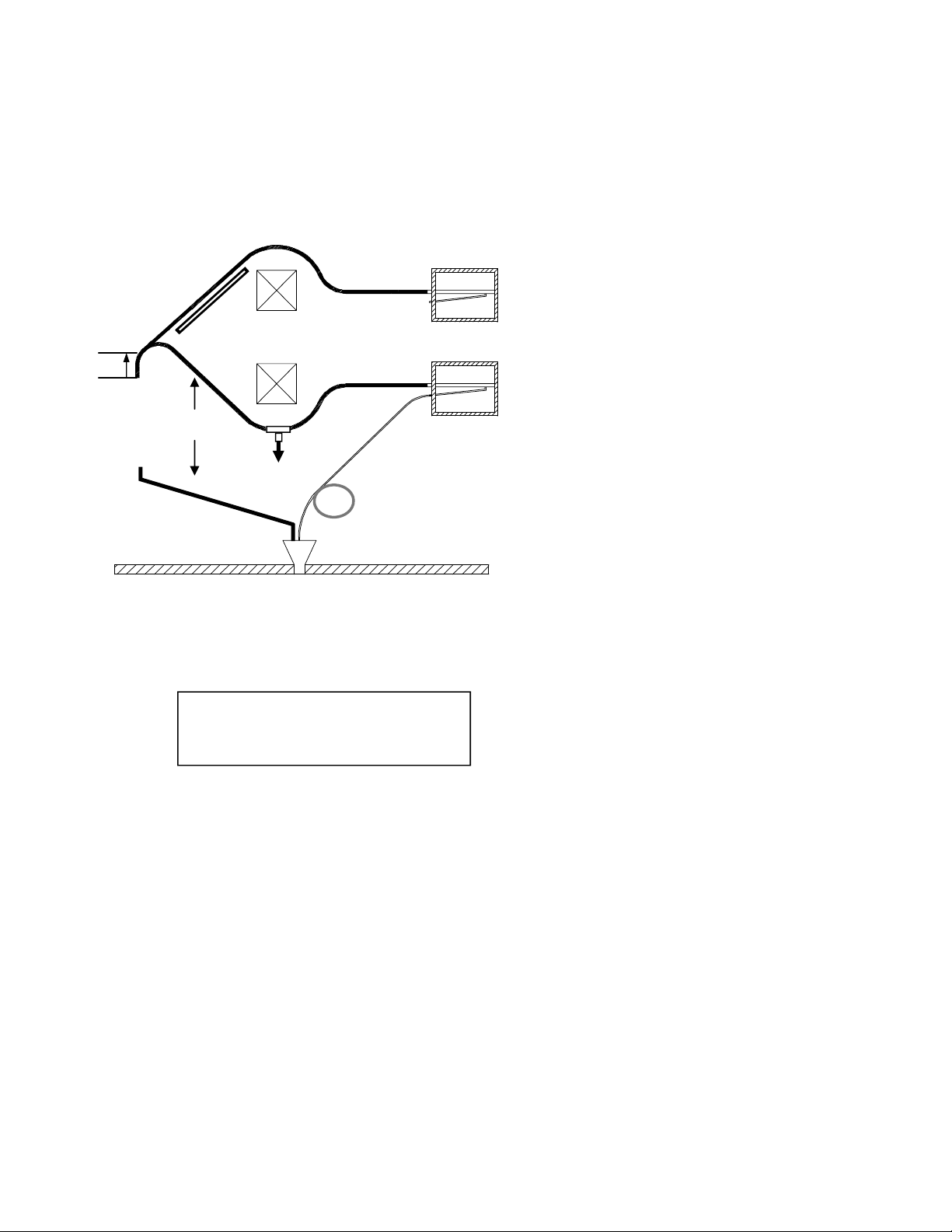

Use only high quality, low pressure steam

hose which is able to withstand steam

humidifier temperatures.

The steam hose alone may be used for

distances up to 6 ft. If the distance from the

humidifier to the duct is greater than 6ft.,

insulated rigid copper tube should be used,

with sections of steam hose for connectors.

