IDROBASE Stella 1000-100/11 User manual

GB

Operator’s Manual

Distributed by Australian Pump Industries (02) 8865 3500

From serial number

1121001 onwards

FAST GUIDE FOR CORRECT USE OF

AUSSIE STELLA HOT WATER PRESSURE CLEANER

Refer to User Manual for guidance on all safety precautions to be taken

when using hot water pressure cleaners and for full set of instructions.

ELECTRICAL SUPPLY

1. The power supply must correspond to the rating of the hot water machine.

2. The hot water machine must be earthed and be used with a circuit breaker.

3. Do not use extension leads.

DIESEL

1. Diesel fuel must uncontaminated.

2. Never let the diesel fuel tank run dry.

STANDARD USE

1. Turn on the machine from the control panel, keeping the gun open. Wait for steady pressure.

2. Wind BY-PASS valve up to highest setting (for maximum flow).

3. Set thermostat to required temperature.

4. To turn off the machine, turn the thermostat to “OFF” and wait for the jet of water to cool before

turning off the machine.

USING STEAM

1. Turn on machine from the control panel, keeping the gun open. Wait for steady pressure.

2. Wind BY-PASS valve down to lowest setting (reduces flow to minimum).

3. Turn thermostat to required “STEAM” setting.

4. Do not release the gun trigger when working in the steam mode.

5. To turn off the machine, turn the thermostat to “OFF”, adjust unloader to highest position and run

unit on ‘cold’ for a minimum of five minutes to ensure coil is cool before turning off machine.

DO NOT….

1. Do not run the machine in BY-PASS for more than three continuous minutes.

2. Do not leave machine unattended unless switched off.

3. Do not use machine if there water is leaking from the hose or the gun/lance.

4. Do not leave machine in environmental conditions below 5° C.

5. Do not remove the gun, the lance or hose without first relieving the pressure in hose.

6. Never tamper with the BY-PASS valve settings. These are factory set.

7. Never close the gun when using steam.

8. Never stop the machine after using steam and without having first cooled it down.

9. Do not use the machine with dirty water.

Not following these procedures could damage the machine and void warranty .

3

1 Application pag. 36

1-1 General warning pag. 36

1-2 Dataplate with “CE” mark pag. 36

1-3 Warranty pag. 36

1-4 Conditions for returns pag. 36

1-5 Cases in witch the manufacturer is not liable pag. 37

1-6 Safety pag. 37

1-7 Symbols pag. 37

1-8 Glossary pag. 38

1-9 Notes on the labels pag. 38

2 Product presentation pag. 39

2-1 Purpose pag. 39

2-2 Composition pag. 39

3 Layout of the manual pag. 40

3-1 Information pag. 40

4Technical data and specications pag. 41

4-1 Technical data pag. 41

5 Unpacking and installation pag. 42

5-1 Unpacking pag. 42

5-2 Inactivity pag. 42

5-3 Transport pag. 43

5-4 Halding pag. 43

5-5 Standard equipment pag. 43

5-6 Installation and connection pag. 43

5-7 Cleaning and disinfecting pag. 45

5-8 Reinstallation and reuse pag. 45

5-9 Destruction and disposal pag. 45

6 Operation and use pag. 46

6-1 Description of operation pag. 46

6-2 Range of applications pag. 46

6-3 Intended usage pag. 46

6-4 Working limits pag. 47

6-5 Positioning of the operator and danger area pag. 47

6-6 Safety features and working indications pag. 47

6-7 Persistent hazards pag. 49

6-8 Safety gear for the operator pag. 49

6-9 Training pag. 49

7 User istructions pag. 49

7-1 Description of the safety controls pag. 49

INDEX

GB

Distributed by Australian Pump Industries (02) 8865 3500

4

7-2 Manoeuring description to be carried out and operation pag. 49

7-3 Trial stage pag. 50

7-4 Interrupting the running (total stop) pag. 50

7-5 Work stoppage pag. 51

7-6 Regulation pag. 51

7-7 Stopping and pausing operation pag. 51

7-8 Stopping operation pag. 51

7-9 Emergency stop pag. 51

7-10 Resetting conditions pag. 51

7-11 Storage operation pag. 52

8 Maintenance pag. 53

8-1 Regular maintenance pag. 53

8-2 Extraordinary maintenance pag. 54

8-3 Technical information pag. 54

9 Troubleshooting pag. 55

10 Spare parts pag. 56

10-1 Spare parts pag. 56

10-2 Spare parts pag. 56

11 Destruction disposal pag. 57

11-1 Destruction disposal pag. 57

Declaration of conformity pag. 60

Distributed by Australian Pump Industries (02) 8865 3500

5

®

1-1) GENERAL WARNINGS

BEFORE INSTALLING AND USING THE MACHINE IT IS COMPULSORY THAT THE INSTALLER AND

USERS READ AND UNDERSTAND ALL OF THE INFORMATION IN THIS MANUAL.

