Heat pumps AIR / WATER

Operation manual 2

1. EXPLANATION OF SYMBOLS, DOCUMENTATION

VALIDITY................................................................2

1.1 Used symbols ............................................................. 2

1.2 Documentation validity.............................................. 2

2. IMPORTANT INFORMATION............................2

2.1 Safety......................................................................... 3

2.1.1 Personal protective equipment ........................... 3

2.1.2 Fire safety equipment.......................................... 3

2.1.3 Device treatment................................................. 4

2.1.4 Installation and maintenance .............................. 4

2.1.5 Risk of death by electric shock............................. 5

2.1.6 Danger of injury due to icing ............................... 5

2.2 Service inspections and maintenance......................... 5

2.2.1 System modifications........................................... 6

2.3 Damage protection..................................................... 6

2.3.1 Water quality and volume ................................... 6

2.3.2 Stainless steel water tanks................................... 6

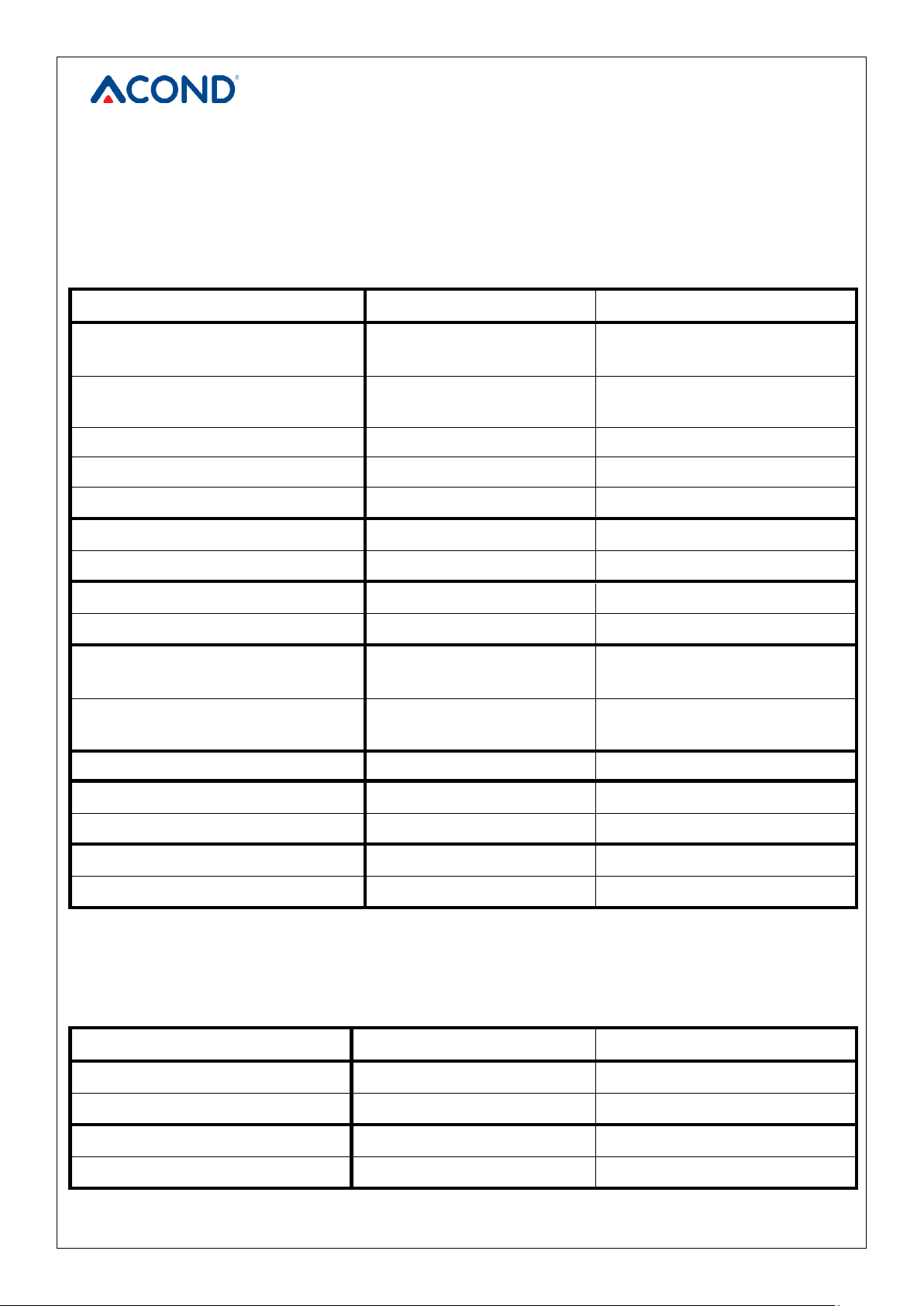

2.4 Technical specifications .............................................. 8

2.4.1 Operating conditions of the ACOND heat pump 10

2.5 Description of heat pump operation ........................ 11

2.5.1 Heating .............................................................. 11

2.5.2 Defrosting .......................................................... 11

2.5.3 Adverse climatic conditions ............................... 12

2.5.4 Summer/winter switching ................................. 12

3. HEAT PUMP CONTROL .................................12

3.1 Heat pump control via indoor control unit ............... 13

3.1.1 RCM2-1 indoor control unit............................... 13

3.1.2 Meaning of individual symbols of the RCM2-1

control unit panel............................................................. 13

3.1.3 Basic view .......................................................... 14

3.1.4 To turn the heat pump on / off:......................... 14

3.1.5 How to set the desired room temperature........ 15

3.1.6 How to Determine Outdoor Temperature ......... 15

3.1.7 How to Detect and Change service water

Temperature..................................................................... 15

3.1.8 How to set the end of heating temperature...... 15

3.1.9 Display, Fault Confirmation................................ 16

3.1.10 Entering heat pump parameters................... 16

3.2 Control via web interface ......................................... 17

3.2.1 Heat pump internet connection......................... 17

3.2.2 Login to the system............................................ 17

3.2.3 Start page........................................................... 21

3.2.4 Meaning of pictograms (symbols)...................... 22

3.2.5 Setting Values.....................................................23

3.2.6 Opting ................................................................ 25

3.2.7 Control mode selection...................................... 25

3.2.8 Solar panel .........................................................26

3.2.9 Swimming pool .................................................. 27

3.2.10 Fault display .................................................. 27

3.2.11 Time plans .....................................................28

3.2.12 Information, HDO selection........................... 31

3.2.13 Equipment.....................................................32

3.2.14 Periods........................................................... 32

3.2.15 Hours of operation ........................................ 33

3.3 Earth / water heat pump, GENIUS! (Z and ZG models)

33

4. ALARMS, FAULTS AND TROUBLESHOOTING.. 33

4.1 Fault acknowledgement........................................... 33

5. REGULAR CHECKS ........................................ 37

5.1 Inspection of intake and exhaust grilles and openings

37

5.2 Checking the cooling circuit...................................... 37

5.3 Operation control..................................................... 38

5.4 Pressure control in the heating system..................... 38

5.4.1 System and expansion vessel pressure control

procedure.........................................................................38

5.5 Cleaning filters in the heating system....................... 39

5.5.1 Filter cleaning process .......................................40

5.6 Ventilating the system.............................................. 40

5.7 Magnesium anode check.......................................... 41

5.7.1 Anode Check (Replace) Procedure..................... 41

5.8 Safety valve.............................................................. 41

6. LIQUIDATION ............................................... 42