Clena SPICEJET 120/10 User manual

SPICEJET

120/10 –200/15 –150/15

Each part of this use and maintenance manual shall carefully be read before utilizing the

machine. This machine has been tested as provided for by the Machinery Directive

2006/42/EC, as well as by the Directives 2004/108/EC, 2006/95/EC, 2000/14/EC as

amended.

ALBERTI INTERNATIONAL

Via G. Galilei

46020 MOTTEGGIANA (MN) –ITALY

Tel:+39 0376 510065 Fax:+39 0376 510034

EDIZIONE 01.04.2011 ( Copyright )

USE AND MAINTENANCE

MANUAL

_____________________________________________________________________________________

USE AND MAINTENANCE MANUAL page 2

WWW.CLENA.NL SPICEJET

DECLARATION OF CONFORMITY

According to Directive 2006/42/CE as amended

The manufacturer

Via G. Galilei –46020 MOTTEGGIANA (MN) –ITALY

HEREBY DECLARES THAT

THE HIGH PRESSURE HOT WATER CLEANERS

SPICEJET 120/10 –150/15 –200/15

Manufactured in year: 2016

Serial n° ______________

are in compliance with the Machinery Directive 2006/42/EC as amended

as well as 2006/95/EC (LOW TENSION)

2000/14/EC (environmental acoustic emissions from machines) 2004/108/EC

(ELECTROMAGNETIC COMPATIBILITY)

The relevant technical literature is owned by Alberti Clementino in Alberti International s.r.l.'s

premises, via G. Galilei, 46020, Motteggiana (MN) - Italy.

MOTTEGGIANA, 1st April 2011 MANAGING DIRECTOR's FULL NAME

Alberti Clementino - (OWNER)

