IDM-Energiesysteme TERRA 5 S/W H Guide

Aus

g

abe 15/09/1

1

THE POWER FAMILY

www.idm-energie.com

Heat pumps with freshwater technology

Technical documentation

Installation instructions

TERRA S/W BA (H) 05 - 45

for Brine and Ground Water Systems

with Navigator®1.0 Control

812216 Rev.7 - Translation of original instruction

THE POWER FAMILY

(C) IDM ENERGIESYSTEME GMBH

1

.

A

llgemei

n

e I

n

formatio

n

e

n

Installation TERRA S/W

2

1

2

3

4

5

6

7

8

9

1

0

1

1

1

2

1

3

Contents

Contents

1. GENERAL INFORMATION 4

1.2. General information 4

1.3. Safety Instructions 4

1.4. Transport 4

1.5. Sound Emission 4

1.6. Construction drying and screed heating 4

1.7. Servicing and Maintenance 4

1.8. Cleaning 4

1.9. Installing Additional Components 4

1.10. Installation Room 5

1.11. Protection of the environment 5

1.12. Standards and directives 5

2. DESCRIPTION 6

2.1. Description 6

2.2. Application range 6

2.3. Scope of delivery 6

2.4. Accessories 6

2.5. Dimensions 7

2.6. Technical data 8

2.7. Operating Limits 20

3. HEATING SIDE INSTALLATION 21

3.1. Installation 21

3.2. Installation Heating Side 25

4. ELECTRICAL INSTALLATION 26

4.1. Power supply 26

4.2. Connection Diagram Electrical Components 27

4.3. Disassembly Cover 28

4.4. Power Supply Connection 28

4.5. Heat Source Pump Connection 29

4.6. EMC 29

4.7. Layout of the Inputs on the Central Unit 30

4.7.1. Sensor design 31

4.7.2. Sensor equipment 31

4.7.3. Flow temperature sensor 31

4.8. Impulse inputs 31

4.9. Layout Outputs 33

4.9.1. Triac outputs (10 - 12): 33

4.9.2. Digital outputs 230V AC (20 - 38): 34

4.10. Connection of the mixers 35

4.11. System Earthing 35

4.12. Maximum restriction for underfloor heating: 35

4.13. Composite signal zone valves 35

THE POWER FAMILY

(C) IDM ENERGIESYSTEME GMBH Installation TERRA S/W 3

1

2

3

4

5

6

7

8

9

1

0

11

1

2

1

3

Contents

Contents

5. HEAT SOURCE 36

5.1. Brine Surfaces Collector 36

5.1.1. Description 36

5.1.2. Application range 36

5.1.3. Scope of delivery 36

5.2. Connection diagram 37

5.2.1. Laying diagram 38

5.3. Brine depth probe 38

5.3.1. Description 38

5.3.2. Application range 38

5.3.3. Scope of delivery 38

5.3.4. Installation diagram 39

5.4. Ground water use 40

5.4.1. Description 40

5.4.2. Application range 40

5.4.3. Installation diagram 41

5.4.4. Accessories 41

6. COMMISSIONING 42

6.1. Commissioning information 42

6.1.1. Selection of the Heat Source Pump 42

6.2. Operation 42

6.3. Faults 42

All rights reserved for modifications to the technology and design.

1

2

3

4

5

6

7

8

9

1

0

1

1

1

2

1

3

THE POWER FAMILY

(C) IDM ENERGIESYSTEME GMBH

G

e

n

eral i

n

formatio

n

Installation TERRA S/W

4

1

General information

1.2. General information

By purchasing this system you have acquired a

modern and efficient heating system. Ongoing qual-

ity controls and improvements as well as functional

checks at the plant guarantee you technically perfect

equipment.

Please read through this documentation carefully.

Itcontainsimportantinformationforcorrectinstallation

and safe and economical operation of the system.

1.3. Safety Instructions

Installation and maintenance work can be hazardous

due to high system pressure, high temperatures and

live parts and may only be operated by specialist

staff.

Heat pumps may only be installed by competent spe-

cialist staff and commissioned by a customer service

company trained to do so by IDM-Energiesysteme

GmbH.

When working on the heat pump, the system must be

deactivated and secured against reactivation.

In addition, all safety instructions in the relevant docu-

mentation,stickersontheheatpumpitselfandallother

applicable safety regulations must be observed.

1.4. Transport

During transport, the heat pump must never be

inclined more than 30°. The heat pump must not be

transported on the connection fittings. The transport

packaging may only be removed if the heat pump is

located at its installation location.

1.5. Sound Emission

TERRAheat pumps are very quiet in operation thanks

to their design. It is however important that the site of

the heater is situated as far as possible from noise-

sensitive living areas. A noise-insulating door should

be fitted door.

1.6. Construction drying and screed heating

The heat pump is not designed for the increased

heat requirements when drying out construction work

or heating plaster or screed. This must be covered

by equipment to be provided by the customer if re-

quired.

1.7. Servicing and Maintenance

Regular maintenance as well as checking and servic-

ing of all system components guarantee its safe and

economical operation in the long term. To achieve

this, we recommend a maintenance contract with the

relevant customer service company.

1.8. Cleaning

If necessary, the TERRA heat pump can be cleaned

with a damp cloth. The use of cleaning agents is not

recommended.

1.9. Installing Additional Components

The installation of additional components which

have not been tested with the equipment may impair

function. No liability is accepted and the guarantee

becomes void in the event of damage caused for this

reason.

1. General information

1

2

3

4

5

6

7

8

9

1

0

11

1

2

1

3

THE POWER FAMILY

(C) IDM ENERGIESYSTEME GMBH Installation TERRA S/W 5

1

General information

General information

1.10. Installation Room 1.11. Protection of the environment

1.12. Standards and directives

General instructions on operating the heat

pump.

Important instructions on assembling and

operating the heat pump. It is imperative

that these are observed.

General instructions on assembling the heat

pump.

Space for customer service

telephone number

Heatpumps are electrical equipment

made from high valuable materials,

which are not allowed to be disposed

like normal household garbage, but

have to be disposed professional and

proper according the regulations of the

local authorities.

A non-proper disposal can cause, apart

from sanctions for the violator, environ-

mental damages and harm for your

health.

-The TERRA heat pumps should be

installed in a frost-proof room. (Room

temperature should be between 5°C

and 35°C)

-In case of a floating floor screed the screed and

the sound damping around the heat pump have

to be omitted.

-Heat pumps should not be installed in wet rooms

or in potentially dust or explosion-endangered

rooms.

-Gas from refrigerants in plant rooms must not es-

cape into vicinal rooms, stair rooms, courtyards,

walks or into the drainage system of the building.

The gas has to be channelled off safely.

-In case of danger, the plant room has to be eva-

cuated immediately.

-For powering off the cooling facility, a remote

power-off switch has to be installed nearby the

door of the plant room.

-In case a natural ventilation is not possible, a

mechanical ventilation has to be provided. A

mechanical ventilation has to be equipped with

an independent emergency control outside of the

machine room near the door.

Note for the installation of the heatpump

follow all effective national and inter-

national piping- and installation rules

same as rules for accident prevention and

safety regulations when installing pipeline

systems and electrical components and

equipment as well as the instructions of

this Installation instruction.

Thereto belongs among other things:

- the general effective rules for accident prevention

and safety regulations

- the regulations for environmental protection

- the provisions/regulations of the professional asso-

ciations.

- the effective laws, standards, guidelines and regu-

lations e.g. DIN,EN,DVGW,VDI and VDE

- regulations of the local suppliers/supply companies

THE POWER FAMILY

(C) IDM ENERGIESYSTEME GMBH

2

.

A

llgemei

n

e I

n

formatio

n

e

n

Installation TERRA S/W

6

1

2

3

4

5

6

7

8

9

1

0

1

1

1

2

1

3

1

2

Description

2. Description

2.1. Description

Heat pump with suction gas cooled scroll compressor

with generously sized stainless steel heat exchangers

as evaporator and condenser built on a robust frame

and fitted with a heat and soundproof casing.

The heat pump also contains an electrical panel with

the Navigator Control and with all the switching and

safety mechanisms built-in.

The heat pump has a compact design, the evaporator

is already fitted in the heat pump housing. The heat

pump is filled with refrigerant and checked to ensure

it functions correctly. It is suitable for brine circuit sur-

face collectors, brine circuit deep boreholes, as well

as for ground water use.

2.2. Application range

For the monovalent heating of detached and semi-

detached houses with geothermal heat utilisation.

When doing so the house should be fitted with a low

temperature heating system (e.g. underfloor heating,

wall heating, low temperature radiator heating).

TERRA heat pumps work with the safety refrigerants

R 407 C or R 134 A which, when properly installed

and commissioned, circulate in a closed circuit and

therefore have virtually no environmental impact.

2.3. Scope of delivery

- Heat pump unit with suction gas cooled scroll com-

pressor

- Stainless steel plate heat exchanger as condenser

- Stainless steel plate heat exchanger as evaporator

- Refrigerant collector and dryer

- Thermostatic expansion valve

- Refrigerant inspection glass

- Refrigerant heat exchanger

- High pressure and low-pressure limiter

- Electrical panel with Navigator Control

- Stable base frame

- Cladding, insulated against heat and noise

-4flexible connection hoses

- Start-up current limiter for compressor

2.4. Accessories

- Brine surface collector made of plastic piping Ø 25

x 2.3 mm in rings for each 100 m, incl. distributors

and connection material and brine circuit pump

- Expansion set for 2 additional mixer circuits

- Charging pump assembly with pump 2 shut-off

valves and pump beater

- Safety heat exchanger (Groundwater heat pumps)

Thelower themaximum flowtemperature

is set, the higher the efficiency of the heat

pump.