THIS MANUAL IS AN INTEGRAL PART OF THE MACHINE; IT MUST ALWAYS BE VAILABLE DURING

THE NORMAL OPERATION OF THE MACHINE AND IT IS IMPERATIVE THAT IT IS RETAINED FOR FU-

TURE REFERENCE UNTIL THE DISPOSAL OF THE MACHINE

THE COPYRIGHT OF THIS MANUAL “INSTRUCTION FOR INSTALLATION AND USE” IS THE

PROPERTY OF IDROBASE S.R.L. ALL OF THE INFORMATION (TEXT, DRAWINGS, DIAGRAMS,

ETC..) CONTAINED IN THIS MANUAL IS CONFIDENTIAL. NO PART OF THIS MANUAL CAN

BE REPRODUCED AND DISTRIBUTED (EITHER IN PART OR COMPLETE) BY ANY MEANS OF

REPRODUCTION, (PHOTOCOPIES, MICROFILM, OR OTHER) WITHOUT WRITTEN AUTHORI-

SATION FROM IDROBASE S.R.L.

1-2) DATAPLATE WITH “CE” MARK

MACHINE IDENTIFICATION

The machine is distinguished by a manufacturer’s plate

1-3) WARRANTY

All of our apparatus are subjected to accurate and rigorous tests and are covered under warranty in

accordance with statutory law from manufacturing defects.

THE WARRANTY IS INVALIDATED IF THE USE OF THE MACHINE DOES NOT CONFORM

TO THE INSTRUCTIONS FOR USE CONTAINED IN THIS MANUAL, AND IF THE ORIGINAL

COMPONENTS, ACCESSORIES, SPARE PARTS AND CONTROL SYSTEMS ARE NOT USED.

The warranty starts from the date of purchase.

The valid date of purchase is that indicated on the receipted or invoice issued at the time the equipment is delivered by

the retailer. IDROBASE undertakes to repair or replace free of charge any parts that have manufacturing faults within

the warranty period. Faults not clearly due to materials or manufacturing shall be examined at one of our Technical

Assistance Centres or at our headquarters and charged according to the results.The following are excluded from the

warranty: accidental damage due to transport, negligence or inappropriate treatment, incorrect or improper use or in-

stallation, i.e. not complying to the instruction manual, and any situations that do not depend on machine standards and

operation, or on electrical and equipment use. The warranty is invalidated if the equipment is repaired or tampered with

by unauthorised third parties. The equipment shall not be replaced nor the warranty extended after it has been repaired

for faults. The warranty does not cover cleaning the working parts or replacing consumable components such as pump

oil, nozzle, lances, etc. IDROBASE is not liable for any damage to persons or objects due to incorrect installation or

improper use of the equipment.

1-4) CONDITIONS FOR RETURNS

It will be the responsibility of the end user to return the product to the retailer; or telephone

+39 049 9335136 for more information.

1) APPLICATIONS

GB

Distributed by Australian Pump Industries (02) 8865 3500

6

1-5) CASES IN WHICH THE MANUFACTURER IS NOT LIABLE

The manufacturer is not liable for damage caused by the following :

- Improper use of the machine or use by untrained personal.

- Use of non genuine spare parts.

- Non-compliance with maintenance.

- Unauthorized modications or operation

- Non-observance, in total or part, of the instruction manual

1-6) SAFETY

To guarantee a long pump life, it is forbidden to circulate liquids with sand or other solid particles that compromise the

efcient running of the valves, pistons and seals. Fit any other lters to the waterfeeding circuit.

Only environmentally friendly chemicais which are fully biodegradable should be used in the machine

Do not use paints, adds, solvents, oily or very dense materials.Never use the machine in or near any ammabie pro-

ducts or environments (e.g. gas or petrol fumes).

Protect the machine from extreme cold and adverse weatherconditions.Avoid starting in extremely cold conditions as

damage may occurto the pump and motor The machine should only be used by an adult perator who has been suitably

trained. Never leave the machine unattended when It is switched on or if children are present.

Do not use the machine in the presence of unauthorized personnel or persons who are not wearing suitable protective

garments.

Although a suitable grip is provided with the lance, the water pressure at the start of the discharge from the nozzle

(opening of the trigger) produces a REACTIVE FORCE (recoil) which needs to be COUNTERBALANCED.

The necessary counterbalance force required is shown In the table below and is expressed in Newlons.

This equipment has been designed for use with the detergentrecommended by the manufacturer The

use of other deter-gents or chemical products other than those specied may af-fect the safety of the

equipment.

1-7) SYMBOLS

In this manual the symbols depicted describe important functions of the machine; for the installation; for the use and

disposal. For correct and safe use of the machine the operator must read carefully all parts of this manual lending spe-

cial attention to the

warning symbols and manufacturer’s plate.

PAY ATTENTION TO SAFETY IN THE WORKPLACE!

Follow the instructions displayed on the warning signs. Failure to do so may cause severe injury or

endanger personal safety. Ensure that the signs are present and legible.

If they are not, they should be tted or replaced.

This manual must be read before using or carrying out maintenance or other operations on

the machine. Do not allow unauthorized personnel to use the machine

GB

Distributed by Australian Pump Industries (02) 8865 3500

7

1-8) GLOSSARY

The following symbols advise the operator of dangerous situations or the important operations for the correct running

of the machine.