Via G. Galilei

–

46020 MOTTEGGIANA (MN)

-

ITALY

_____________________________________________________________________________________

USE AND MAINTENANCE MANUAL page 3

WWW.CLENA.NL

SPICEJET

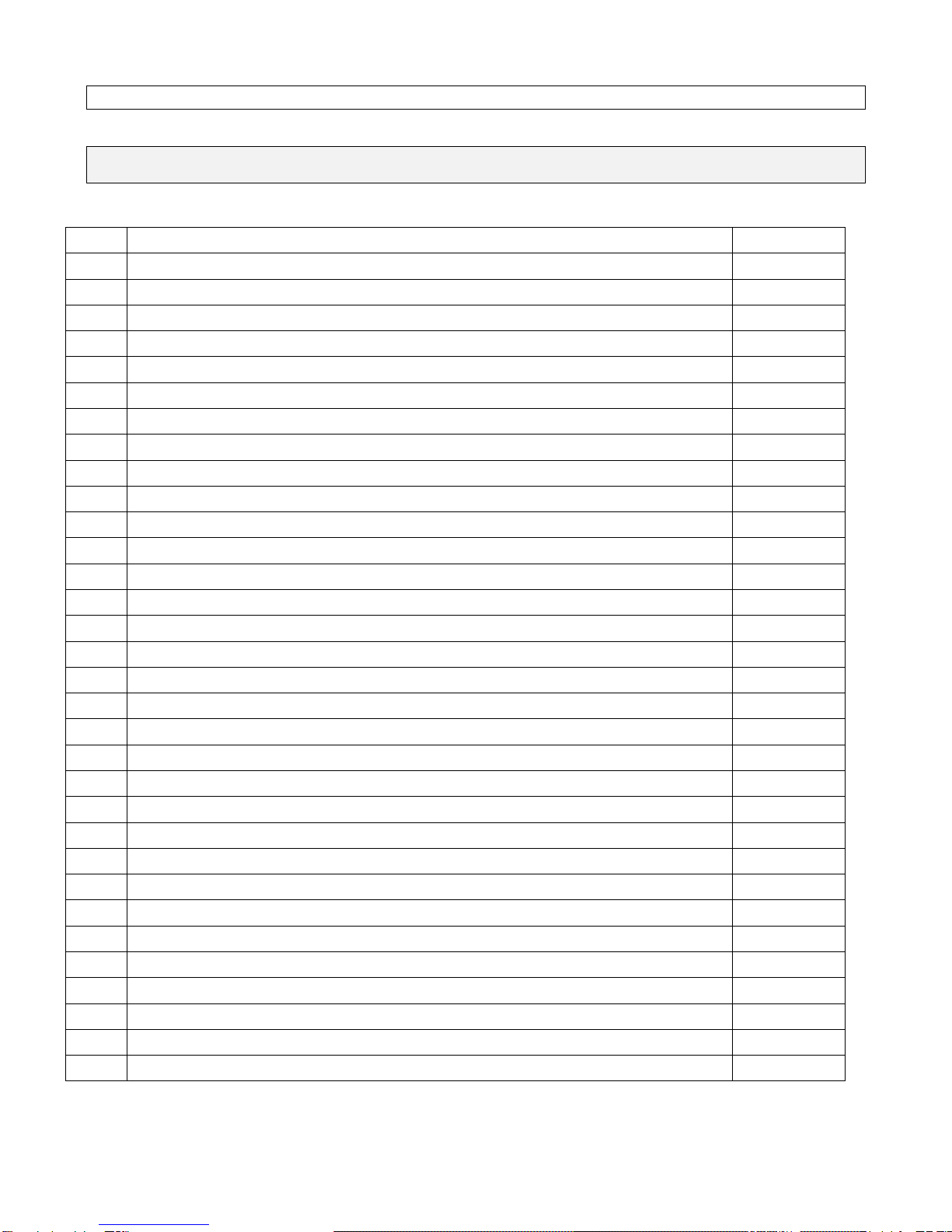

TABLE OF CONTENTS

N°

PARAGRAPH

PAGE

1

General directions

4

2

Personnel

4

3

Proper use

5

4

Machine identification plate

5

5

Technical data

6

6

Main parts

6

7

Use and safety instructions

7

8

Delivery

8

9

Standard accessories

9

10

Handling and transport

9

11

Installation

9

11.1

Water supply

9

11.2

Power supply

10

11.3

Prearrangement of accessories

10

11.4

Tank filling

10

12

Starting

11

13

Reduction of working pressure

11

14

Storage

12

15

Accessories

12

16

Residual risks

12

17

Symbols and labels utilized on the machine

14

18

Maintenance

15

19

Spare parts

16

20

Scrapping

16

21

Single-phase electric equipment

17

22

Three-phase electric equipment

18

23

Troubles, cause and cure

19

24

Warranty

20

25

Phonometry and vibrations

20

25.1

Pressure level and sound power

20

25.2

Emitted vibrations

20

26

Warranty rules

21

_____________________________________________________________________________________

USE AND MAINTENANCE MANUAL page 4

WWW.CLENA.NL

SPICEJET

1. GENERAL DIRECTIONS

We congratulate you on the purchase of your new water pressure cleaner, this is a clear indication

of your technical knowledge level as well as a very good taste for nice designs.

Innovation and state-of-the-art technology, high performances and solidity are the main

characteristics of SPICEJET water pressure cleaners. This manual shall be considered as an

integral part of the machine and shall be within reach of the personnel in charge of use and

maintenance. The user and the person in charge of the maintenance of the machine shall know the

contents of this manual. In case of troubles or doubts referred to the understanding of this manual,

we recommend to contact Company ALBERTI INTERNATIONAL Via G. Galilei –46020

MOTTEGGIANA (MN) –ITALY. Phone +39 0376 510065, Telefax +39 0376 510034.

This handbook contains non-binding descriptions and pictures, therefore the Manufacturer

reserves the right to modify the machine, at any moment and without notice.

Before utilizing the machine make sure the data badge is placed on the latter; if it is not the case,

immediately contact the dealer concerned and do not utilize the machine.

Never leave the machine unattended in the workplace.

At the end of each working day, the machine should be stored in cool and dry conditions,

sheltered from the bad weather.

Before using the machine make sure the latter will run under safety conditions.

In case of dismantling, the rules in force in the machine utilization Country shall be followed.

IMPORTANT! The working pressure shall not exceed the pressure value

being mentioned on the pumpe badge. (Paragraph 4 TECHNICAL DATA)

2. PERSONNEL

The following terminology is used according to the legislation in force:

UNSKILLED USER

Unskilled personnel being able to run the machine by using the control elements on the latter.