The respective charging pumps are not

included in the scope of delivery. These

can be ordered as accessories.

THE POWER FAMILY

(C) IDM ENERGIESYSTEME GMBH Installation TERRA S/W 7

1

2

3

4

5

6

7

8

9

1

0

11

1

2

1

3

1

2

7

762

B

A

2

1

3

2

1

3

C

D

F

E

G

6

7

4

5

6

7

4

5

Vorderseite Linke Seite Rückseite

210

725

145 230

1

2

3

4

5

8

7

6

Wärmepumpe

MM

620 1100

1200

70

300

210

725

1

3

4

5

2

7

6

Description

Description

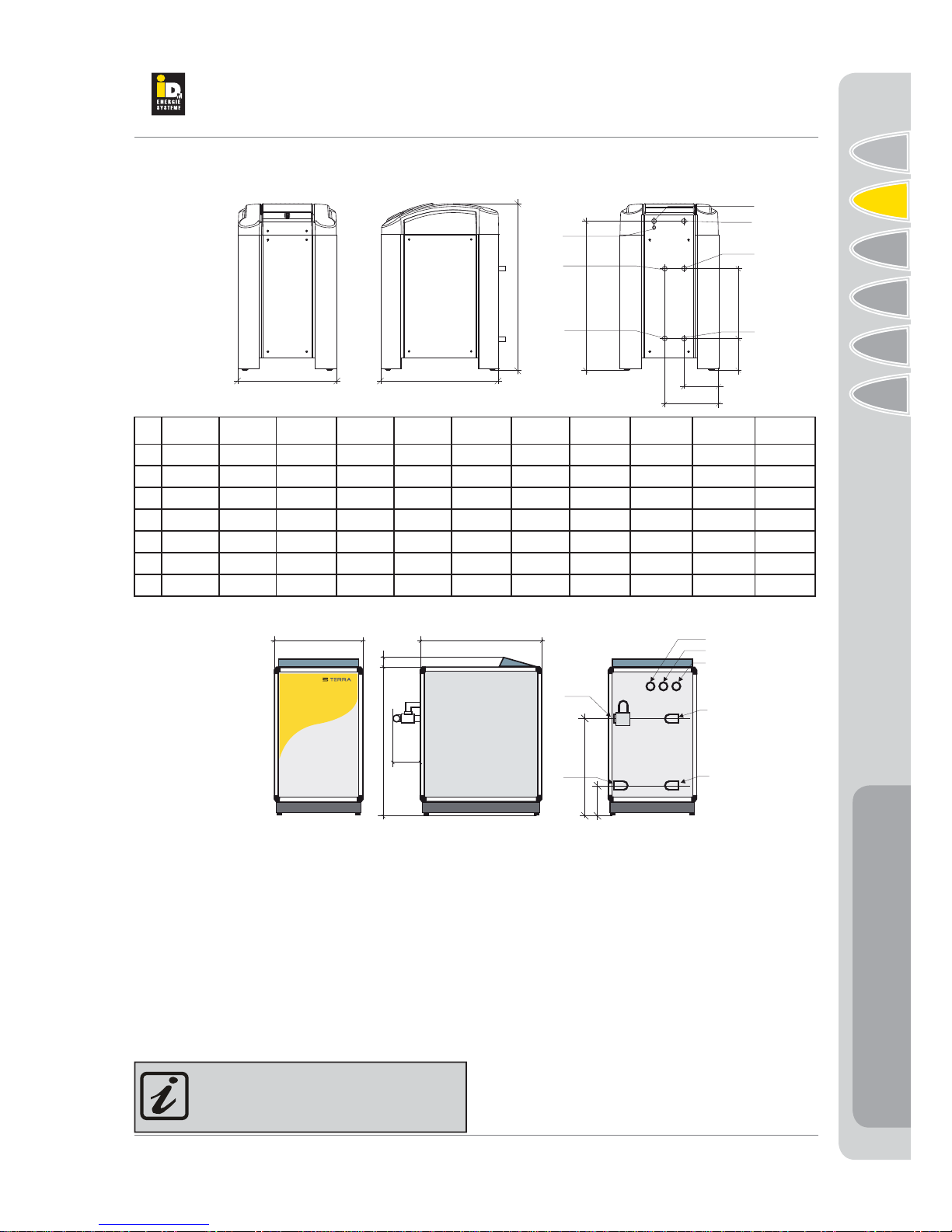

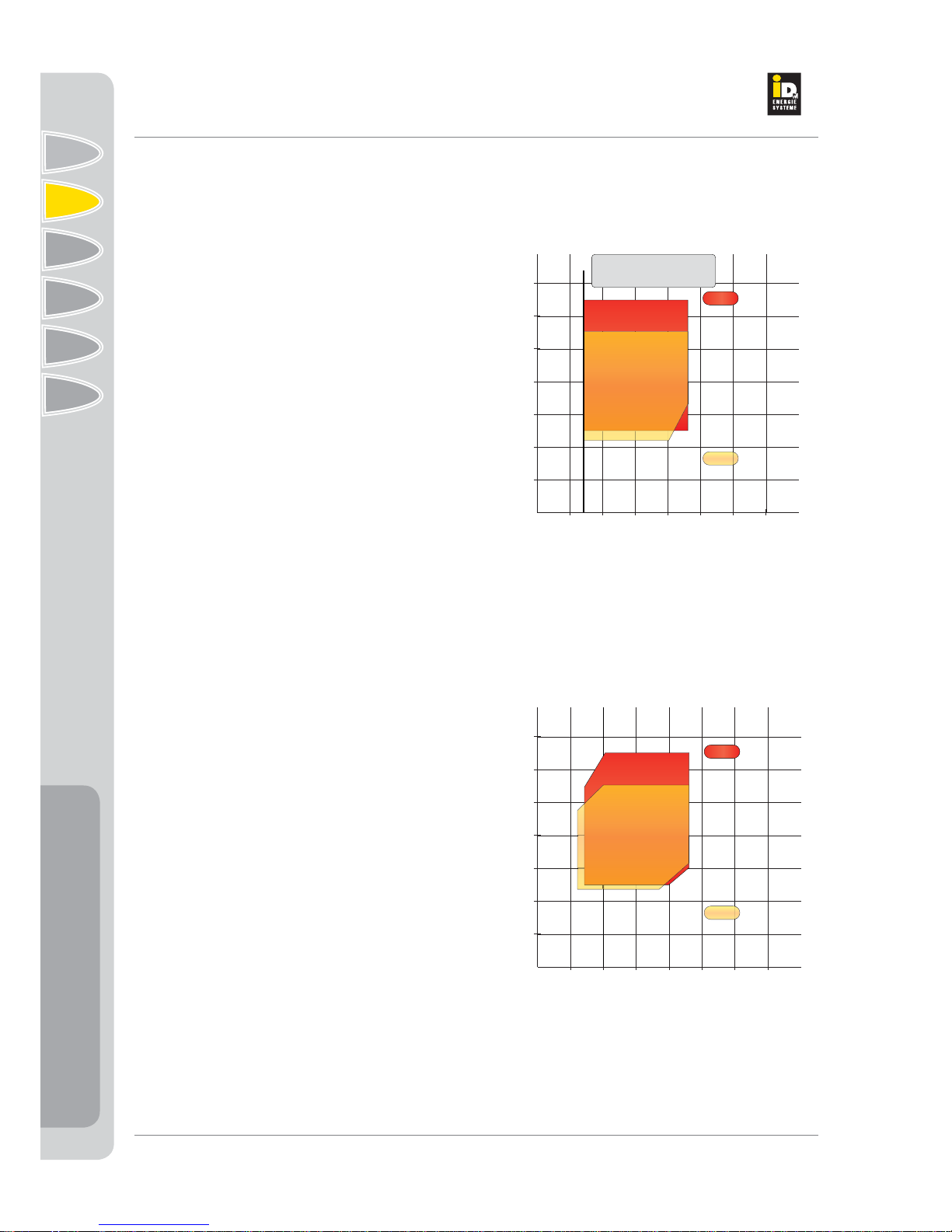

2.5. Dimensions

5 S/W 7 S/W 8 S/W 10S/W 12S/W 15S/W 17S/W 19S/W 22S/W 26S/W 30S/W

A622 622 622 622 622 622 622 622 750 750 750

B1160 1160 1160 1160 1160 1160 1160 1160 1160 1160 1160

C1025 1025 1025 1025 1025 1025 1025 1025 1025 1025 1025

D466 466 466 466 466 466 466 466 457 457 457

E220 220 220 220 220 220 220 220 210 210 210

F190 190 190 190 190 190 190 190 264 264 264

G322 322 322 322 322 322 322 322 469 469 469

Key:

1 Heat pump flow connection (please use enclosed connection hose)

2 Opening for main current connection

3 Heat pump return connection (please use enclosed connection hose)

4 Brine inlet (please use enclosed connection hose)

5 Brine outlet (please use enclosed connection hose)

6 Opening for ground water pump control

7 Opening for low voltage cable (sensor and data lines)

Dimensions of the connections: see technical data on the following pages.

