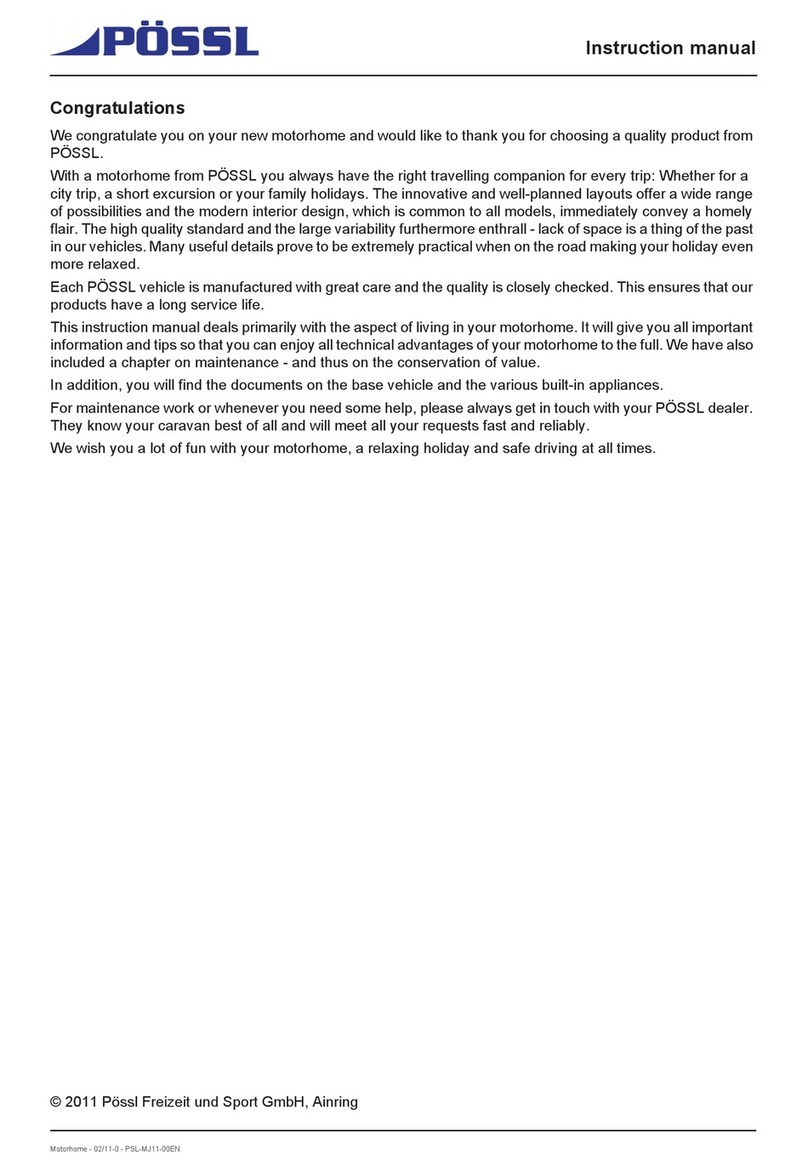

OPERATING PROCEDURES

LEVELING PROCEDURE

MP35.34

19NOV07

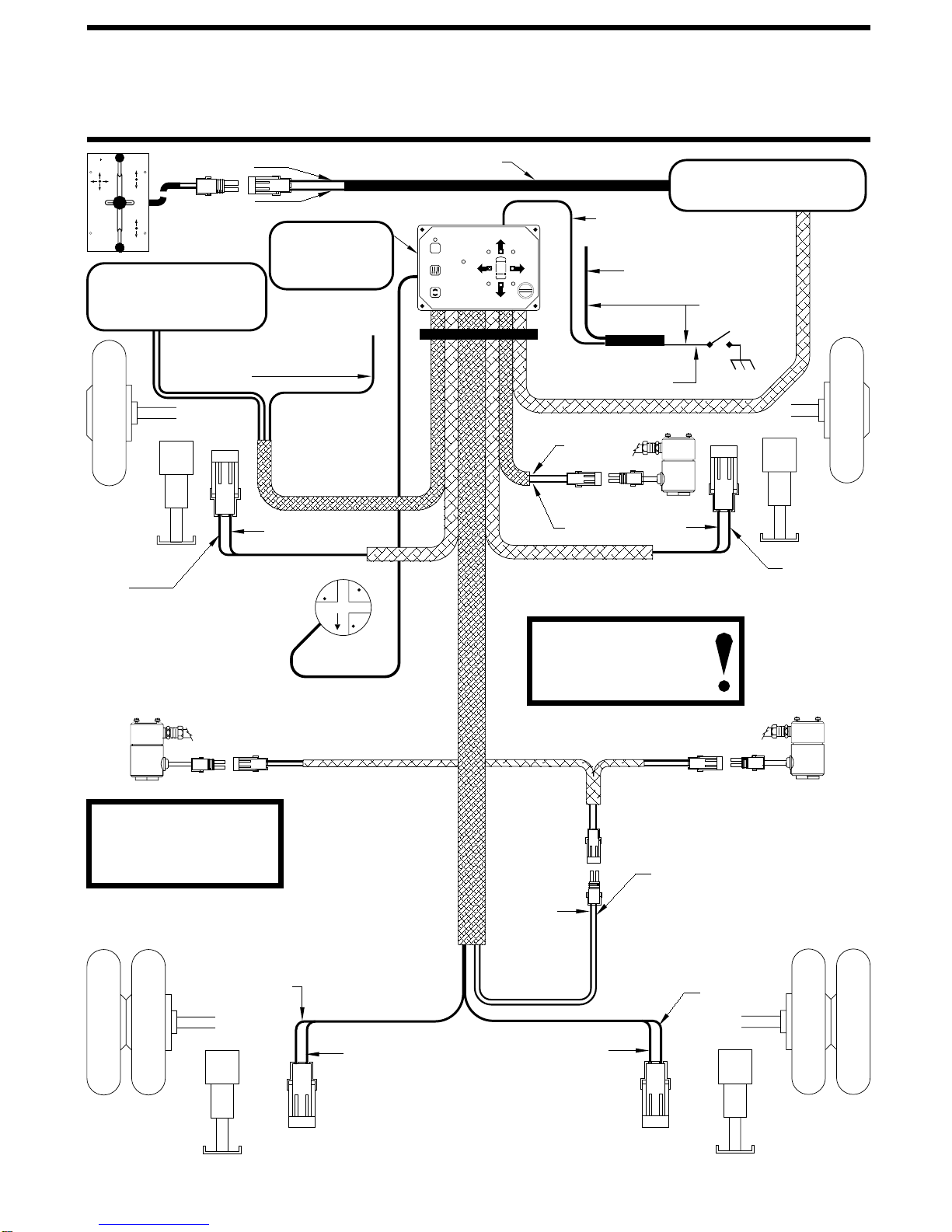

3. Push the "ON" button on the light plate. The POWER ON

light will be lit. 8. Push the "OFF" button on the light panel.

SITE SELECTION

1. Place gear selector in the parking position, apply park

7. After the vehicle is level, the jacks not used for leveling

may be extended until they touch the ground. This provides

additional stability against wind and activity in the vehicle.

Do this by pushing the jack control lever to the rear and/or

front as needed to extend any remaining jacks. Do not use

PARK/BRAKE" light will come on while the "ON" button is

pushed. The panel will not turn on if the park brake is not set.

REMOVING TIRES OR CRAWLING UNDER VEHICLE.

BLOCK FRAME AND TIRES SECURELY BEFORE

UNDERSTAND OPERATOR’S MANUAL BEFORE USING.