MECHANICAL MAINTENANCE PERSONNEL

Skilled personnel able to run the machine under normal conditions, to operate the mechanical

elements of the latter in order to carry out the adjustments required, to carry out both maintenance

operations and repairs, in case of need.

CERTIFIED PERSONNEL

Skilled Alberti International s.r.l.'s personnel able to carry out complex operations.

SKILLED OUT-HOUSE PERSONNEL

Skilled personnel working on behalf of manufacturer or distributor of components or commercial

machines, able to modify, repair or replace the latter.

PERSONS EXPOSED

Any person who totally or partially stand in a dangerous area.

_____________________________________________________________________________________

USE AND MAINTENANCE MANUAL page 5

WWW.CLENA.NL

SPICEJET

3. PROPER USE

The machine consists of a base made of pressed steel, which bears some components such as a

boiler, an electric motor and a high pressure pump. A gas oil tank made of moulded plastic

material as well as a sheet metal hood lend it a likeable line.

The machine shall only be used to clean and wash with cold or hot treated water objects and

surfaces being suited to be submitted to a mechanical high pressure water jet treatment and a

possible chemical detergent action. It is suggested not to use powder-based detergents, but to

utilize liquid-based products. Moreover, the latter shall be biodegradable as provided for by the

relevant rules in force.

Do not use the machine to wash animals and/or persons, or the machine itself. Do not direct the

machine jet toward yourself or other persons to clean your/their clothes and/or shoes.