WARNING SIGNS

This manual must br read before using or carrying out maintenance or other

operations on the machine.

INFORMATION

The informations contained in this manual shows the right procedures for the correct maintenance and use of

the machine

WARNING

The caution indicates special procedures that if not observed can cause damage to persons or property.

WARNING

Maintenance or repairs must never be carried out white the machine is live/switched on. Always discon-

nect from the electrical supply before carrying out repairs or removing the cover.

WARNING

Avoid storing or using the machine in extreme temperatures. Frost may cause serious damage to the high pressure pump.

WARNING

Protective garments should be worm

WARNING

This manual must be read before using.

WARNING

Only use recommended liquid detergents. the use of other materials may endanger the safety of the user

or damage the machine.

WARNING

Do not aim the jet at electrical sockets, people, animals, or in order to clean clothes or footwear.

The high pressure jet can be dangerous if used inappropriately.

1-9) NOTES ON THE LABELS

Never remove the labels from the machine. If they have deteriorated, ask your retailer or the manufacturer directly

for a replacement.

THE MANUFACTURER IS NOT LIABLE IN ANY WAY IN THE EVENT OF ACCIDENTS OR

BREAKAGE DUE TO NON-OBSERVANCE OF THE WARNINGS.

IN CASE OF ANY CONFUSION REGARDING ANYTHING IN THIS MANUAL CONTACT

THE RETAILER IMMEDIATELY

THE STICKER SHOWING THE WAY OF USE AND RESTRICTIONS HAS NEVER TO BE

REMOVED FROM THE CASE WHERE IT IS.

GB

Distributed by Australian Pump Industries (02) 8865 3500

8

2-1) PURPOSE

The high pressure washer Stella was conceived to be the best tool for pressure cleaning in industries like shipyards, he-

avy road haulage, construction machinery, industrial machine shops, industrial tanning, food industry, etc. The machine

can be used in the cleaning, for example of, motor parts, production machinery encrusted with oil, layers of combusta-

ble waste products, the removal of barnacles encrusted on ship hulls, washing trailers encrusted with salt (salt on the

streets in winter), greasy smog, also to wash trains, buses, and anywhere paint is covered by layers of dirt and grime.