On the rear of the heat pump there is

a sticker with the description of the con-

nection.

SW 05-30:

SW 37-45:

THE POWER FAMILY

(C) IDM ENERGIESYSTEME GMBH

2

.

A

llgemei

n

e I

n

formatio

n

e

n

Installation TERRA S/W

8

1

2

3

4

5

6

7

8

9

1

0

1

1

1

2

1

3

1

2

Description

Description

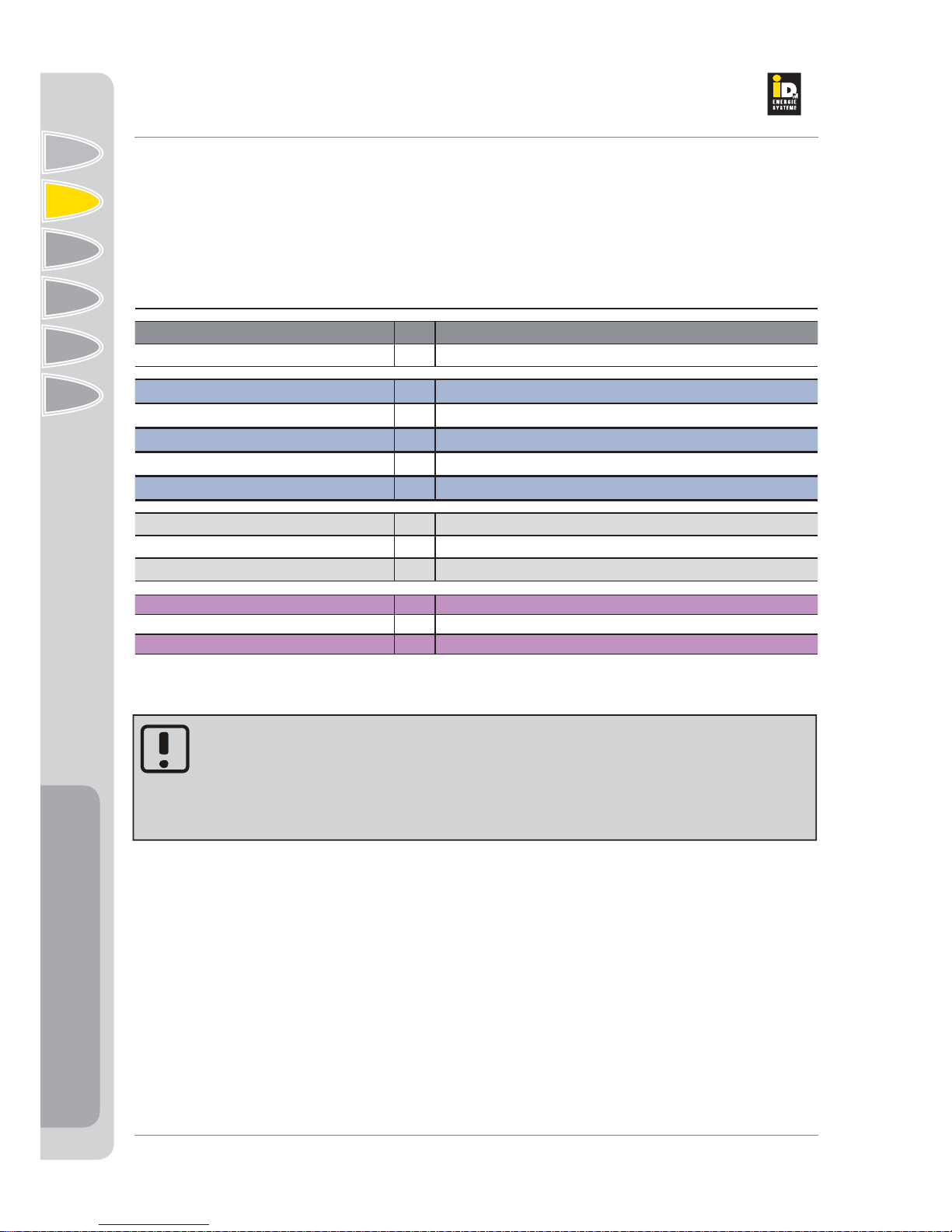

Technical Data TERRA S/W with R407C

Type TERRA (BA) (HGL) Unit 5 S/W 7 S/W 8 S/W 10 S/W 12 S/W

Dimensions (H x W x D) cm 116/62/76 116/62/76 116/62/76 116/62/76 116/62/76

Weight HGL/Basic kg 130/116 136/122 144/130 150/136 156/140

Electrical connection of the primary circuit V/Hz 3x400 / 50 3x400 / 50 3x400 / 50 3x400 / 50 3x400 / 50

Power consumption compressor A 4.2 5.1 6.3 7 10

Start-up current compressor (with soft start) A 10.5 12.75 15.75 17.5 25

Electrical connection control circuit V/Hz 230 / 50 230 / 50 230 / 50 230 / 50 230 / 50

Fuse control circuit A 13 13 13 13 13

Refrigerant R 407 C R 407 C R 407 C R 407 C R 407 C

Filling volume kg 1.8 2.05 2.2 2.5 2.6

Filling volume compressor oil l 1 1 1.1 1.1 1.36

Minimum size installation room m³ 5.8 6.1 6.5 6.8 8.4

Minimum size ventilation opening (natural) m² 0.19 0.19 0.20 0.20 0.23

Minimum air flow (mechanical) m³/h 75 77 80 83 95

2.6. Technical data

For the dimensioning of the fuse to be connected in series in the primary circuit, the nominal

current of the compressor and the on-site heat source pump as well as, if available, of the inter-

mediate circuit pump must be added.

Recommended power protection switch types: 3-pole Type C, K

THE POWER FAMILY

(C) IDM ENERGIESYSTEME GMBH Installation TERRA S/W 9

1

2

3

4

5

6

7

8

9

1

0

11

1

2

1

3

1

2

Description

Description

15 S/W 17 S/W 19 S/W 22 S/W 26 S/W 30 S/W 37 S/W 45 S/W

116/62/76 116/62/76 116/62/76 126/75/76 126/75/76 126/75/76 130/62/110 130/62/110

164/148 172/154 178/160 248/230 262/244 268/250 320/300 342/322

3x400 / 50 3x400 / 50 3x400 / 50 3x400 / 50 3x400 / 50 3x400 / 50 3x400 / 50 3x400 / 50

11 13 15 15.9 16.8 19.6 28 34

27.5 32.5 37.5 39.8 42 49 70 85

230 / 50 230 / 50 230 / 50 230 / 50 230 / 50 230 / 50 230 / 50 230 / 50

13 13 13 13 13 13 13 13

R 407 C R 407 C R 407 C R 407 C R 407 C R 407 C R 407 C R 407 C

2.9 3.2 3.4 3.95 8.4 9.4 10.5 10.8

1.85 1.65 1.65 4.1 4.1 4.1 4.1 4.1

9.4 10,0 11.0 12.3 26.5 30.0 33.9 34.8

0.24 0.25 0.26 0.27 0.40 0.43 0.45 0.46

102 107 114 123 205 223 242 246

THE POWER FAMILY

(C) IDM ENERGIESYSTEME GMBH

2

.

