8

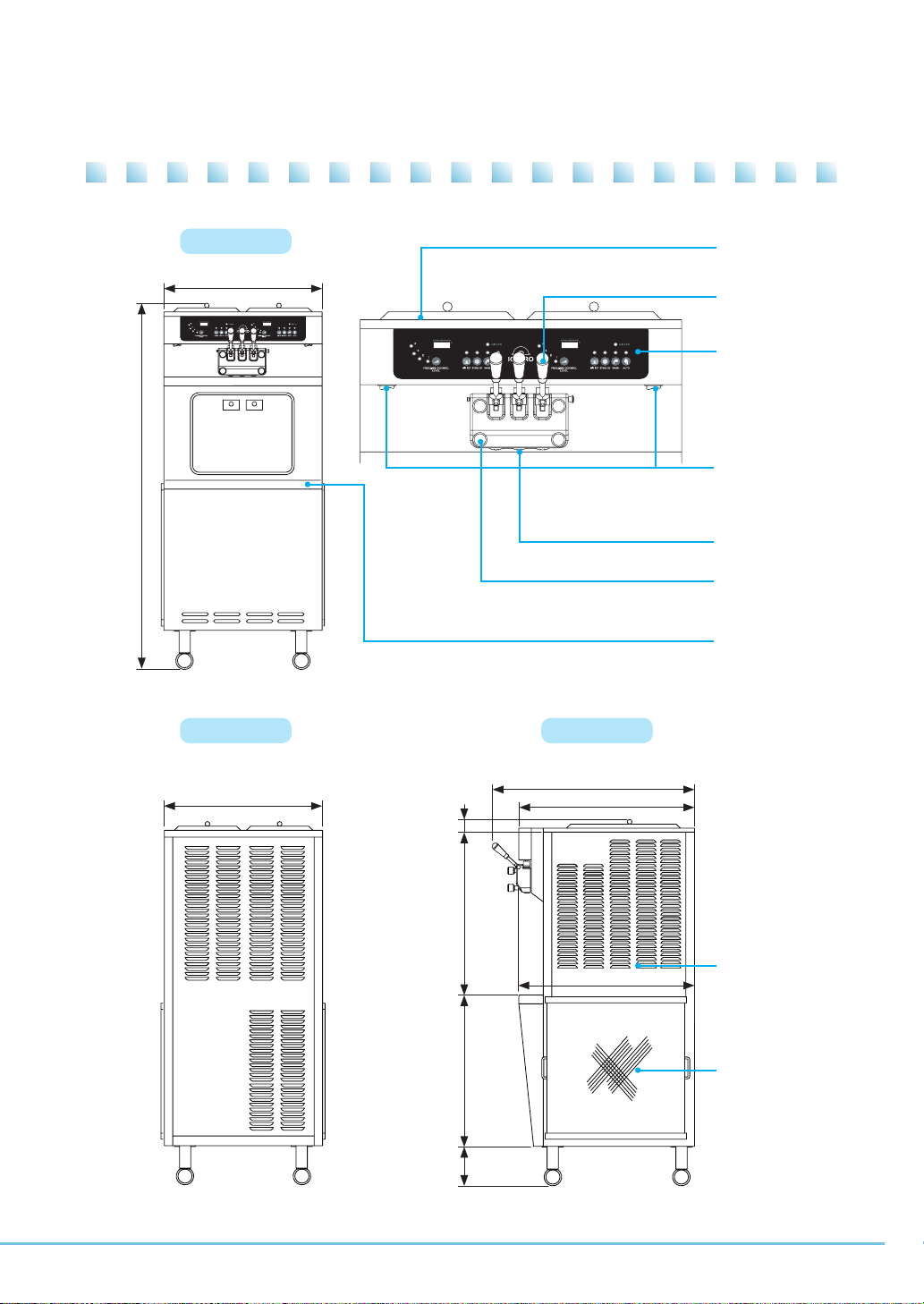

■ Make sure to check them prior to use ! ■

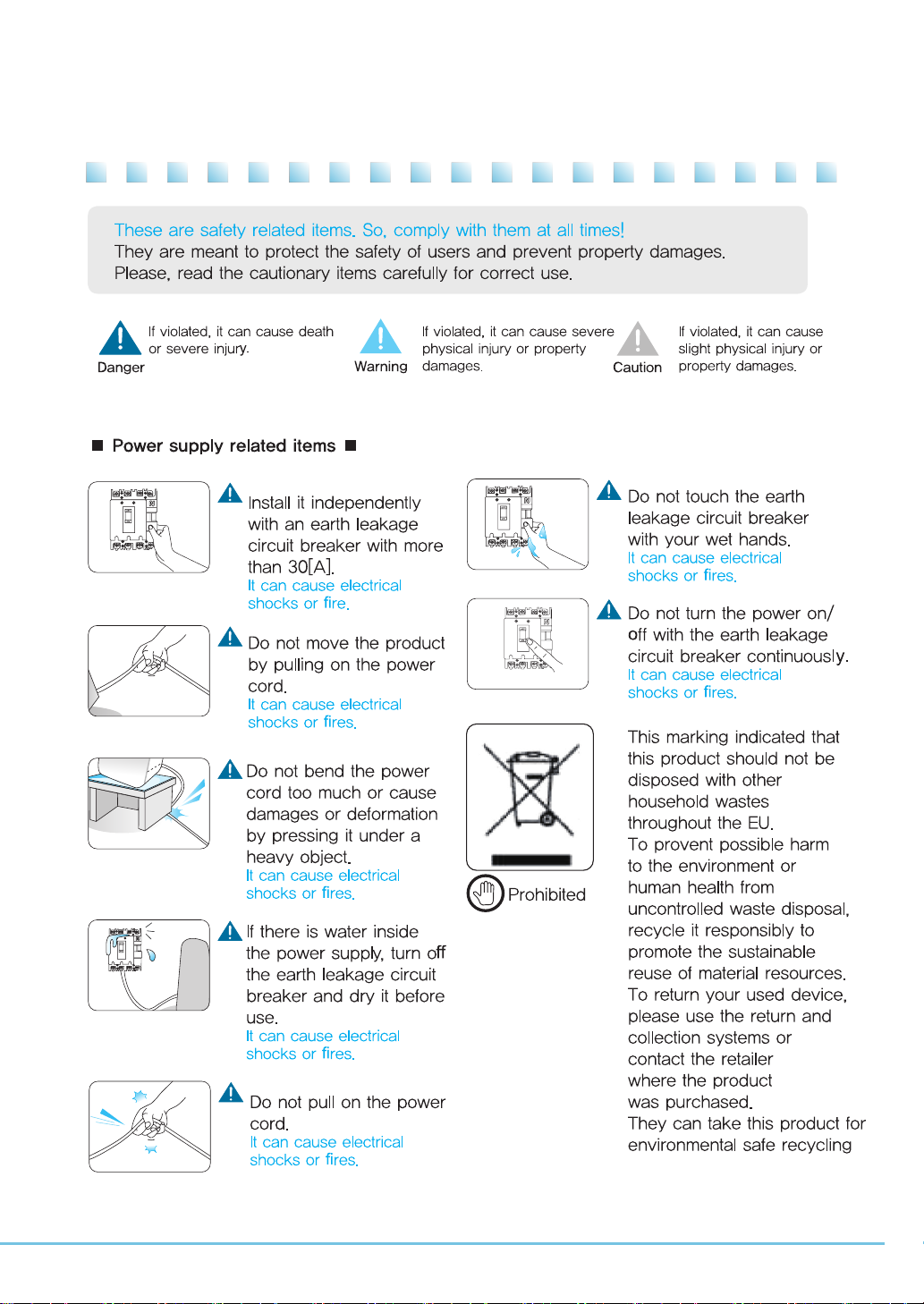

Install it independently with an earth leakage circuit breaker with more than 30 A

and provide anexternal grounding.

(Ask a qualified electrical technician for the installation.)

The power cable should be connected before the product can operate normally.

If you intend to leave it unused for a long time, wash it and turn off the water

supply valve and turn off the earth leakage circuit breaker.

The air suction and discharge should be facilitated so that the cooling

performance can be optimized.

If you leave it open, bugs or contaminants may enter the mixing tank.