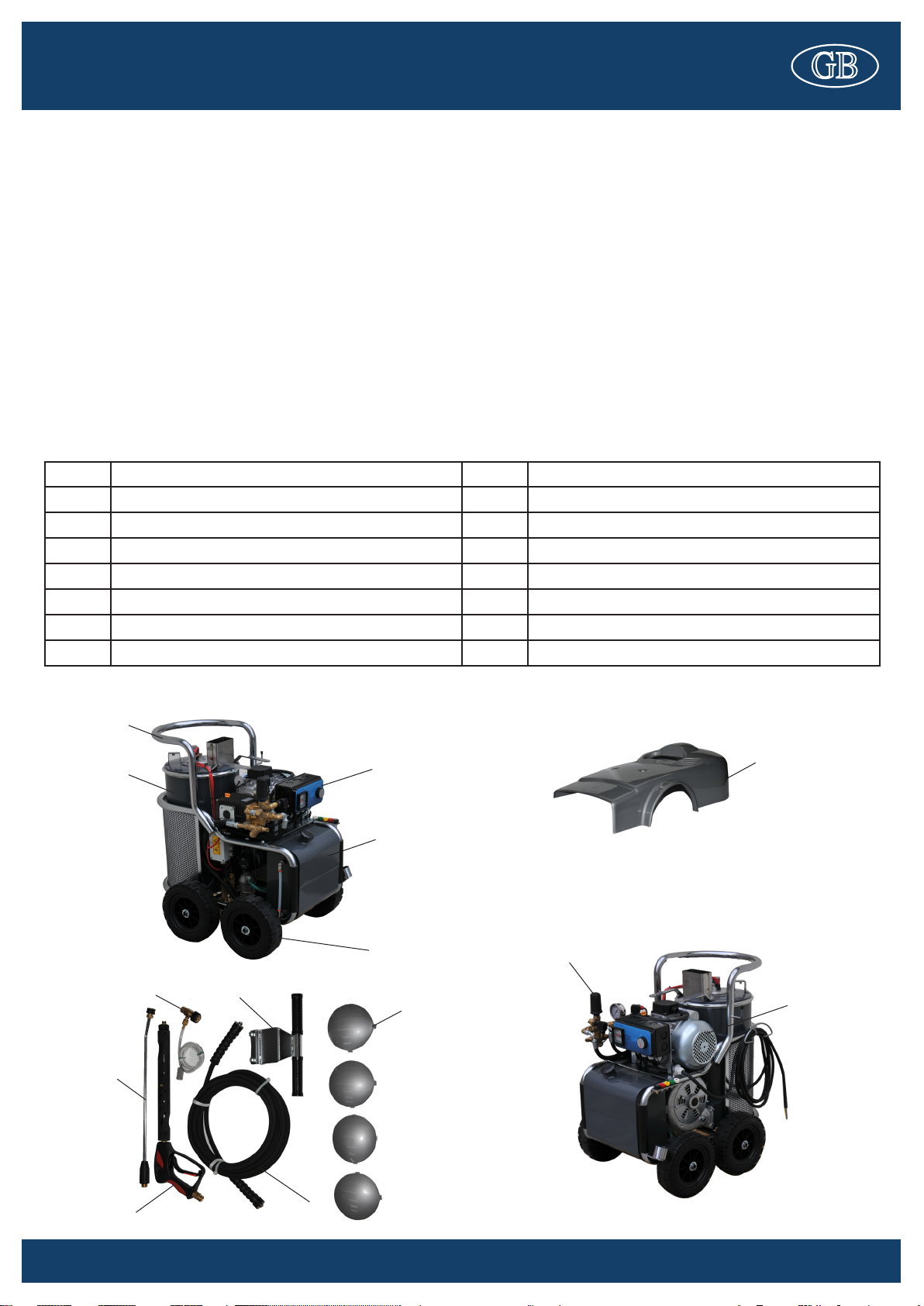

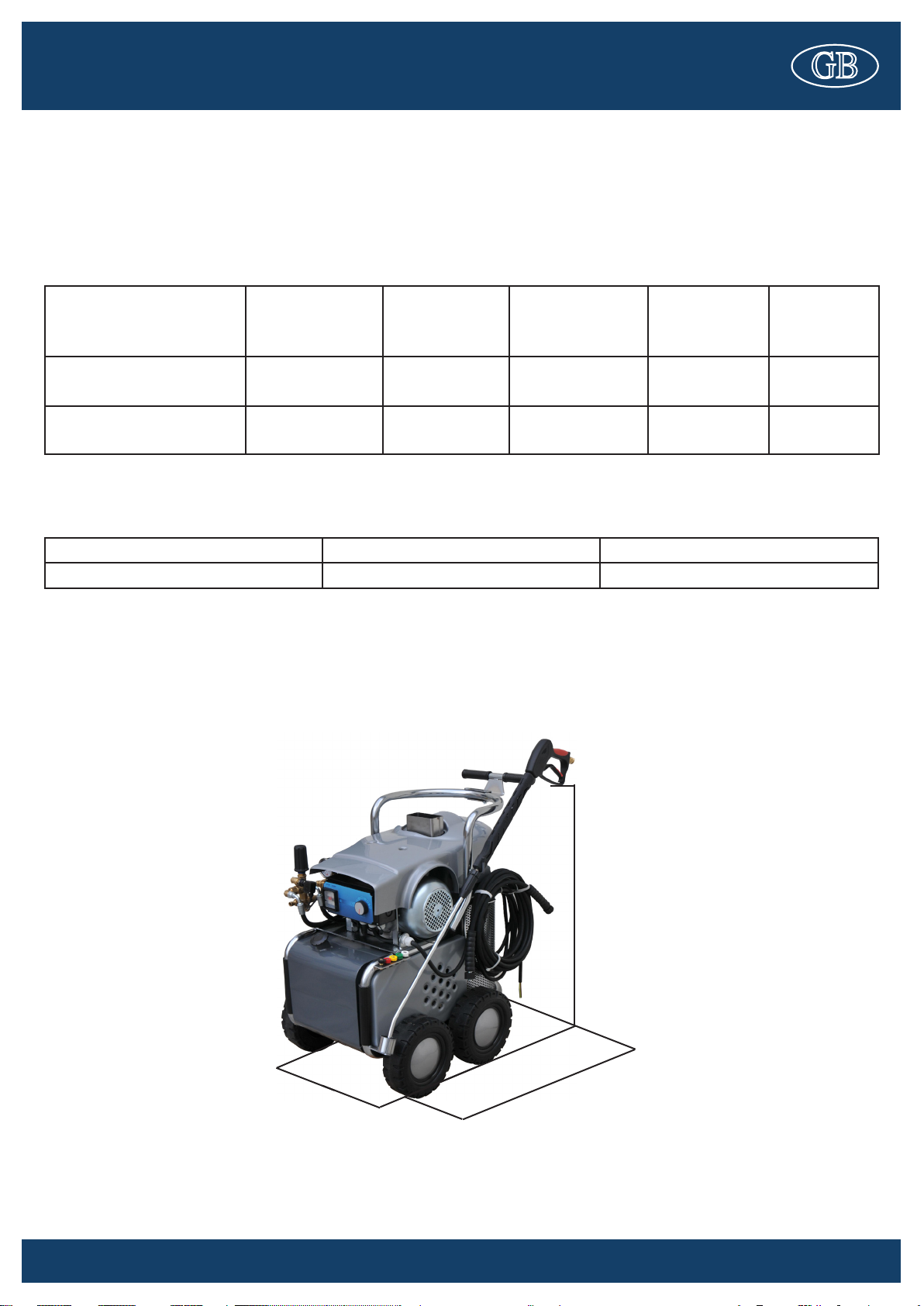

2-2) COMPOSITION

Referring to the picture below, the pressure washer is composed of a stainless steel frame, equipped with wheels, and

with a plate on which are tted the motor, pump, regulating valve, control panel, and hoses. The heating unit which

produces hot water, is composed of an electric motor, diesel pump, lter and heating coil, and is attached between the

base and the handlebars. At the front of the machine is placed the diesel tank which is equipped with a visible level

indicator to determine the amount of diesel remaining, and at the back there is the water tank with a oating switch

inside..

