STEP 1 Prepare pipe end by de-scaling if required. Clean the pipe as required with

water. Make sure that the pipe is clean from debris and defects that interfere

with HYMAX GRIP's proper seal.

NOTE: Except steel, PVC, and PE pipes, all rough-surfaced pipes must be lubricated

with a water-based gasket lubricant in order to achieve a proper seal.

STEP 2 Measure the pipe’s Outer Diameter and make sure the coupling’s size fits properly.

NOTE: Each coupling’s size range is shown on the product’s label. Make sure that

the pipe is not out of round! The pipe should be free of scratches, dents, flats or

other defects which may interfere with the HYMAX GRIP Flange Adaptor's proper

seal. The GRIP Flange Adaptor may not fit well or function properly on a pipe which

is damaged or is out of round.

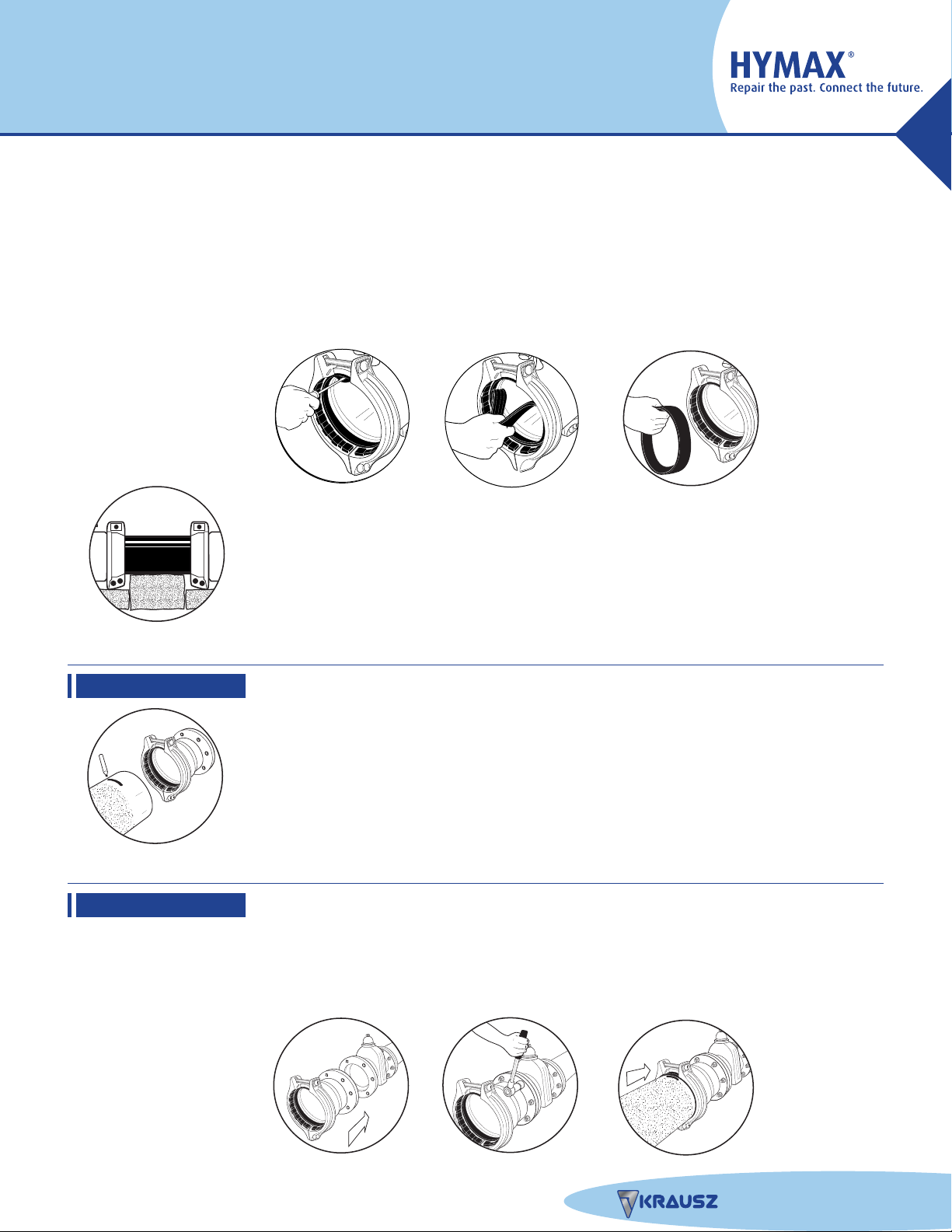

STEP 3 Unpack the HYMAX GRIP Flange Adaptor carefully. Inspect the product and end ring

for shipping damage and assure all parts are present.

Inspect the end ring. If it is not centered on the HYMAX GRIP Flange Adaptor - DO

NOT USE! Contact your distributor for return and replacement.