A

llgemei

n

e I

n

formatio

n

e

n

Installation TERRA S/W

10

1

2

3

4

5

6

7

8

9

1

0

1

1

1

2

1

3

1

2

Description

Description

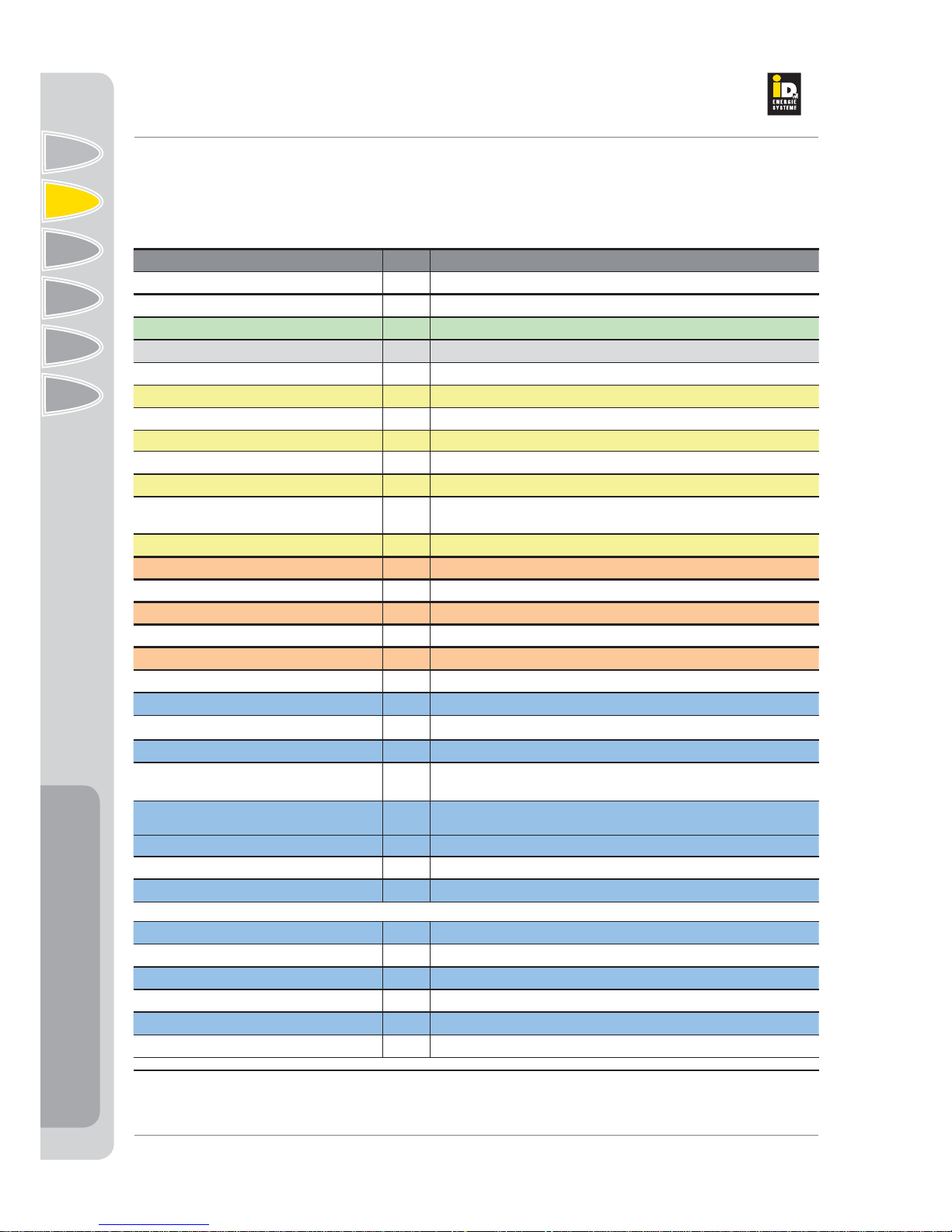

Technical Data TERRA S/W for Brine Application with R407C

Type TERRA (BA) (HGL) Unit 5 S/W 7 S/W 8 S/W 10 S/W 12 S/W

Heating performance for S0°C/W35°C EN 255 kW 5.4 6.8 8.3 9.7 12.0

Heating performance for A2°C/W35°C kW 5.37 6.76 8.25 9.64 11.93

Power consumption for S0°C/W35°C EN 255 kW 1.23 1.55 1.80 2.10 2.59

Power consumption for S0°C/W35°C kW 1.29 1.63 1.89 2.20 2.72

COP for S0°C/W35°C EN 255 4.40 4.40 4.60 4.62 4.63

COP for S0°C/W35°C 4.15 4.15 4.37 4.38 4.38

Radiator flow and return pipe P [O.T.] 1" 1" 1" 1" 1"

HGL connection P [O.T.] 1" 1" 1" 1" 1"

Max. flow temperature °C 55 55 55 55 55

Min. heating circuit water volume l/h 900 1100 1.400 1600 2.000

Pressure loss, heating side kPa 9 12 12 16 14

Recommended or installed storage tank

charging (Grundfos/ Wilo) UPS 25-60

EAS 25/6 UPS 25-60

EAS 25/6 UPS 25-60

EAS 25/6 UPS 25-60

EAS 25/6 UPS 25-60

EAS 25/6

Free residual pressure of the charging pump kPa 40 36 32 26 24

In heat pumps with process reversal

Cooling performance for W/B 15°C/8W°C kW 4.60 6.00 7.10 8.35 10.35

Cooling performance for W/B 15°C/18W°C kW 6.45 8.40 9.95 11.70 14.45

Power consumption for W/B15°C/8°C kW 0.96 1.23 1.44 1.70 2.10

Power consumption for W/B15°C/18°C kW 0.96 1.23 1.44 1.70 2.05

ERR at W/B 15°C/W8°C 4.79 4.88 4.93 4.91 4.93

Brine inlet and outlet P [O.T.] 1" 1" 1" 1" 1"

Minimum brine circulation volume kg/h 1050 1300 1600 1900 2350

Pressure loss on the brine side kPa 7 10 14 12 14

Recommended brine circuit pump Wilo

Top S 25/7 Wilo

Top S 25/7 Wilo

Top S 25/7 Wilo

Top S 25/7 Wilo

Top S 25/7

Dimension of the connection lines up to 40 m

total length mm 32 x 2.0 32 x 2.0 40 x 2.3 40 x 2.3 40 x 2.3

Number of brine circuits 3 3 4 5 6

Total pipe length m 300 300 400 500 600

Brine filling volume (mix) l 105 105 140 175 210

Depth probe 1/80 1/100 2/130 2/150 2/190

Number of depth probes 1 1 2 2 2

Total probe length m 80 100 130 150 190

Filling volume brine mix (1 x 40 mm probe) l 140 175 225 260 325

Filling volume brine mix (2 x 32 mm probe) l 175 220 285 325 410

Sound power level dBA 53 53 55 55 55

*Reference values for 50 W/m extraction performance

THE POWER FAMILY

(C) IDM ENERGIESYSTEME GMBH Installation TERRA S/W 11

1

2

3

4

5

6

7

8

9

1

0

11

1

2

1

3

1

2

Description

Description

15 S/W 17 S/W 19 S/W 22 S/W 26 S/W 30 S/W 37 S/W 45 S/W

14.9 17.2 19.6 22.1 24.2 27.9 34.8 41.8

14.81 17.10 19.48 21.97 24.15 27.84 34.73 41.72

3.16 3.64 4.10 4.77 5.23 6.04 8.25 9.88

3.34 3.86 4.41 5.02 5.51 6.49 8.66 10.38

4.72 4.73 4.71 4.63 4.63 4.62 4.22 4.23

4.43 4.43 4.42 4.38 4.38 4.29 4.01 4.02

1" 1 1/4" 1 1/4" 1 1/2" 1 1/2" 1 1/2" 2" 2"

1" 1" 1" 1" 1 1/4" 1 1/4" 1 1/4" 1 1/4"

55 55 55 55 55 55 55 55

2.400 2.700 3.100 3600 4.300 5.000 6000 7.400

21 17 17 15 22 22 18 21

UPS 25-80 UPS 25-80 UPS 25-80 UPS 25-80

Top S 30/7 UPS 25-80

Top S 30/7 TOP S 30/10 TOP S 40/10 TOP S 40/10

44 44 42 40 28 60 74 67

12.65 15.40 17.10 19.30 23.30 27.00 33.50 40.50

18.00 21.40 23.90 27.20 32.50 37.50 46.00 56.00

2.58 2.99 3.33 3.91 4.65 5.25 6.70 8.00

2.76 3.12 3.52 4.20 4.70 5.35 7.10 8.90

4.90 5.15 5.14 4.94 5.01 5.14 5.00 5.06

1" 1 1/4" 1 1/4" 1 1/2" 1 1/2" 1 1/2" 2" 2"

2900 3.400 3.850 4.300 5150 5.900 7.200 8.800

13 16 16 16 20 20 20 21

Grundfos

UPS 25-80 Grundfos

UPS 32-80 Grundfos

UPS 32-80 Grundfos

UPS 32-80 Wilo

TOP S 40/10 Wilo

TOP S 40/10 Wilo

TOP S 50/10 Wilo

TOP S 50/10

50 x 2.9 50 x 2.9 50 x 2.9 50 x 2.9 63 x 3.6 63 x 3.6 63 x 3.6 75 x 4.3

7 7 8 9 11 13 15 18

700 700 800 900 1100 1300 1500 1800

245 245 280 315 385 455 525 630

3/225 3/270 3/300 4/340 4/400 5/475 6/570 7/700

33344567

225 270 300 340 400 475 570 700

350 460 510 580 680 810 970 1180

485 580 645 730 860 1020 1220 1500

56 57 57 59 61 61 63 65

THE POWER FAMILY

(C) IDM ENERGIESYSTEME GMBH

2

.