N° Descrizione N° Descrizione

1 FRAME 2 PROTECTION OF THE COVER

3 HEATER 4 MOTOR PUMP

5 ELECTRIC PANEL WITH THERMOSTAT 6 BY PASS

7 FUEL TANK 8 WHEEL

9 HYDRO SPRAY GUN 10 WASHING LANCE

11 DETERGENT HOSE 12 HIGH PRESSURE HOSE

13 WHEEL STUDS 14 UNIT HANDLE

2) PRODUCT PRESENTATION

GB

1

3

8

7

52

4

6

13

14

11

10

9 12

Distributed by Australian Pump Industries (02) 8865 3500

9

This manual shows the correct use and maintenance of the machine.

3-1) INFORMATION

This manual is an essential document for the safe use of the equipment. It should be

kept in a safe place and must be accessible to the user / repairer to ensure the correct

use of the machine and thereby avoid any risks through incorrect Installation, misuse

or negligence.

This manual should always be available to the user and / or maintenance, which must

be informed about the correct use of the machine and any residual risks.

The instructions in this manual does not supersede the safety and technical data,

installation and also use for operating, which are applied directly on the machine.

The user must follow the safety regulations to the country of installation, in addition to the rules dictated by common

sense.

You should not use the machine if you experience any defects or damage that could compromise the original security;

the responsible for the installation, the user or maitenance technician has to report any anomalies to the manufacturer.

The machine is built for specic applications. Should not be changed and / or used for applications different than

those specied in the eld of use.

Instructions, drawings, tables and all that is contained in the following documents are of technical nature, and there-

fore any condential information can not be provided to third parties without the written permission of IDROBASE

which is the sole owner.

Descriptions and illustrations contained in this publication does not mean demanding; IDROBASE therefore reserves

the right to make changes at any time to bodies, details, accessories supplies, appropriate for

any manufacturing or commercial improvement.

3) LAYOUT OF THE MANUAL

GB

Distributed by Australian Pump Industries (02) 8865 3500

10

4-1) TECHNICAL DATA

The following table describes the models and specications of the machine.

TECNICAL DATA

MODEL Pressure

(bar)

Flow-rate

(l/min.)

Power

(Kw)

Temperature

( Max °C )

Weight

(kg)

1000-100/11 100 11 2.2 90 160

1000-200/15 200 15 5.5 80 165

OVERALL DIMENSIONS

(cm)

A B C

570 1130 890

4) TECHNICAL DATA AND SPECIFICATIONS

GB

AB

C

Distributed by Australian Pump Industries (02) 8865 3500

11

5-1) UNPACKING

The machine is packed in a plain cardboard box for protection..

The cardboard can be removed with the appropriate equipment; however, cellophane,

staples and adhesive tape can cut or injure if not handled with care The machine should be

unpacked and set up on a level surface, near a drain & water supply and the components

carefully checked.

WARNING:

Use the appropriate safety equipment and give maximum care in the opening of the packaging.

Straps or staples if not handled with care can cause injury.

The disposal of the packaging must be carried out to conform to all local laws and regulations. After having unpacked

the machine make sure that the pressure washer is complete, including all of the requested accessories.

5-2) INACTIVITY

During a period of inactivity store the machine in a cool, dry place not below 5 ºC.

WARNING:

The pressure washer does not function in extreme cold. If storing in a cold enviroment with a temperature less than 5

ºC, antifreeze must be introduced into the machine while running, and only after having consulted a qualied techni-

cian.The use of unsuitable antifreeze can damage the seals in the pump. To disregard these

instructions can seriously damage the pressure washer.

5) UNPACKING AND INSTALLATION

GB

Distributed by Australian Pump Industries (02) 8865 3500

12

5-3) TRANSPORT

The machine comes delivered on a wooden pallet and covered with cardboard packaging, rmly bound with plastic

straps by staples.

The machine is usually transported by truck. The unloading of the truck is carried out by means of fork-lift truck with

appropriate equipment, or manually using appropriate equipment while respecting the normal health and safety regula-

tions.

5-4) HANDLING

Always use a fork-lift truck to move or handle the machine.

5-5) STANDARD EQUIPMENT

Check that the packaging contains the following components:

- High pressure washer

- High pressure hose with quick connection M22x1.5

- Gun

- Lance

- Injector

- Unit handle

- Wheel studs

5-6) INSTALLATION AND CONNECTION

For easier understanding of the operation and of the terms used, refer to the illustration in

section 2-2 on page 9.

GB

Distributed by Australian Pump Industries (02) 8865 3500

13

GB

MOUNTING ACCESSORIES

1 Unroll the high pressure tube and insert the connection to the nipple and tighten by hand.

2 Screw the other end of the lance onto the thread of the gun and tighten by hand.

3 Assemble the handle

4 Assemble the wheels’ studs

5 Assemble the injector

CONNECTION AND INSTALLATION OF THE WATER SUPPLY

6 Connect the “Stella” to a source of clean water at a minimum pressure of 2 bar.

7 The quantity of the water supply must be at least three times the maximum capacity of the “Stella”.

8 The water that feeds the “Stella” must be free from any impurities. If impurities exist, they must not exceed 50

microns. Otherwise you have to adopt a proper ltration system.

