Safety

Safety definitions

Warnings, cautions and notes are used to point out

specially important parts of the manual.

WARNING: Used if there is a risk of injury or

death for the operator or bystanders if the

instructions in the manual are not obeyed.

CAUTION: Used if there is a risk of damage

to the product, other materials or the

adjacent area if the instructions in the

manual are not obeyed.

Note: Used to give more information that is necessary in

a given situation.

General safety instructions

WARNING: Read the warning instructions

that follow before you use the product.

• This product produces an electromagnetic field

during operation. This field may under some

circumstances interfere with active or passive

medical implants. To reduce the risk of serious or

fatal injury we recommend persons with medical

implants to consult their physician and the medical

implant manufacturer before operating this product.

• This product is a dangerous tool if you are not

careful or if you use the product incorrectly. This

product can cause serious injury or death to the

operator or others.

• It is very important that you read and understand the

contents of this operator’s manual. If you feel

uncertainty about a work situation or the operating

procedures after you read the operator's manual,

speak to a service agent before you continue.

• Under no circumstances may the design of the

product be modified without the permission of the

manufacturer. Do not use a product that appears to

have been modified by others and only use

accessories recommended for this product. Non-

authorized modifications and/or accessories can

result in serious personal injury or the death of the

operator or others.

• Do a check of the product before use. Do not use a

defective product. Do the safety checks,

maintenance and service instructions described in

this manual.

Safety instructions for assembly

WARNING: Read, understand and obey

these instructions carefully before you use

the product.

• The complete clutch cover and shaft must be fitted

before the machine is started, otherwise the clutch

can come loose and cause personal injury.

• The only accessories you can operate with this

product are the cutting attachments we recommend.

• Use approved protective gloves.

• Make sure that you assemble the protective cover

and shaft correctly before you start the engine.

• To operate the product safely and prevent injury to

the operator or other persons, the product must

always be attached correctly to the harness.

Safety instructions for operation

WARNING: Read the warning instructions

that follow before you do maintenance on

the product.

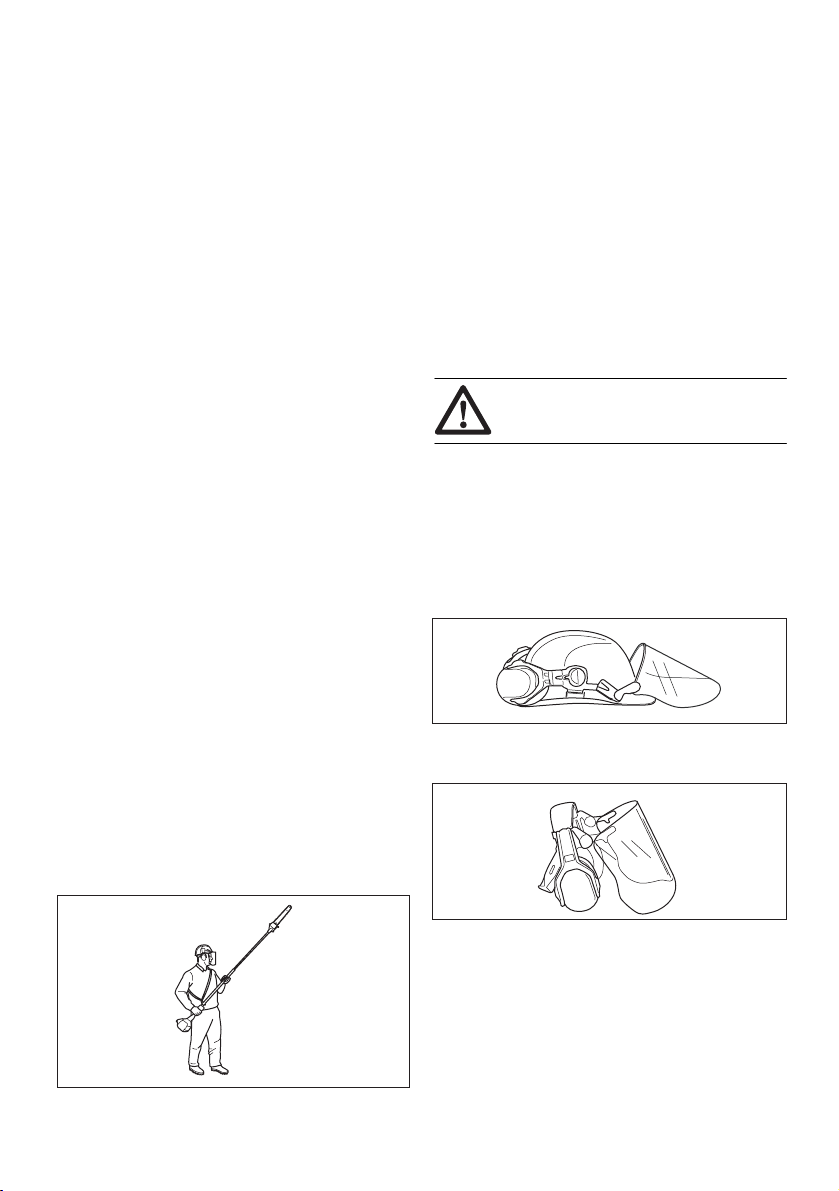

• Use personal protective equipment.

• This product is not electrically insulated. If the

product touches or comes close to high-voltage

power lines it could lead to death or serious bodily

injury. Electricity can jump from one point to another

by arcing. The higher the voltage, the greater the

distance electricity can jump. Electricity can also

travel through branches and other objects, especially

if they are wet. Always keep a distance of at least 10

m between the product and high-voltage power lines

and/or any objects that are touching them. If have to

work within this safe distance you should always

contact the relevant power company to make sure

the power is switched off before you start work.

• Overexposure to vibration can lead to circulatory

damage or nerve damage in persons who have poor

circulation. Speak to your physician if you

experience symptoms of overexposure to vibration.

Such symptoms include numbness, loss of feeling,

tingling, pricking, pain, loss of strength, changes in

skin colour or condition. These symptoms usually

show in the fingers, hands or wrists. The risk

increases at low temperatures.

• The inside of the muffler contain chemicals that may

be carcinogenic. Avoid contact with these elements

in the event of a damaged muffler. Long term

inhalation of the engine’s exhaust fumes, chain oil

mist and sawdust can represent a health risk.

4

• Never use the machine indoors or in spaces lacking

proper ventilation. Exhaust fumes contain carbon

monoxide, an odourless, poisonous and highly

dangerous gas.