"CAUTION" OPERATE

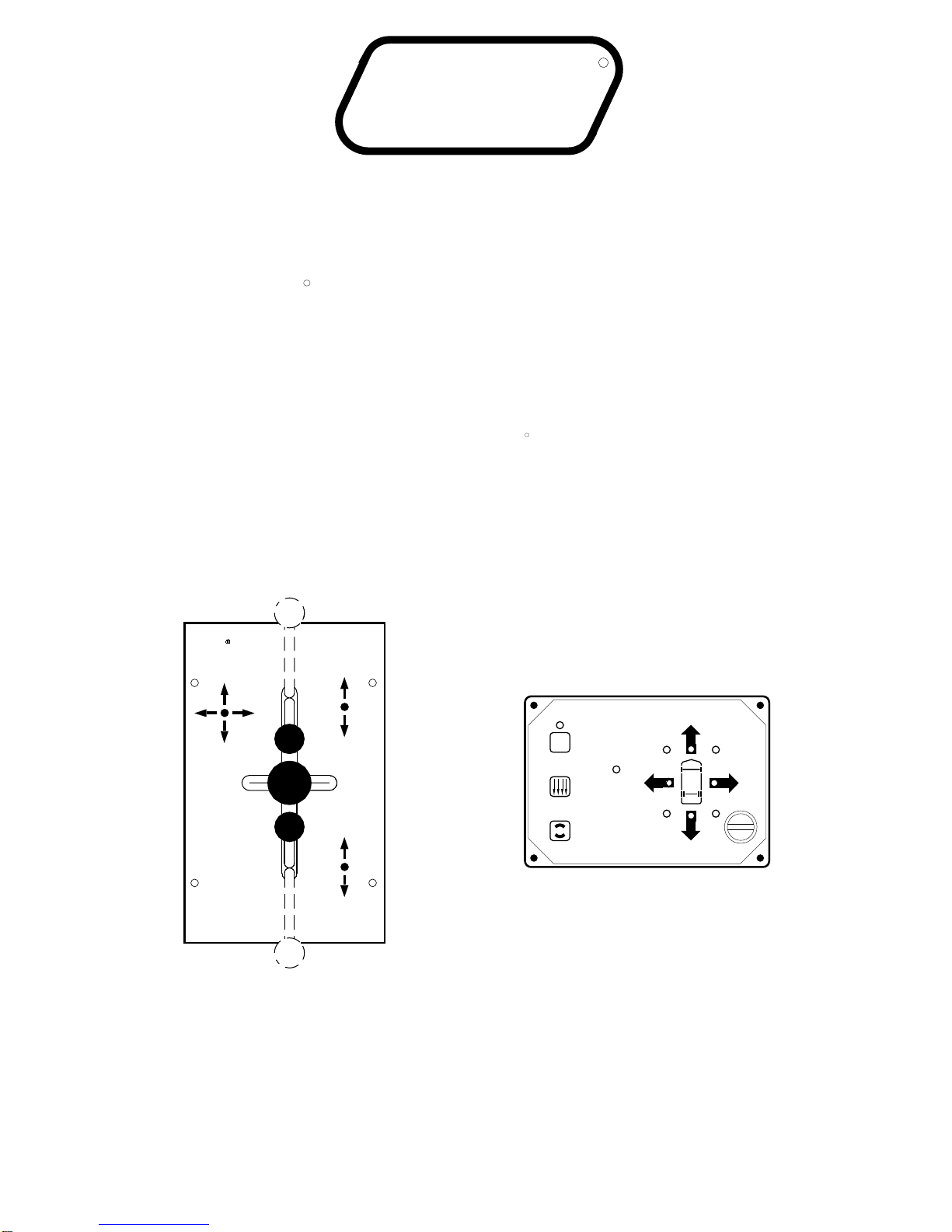

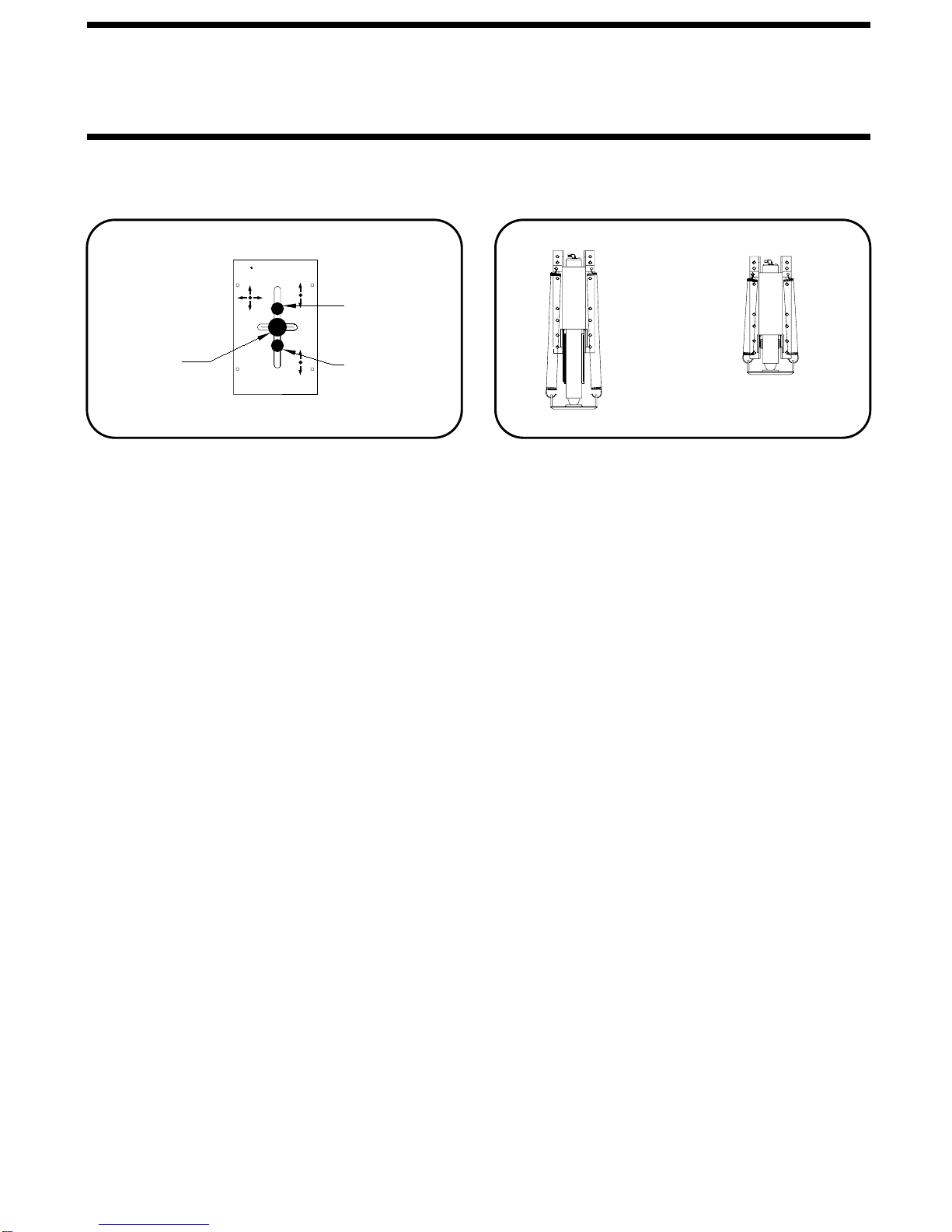

LEFT RIGHT

EXTENDEXTEND

REAR

EXTEND

STORE

REAR

FRONT

STORE

HWH HYDRAULIC LEVELING

FRONT

EXTEND OPERATE

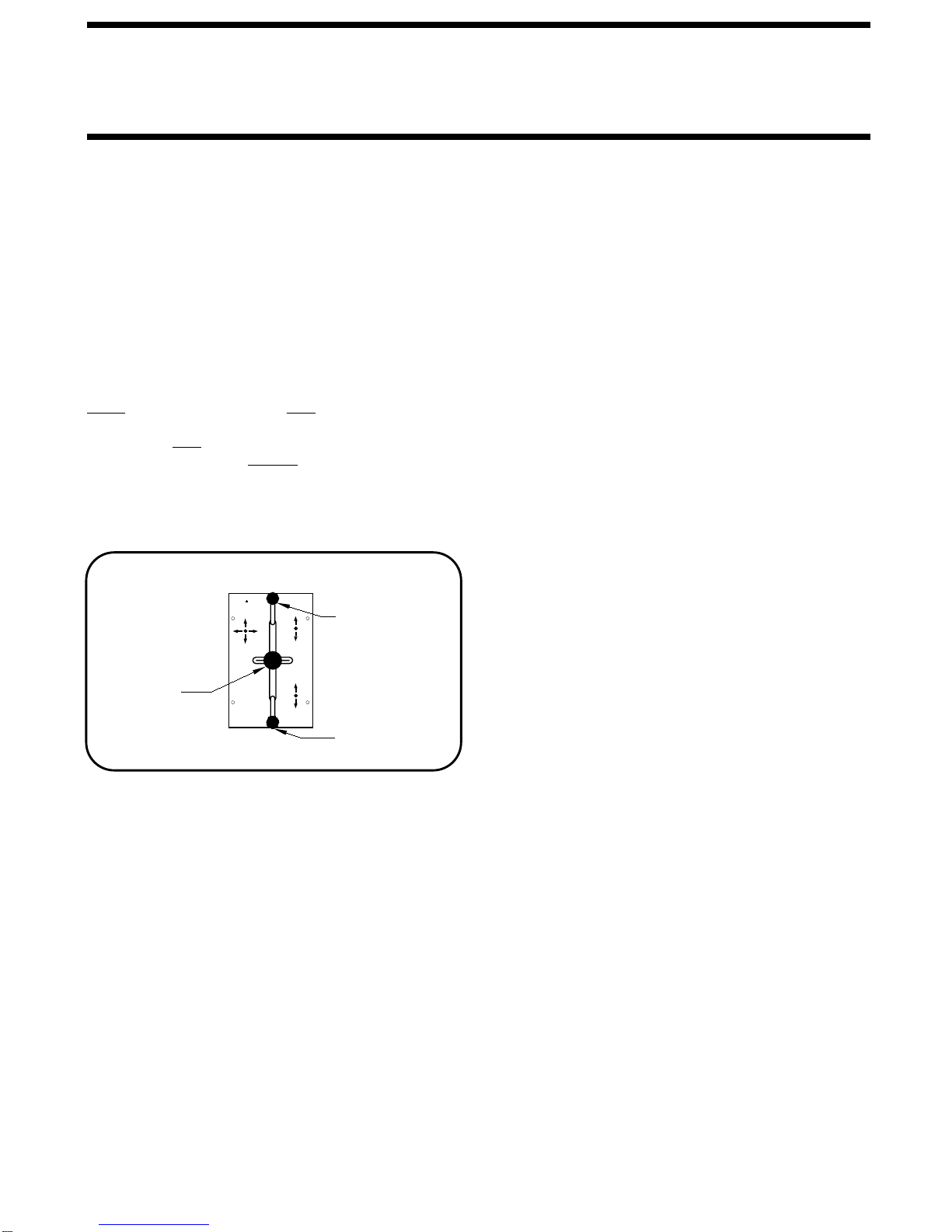

JACK

LEVER POSITIONS

OPERATE POSITION

CONTROL

LEVER

FRONT

STORE

LEVER

REAR

STORE

LEVER

2. Place the ignition switch in the "ACC" position.

The vehicle’s engine must be off. Running the engine during

or after leveling may inflate the air suspension lifting the

9. Turn the ignition switch off.

4. Push and hold the "DUMP" button until all air is exhausted

from the vehicle’s suspension system.

ROOM EXTENSION PROCEDURES

extension read this section carefully.

