1

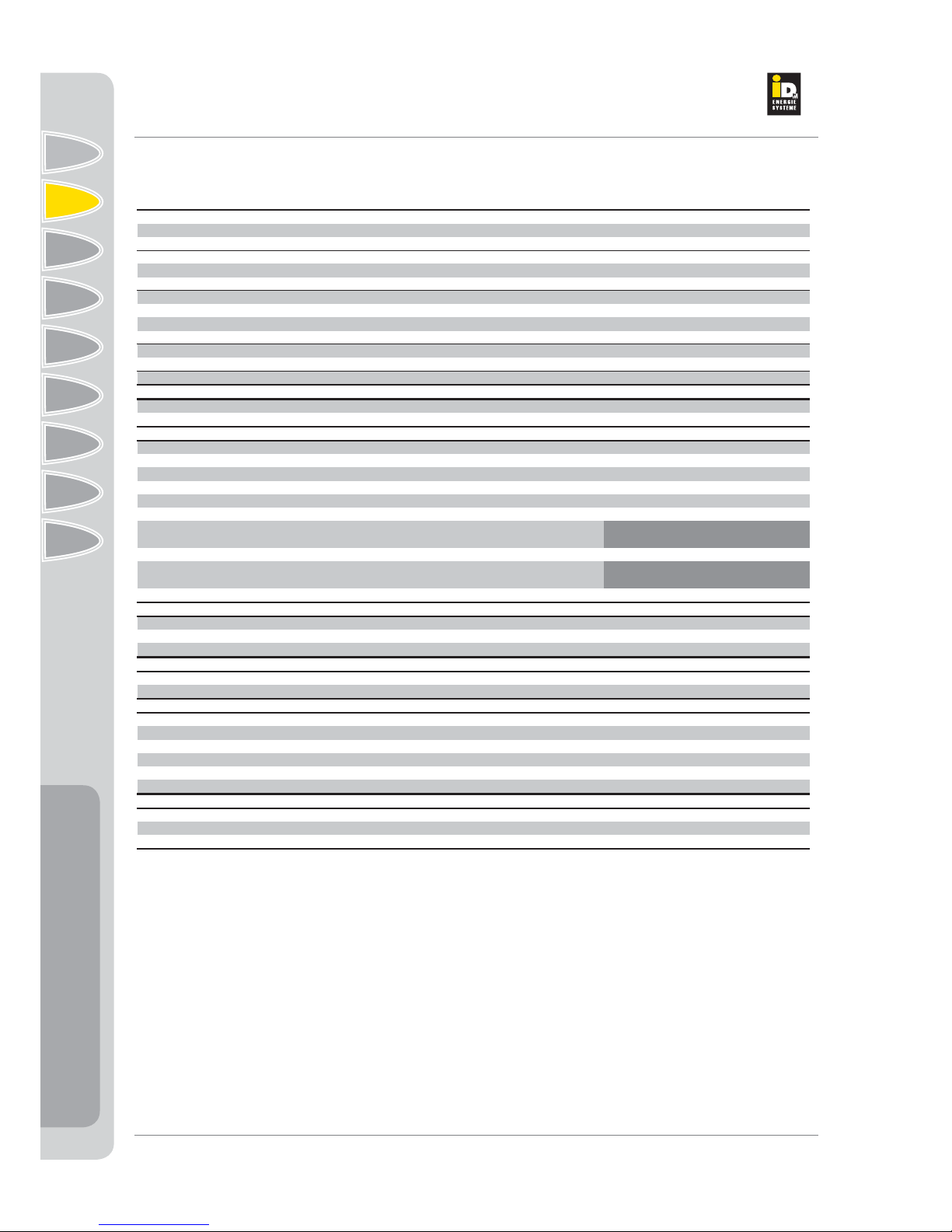

Description

1. Description

1.1. General Information

By purchasing this system you have acquired a

modern and efficient heating system. Ongoing qua-

lity controls and improvements as well as functional

checks at the plant guarantee you technically perfect

equipment.

Please read through this documentation carefully. It

contains important information for correct installation

and safe and economical operation of the system.

Safety instructions:

Installation and maintenance work can be hazardous

due to high system pressure, high temperatures and

live parts and may only be operated by specialist staff.

Heat pumps may only be installed by competent spe-

cialist staff and commissioned by a customer service

company trained to do so by IDM-Energiesysteme

GmbH. When working on the heat pump, the system

mustbedeactivatedandsecuredagainstreactivation.

In addition, all safety instructions in the relevant do-

cumentation, stickers on the heat pump itself and all

other applicable safety regulations must be observed.