A

llgemei

n

e I

n

formatio

n

e

n

Installation TERRA S/W

12

1

2

3

4

5

6

7

8

9

1

0

1

1

1

2

1

3

1

2

Description

Description

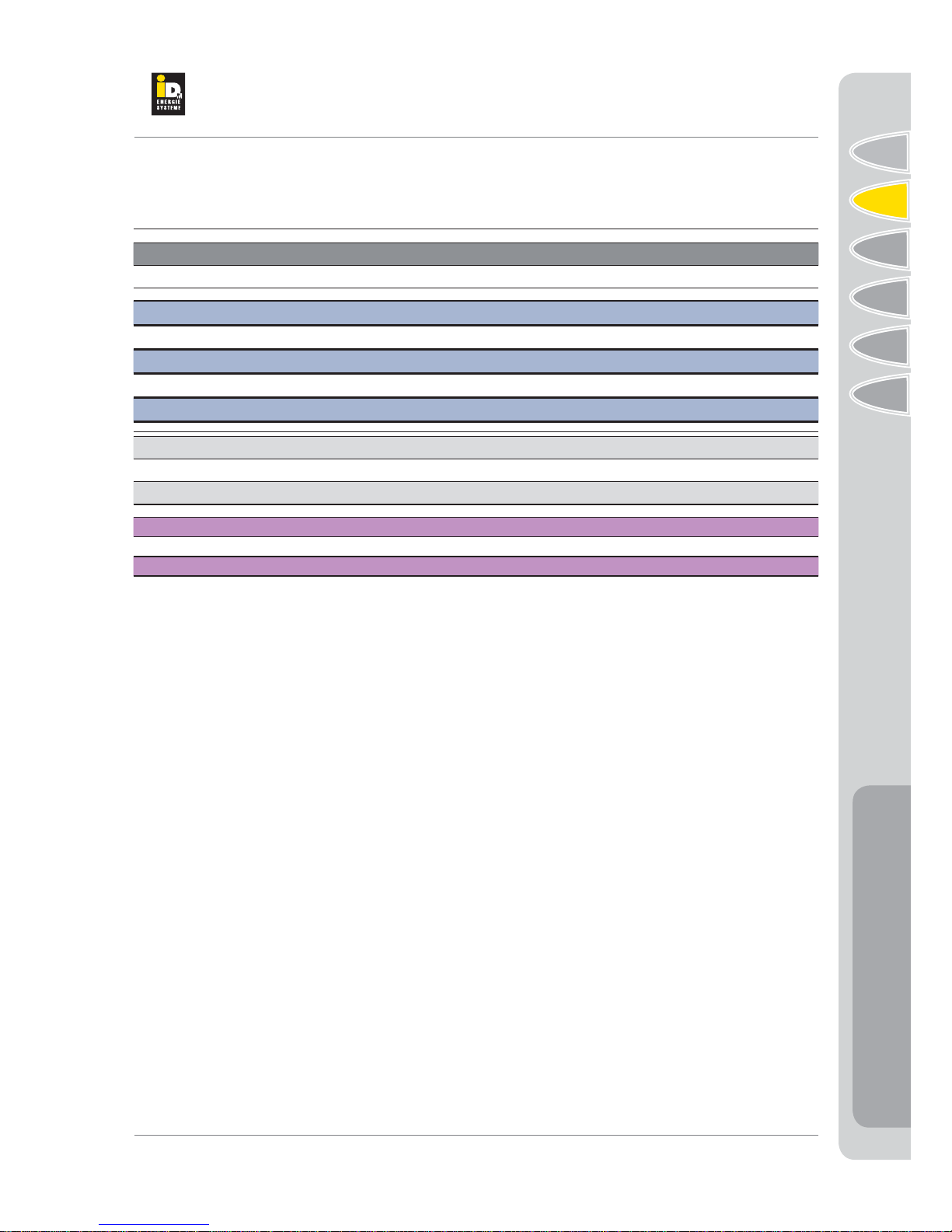

Technical Data TERRA S/W H with R134A

Type TERRA (BA) (HGL) Unit 5 S/W H 7 S/W H 8 S/W H 10 S/W H 12 S/W H

Dimensions (H x W x D) cm 116/62/76 116/62/76 116/62/76 116/62/76 116/62/76

Weight HGL/Basic kg 130/116 136/122 144/130 150/136 156/140

Electrical connection of the primary circuit V/Hz 3x400 / 50 3x400 / 50 3x400 / 50 3x400 / 50 3x400 / 50

Power consumption compressor A 3,59 4,48 5,3 6,06 7,34

Start-up current compressor (with soft start) A 10.5 12.75 15.75 17.5 25

Electrical connection control circuit V/Hz 230 / 50 230 / 50 230 / 50 230 / 50 230 / 50

Fuse control circuit A 13 13 13 13 13

Refrigerant R 134A R 134A R 134A R 134A R 134A

Filling volume kg 1.6 1.8 1.9 2 2.4

Filling volume compressor oil l 1 1 1.1 1.1 1.36

Minimum size installation room m³ 6.4 7.2 7.6 8 9.6

Minimum size ventilation opening (natural) m² 0.18 0.19 0.19 0.20 0.22

Minimum air flow (mechanical) m³/h 69 75 77 80 90

For the dimensioning of the fuse to be connected in series in the primary circuit, the nominal

current of the compressor and the on-site heat source pump as well as, if available, of the inter-

mediate circuit pump must be added.

Recommended power protection switch types: 3-pole Type C, K

THE POWER FAMILY

(C) IDM ENERGIESYSTEME GMBH Installation TERRA S/W 13

1

2

3

4

5

6

7

8

9

1

0

11

1

2

1

3

1

2

Description

Description

15 S/W H 17 S/W H 19 S/W H 22 S/W H 26 S/W H 230 S/W H 37 S/W H 45 S/W H

116/62/76 116/62/76 116/62/76 126/75/76 126/75/76 126/75/76 130/62/110 130/62/110

164/148 172/154 178/160 248/230 262/244 268/250 320/300 342/322

3x400 / 50 3x400 / 50 3x400 / 50 3x400 / 50 3x400 / 50 3x400 / 50 3x400 / 50 3x400 / 50

8,59 10,04 11,56 13,03 14,06 15,94 23,09 28,71

27.5 32.5 37.5 39.8 42 49 70 85

230 / 50 230 / 50 230 / 50 230 / 50 230 / 50 230 / 50 230 / 50 230 / 50

13 13 13 13 13 13 13 13

R 134 A R 134 A R 134 A R 134 A R 134 A R 134 A R 134 A R 134 A

2.7 2.9 3.1 4.1 7.7 8.9 10.6 10.9

1.85 1.65 1.65 4.1 4.1 4.1 4.1 4.1

10.8 11.6 12.4 16.4 30.8 35.6 42.4 43.6

0.23 0.24 0.25 0.28 0.39 0.42 0.46 0.46

98 102 107 129 197 216 243 248

THE POWER FAMILY

(C) IDM ENERGIESYSTEME GMBH

2

.

A

llgemei

n

e I

n

formatio

n

e

n

Installation TERRA S/W

14

1

2

3

4

5

6

7

8

9

1

0

1

1

1

2

1

3

1

2

Description

Description

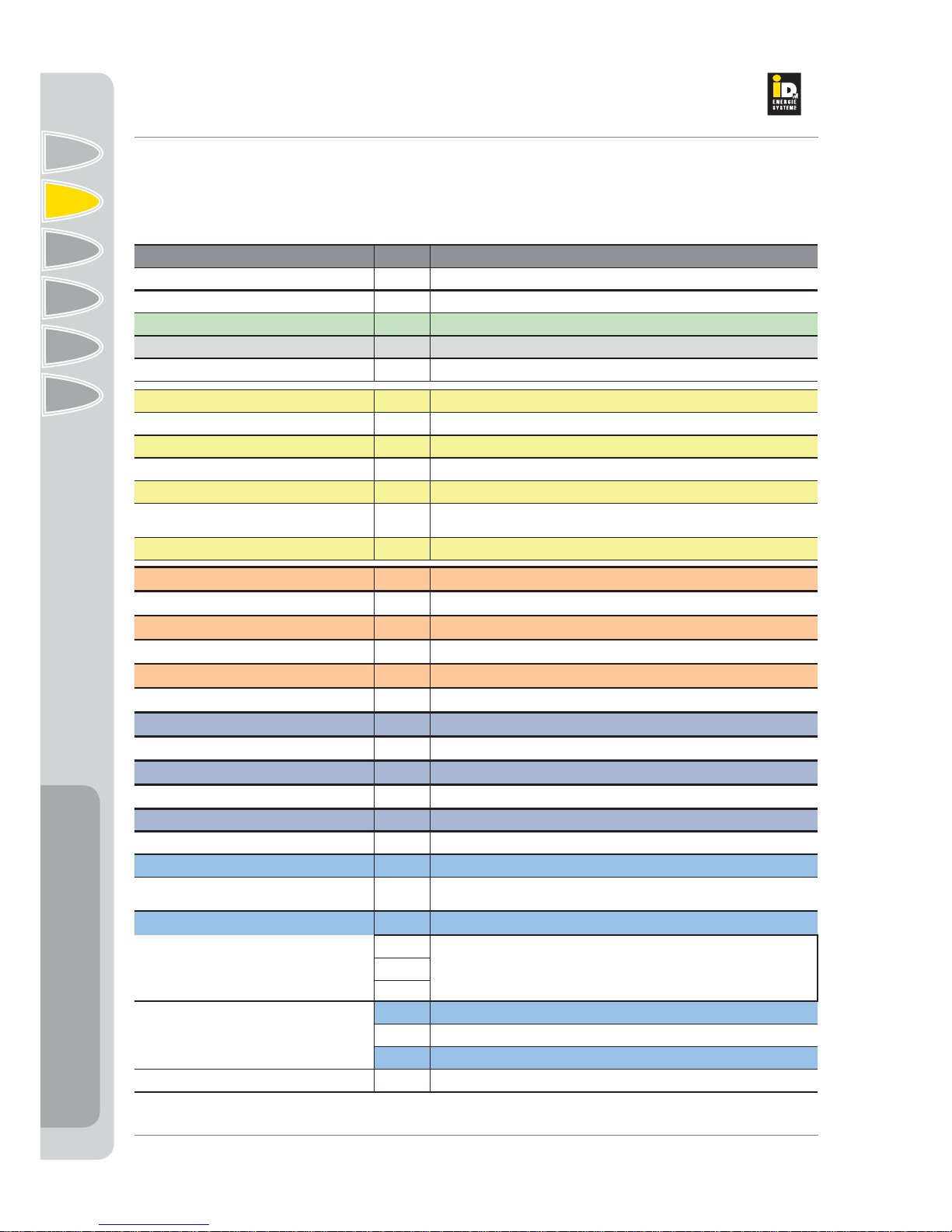

Type TERRA (BA) (HGL) Unit 5 S/W H 7 S/W H 8 S/W H 10 S/W H 12 S/W H

Heating performance for S0°C/W35°C EN 255 kW 3.50 4.40 5.36 6.12 7.38

Heating performance for A2°C/W35°C kW 3.40 4.27 5.20 5.94 7.16

Power consumption for S0°C/W35°C EN 255 kW 0.80 1.00 1.15 1.31 1.58

Power consumption for S0°C/W35°C kW 0.82 1.02 1.19 1.36 1.63

COP for S0°C/W35°C EN 255 4.40 4.41 4.66 4.67 4.68

COP for S0°C/W35°C 4.15 4.17 4.38 4.38 4.39

Radiator flow and return pipe P [O.T.] 1" 1" 1" 1" 1"

