5

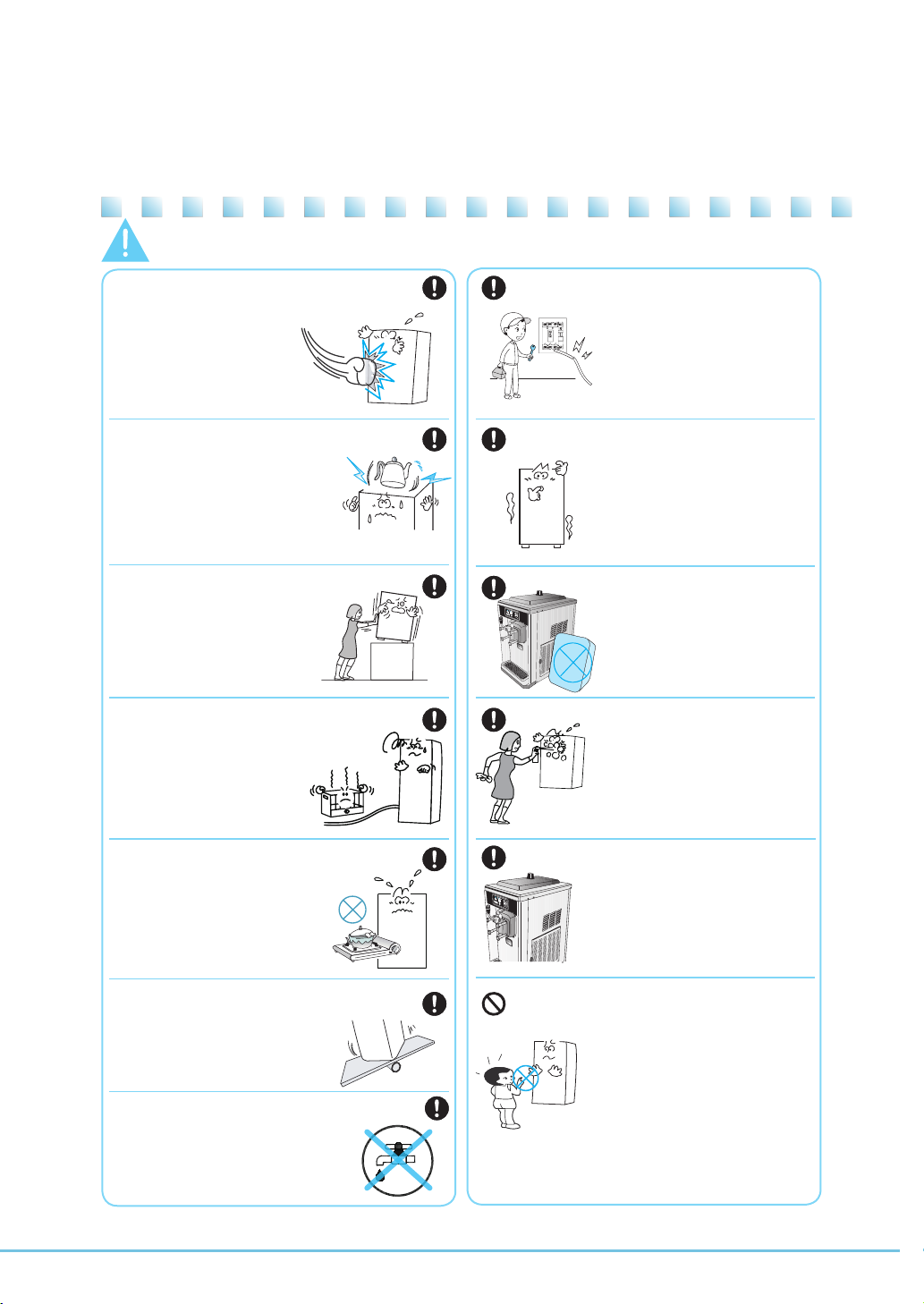

Warning

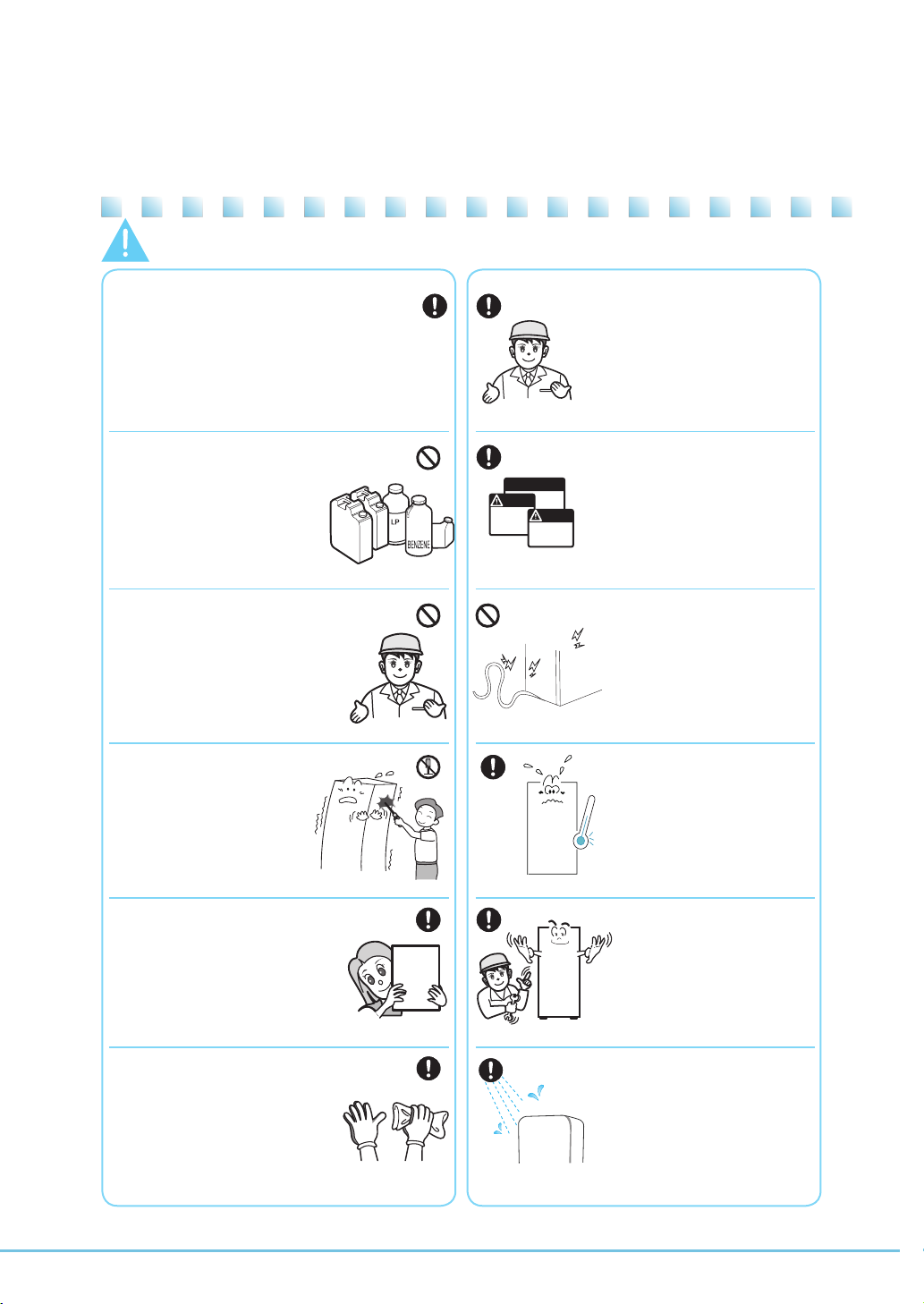

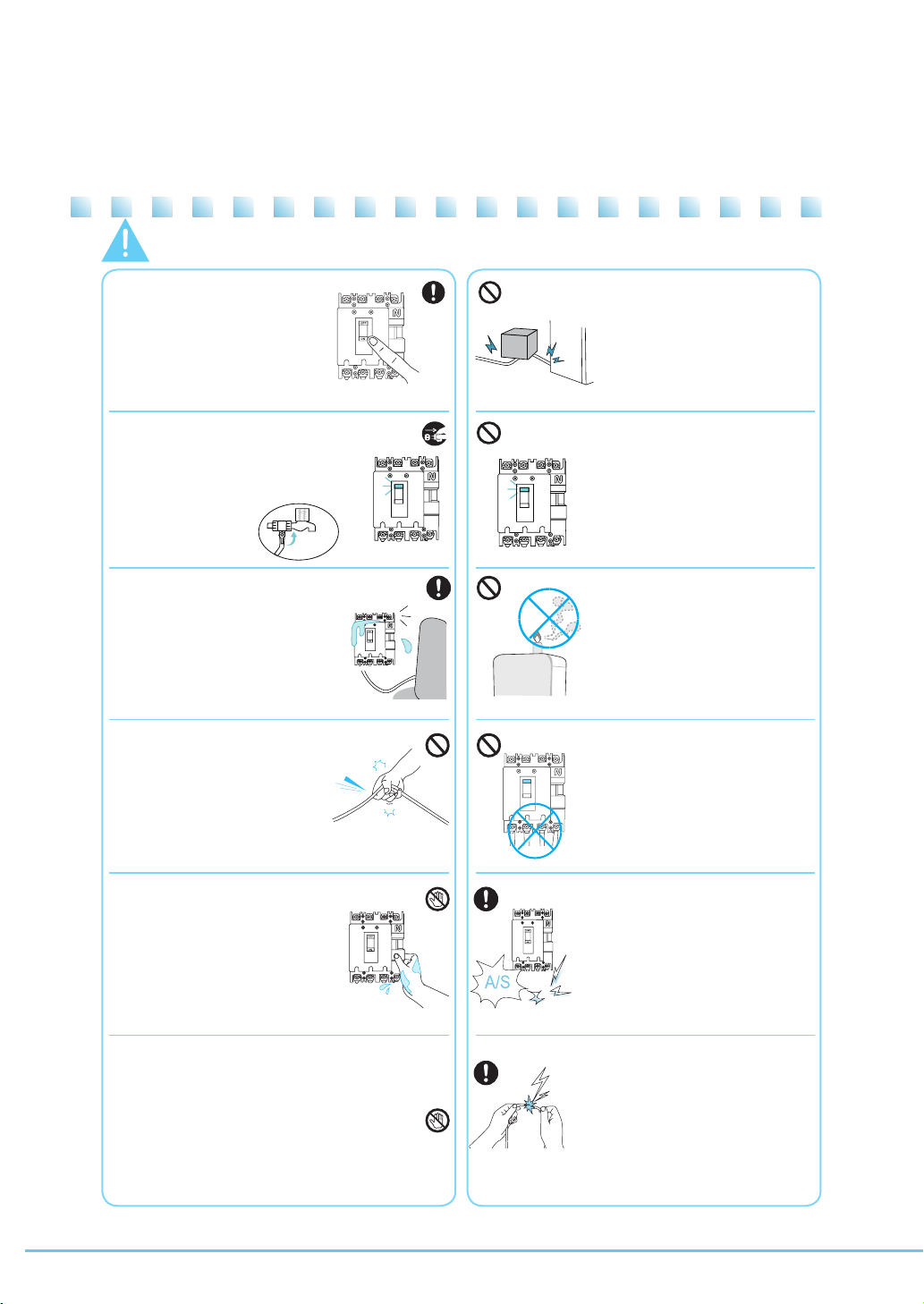

Do not disassemble or

modify the product.

It may cause electric

shock, fire, or injury.

Contact a professional service

supplier to repair the product.

Incomplete repair may cause

electric shock, fire, or injury.

For relocation of the product, call an expert.

Incorrect installation may cause damage

due to electric conduction.

Installation requires construction work in accordance with

related standards or laws including, but not limited to, KS,

road traffic act, fire service act, food sanitation act, etc.

Improper installation may cause accidents.

※: Please contact the agent where the product was purchased.

Keep your warning and

cautionlabels clean for easy

legibility.

If the user misunderstands

the content of such a label,

an accident may occur.

※: Contact the customer service

center if the product appears to

be defective or acts abnormally.

※: Check your labels.

Stop using the product if the

power cord is damaged.

It may cause fire or electric

shock.

Combustible gas or flammable

material (benzene, gasoline,

thinner, LP gas, etc.) must be

kept away from the product

and should never be put on

the product.

It may explode or cause fire

or injury.

Oh! NO

To replace or repair the power cord,

contact a professional technician or

our customer service center.

If you sell or hand over

the product, make sure

to hand over the user’s

manual with it.

without the manual, an accident

may occur because of erroneous

handing or operation.

Contact a professional

disposal service

provider when disposing

of the product.

Failure to dispose of the

product properly may result

in accidents.

This product shows

the Optimal performance

at temperature of 10~30°C.

Do not install it near dust,

moisture or rainwater(water) popping.

It can cause electrical

shocks or fires.

MANUAL

When cleaning the inside of the

product, remove the power cord

from the outlet and wear

protective gear such as rubber

gloves.

Failure to do so may cause electric

shock or injury.