9 The hardness of the water must be within the following values: from 7° F to 14° F.

CONNECTION AND INSTALLATION OF THE ELECTRICAL SUPPLY

10 The power supply must respond to the rating of the “Stella”.

11 The “Stella” must be properly connected to an efcient grounded system matching and combined with a circuit

breaker with a sensitivity of <=30mA in “A” class.

12 The electrical connection must be done in accordance with the IEC 309 Rule and without the use of extensions.

PRELIMINARY CHECK AND FIRST START

13 Put the pressure washer in a stable position on a at and dry surface.

14 Make sure that the electric plug of the pressure washer has not been inserted into the socket of the general

switch.

15 Make sure that the electric switch and the thermostat regulator of the pressure washer are in the OFF position.

16 In case you ll up the tank of the pressure washer using a can, make sure that it doesn’t contain impurities or

water.

17 Never let the fuel tank empty.

18 Turn the water supply tap on, and make sure that there aren’t any drippings.

19 Make sure that the detergent tap is closed

20 Turn the general switch on I position (ON).

Distributed by Australian Pump Industries (02) 8865 3500

14

5-7) CLEANING AND DISINFECTING

To clean the machine use only liquid detergents. The use of other detergents can impair the safety and correct opera-

tion of the machine.

Check that the water lters that are used with the machine are of the correct size and that they are periodically remo-

ved, checked, and cleaned.

5-8) REINSTALLATION AND REUSE

To reuse the machine after a period of inactivity carry out the steps in section 5-7 “Setting up”

5-9) DESTRUCTION AND DISPOSAL

When it has been decided to destroy the machine and to render it unusable, empty the contents of the fuel tank, and

drain the lubricanting oil from the high pressure pump.

It is recommended that all parts which could be dangerous are rendered safe, removing all of the electrical compo-

nents, while conforming to current legislation regarding the scrapping of these materials. The various components

should be disposed of at an appropriate recycling centre.

FOR MORE INFORMATION CALL +39 049 933 5903

GB

WARNING:

Before starting the pressure washer put on suitable protective clothing that will not interfere with the high

pressure jet. Do not use the machine if in the presence of people without suitable protective clothing.

WARNING:

The destruction of the pressure washer must only be carried out by a qualied person or by a qualied technician.

THE DISPOSAL OF THE MACHINE MUST BE CARRIED OUT ACCORDING TO THE LAWS OF

THE COUNTRY IN WHICH IT IS TO BE DISPOSED

Distributed by Australian Pump Industries (02) 8865 3500

15

6-1) DESCRIPTION OF OPERATION

The pressure cleaner is ready for use only after having carried out the steps 1 to 12 detailed in section 5-6. Starting up

the pressure washer will rst increase the pressure and if required the temperature of the water to the maximum values

found in the technical data table, and then discharge a volume of water according to the quantity described in section

2-1 “USES” and in the section 6-3 “Intended Usage”.

6-2) RANGE OF APPLICATIONS

The pressure washer “STELLA MAGGIORE” is the optimum product for all businesses who equire a more reliable,

durable and safe pressure washer, that can be used continuously for up to 12 hours a day

.

6-3) INTENDED USAGE

The pressure washer is designed for the following uses:

- cleaning machines such as industrial vehicles for the transportation of goods and

people, trains, hulls of boats, lorries and trailers, buildings, persistent dirt with or without

the use of detergents

- descaling in general, unblocking of hoses using suitable accessories from the manufacturer

- washing pavements and oors

6) OPERATION AND USE

GB

1. Do not leave the “Stella” for more than three continuous minutes in BY-PASS.

2. Do not leave the “Stella” in the “TOTAL STOP” position without the presence of the operator.

3. Do not leave the “Stella” in the “TOTAL STOP” position when there is loss of water from the hose, from the

gun/nozzle.

4. Do not leave the “Stella” in environmental conditions with a low temperature (below 5° C).

5. Do not remove the gun, the lance or hose without rst relieving the pressure

6. Do ”NEVER” tamper with the setting of the BY-PASS valve. The right setting is made from the producer and

never can be change.

7. Do never close the gun when it works in the steam position.

8. Do never stop the “Stella” after working in the steam position and without having rst cooled it down.

9. Do not use the “Stella” with water in which impurities are bigger than 50 microns.

WARNING:

If you have to use this machine inside vehicles, boats, trains, or aeroplanes consult the technical department of the

manufacturer, because further instructions may be required.

WARNING:

Every other use is inappropriate! The manufacturer can not be considered responsible for any damage resulting from

improper use or from failing to observe the instructions in this manual.

Distributed by Australian Pump Industries (02) 8865 3500

16

6-4) WORKING LIMITS

Prolonged inactivity (machine stopped) in temperatures less than 5°C (5 degrees

centigrade) can cause damage or breakage to the pump, hoses, and to the parts in general. It is therefore advisable to

completely empty the machine. Read the warning notice in section 5-2 of this manual and if more information is requi-

red contact the retailer or manufacturer.