HGL connection P [O.T.] 1" 1" 1" 1" 1"

Max. flow temperature °C 65 65 65 65 65

Min. heating circuit water volume l/h 600 750 920 1050 1270

Pressure loss, heating side kPa 5 6 5 7 6

Recommended or installed storage tank charging

(Grundfos / Wilo) UPS 25-60

EAS 25/6 UPS 25-60

EAS 25/6 UPS 25-60

EAS 25/6 UPS 25-60

EAS 25/6 UPS 25-60

EAS 25/6

Free residual pressure of the charging pump kPa 51 48 47 44 42

In heat pumps with process reversal

Cooling performance for W/B 15°C/8W°C kW 3.20 4.20 4.90 5.75 6.95

Cooling performance for W/B 15°C/18W°C kW 4.60 6.00 7.00 8.00 9.85

Power consumption for W/B15°C/8°C kW 0.71 0.90 1.06 1.18 1.45

Power consumption for W/B15°C/18°C kW 0.69 0.90 1.05 1.20 1.47

ERR at W/B 15°C/W8°C 4.51 4.67 4.62 4.87 4.79

Brine inlet and outlet P [O.T.] 1" out.thread 1" out.thread 1" out.thread 1" out.thread 1" out.thread

Minimum brine circulation volume kg/h 830 1040 1280 1470 1770

Pressure loss on the brine side kPa 9 9 9 7 8

Recommended brine circuit pump Wilo

Top S 25/7 Wilo

Top S 25/7 Wilo

Top S 25/7 Wilo

Top S 25/7 Wilo

Top S 25/7

Dimension of the connection lines up to 40 m

total length mm 32 x 2.0 32 x 2.0 40 x 2.3 40 x 2.3 40 x 2.3

Number of brine circuits 2 2 3 3 4

Total pipe length m 200 200 300 300 400

Brine filling volume (mix) l 70 70 105 105 140

Depth probe 1/60 1/70 1/80 1/100 2/130

Number of depth probes 1 1 1 1 2

Total probe length m 60 70 80 100 130

Filling volume brine mix (1 x 40 mm probe) l 100 120 140 170 220

Filling volume brine mix (2 x 32 mm probe) l 130 150 170 220 280

Sound power level dBA 53 53 55 55 55

*Reference values for 50 W/m extraction performance

Technical Data TERRA S/W H for Brine Application with R134A

THE POWER FAMILY

(C) IDM ENERGIESYSTEME GMBH Installation TERRA S/W 15

1

2

3

4

5

6

7

8

9

1

0

11

1

2

1

3

1

2

Description

Description

15 S/W H 17 S/W H 19 S/WH 22 S/W H 26 S/W H 30 S/W H 37 S/W H 45 S/W H

9.40 10.9 12.5 14.0 16.1 18.7 22.9 27.3

9.12 10.55 12.11 13.58 15.66 18.09 22.25 26.43

2.00 2.29 2.63 2.98 3.46 4.03 5.41 6.42

2.07 2.37 2.73 3.08 3.56 4.21 5.53 6.56

4.70 4.75 4.75 4.70 4.65 4.64 4.23 4.25

4.40 4.45 4.44 4.41 4.40 4.30 4.02 4.03

1" 1 1/4" 1 1/4" 1 1/2" 1 1/2" 1 1/2" 2" 2"

1" 1" 1" 1" 1 1/4" 1 1/4" 1 1/4" 1 1/4"

65 65 65 65 65 65 65 65

1610 1870 2140 2400 2520 2660 3280 3890

98878645

UPS 25-80 UPS 25-80 UPS 25-80 UPS 25-80

Top S 30/7 UPS 25-80

Top S 30/7 TOP S 30/10 TOP S 40/10 TOP S 40/10

63 62 60 59 57 90 90 90

8.85 10.70 11.80 12.80 15.70 18.20 22.30 26.60

12.55 15.00 16.60 18.00 22.20 25.70 31.50 37.50

1.80 2.09 2.37 2.82 3.41 3.92 4.73 5.75

1.88 2.19 2.47 2.92 3.55 4.07 5.10 5.80

4.92 5.12 4.98 4.54 4.60 4.64 4.71 4.63

1" out.thread 1 1/4" out.thread 1 1/4" out.thread1 1/2" out.thread1 1/2" out.thread 1 1/2" out.thread 2" out.thread 2" out.thread

2280 2650 3040 3340 3280 3320 4090 4830

81010108 7 78

"Wilo

Top S 25/7" "Wilo

Top S 25/7" "Wilo

Top S 25/7" "Grundfos

UPS 25-80" "Grundfos

UPS 32-80" "Grundfos

UPS 32-80" "Wilo Top

S 40/10" "Wilo Top

S 40/10"

40 x 2.3 40 x 2.3 40 x 2.3 50 x 2.9 50 x 2.9 50 x 2.9 63 x 3.6 63 x 3.6

5567891113

500 500 600 700 800 900 1100 1300

175 175 210 245 280 315 385 455

2/150 2/190 2/200 3/225 3/270 3/300 4/340 5/475

22233345

150 190 200 225 270 300 340 475

260 320 340 380 460 510 580 810

320 410 430 480 580 650 730 1020

56 57 57 59 61 61 63 65

THE POWER FAMILY

(C) IDM ENERGIESYSTEME GMBH

2

.

A

llgemei

n

e I

n

formatio

n

e

n

Installation TERRA S/W

16

1

2

3

4

5

6

7

8

9

1

0

1

1

1

2

1

3

1

2

Description

Description

Technical Data TERRA S/W for Ground Water Application with R407C

Type TERRA (BA) (HGL) Unit 5 S/W 7 S/W 8 S/W 10 S/W 12 S/W

Heating performance for W10/W35 EN 255 kW 6.90 8.60 10.50 12.50 15.70

Heating performance for W10/W35 kW 6.80 8.50 10.40 12.40 15.50

Power consumption for W10/W35 EN 255 kW 1.26 1.54 1.81 2.19 2.75

Power consumption for W10/W35 kW 1.32 1.62 1.90 2.30 2.89

COP for W10/W35 EN 255 5.48 5.58 5.80 5.71 5.71

COP for W10/W35 5.15 5.25 5.47 5.39 5.37

Radiator flow and return pipe P [O.T.] 1" 1" 1" 1" 1"

HGL connection P [O.T.] 1" 1" 1" 1" 1"

Maximum flow temperature °C 55 55 55 55 55

Minimum heating water volume l/h 1.050 1350 1.650 1.950 2.450

Pressure loss, heating side kPa 11 18 17 22 21

Recommended or installed storage tank

charging pump (Grundfos / Wilo) UPS 25-60

EAS 25/6 UPS 25-60

EAS 25/6 UPS 25-60

EAS 25/6 UPS 25-60

EAS 25/6 UPS 25-60

EAS 25/6

Free residual pressure of the charging pump kPa 37 26 25 16 11

In heat pumps with process reversal

Cooling performance for W/B 15°C/8W°C kW 4.60 6.00 7.10 8.35 10.35

Cooling performance for W/B 15°C/18W°C kW 6.45 8.40 9.95 11.70 14.45

Power consumption for W/B15°C/8°C kW 0.96 1.23 1.44 1.70 2.10

Power consumption for W/B15°C/18°C kW 0.96 1.23 1.44 1.70 2.05

ERR at W/B 15°C/W8°C 4.79 4.88 4.93 4.91 4.93

Electrical connection of the primary circuit V/Hz 3x400 / 50 3x400 / 50 3x400 / 50 3x400 / 50 3x400 / 50

Power consumption compressor A 4.2 5.1 6.3 7 10

Start-up current compressor (with soft start) A 10.5 12.75 15.75 17.5 25

Electrical connection control circuit V/Hz 230 / 50 230 / 50 230 / 50 230 / 50 230 / 50

Fuse control circuit A 13 13 13 13 13

Ground water inlet and outlet P [O.T.] 1" 1" 1" 1" 1"