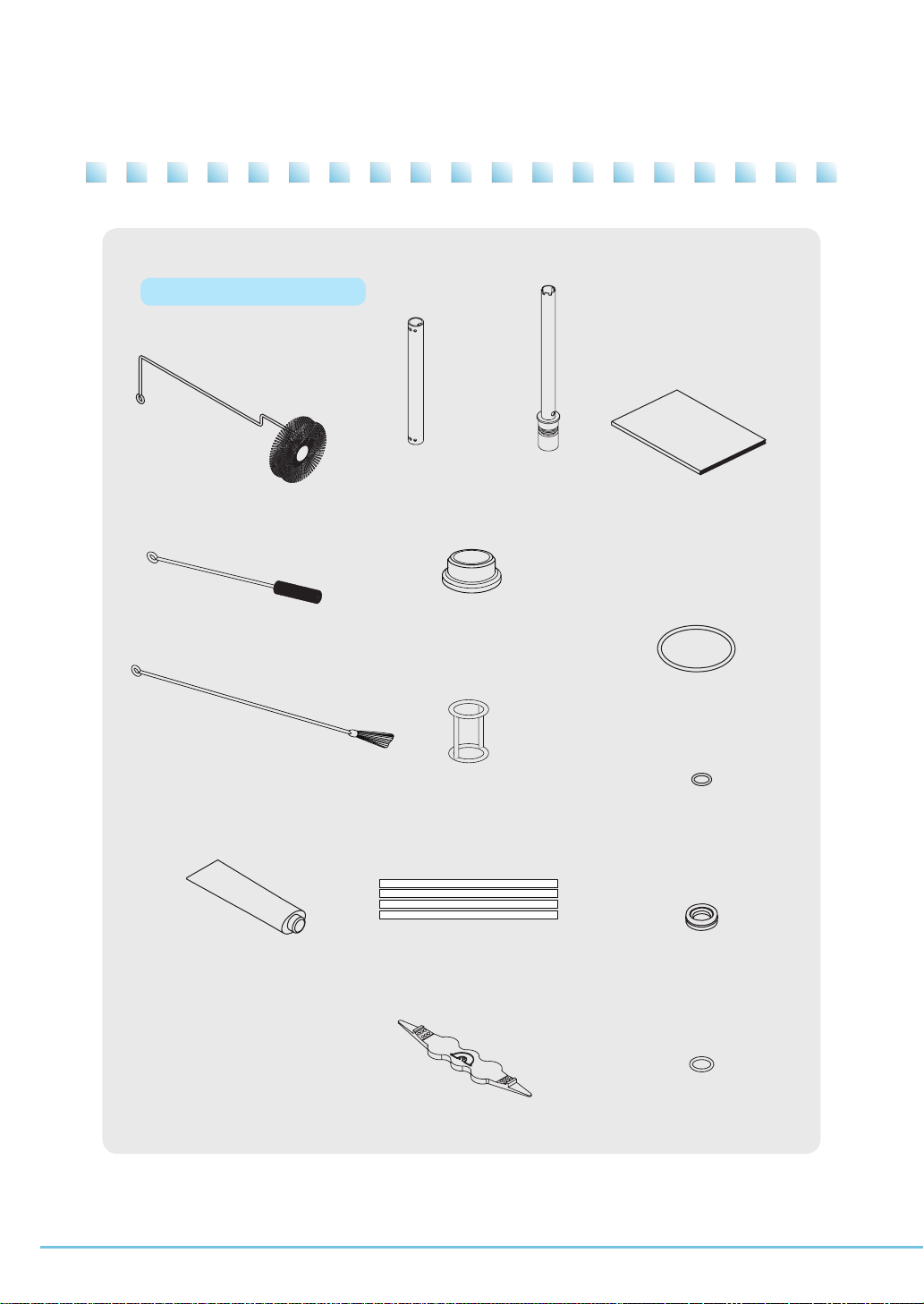

It is recommended to clean the cylinder, the mixing tank, the impeller,

the dasher, and the piston every day.

Clean the condenser at least once a month or more often.

The cylinder, mix tank, impeller, dasher, and piston inside the product make

contact with the ingredients, so you should clean them once every day.

This product is exclusively for 1Ø, 230 V~, 50 Hz / 220 V~, 60 Hz

■ Do not block the air vent.

■ Close the mixing tank.

■ Clean the condenser once a month.

■ Clean it at least once a day.

■ Clean the filter once a week.

Check prior to use

information

For your