6-5) POSITIONING OF THE OPERATOR AND DANGER AREAS

The machine is equipped with a 10 metre long High Pressure hose so the operator never loses sight of the machine and

the relevant electrical and hydraulic connections, he can

move around freely and wash within this area.

6-6) SAFETY FEATURES AND WARNING INDICATIONS

The pressure washer is equipped with the following safety features:

A- PROTECTIVE AMMETER: it is an integrated safety feature of the power switch that turns off the pressure cleaner

in case of electrical overload, automatically tripping the power

switch into the OFF position.

Whenever this safety feature is activated this sequence must be followed:

- remove the plug from the wall socket

- press the trigger on the pressure cleaner to release any residual pressure remaining

- wait for 10 minutes for the pressure washer to cool down

- disconnect the electric plug and verify that it complies with the instructions contained in

the paragraph “Connection and installation of the electricity supply,” checking the extension lead used.

- reconnect the electric plug and repeat the procedure for start up descibed in the aragragh, “initial activity and start-up”

GB

WARNING:

The pressure washer has an exhaust for the evacuation of exhaust fumes that is considered a DANGER AREA because

it emits hot fumes from the combustion of diesel. DO NOT TOUCH the exhaust because it can be very hot and it is

EXPRESSLY FORBIDDEN to cover the exhaust with objects, clothes, or any other items. Do not expose the face or

any other part of the body to the exhaust fumes.

WARNING:

The pressure washer produces a jet of high pressure water from the nozzle at the end of the lance that is considered a

DANGER AREA because it can produce serious damage due to the high force of the water.

IT IS EXPRESSLY FORBIDDEN

to direct the jet against people or parts of the body, animals or fragile objects. The failure to

observe this warning can cause serious injury or damage like cuts and lacerations.

The manufacturer can not be held liable for any damage, accidents or injuries to people or

animals due to the disregard of this prohibition

Distributed by Australian Pump Industries (02) 8865 3500

NEVER direct spray jet at any surface that may contain asbestos material.

17

GB

B- SAFETY VALVE: is a maximum pressure valve, correctly calibrated by the manufacturer,

that discharges excess pressure whenever you need to check an anomaly in the pressure

regulating system.

C- PRESSURE REGULATING VALVE: is a valve, correctly calibrated by the Manufacturer, that prevents the pressure

from increasing past the maximum value allowed, by recirculating the excess water through the pump.

D- LOCKING MECHANISM FOR THE GUN TRIGGER: is a safety catch that allows you to lock the trigger of the

gun in the closed position, preventing accidental use.

Furthermore, on the machine there are a series of adhesive labels on the casing and on the

protective cover for the belt drive that prohibit the use of the pressure washer without the respective protection.

Refer to section 1-8 for the complete description of the graphical symbols.

E- the THERMOSTAT : device that operates the boiler and manages the regulation of the temperature.

F- FLOW SWITCH : device that detects the passage of water internally within a line.

G- PRESSURE SWITCH : device that detects the pressure difference in the water inlet and outlet.

6-7) PERSISTENT HAZARDS

The pressure washer was designed to eliminate as much as possible any cause of danger when in use, however:

- RISK OF BURNS from the heating unit exhaust, described in the warning section of this manual and indicated below.

This label is placed on the casing of the machine near the danger.

- RISK OF INJURY from the nozzle at the end of the lance, described in the warning section of this manual and indica-

ted below. This label is placed on the casing of the machine near the danger.

6-8) SAFETY GEAR FOR THE OPERATOR

During the running of the pressure washer it is obligatory to wear the following safety gear:

- goggles, if possible a protective mask

- boots with anti-slip soles

- safety gloves

6-9) TRAINING

It is the responsibility of the proprietor and/or supervisor to assign an operator and train them in the use of the pressure

washer according to the instructions in this manual.

THE MACHINE MUST ONLY BE OPERATED BY A TRAINED OPERATOR, WHO USES THE MACHINE IN

ACCORDANCE WITH THE INSTRUCTIONS CONTAINED IN THIS MANUAL AND/OR THE MANUAL FOR

ANY EXTERNAL EQUIPMENT.

WARNING:

In case of repeated intervention by the safety systems, do not use the pressure washer before having it checked by a

qualied technician

Distributed by Australian Pump Industries (02) 8865 3500

18

7-1) DESCRIPTION OF THE SAFETY CONTROLS

The high pressure washer is equipped with a watertight control panel where there is the ower switch (ON-OFF), the

thermostat to regulate the water temperature, and the electrical connections to the motors and the control/adjustment

components

Refer to the electrical diagram in section 12 for the graphical representation of the components.

7-2) MANOEUVRING DESCRIPTION TO BE CARRIED OUT AND OPERATION

After going through all the operating stages listed in chapters 5-6 and from point 1 to 12, to get the h.p washer to start:

13 Turn on the “Stella” with the general switch, keep the gun open and wait for the pressure to go steady.

14 Turn on the burner with the thermostat knob and position it at the desired temperature.

15 The rst step to turn off the “Stella” is to turn OFF the burner by putting the thermostat knob on the “OFF” posi-

tion, wait for the water coming out to become cold, then you can continue with turning off the “Stella”.