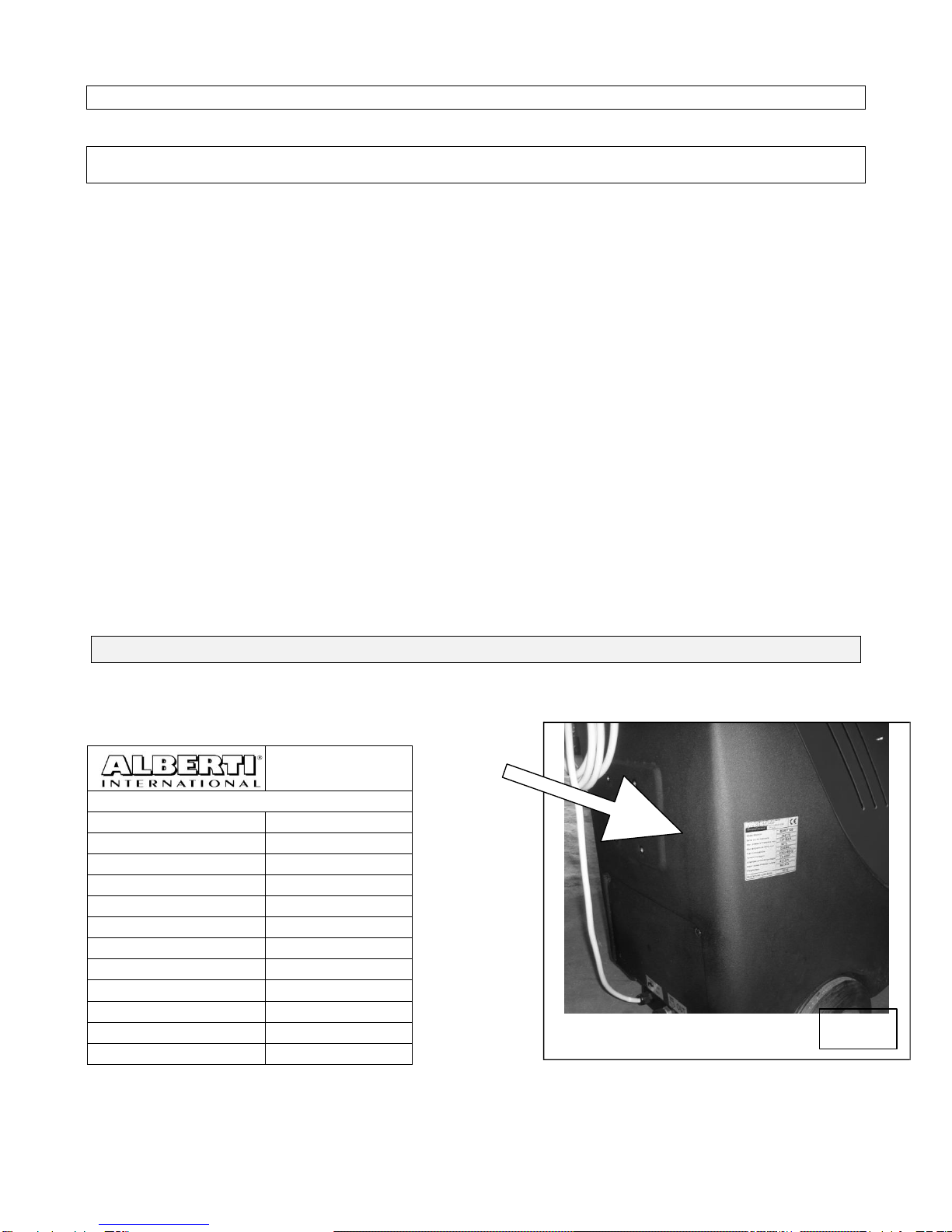

4. MACHINE IDENTIFICATION

Here below, the picture indicates the position the machine identification plate is placed in.

Alberti International s.r.l.

46020 Motteggiana (MN)

MADE IN ITALY

High pressure HOT water cleaner

Model

SPICEJET 150/15

Serial number

2364856

Working pressure

150bar –15Mpa

Max pressure

160bar –16Mpa

Capacity

900lt/h –15lt/min

Maximum temperature

140°C –284°F

Burner power

48.1 kW

Motor power

4 kW

Power supply

400V/50Hz

Diesel tank

16 lt

Weight

98 kg

Year of manufacture

2016

Fig.1

_____________________________________________________________________________________

USE AND MAINTENANCE MANUAL page 6

WWW.CLENA.NL

SPICEJET

5. TECHNICAL DATA

SPICEJET

120/10

150/15

200/15

Rated pressure

bar

120

150

195

Max pressure

bar

130

160

200

Capacity

lt / min

10

15

15

lt / h

600

900

900

Motor power

kW

2.2

4

5.5

HP

3

5.5

7.5

Power supply

V / Hz

230/50

400/50

400/50

Electric current required

A

12.6

10

12.6

Max temperature of water jet

°C

140

140

140

RPM

Rounds per

minute

1450

1450

1450

Burner power

kW

48.8

48.1

48.1

Sound pressure

dB(A)

80.1

80.1

80.1

Sound level

dB(A)

