GAS SUPPLY

planning stage, in order to establish the availability of an adequate

A gas meter can only be connected by the local gas supplier or

An existing meter should be checked, preferably by the gas

supplier, to ensure that the meter is adequate to deal with the rate

It is the responsibility of the Gas Installer to size the gas

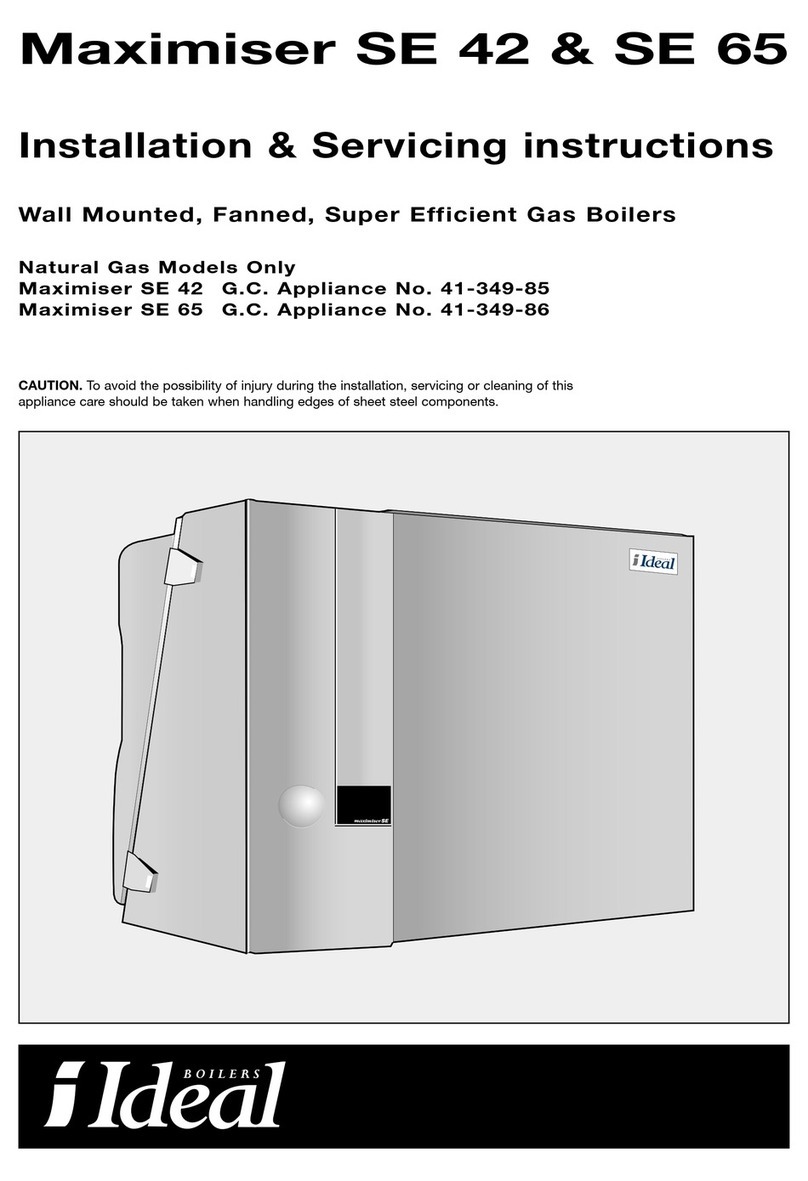

the principle of the 1:1 gas valve ensures the boiler range is

When operating pressures are found to be below the minimum

Allowing for the acceptable pressure loss of 1mb across the

installation pipework, it can be assumed that a minimum permitted

0

0.5

1

1.5

2

2.5

3

010 20 30 40 50

Pressure drop (mbar )

Heat Input to Boiler (kW)

Gas Cock Pressure Drop

IMPORTANT.

FLUE INSTALLATION

1.

2. It is important that the position of the terminal allows the free

* Only one reduction down to 25mm is allowable per installation

otherwise BS5440-1 2008 dimensions must be followed.

Flue Terminal Positions

Min. Spacing*

1. Directly below, above or alongside an opening

2.

BS5440-1 2008 75mm (3”)

3.

BS5440-1 2008 200mm (8”)

4.

BS5440-1 2008 200mm (8”)

5.

BS5440-1 2008 150mm (6”)

6.

BS5440-1 2008 300mm (12”)

7.

8.

9.

10. From an opening in a car port

11.

12.

Vertical Terminals

13.

14.

15.

16.

Table 4 - Balanced Flue Terminal Position

3. Minimum acceptable spacing from the terminal to obstructions

4.

5.

6.

Detailed recommendations on the protection of combustible

IMPORTANT

of combustion discharging from the terminal cannot re-enter the

building or buildings through any openings into the building such

as ventilators, windows, doors, or other sources of natural air

should be immediately investigated and corrected following the

guidance provided in the current Gas Industry Unsafe Situation