ENGLISH

24

GB

5. Do not operate a chain saw with one hand! Serious

injurytotheoperator,helpers orbystandersmayresult

fromone-handedoperation.Forpropercontrol,always

usetwo handswhenoperating a chainsaw,one hand

whichoperates thetrigger.This canresultinthe chain

saw“skating” or skidding,whichcanresult inpersonal

injury due to loss of control.

6. Keepagood firm griponthesawwith both hands,with

the right hand on the rear handle and the left hand on

the front handle, when the engine is running. Use a

firm grip with thumbs and fingers encircling the chain

sawhandles.Afirm grip willhelp you reducekickback

and maintain control of the saw. Two hands must be

used to control the saw at all times.

7. Donot overreachorcut above chestheight.

8. Make sure that the area in which you are cutting is

freefrom obstructions.Donotlet thebarnose contact

alog, branch,orany otherobstructionwhich couldbe

hit while you are operating the saw.

9. Cuttingathighenginespeedsmayreducethelikelihood

of kickback.

5.

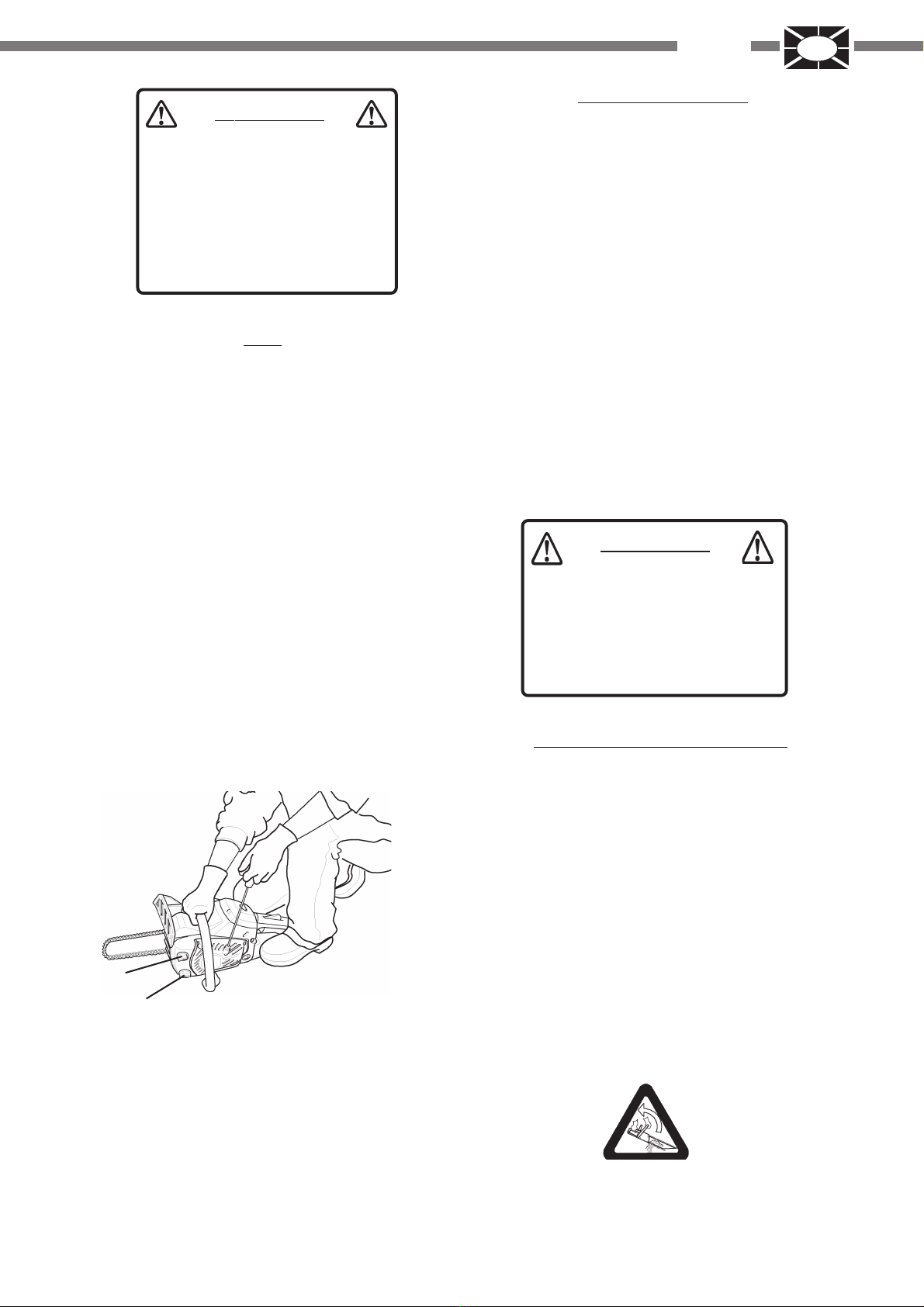

WARNING

KICKBACKMAYOCCURWHEN

THENOSEORTRIPOFTHEGUIDE

BAR TOUCHES AN OBJECT OR

WHEN THE WOOD CLOSES IN

ANDPINCHESTHESAWCHAININ

THECUT

10.But cuttingat part-throttleorlow enginespeeds may

bepreferabletocontrolthechain saw intight situations

and may also reduce the likelihood of kickback.

11. Followmanufacturer’ssharpeningand maintenance

instructions for the saw chain.

12.Useonly replacementguidebarand chainsspecified

bythe manufacturer, orthe acceptable equivalents of

theseguide barand chains.