90

90

90

Weight

kg

118

118

122

Dimensions

mm

880x580x900

880x580x900

880x580x900

Gas oil tank capacity

lt

16

16

16

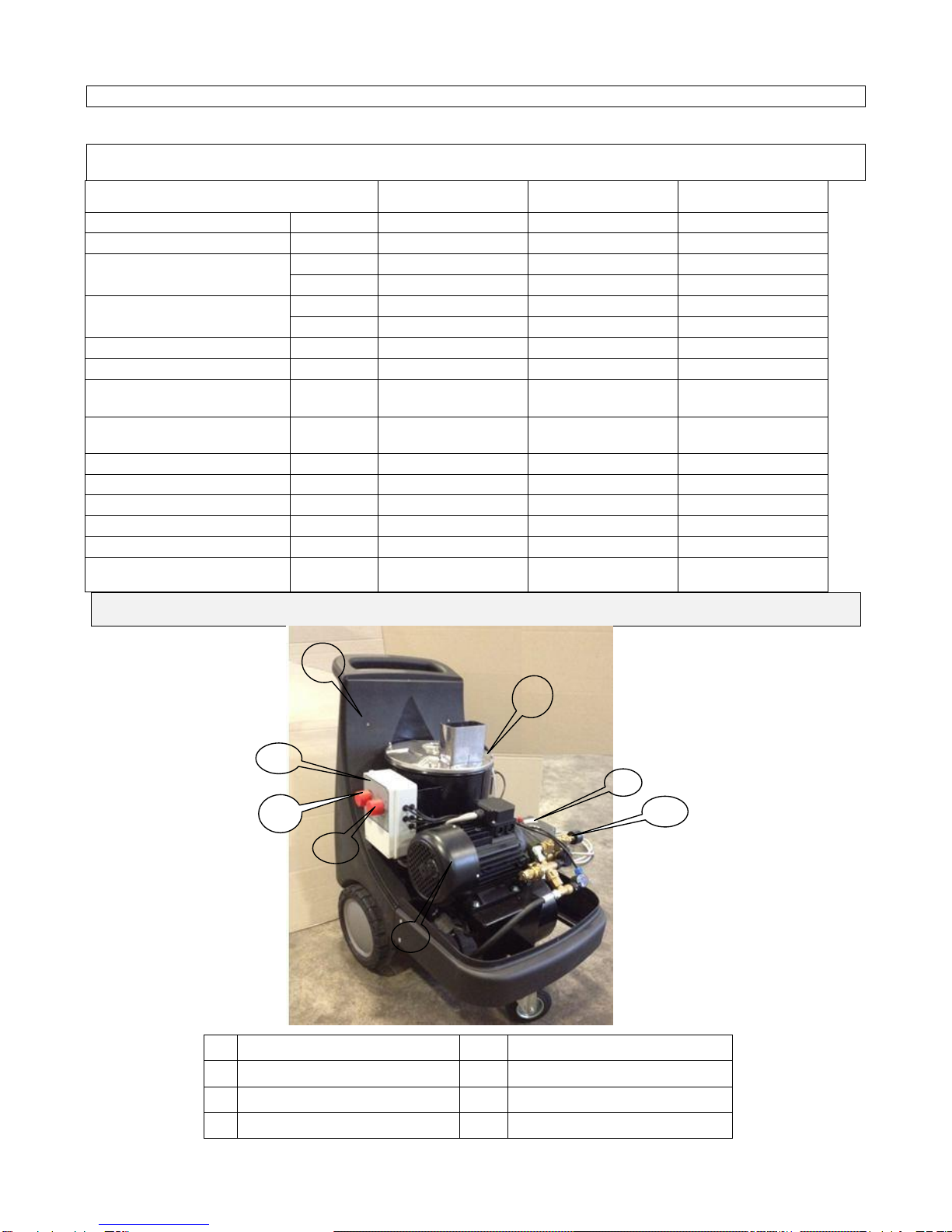

6. MAIN PARTS

1

MANOMETER

5

ELECTRIC BOX

2

HIGH PRESSURE PUMP

6

ON/OFF KNOB

3

BOILER

7

TEMPERATURE KNOB

4

FUEL TANK

8

ELECTRIC MOTOR

3

2

7

5

8

6

4

1

_____________________________________________________________________________________

USE AND MAINTENANCE MANUAL page 7

WWW.CLENA.NL

SPICEJET

7. USE AND SAFETY INSTRUCTIONS

•Before utilizing the machine, the users shall be trained for the operations they have to

carry out.

•Only adults being in perfect psychophysical condition may operate the machine.

•Make sure the machine is constantly supplied with water. Dry operations could result in

serious damages to the seal system.

•The electric connections shall only be carried out by skilled technicians or persons being

trained for this purpose.

•Neither pull the electric cable to disconnect the plug nor the hose to move the machine.

•The machine shall not be installed/stored at very low temperatures, to avoid a possible

frost forming.

•The machine being the subject-matter of this use and maintenance manual shall

constantly be controlled during its running.

•In case of bad weather, the machine shall be used in well-sheltered places (at least

under a roofing), in order not to jeopardize its functioning.

•Only use original spare parts supplied by the Manufacturer or approved by the latter.

•Vehicles shall not tread on the high pressure hose.

•While the machine is running, avoid to cover it or to position it in insufficiently ventilated

areas.

•If the working environment is closed, it is compulsory to install a chimney for the intake

of fuel gas.

•The chimney terminal shall never be obstructed. Do not lean objects or the lance close

to the fume exhaust.

•Fume exhaust procedure is to be considered as dangerous, both for exhaust gas and

for high temperature. In order to avoid any skin burn, suitably inform users, provide for a

suitable ventilation of the environment and make sure exhaust gas is appropriately

eliminated.