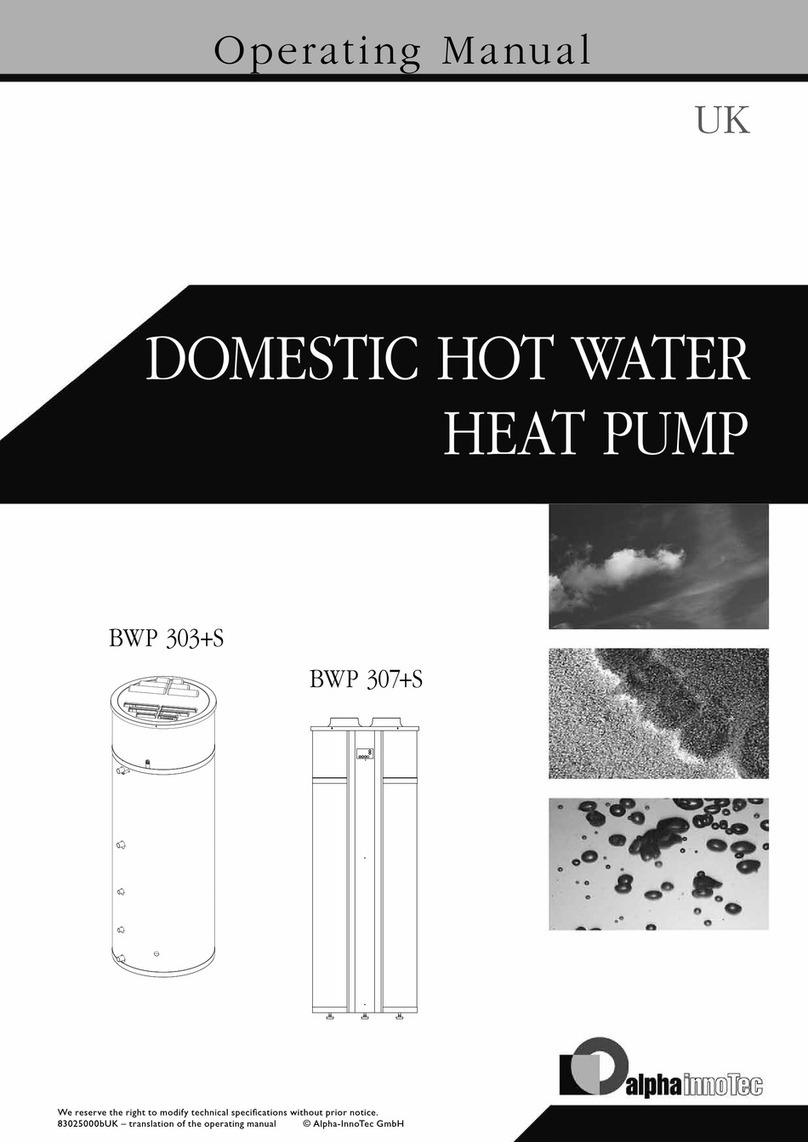

Transport:

During transport, the heat pump must never be

inclined more than 30°. The heat pump must not be

transported on the connection fittings. The transport

packaging may only be removed if the heat pump is

located at its installation location.

Sound emission:

TERRAheat pumps are very quiet in operation thanks

to their design. It is however important that the site of

the heater is situated as far as possible from noise-

sensitive living areas. A noise-insulating door should

be fitted door.

Construction drying and screed heating

The heat pump is not designed for the increased heat

requirements when drying out construction work or

heating plaster or screed. This must be covered by

equipment to be provided by the customer if required.

Servicing and maintenance:

Regular maintenance as well as checking and servi-

cing of all system components guarantee its safe and

economical operation in the long term. To achieve

this, we recommend a maintenance contract with the

relevant customer service company.

Cleaning:

If necessary, the TERRA heat pump can be cleaned

with a damp cloth. The use of cleaning agents is not

recommended.

Installing additional components:

The installation of additional components which

have not been tested with the equipment may impair

function. No liability is accepted and the guarantee

becomes void in the event of damage caused for this

reason.

Standards and directives:

Note for the installation of the heatpump

follow all effective national and inter-

national piping- and installation rules

same as rules for accident prevention and

safety regulations when installing pipeline

systems and electrical components and

equipment as well as the instructions of

this Installation instruction.

Thereto belongs among other things:

- the general effective rules for accident prevention

and safety regulations

- the regulations for environmental protection

- the provisions/regulations of the professional asso-

ciations.

- the effective laws, standards, guidelines and regu-

lations e.g. DIN,EN,DVGW,VDI and VDE

- regulations of the local suppliers/supply companies