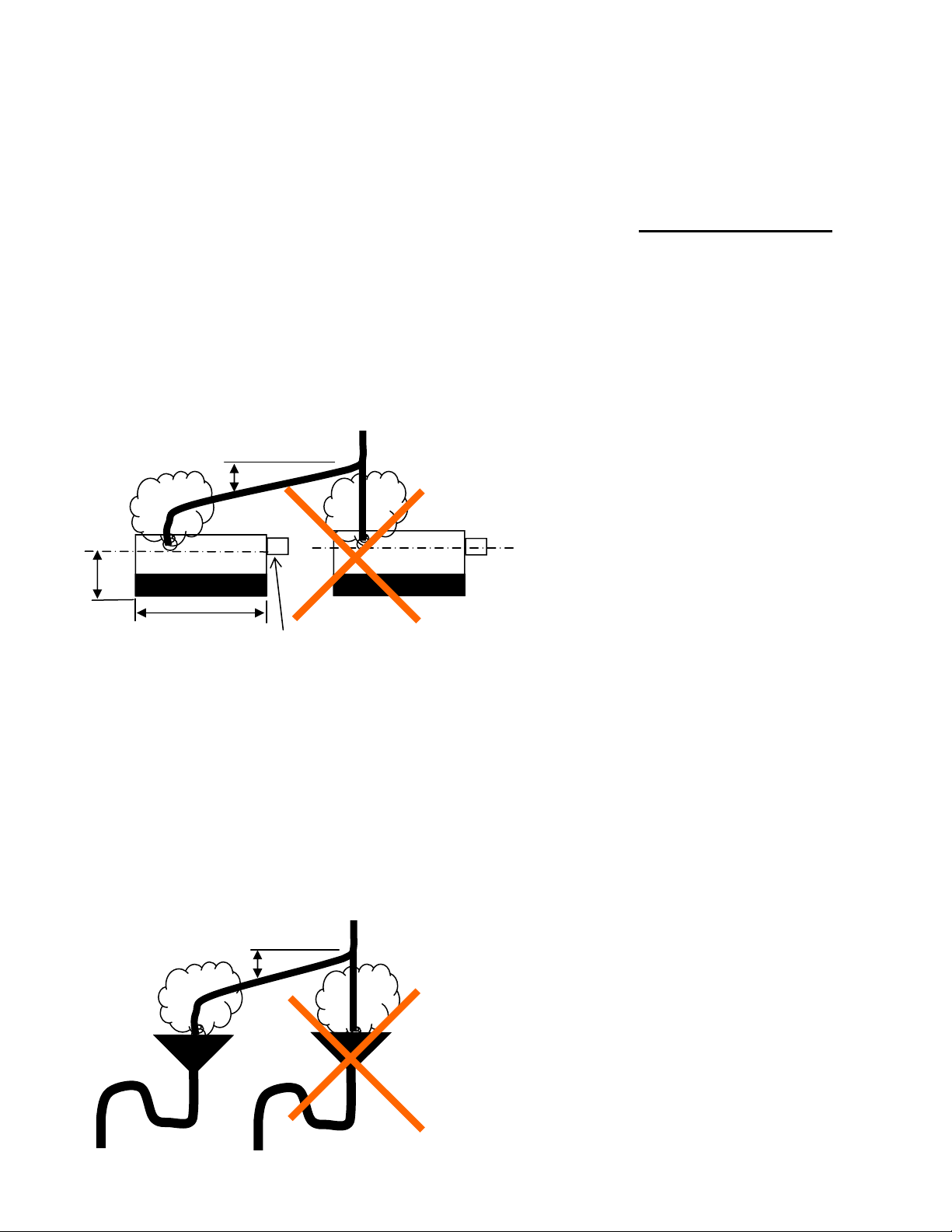

All steam lines must be pitched so that

condensate which forms in the lines will be

drained back to the steam generator or to a

separator & trap in the steam line.

a. Provide vertical rise at least 20 in. before

bending the hose to horizontal.

b. The steam hose should be rigidly suported

to promote rapid draining.

c. Steam hose (radius of bend should be 30

in. Minimum.)

d. Duct work.

e. Obstacle.

f. A condensate separator and trap is needed

at this point to drain condensate.

g. 8 mm condensate hose. Fill the

condensate hose trap with water before

starting the humidifier to prevent steam

from escaping.

h. Humidifier height (see page 3. )