16 Turn on the “Stella” with the general switch, keep the gun open and wait for the pressure to go steady

17 Adjust the BY-PASS valve in the “STEAM STAGE”position.

18 Turn on the burner via the thermostat and position it at the desired temperature

19 During the washing operation with steam, do never close the gun.

20 The rst step to turn off the “Stella” is to turn off the burner by putting the thermostat knob on the “OFF” posi-

tion, wait for the water coming out to be cold, then you can close the gun and continue with turning off the “Stella”.

THE MANUFACTURER DOES NOT ACCEPT ANY RESPONSIBILITY FOR ANY IMPROPER USE OF THE

MACHINE NOT FORESEEN IN THIS MANUAL

WARNING:

Care and attention must be taken when using the pressure washer. The machine must only be used by an operator who

has been correctly instructed in its use. Do not allow anyone else to use the pressure washer without rst verifying that

they have been properly trained in its use, and that they have read this manual and fully understood the instructions for

use and the safety regulations.

WARNING:

If the pressure washer is used in a closed enviroment, make sure that the exhaust fumes are expelled in an appropriate

way and that there is sufcient ventilation (there is danger of asphyxiation).

WARNING:

The machine must not be left running for more than 2 or 3 minutes maximum with the gun trigger in the closed posi-

tion.

7) USER INSTRUCTIONS

Distributed by Australian Pump Industries (02) 8865 3500

19

USING WITH DETERGENT

The machine was designed to be used with detergents recommended by the manufacturer. The

recommended detergents are those that are 90% biodegradable. The use of other detergents or

chemical products can negatively affect the safety and the correct running of the pressure washer

To ll the pressure washer with detergent, insert the suction hose (n°14 pag.9) into the tank con-

taining the detergent and open the tap.

7-3) TRIAL STAGE

The “NEW” high pressure washer needs to pass a fast trial stage of the motor-pump group.

The trial stage consists in making the unit run for no longer than 1 hour and then wait for another 1 hour so it cools

down. This should be done 5 times.

7-4) INTERRUPTING THE RUNNING (TOTAL STOP)

The pressure washer model with total stop will stop running automatically when the trigger on the gun is released.

The pressure washer will restart as soon as the trigger on the gun is pressed..

WARNING

After the use of detergents or disinfectants it is useful to run the machine for a few minutes with clean water, to rinse

out the circuit.

WARNING

Do not use the pressure washer to suck in any products containing solvents, petrol, thinners, acetone, combustable oils,

toxic products or irritants because the vapours are highly inammable, explosive, toxic or irritant.

Read carefully the instructions and warnings recorded on the label on the detergent used.

WARNING:

Keep separate and clearly marked the tanks containing the diesel and the detergents. If one of the tanks is lled with

the wrong product, do not use the pressure cleaner and refer to a qualied technician or the retailer for advice

WARNING:

Remember that when the pressure washer is in total stop it is still in effect running.

Do not leave the machine unsupervised even for a short time, without having previously taken the following steps:

- press the power switch to the OFF position

- remove the plug from the wall socket

- close the tap of the water supply

press the trigger on the gun to discharge the residual pressure inside the hoses

Distributed by Australian Pump Industries (02) 8865 3500

20

7-5) WORK STOPPAGE

The pressure washer stops supplying a jet of high pressure water when the trigger on the gun is released. Using this

function it is possible to temporally suspend the washing process.

7-6) REGULATION

The machine is tested by the manufacturer and the working pressure already regulated before being despatched. In case

you wish to work with a lower pressure, manually rotate the pressure regulating valve anticlockwise.

In normal working circumstances it is also possible to regulate the temperature of the water jet by adjusting the thermo-

stat control, until the maximum temperature allowed is reached, as recorded in the technical data table (page 11).

Reference to operation of smaller steam units is not allowed.

7-7) STOPPING AND PAUSING OPERATION

When you have nished the washing procedure stop the machine and store it according to the following sections

7-8) STOPPING OPERATION

1 When using a hot water machine, run the pressure washer with cold water for a few minutes by turning the ther

mostat to 0°C (zero °C)

2 Completely close the tap connected to the water supply.

3 Empty the pressure washer of any residual water by pressing the trigger of the gun for a few seconds

4 Turn the power switch to the OFF position

5 Remove the plug from the wall socket.

6 Eliminate any remaining pressure in the high pressure hose by keeping pressed the trigger on the gun for a few

seconds

7-9) EMERGENCY STOP

To carry out an emergency stop press the ON-OFF switch on the control panel to the OFF position

7-10) RESETTING CONDITIONS

To reset the initial conditions refer to the section “7.2 DESCRIPTION OF THE OPERATIONS”

WARNING:

The machine must not be operated with the pistol closed (trigger released) for more than 2 or at max. 3 minutes

WARNING:

The machine in this condition is considered to be operating.

DO NOT REMOVE YOUR GRIP FROM THE GUN.

Distributed by Australian Pump Industries (02) 8865 3500

This manual suits for next models

1

Table of contents

Other IDROBASE Pressure Washer manuals