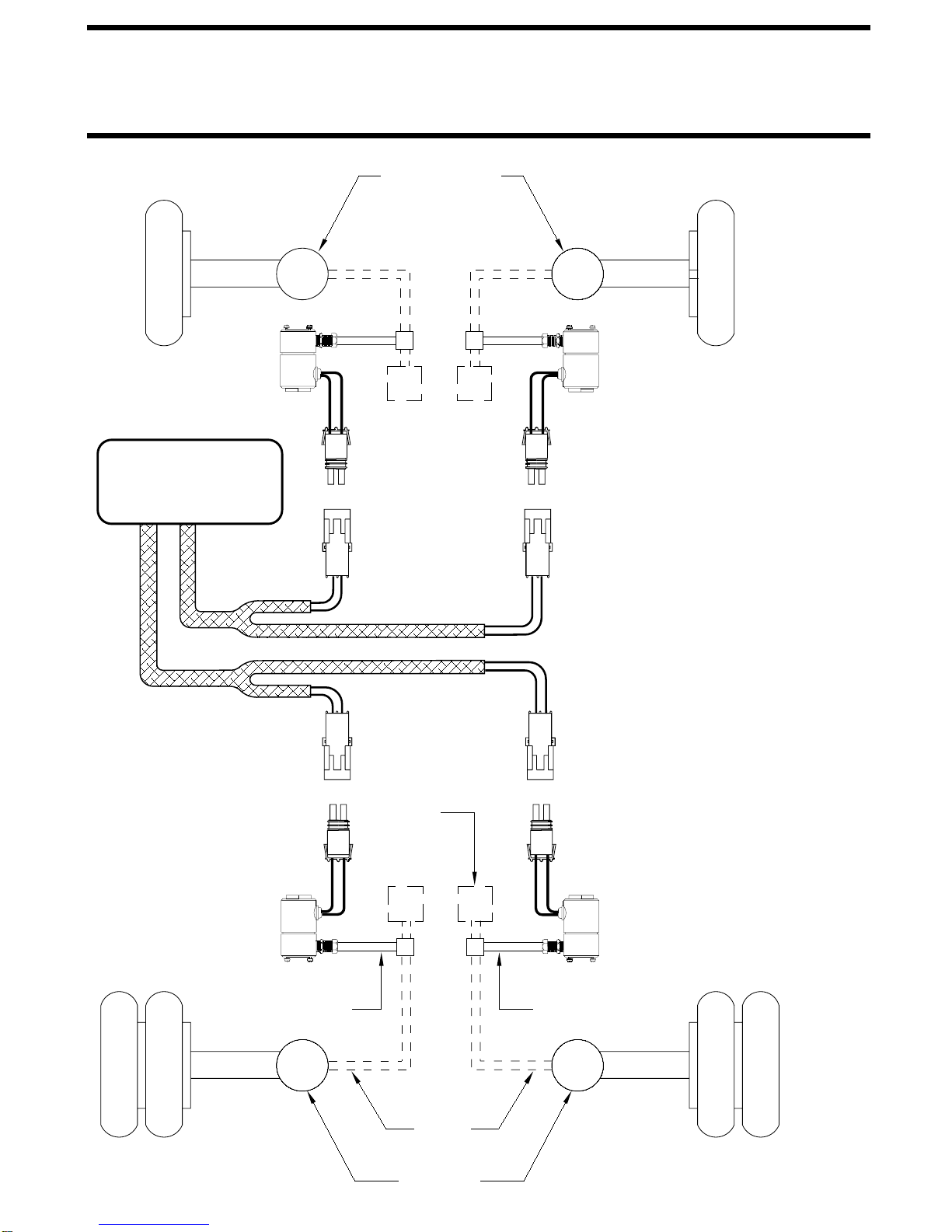

If the vehicle is equipped with kick-down jacks, the wheels

MUST be blocked securely. Do NOT operate any room

extension until the leveling and stabilizing procedure is

If the vehicle is equipped with a roomIMPORTANT:

complete. Do NOT retract the leveling system until all room

extensions are retracted. NEVER operate the leveling system

Refer to the vehicle owner’s manual for proper operation of

when any room extensions are extended.

room extensions.

IMPORTANT: Do not use a room extension support when

the vehicle is supported by the leveling system.

5. Move the FRONT and REAR STORE LEVERS to the

OPERATE POSITION. Nothing should happen at this time.

Place pads under jacks if necessary at this time.

brake and block tires securely.

Move the JACK CONTROL LEVER to the EXTEND position

to extend jack pairs corresponding to a lit yellow light. Extend

jack pairs accordingly until all yellow lights are out. It may

take several movements from side to front, or side to rear to

raise a low corner. If the ground is too uneven, the jacks may

not have enough stroke to level the vehicle. The vehicle may

have to be moved.NOTE:

NOTE:

The respective RED WARNING LIGHT will come on

when a jack is extended 2 or more inches.

the right or the left extend positions. Jacks used to stabilize

If the hand/auto park brake is not set, the "NOT IN

6. A lit yellow LEVEL light indicates that the end, side or

corner of the vehicle is low. Only one yellow LEVEL light

should be lit at a time. If a corner of the vehicle is low a side

LEVEL light will be on by itself.

vehicle out of level. the vehicle should lift the vehicle 3/4" to 1" after touching the

ground.

Maintain adequate clearance in all directions for vehicle,

room extensions, awnings, doors, steps ect. Vehicle may

move in any direction due to jack extending or retracting,

settling of jacks or vehicle, equipment malfunction etc.

If parking on soft ground or asphalt paving, wood blocks or

pads should be placed under the jacks.