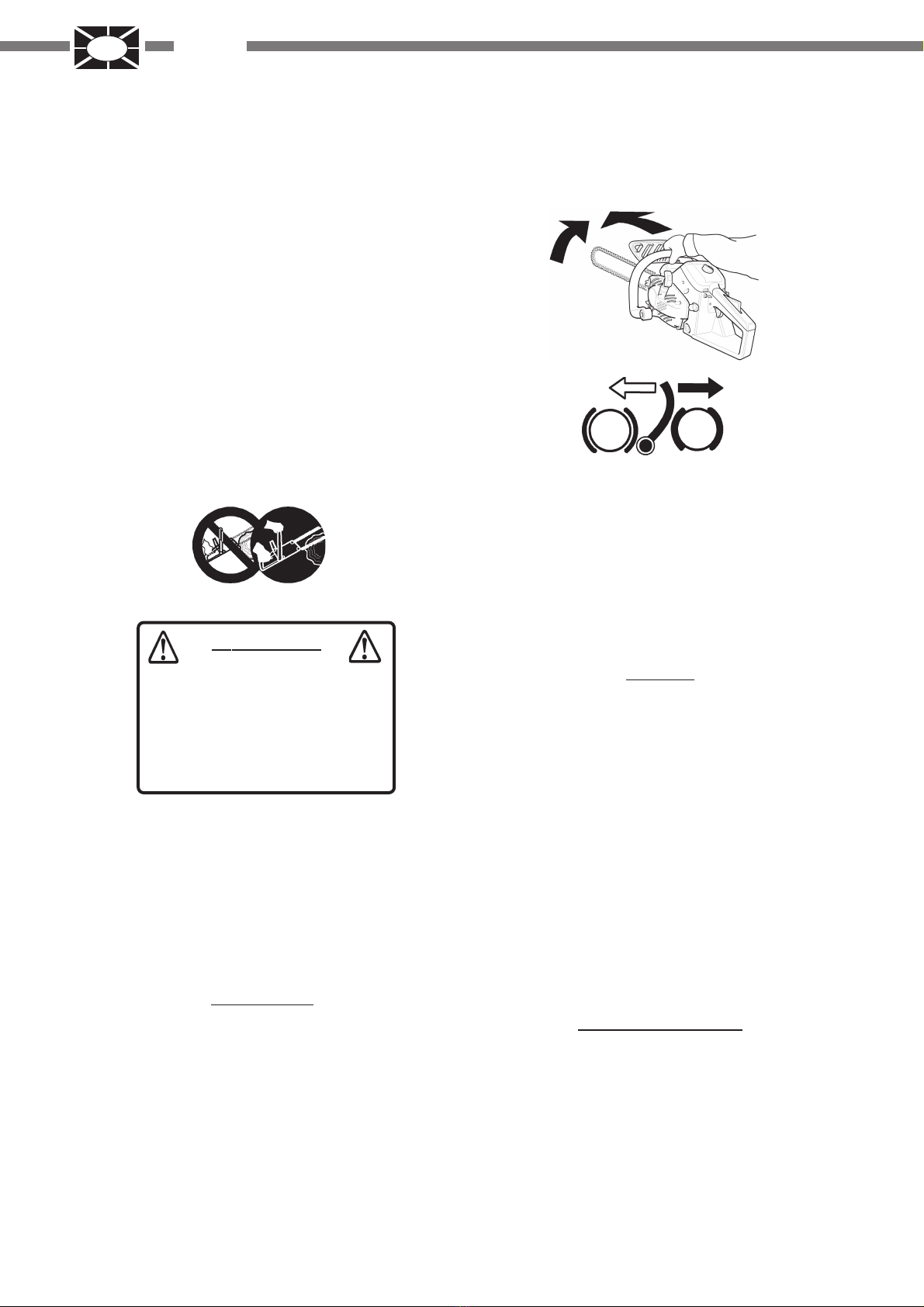

CHAINBRAKE

Thechainbrake’s functionistostop chain rotationaftera

kickback. It neither prevents nor reduces kickback. Do

not depend on the chain brake for protection against

kickback.

Evenwithachainbrake,dependonyour own goodsense

andproper cuttingmethodsjustas thoughtherewere no

chainbrake.

Even with normal use and proper maintenance, the

response time of the brake may lengthen. The following

mayinterferewiththebrake’sabilitytoprotecttheoperator.

1. Sawwronglyheldtooclosetooperator’sbody.Kickback

time may be too fast even for a perfectly maintained

brake to work in time.

2. The operator’s hand may not be in position to contact

thehand guard.Thebrake willnotbe tripped.

3. Lack of proper maintenance lengthens the brake’s

stopping time, making it less effective.

4. Dirt, grease, oil, pitch, etc. getting into the working

partsofthemechanismmaylengthenthestoppingtime.

5. Wear and fatigue of the activating brake spring, and

wear of the brake/clutch drum and pivot points may

lengthenthe brake’sstopping time.

6. Adamagedhandguardandlevermayrenderthebrake

inoperative.

INJURIES

It is believed that overusing the muscles and tendons of

the fingers, hands, arms and shoulders may cause

soreness, swelling, numbness, weakness and extreme

pain to the areas just mentioned. To reduce the risk of

repetitivestress injury,do thefollowing.

1. Avoid using your wrist in a bent, extended or twisted

position.Instead,trytomaintainastraightwristposition.

Also, when grasping, use your whole hand, not just

thethumb andindexfinger.

2. Take periodic breaks to minimize repetition and rest

yourhands.

3. Reduce the speed and force in which you do the

repetitivemovement.

4. Doexercisestostrengthen thehand andarm muscles.

5. See a doctor if you feel tingling, numbness or pain in

the fingers, hands, wrists or arms.

VIBRATIONANDCOLD

Exposure to cold and vibration may cause tingling and

buming followed by loss of color and numbness in the

fingers.Westronglyrecommend yourtaking thefollowing

precautionsbecausethe minimumexposure whichmight

triggerthe ailmentis unknown.

1. Keep your body warm, especially the head and neck,

feet and ankles, and hands and wrists

2. Maintaingoodbloodcirculationbyperforming vigorous

arm exercises during frequent work breaks and also

by not smoking.