Minimum ground water volume l/h 1200 1500 1800 2150 2.700

Pressure loss, groundwater side kPa 7 9 13 12 14

"Dimension of the ground water inlet and outlet

line up to 40 m total length" 32 x 2.0 32 x 2.0 40 x 2.3 40 x 2.3 40 x 2.3

Recommended well pump Well depth

Model Grundfos

15m

SQE2-35

20m

25m

Model Garvens

15m CC1606B5 CC1606B8 CC1606B8 CC2606BC11 CC2606BC11

20m CC1606B8 CC1606B8 CC1606B12 CC2606BC11 CC2606BC11

25m CC1606B8 CC1606B12 CC1606B12 CC2606BC11 CC3606D8

Sound power level dBA 53 53 55 55 55

* Basic design data: pipeline plastic, line length = well depth + 10 m, water level of 2 m required in the well, residual pressure 1 bar

before the heat pump

THE POWER FAMILY

(C) IDM ENERGIESYSTEME GMBH Installation TERRA S/W 17

1

2

3

4

5

6

7

8

9

1

0

11

1

2

1

3

1

2

Description

Description

15 S/W 17 S/W 19 S/W 22 S/W 26 S/W 30 S/W 37 S/W 45 S/W

19.30 21.50 25.30 27.90 32.50 37.40 46.40 56.30

19.10 21.30 25.00 27.60 32.20 37.00 45.90 55.70

3.41 3.80 4.47 5.19 5.95 6.75 8.50 10.20

3.58 3.99 4.69 5.45 6.25 7.09 8.93 10.71

5.66 5.66 5.66 5.38 5.46 5.54 5.46 5.52

5.33 5.34 5.33 5.06 5.15 5.22 5.14 5.20

1" 1 1/4" 1 1/4" 1 1/2" 1 1/2" 1 1/2" 2" 2"

1" 1" 1" 1" 1 1/4" 1 1/4" 1 1/4" 1 1/4"

55 55 55 55 55 55 55 55

3.000 3.350 4000 4.400 5.300 6.100 7.100 9.100

29 25 27 22 30 32 25 32

UPS 25-80 UPS 25-80 UPS 25-80 UPS 25-80

Top S 30/7 UPS 25-80

Top S 30/7 TOP S 30/10 TOP S 40/10 TOP S 40/10

30 32 25 26 12 40 65 55

12.65 15.40 17.10 19.30 23.30 27.00 33.50 40.50

18.00 21.40 23.90 27.20 32.50 37.50 46.00 56.00

2.58 2.99 3.33 3.91 4.65 5.25 6.70 8.00

2.76 3.12 3.52 4.20 4.70 5.35 7.10 8.90

4.90 5.15 5.14 4.94 5.01 5.14 5.00 5.06

3x400 / 50 3x400 / 50 3x400 / 50 3x400 / 50 3x400 / 50 3x400 / 50 3x400 / 50 3x400 / 50

11 13 15 15.9 16.8 19.6 27 34

27.5 32.5 37.5 39.8 42 49 70 85

230 / 50 230 / 50 230 / 50 230 / 50 230 / 50 230 / 50 230 / 50 230 / 50

13 13 13 13 13 13 13 13

1" 1 1/4" 1 1/4" 1 1/2" 1 1/2" 1 1/2" 2" 2"

3.350 3.700 4.350 4.800 5.800 6.750 7.800 10.050

16 16 16 16 20 21 22 28

50 x 2.9 50 x 2.9 50 x 2.9 50 x 2.9 63 x 3.6 63 x 3.6 63 x 3.6 75 x 4.3

SQE3-55 SQE5-35 SQE5-50 SQE7-45 SP8A-10

CC3606D8 CC3606D8 CC3606D8 CC3606D8 CC3606D10 CC4606F6 CC4606F9 CC5606G7

CC3606D8 CC3606D8 CC3606D8 CC3606D10 CC3606D14 CC4606F9 CC4606F9 CC5606G7

CC3606D10 CC3606D10 CC3606D10 CC3606D14 CC3606D14 CC4606F9 CC4606F9 CC5606G10

56 57 57 59 61 61 63 65

THE POWER FAMILY

(C) IDM ENERGIESYSTEME GMBH

2

.

A

llgemei

n

e I

n

formatio

n

e

n

Installation TERRA S/W

18

1

2

3

4

5

6

7

8

9

1

0

1

1

1

2

1

3

1

2

Description

Description

Type TERRA (BA) (HGL) unit 5 S/W H 7 S/W H 8 S/W H 10 S/W H 12 S/W H

Heating performance for W10/W35 EN 255 kW 4.40 5.40 6.67 7.68 9.40

Heating performance for W10/W35 kW 4.27 5.24 6.47 7.45 9.12

Power consumption for W10/W35 EN 255 kW 0.80 0.98 1.25 1.41 1.71

Power consumption for W10/W35 kW 0.81 0.99 1.26 1.42 1.73

COP for W10/W35 EN 255 5.50 5.51 5.34 5.45 5.50

COP for W10/W35 5.27 5.29 5.13 5.25 5.27

Radiator flow and return pipe P [O.T.] 1" 1" 1" 1" 1"

HGL connection P [O.T.] 1" 1" 1" 1" 1"

Maximum flow temperature °C 65 65 65 65 65

Minimum heating water volume l/h 750 930 1140 1320 1610

Pressure loss, heating side kPa 5 5 5 6 5

Recommended or installed storage tank

charging pump (Grundfos / Wilo) UPS 25-60

EAS 25/6 UPS 25-60

EAS 25/6 UPS 25-60

EAS 25/6 UPS 25-60

EAS 25/6 UPS 25-60

EAS 25/6

Free residual pressure of the charging pump kPa 50 47 44 41 38

In heat pumps with process reversal

Cooling performance for W/B 15°C/8W°C kW 3.20 4.20 4.90 5.75 6.95

Cooling performance for W/B 15°C/18W°C kW 4.60 6.00 7.00 8.00 9.85

Power consumption for W/B15°C/8°C kW 0.71 0.90 1.06 1.18 1.45

Power consumption for W/B15°C/18°C kW 0.69 0.90 1.05 1.20 1.47

ERR at W/B 15°C/W8°C 4.51 4.67 4.62 4.87 4.79

Electrical connection of the primary circuit V/Hz 3x400 / 50 3x400 / 50 3x400 / 50 3x400 / 50 3x400 / 50

Power consumption compressor A 4.2 5.1 6.3 7 10

Start-up current compressor (with soft start) A 10.5 12.75 15.75 17.5 25

Electrical connection control circuit V/Hz 230 / 50 230 / 50 230 / 50 230 / 50 230 / 50

Fuse control circuit A 13 13 13 13 13

Minimum ground water volume l/h 840 1030 1270 1470 1800

Pressure loss, groundwater side kPa 6 5 9 5 7

"Dimension of the ground water inlet and outlet

line up to 40 m total length" 32 x 2.0 32 x 2.0 32 x 2.0 32 x 2.0 40 x 2.3

Recommended well pump Well depth

Model Grundfos

15m

SQE2-35

20m

25m

Model Garvens

15m CC1606B5 CC1606B5 CC1606B5 CC1606B8 CC1606B8

20m CC1606B8 CC1606B8 CC1606B8 CC1606B8 CC1606B12

25m CC1606B8 CC1606B8 CC1606B8 CC1606B12 CC1606B12

Sound power level dBA 53 53 55 55 55

* Basic design data: pipeline plastic, line length = well depth + 10 m, water level of 2 m required in the well, residual pressure 1 bar

before the heat pump

Technical Data TERRA S/W H for Ground Water Application with R134A

THE POWER FAMILY

(C) IDM ENERGIESYSTEME GMBH Installation TERRA S/W 19

1

2

3

4

5

6

7

8

9

1

0

11

1

2

1

3

1

2

Description

Description

15 S/W H 17 S/W H 19 S/W H 22 S/W H 26 S/W H 30 S/W H 37 S/W H 45 S/W H

11.97 13.85 15.89 17.82 22.40 25.80 31.80 37.40

11.61 13.43 15.41 17.29 21.73 25.03 30.85 36.28

2.10 2.40 2.76 3.31 4.05 4.65 5.75 6.80

2.12 2.43 2.79 3.34 4.09 4.70 5.81 6.87

5.70 5.77 5.76 5.38 5.53 5.55 5.53 5.50

5.48 5.53 5.52 5.17 5.31 5.32 5.31 5.28

1" 1 1/4" 1 1/4" 1 1/2" 1 1/2" 1 1/2" 2" 2"

1" 1" 1" 1" 1 1/4" 1 1/4" 1 1/4" 1 1/4"

65 65 65 65 65 65 65 65

2050 2370 2720 3050 3300 3690 4540 5340

87666645

UPS 25-80 UPS 25-80 UPS 25-80 UPS 25-80

Top S 30/7 UPS 25-80

Top S 30/7 TOP S 30/10 TOP S 40/10 TOP S 40/10

60 59 57 54 52 87 90 90

8.85 10.70 11.80 12.80 15.70 18.20 22.30 26.60

12.55 15.00 6.66 18.00 22.20 25.70 31.50 37.50

1.80 2.09 2.37 2.82 3.41 3.92 4.73 5.75

1.88 2.19 2.47 2.92 3.55 4.07 5.10 5.80

4.92 5.12 4.98 4.54 4.60 4.64 4.71 4.63

3x400 / 50 3x400 / 50 3x400 / 50 3x400 / 50 3x400 / 50 3x400 / 50 3x400 / 50 3x400 / 50

11 13 15 15.9 16.8 19.6 27 34

27.5 32.5 37.5 39.8 42 49 70 85

230 / 50 230 / 50 230 / 50 230 / 50 230 / 50 230 / 50 230 / 50 230 / 50

13 13 13 13 13 13 13 13

2310 2680 3070 3390 4090 4710 5800 6810

7 8 8 8 10 12 15 16

40 x 2.3 40 x 2.3 50 x 2.9 50 x 2.9 50 x 2.9 63 x 3.6 63 x 3.6 63 x 3.6

SQE2-35 SQE3-55 SQE5-35 SQE-50

CC2606BC7 CC2606BC11 CC3606D8 CC3606D8 CC3606D8 CC3606D8 CC3606D10 CC4606F6

CC2606BC11 CC2606BC11 CC3606D8 CC3606D8 CC3606D8 CC3606D10 CC3606D14 CC4606F9

CC2606BC11 CC3606D8 CC3606D10 CC3606D10 CC3606D10 CC3606D14 CC3606D14 CC4606F9

56 57 57 59 61 61 63 65

THE POWER FAMILY

(C) IDM ENERGIESYSTEME GMBH

2

.