NOTE: HYMAX GRIP Flange Adaptor is a stab-on type product. Do not loosen or

remove the end ring bolts.

NOTE: Make sure that the product fits the flange standard of the flanged product

you need to connect it to. The Flanged standard types appear in the submittal

drawings.

GENERAL INSTRUCTIONS:

THE HYMAX GRIP FLANGE ADAPTOR IS A STAB-ON TYPE RESTRAINT THAT IS APPROVED FOR USE WITH METAL

AND PLASTIC PIPES.

WARNING: DO NOT ATTEMPT TO USE THE HYMAX GRIP ON AC OR FRP PIPE!

PRECAUTIONS FOR HDPE PIPE:

FOR OTHER MATERIALS, PLEASE CONTACT KRAUSZ USA OR YOUR KRAUSZ DEALER.

DO NOT DISASSEMBLE THE COUPLING. DO NOT LUBRICATE THE BOLTS.

HYMAX GRIP FLANGE ADAPTOR

3”-12”

STEP 1: Clean the pipe as required

with water. Make sure that the pipe is

clean from debris and defects that

interfere with HYMAX Grip’s proper seal.

STEP 2: Measure the pipe's Outer

Diameter and make sure the coupling's

size fits properly.

STEP 4: Mark pipe end to a minimum

required stab depth of 3.5”. These marks

indicate the required stab depth of the

pipe on the Flange Adaptor.

STEP 6a: Connect the GRIP Flange Adaptor

to the existing flange....

STEP 6b: .... and tighten bolts

to maximum.

STEP 6c: .... Bring in the pipe.

Stab the pipe onto the Flange

Adaptor so it covers the

mark on the pipe drawn

in step #4 above.

STEP 7: Tighten the end ring

using a torque wrench, to the

correct torque shown on the

product's label. By tightening

bolts the Flange Adaptor is steadily

stabbed on the pipe.

HYMAX GRIP FLANGE ADAPTOR 3”-12”

STEP 8: Make sure that the pipes

are not touching each other inside

the body of the HYMAX GRIP.

There must be space between the

pipes in order for “Continuous

Dynamic Deflection” (CDD) to

take place.

HYMAX GRIP FLANGE ADAPTOR

3”-12”

STEP 1: Clean the pipe as required

with water. Make sure that the pipe is

clean from debris and defects that

interfere with HYMAX Grip’s proper seal.

STEP 2: Measure the pipe's Outer

Diameter and make sure the coupling's

size fits properly.

STEP 4: Mark pipe end to a minimum

required stab depth of 3.5”. These marks

indicate the required stab depth of the

pipe on the Flange Adaptor.

STEP 6a: Connect the GRIP Flange Adaptor

to the existing flange....

STEP 6b: .... and tighten bolts

to maximum.

STEP 6c: .... Bring in the pipe.

Stab the pipe onto the Flange

Adaptor so it covers the

mark on the pipe drawn

in step #4 above.

STEP 7: Tighten the end ring

using a torque wrench, to the

correct torque shown on the

product's label. By tightening

bolts the Flange Adaptor is steadily

stabbed on the pipe.

HYMAX GRIP FLANGE ADAPTOR 3”-12”

STEP 8: Make sure that the pipes

are not touching each other inside

the body of the HYMAX GRIP.

There must be space between the

pipes in order for “Continuous

Dynamic Deflection” (CDD) to

take place.

HYMAX GRIP FLANGE ADAPTOR

3”-12”

STEP 1: Clean the pipe as required

with water. Make sure that the pipe is

clean from debris and defects that

interfere with HYMAX Grip’s proper seal.

STEP 2: Measure the pipe's Outer

Diameter and make sure the coupling's

size fits properly.

STEP 4: Mark pipe end to a minimum

required stab depth of 3.5”. These marks

indicate the required stab depth of the

pipe on the Flange Adaptor.

STEP 6a: Connect the GRIP Flange Adaptor

to the existing flange....

STEP 6b: .... and tighten bolts

to maximum.

STEP 6c: .... Bring in the pipe.

Stab the pipe onto the Flange

Adaptor so it covers the

mark on the pipe drawn

in step #4 above.

STEP 7: Tighten the end ring

using a torque wrench, to the

correct torque shown on the

product's label. By tightening

bolts the Flange Adaptor is steadily

stabbed on the pipe.

HYMAX GRIP FLANGE ADAPTOR 3”-12”

STEP 8: Make sure that the pipes

are not touching each other inside

the body of the HYMAX GRIP.

There must be space between the

pipes in order for “Continuous

Dynamic Deflection” (CDD) to

take place.

THE USE OF FULL CIRCLE STIFFENERS IS REQUIRED

WHEN USING THE HYMAX GRIP FLANGE ADAPTOR ON HDPE PIPE.

1

(1.5”-12”)

HYMAX

®

GRIP

FLANGE ADAPTOR

INSTALLATION INSTRUCTIONS

is the creator of HYMAX