Connecting with Hydro-Control VI Chapter 3

22 Hydronix Ethernet Adapter User Guide HD0333 Rev 2.1.0

2.1.1 Location of the Ethernet Adapter (EA01)

The Ethernet Adapter should be mounted in the wiring junction box as close to the Hydro-

Control VI as possible, and protected from water and excessive dust. Connect the

Ethernet drop cable from the network connection to the Ethernet port of the Adapter.

Connect a 24V dc supply to the 24V+ and 0V input terminals of the Ethernet Adapter,

ensuring that the power supply and wire is of a sufficient power rating to carry the power

for the number of sensors connected.

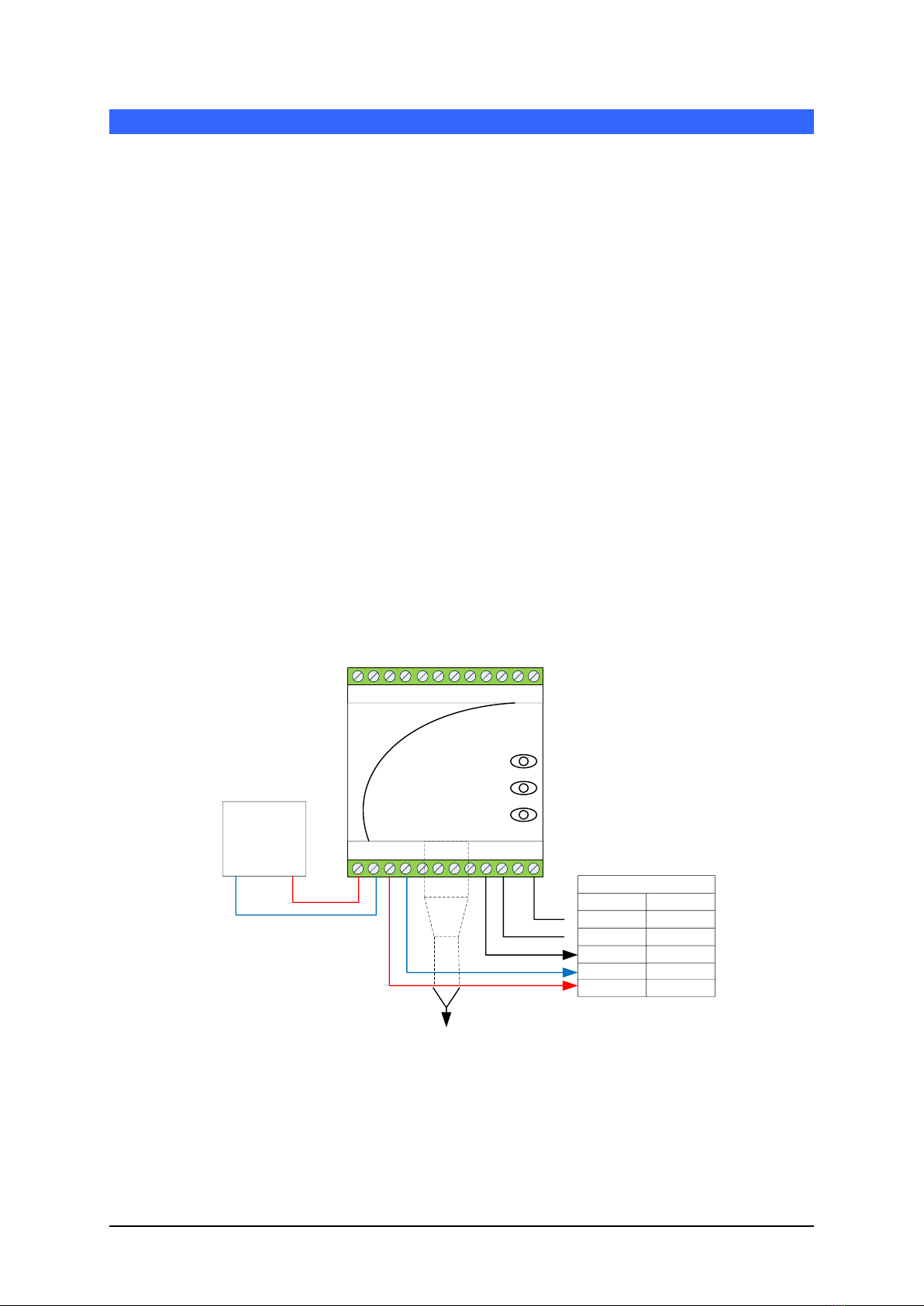

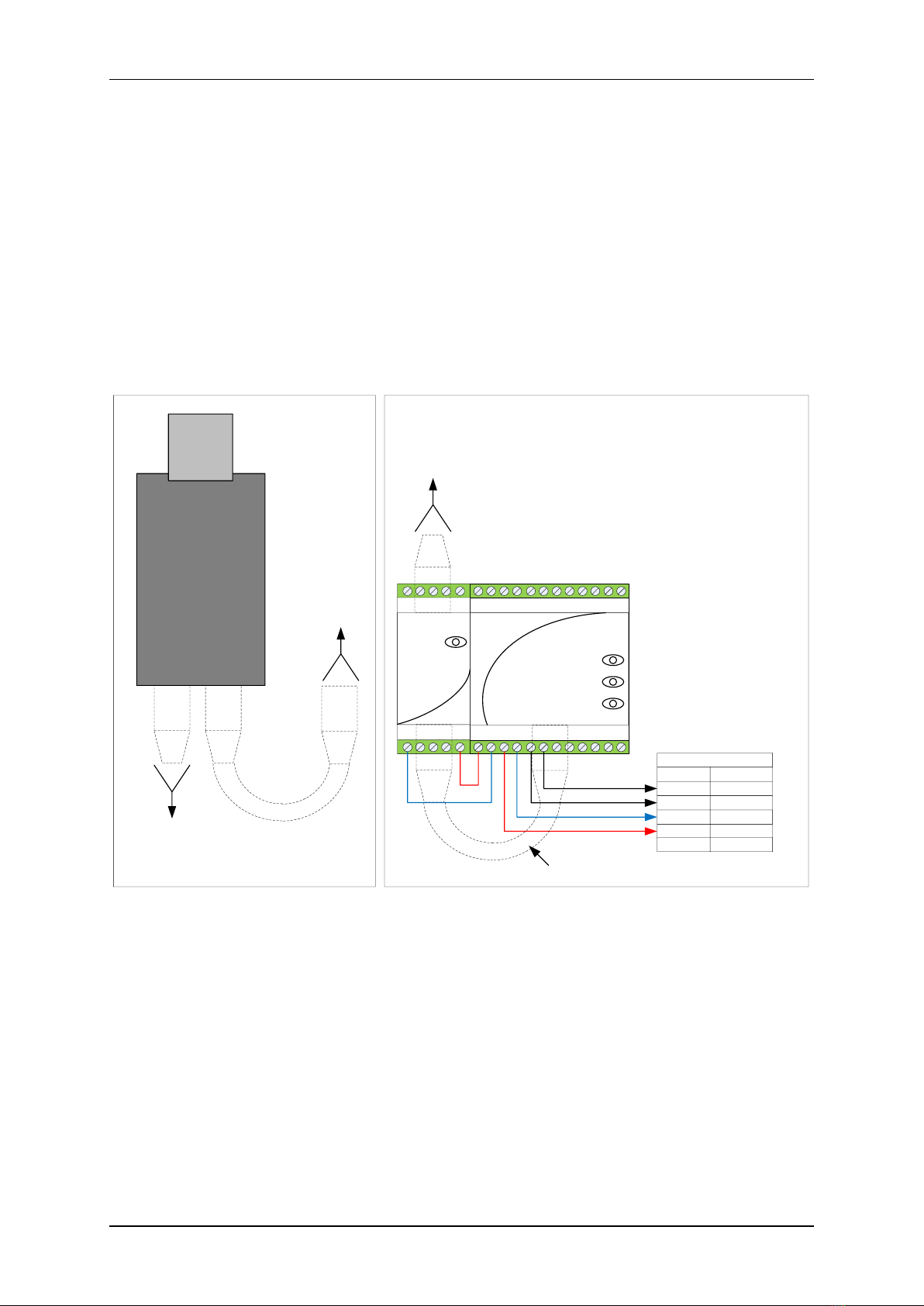

2.2 Power over Ethernet (EPK01)

A single Hydro-Control VI unit (with attached Hydro-Mix sensor) can be powered using the

Power over Ethernet kit. Connect one of the Sensor 24V and 0V connections to the Hydro-

Control VI power input pins. The arrangement is as shown below:

10/100baseT

CAT5e

Linking EPA01 and EA01

Connections to Hydro-Control VI

Description Connector Pin

RS232 Gnd 28

RS232 Rx 26

RS232 Tx 27

0v DC 34

Ethernet

Adapter

Model: EA01

24V

Receive

Transmit

Ethernet

Power

Adapter

Model: EPA01

IN

24V

OUT

Junction box close to Hydro-Control VI

Control Room Cabinet

10/100baseT

CAT5e

Ethernet

to EPI01

10/100baseT

CAT5e

Ethernet

to Network

Switch

EPI01

Ethernet

Power

Injector

OUT IN

10/100baseT

CAT5e

Ethernet

to EPA01

IEC Mains

Cable

100-240v AC

50-60Hz

24v DC 32

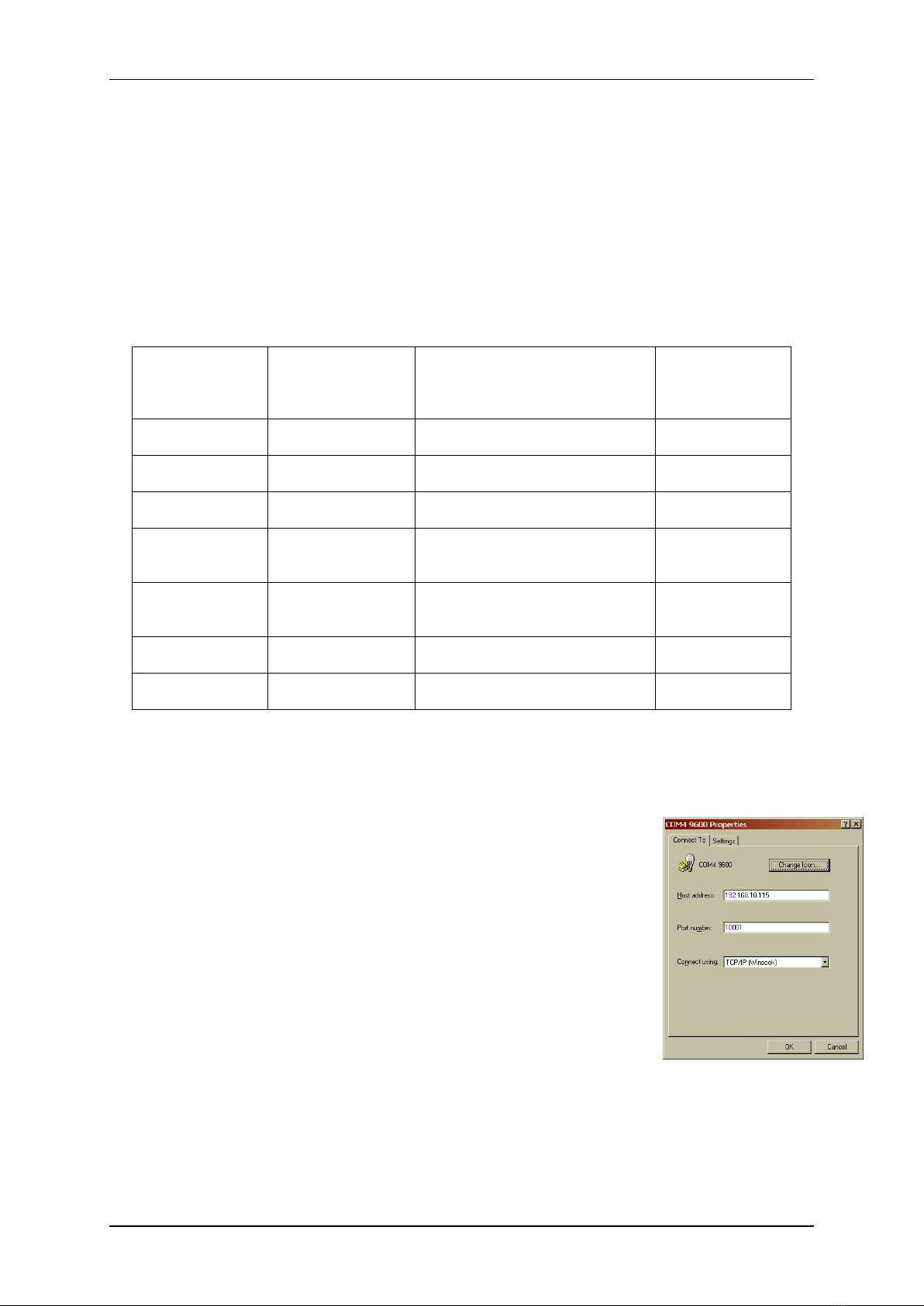

Figure 6: Connecting the Ethernet Adapter to Hydro-Control VI

with Power Over Ethernet Option

2.2.1 Location of the Power Adapter (EPA01)

The Power Adapter Module (EPA01) should be mounted in the wiring junction box with the

Hydro-Control and beside the Ethernet Adapter, protected from water and excessive dust.

Connect the Ethernet drop cable from the router to the IN port of the Power Adapter. This

cable carries both the power and the Ethernet communications signals. Connect a short

Ethernet cable from the OUT port of the Power Adapter to the Ethernet port on the

Adapter. This cable carries only the Ethernet communications. Connect short insulated

wires from the 24V+ and 0V outputs of the Power Adapter to the 24V+ and 0V inputs of

the Ethernet Adapter, ensuring that the wire is of sufficient power rating to carry the power

for the Hydro-Control VI and it’s sensor.

Connect RS232 cables between the Ethernet Adapter and the Hydro-Control VI.