A

llgemei

n

e I

n

formatio

n

e

n

Installation TERRA S/W

20

1

2

3

4

5

6

7

8

9

1

0

1

1

1

2

1

3

1

2

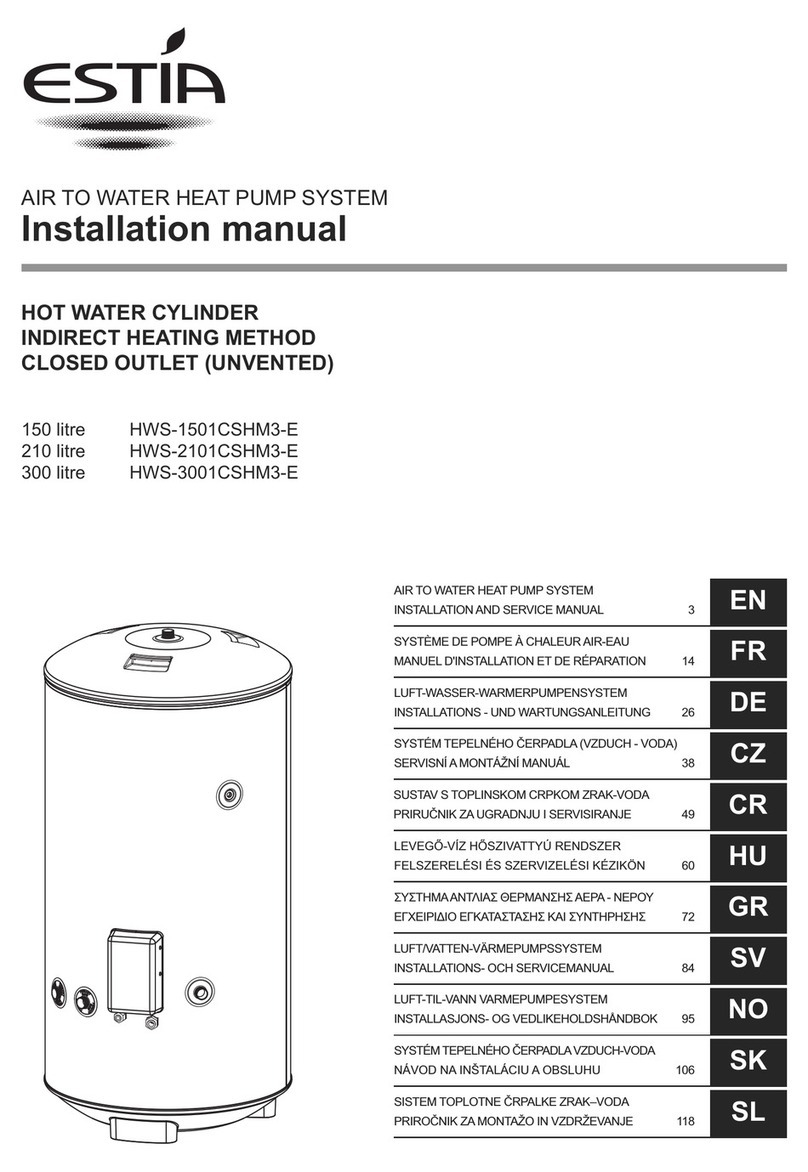

05101520253035

10

Groundwater inlet temperature

Flow temperature

20

30

40

50

60

70

[°C]

[°C]

R134a

R407c

Minimum groundwater

inlet temperature 7°C

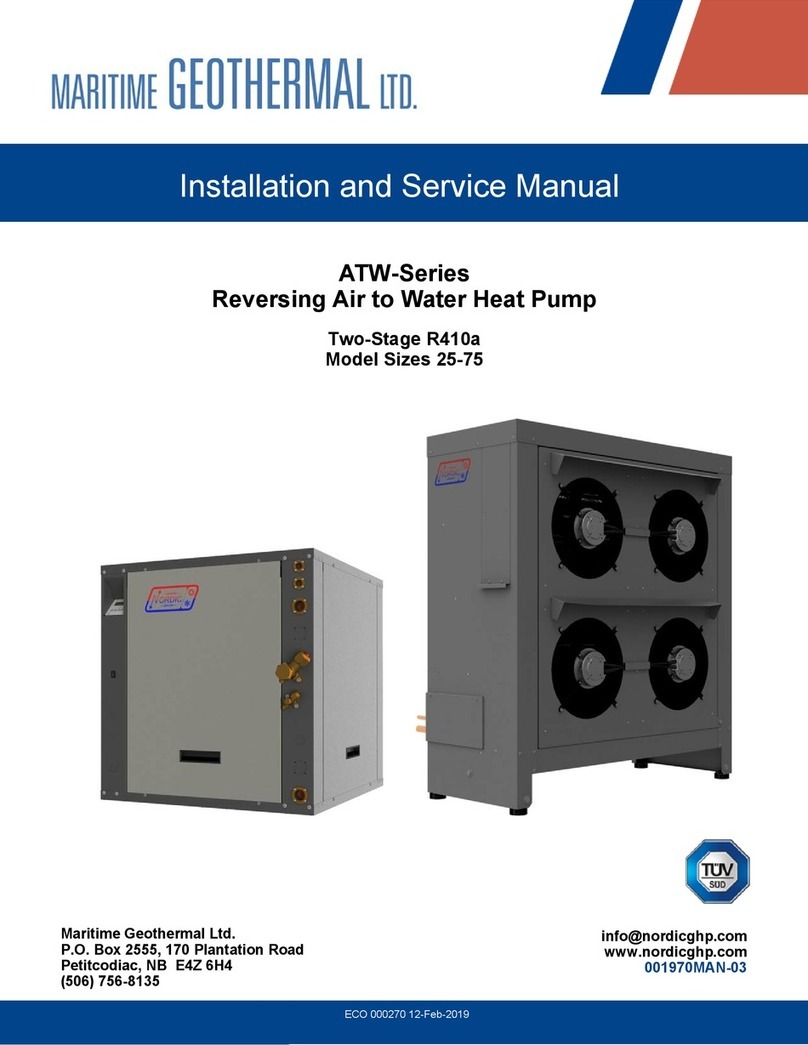

-20 -10 010 20 30 40 50

10

Brine inlet temperature

Flow temperature

20

30

40

50

60

70

[°C]

[°C]

R134a

R407c

Description

Description

2.7. Operating Limits

TERRA-S/W heat pumps may only be used with heat

conducting media, brine or ground water. Other heat

conducting media are not allowed.

Furthermore, the heating of other liquids as heating

water is not permitted (heating water quality see

Page 25).

By definition, heat pumps are subject to pressure

or temperature-dependent operating limits (see dia-

gram).

The operation of the TERRAheat pump outside these

operating limits is not allowed.

Note:

- The following safety mechanisms are provided for

the safety of the heat pump against potential mal-

functions:

- Combined high and low pressure switch with auto-

matic locking or unlocking by switching the system

off and on (after 3 errors within 24 hours).

- Flow maximum temperature limit with automatic

reset via the Navigator Control.

- Start-up current limiter with rotating field monitoring,

motor current monitoring and phase monitoring for

the compressor.

- Internal winding protection in the compressor

Application range for ground water heat pumps

Application range for brine heat pumps

This manual suits for next models

25

Table of contents

Other IDM-Energiesysteme Heat Pump manuals

Popular Heat Pump manuals by other brands

York

York HMH7 Series Technical guide

Estia

Estia HWS-2101CSHM3-E installation manual

Glen Dimplex

Glen Dimplex LIK 8TES Installation and operating instruction

Automatic Heating

Automatic Heating AHGR32AW17 Installation and instruction manual

Bryant

Bryant EVOLUTION V 288BNV owner's manual

Nibe

Nibe S1256PC Installer manual

Maritime Geothermal

Maritime Geothermal ATW-55 Installation and service manual

AIT

AIT L Split Series operating manual

Friedrich

Friedrich Twintemp YQ07 operating guide

SILENSYS

SILENSYS SILFH4524Z Technical data

Heat Controller

Heat Controller RAH-183G owner's manual

Daikin

Daikin ETSHB16P50EF installation manual