9P300-991-2400C

3. Inspect and Replace

Diaphragms (17)

a.Liftdiaphragm(17) byoneedge,andturnpumpshaft

(use the shaft rotator from the Wanner Tool Kit)

untildiaphragmmovesupto“topdeadcenter”.Thiswill

expose machined cross-holes in plunger shaft behind

diaphragm.

b. Inser ttheplungerholdertoolthroughoneofthemachined

cross-holes,toholdthediaphragm(17)up.(Don’tremove

tooluntilnewdiaphragmisinstalledinstepfbelow.)

c. Unscrewthediaphragm.Usea5/16 -in.(8 -mm)open- end

wrench,andturncounterclockwise.

d.Inspect diaphragm carefully. A damaged diaphragm

generallyindicatesapumpingsystemproblem.Replacing

diaphragmonly,willnotsolvethelargerproblem.Inspect

diaphragmforthefollowing:

• Small puncture.Usuallycausedbysharpforeignobject

inuid.

• Diaphragm pulled away from metal insert. Usually

causedbyexcessiveinletvacuum,orbyoverpressurization

ofpumpinlet.

• Outer diaphragm bead extruded.Usuallycausedby

overpressurizationofpump.

• Diaphragm becoming stiff and losing flexibility.

Usuallycausedbypumpinguidthatisincompatiblewith

diaphragmmaterial.

• Cut diaphragm convolute. Usually caused by

excessiveinletvacuum.

CAUTION: If a diaphragm has ruptured and foreign

material or water has entered the oil reservoir, do

not operate the pump. Check all diaphragms, then

ush the reservoir completely (as outlined below)

and rell it with fresh oil. Never let the pump stand

with foreign material or water in the reservoir, or with

the reservoir empty.

e.Cleanawayanyspilledoil.

f. Installdiaphragm(17)andtightento10in-lbs(113N-cm).

g.Repeat above inspection procedure with other two

diaphragms(17).Replaceifnecessary.

4. Flush Contaminant from

Hydraulic End

(only if a diaphragm has ruptured)

a.Remove the brass cap (60) and allow all oil and

contaminatetodrainout.

b. Fillreservoirwithcompatiblesolvent.Manuallyturnpump

shafttocirculatecompatiblesolventanddrain.Usethe

shaftrotatorprovidedinWannerToolKit(PartNo.A03-

175-1106).Disposeofcontaminateduidproperly.

CAUTION: If you have an EPDM diaphragm, or if food

grade oil is in the reservoir, do not use kerosene or

solvents. Instead, ush with the same lubricant that

is in the reservoir.

c. Repeatstepbushingprocedure.

d.Fillreservoirwithfreshoilandmanuallyturnpumpshaft

tocirculateoil.Drainoil.

Note: P Series replacement parts kits (complete kits

and diaphragm kits) include the correct oil for each

specic P Series pump conguration.

e.Rellreservoirwithfreshoil.Ifoilappearsmilky,thereis

stillcontaminantinreservoir.Repeatstepscandduntil

oilappearsclean.

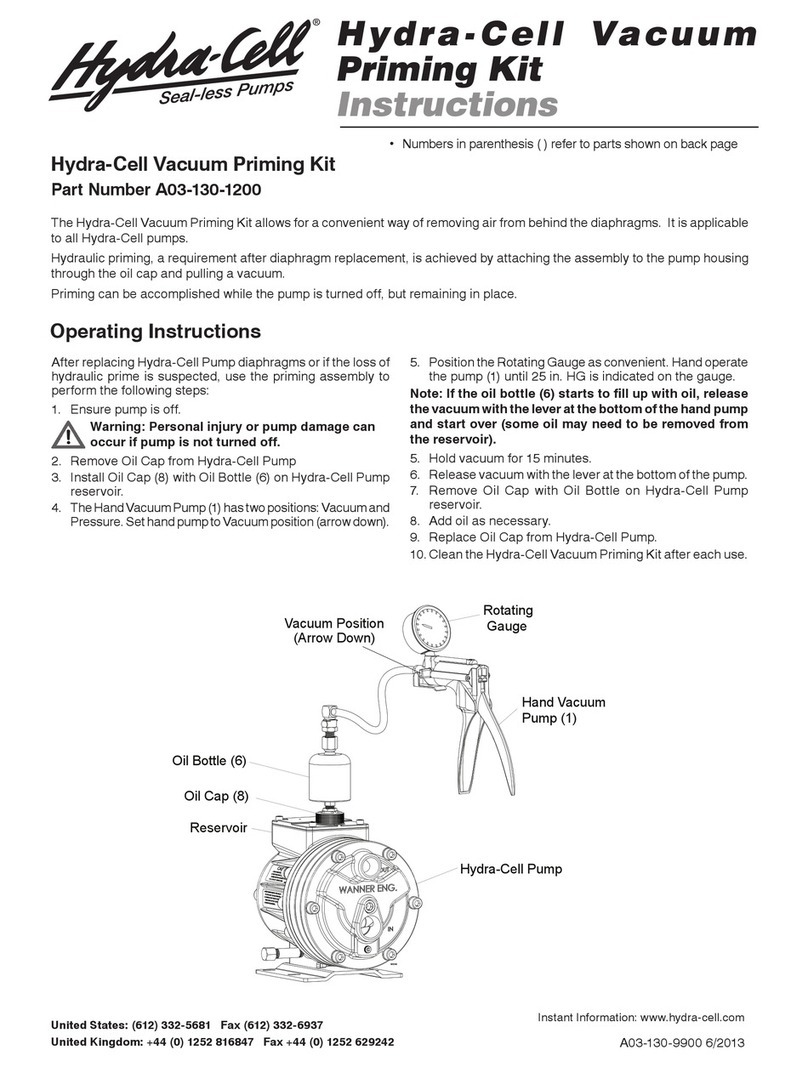

5. Prime Hydraulic Cells

a.Ifnecessary,withpumphorizontal,llreservoirwiththe

correctHydraoilforapplication.

Note: P Series replacement parts kits (complete kits

and diaphragm kits) include the correct oil for each

specic P Series pump conguration.

b.Airbehindthediaphragmmustbeforcedoutbyturning

shaftandpumpingpiston.Anyairinthehydraulicend

willcausethepumptohavelossinowandre-priming

willbenecessary.

c. Turnshaf tuntilbubble-freeowofoilcomesfrombehind

diaphragm. Use the shaft rotator provided in Wanner

Tool Kit (Part No. A03-175-1106). Make sure oil level

inreservoirdoesn’tgettolow.Addoilasnecessary.If

oilgetstoolow,airwillbedrawnintohydraulicsideof

piston.

d.Whenoilisbubble-free,refreshoilreservoir.

c. Wipe excess oil from the diaphragm plate (18) and

diaphragms(17).

6. Reinstall Valve Plate (12) and

Manifold (3)

a.Reinstallvalveplate(12),withvalveassembliesinstalled

as outlined above, onto diaphragm plate (18) and

alignmentpins(29).

Tighten two socket-head capscrews (14) evenly and

snugly to compress outer diaphragm beads and hold

valveplate(12)inplace.

b. ReinstallO-rings(4)onfrontsideofthevalveplate(12).

Use petroleum jelly or lubricating gel to hold them in

place.

c. Reinstallmanifold(3)ontovalveplate(12).

d. Insertallcapscrews(1),withwashers(2),aroundedgeof

themanifold,andalternatelytightenoppositeboltsuntil

allaresecure.Torqueto50ft-lbs(70N-m).

e.Recheckallboltsfortightnessandpropertorque.

P300 Fluid End Service (Cont’d)