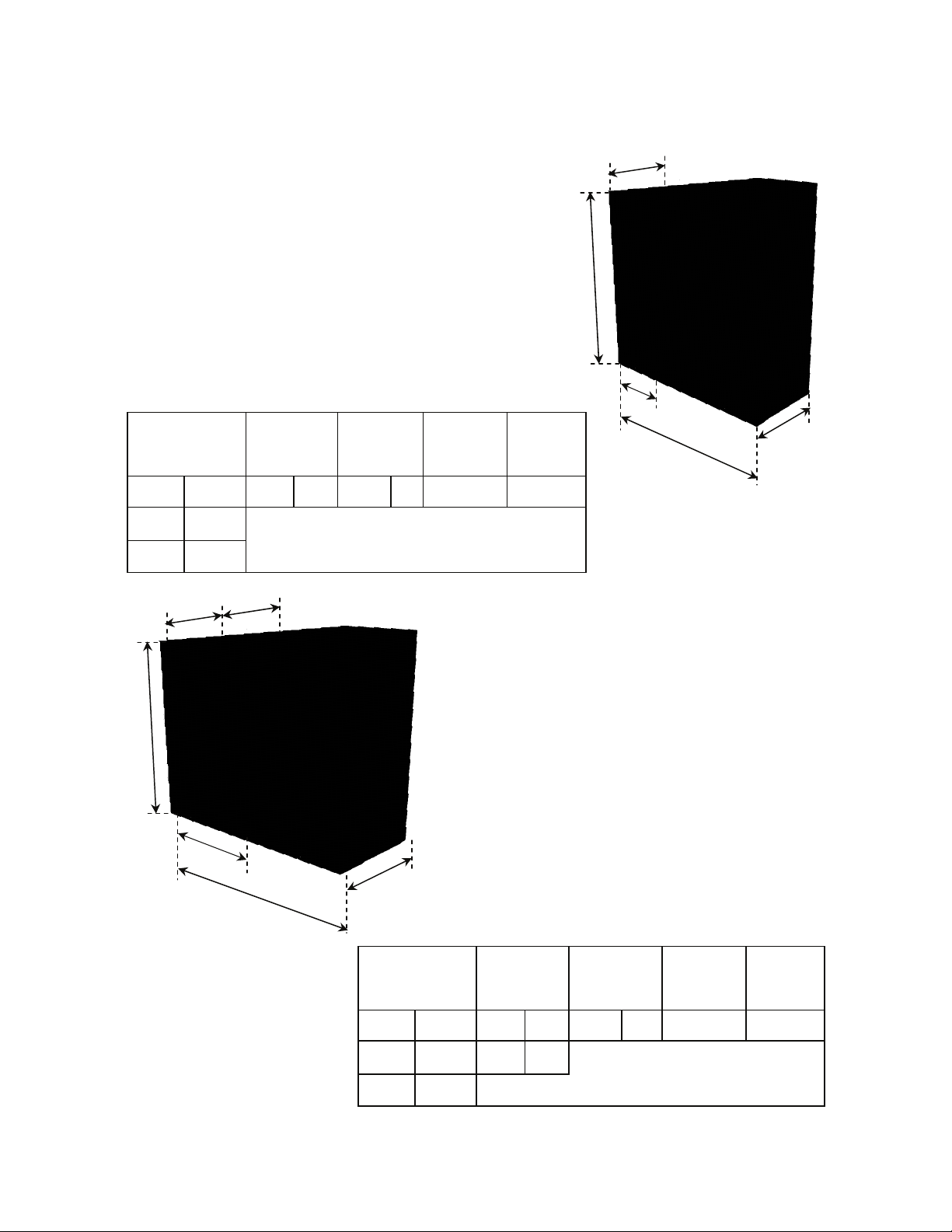

Number of steam outlets:

RTH 5 to 20 = 1 outlet 60mm ( 2.4 ‘’)

Reducer may be used (see page 9)

RTH 30 to 50 = 1 outlet 60mm (2.4’’)

RTH 60 to 100 = 2 outlets 60mm (2.4’’)

The RTH humidifier can work with duct

pressure up to 10’’ of water column.

b

h

g

f

To Drain

c

e

Steam Hose Sizes

40mm (1.6 in.) Dia. for RTH 5 to 20

60mm (2.4 in.) Dia. for RTH 30 to 100

7