•Do not use the machine in case of rain and/or storm.

•Use protective clothes such as gloves, spectacles, shoes with non-slipping sole.

•It is fundamental to avoid leaving the machine in operation for more than 5 minutes with

the gun closed; after this period of time, the temperature of the water rapidly increases

causing serious damages to sealing system.

•Whenever you need to switch off the machine, release the residual pressure of the hose

by using the gun.

•Do not put your hands in front of the lance.

•Do not use the machine in case the power lead and/or other parts of the latter are

damaged.

•Never leave the machine unattended in the workplace.

At the end of each working day, the machine should be stored in cool, dry conditions, sheltered

from the bad weather.

WARNING!

•Before carrying out any maintenance operation, remove the machine plug from the

socket to disconnect the machine.

_____________________________________________________________________________________

USE AND MAINTENANCE MANUAL page 8

WWW.CLENA.NL SPICEJET

•Do not tamper with the power lead and make sure it is not damaged.

•Minors and unskilled personnel may not use the water pressure cleaner.

•Hoses, accessories and fittings are very important parts for the safety of the machine.

Only use hoses, accessories and fittings being recommended by the manufacturer.

•High pressure jets can represent a danger, in case they are improperly used. The high

pressure jets shall not be directed toward people, energized electric equipment and/or

the machine itself.

•Always utilize clean and treated water. Unfiltered water and corrosive chemicals

represent a danger.

•Always use clean fuel.

•A machine inclination shall not exceed 20° (in case of full tanks).

•The use of movable extension leads and/or plugs is prohibited. The working environment

is exposed to water and humidity and both these elements prevent the system from

having its normal insulation. Make sure the electric cable is intact and well insulated and

the equipment is in good condition.

•Do not use unsuitable fuel, in order to avoid dangerous situations.

•Do not use in the working environment instruments having a combustion engine, if it is

not sure that a suitable ventilation is present and make sure exhaust gas is appropriately

eliminated, checking for exhaust gas emissions not to be close to air inlets.

•Only use detergent being supplied or suggested by the manufacturer. Different

detergents or different chemical product could jeopardize the machine safety conditions.

•Only use original spare parts.

•Do not utilize the machine in potentially explosive environments.

8. DELIVERY

ATTENTION

On the date of the receipt of the machine, make sure the packing is intact and has not been

damaged during the transport, as well as it has not been tampered with to steal parts of the

machine.

In case of damages or missing parts, immediately inform the forwarder, the insurance company

and Alberti International s.r.l. by giving them all details as required.

Upon receipt of the machine, make sure the supply is in compliance with the specifications

mentioned in the transport document.

Before handling the machine, always make sure the hoisting equipment and the relevant parts of

the latter (ropes, hooks, etc.) are suited to lift the weight to be handled and have the stability

required to carry out the lifting.

Use the specially provided accident prevention protections while operating.

Alberti International s.r.l. utilizes packings suited to ensure intactness and preservation of the

product during the transport.

To dispose of the packing, please refer to the legislation in force in the Country the

machine is destined to.

_____________________________________________________________________________________

USE AND MAINTENANCE MANUAL page 9

WWW.CLENA.NL

SPICEJET

9. STANDARD ACCESSORIES

Upon the receipt of the machine, make sure the latter is intact and equipped with the following

accessories: a thermal lance, a high pressure 10mtr hose, a nozzle suitable for the version

concerned.

10. HANDLING AND TRANSPORT

To carry out the transport of the machine you shall:

1. disconnect it from its supply sources;

2. remove all connected accessories, such as gun and high pressure hose;

3. position the machine body on a bed and fix it;

4. lock the machine by braking it;

5. Position the hoisting equipment forks under the bed and verify the stability level of the

system.

Make sure weight, capacity and overall dimensions are the same as specified in

the “technical data”.

Handle the machine on even, smooth, firm surfaces; do not move the machine

on sloping surfaces.

Non-authorized personnel shall keep at a distance from the machine.

WARNING!

11. INSTALLATION

In order the machine running to result in highest performances, the machine installation shall be

carried out by carefully following our instructions. Before starting the machine, make sure it is

perfectly horizontal on the support structure.

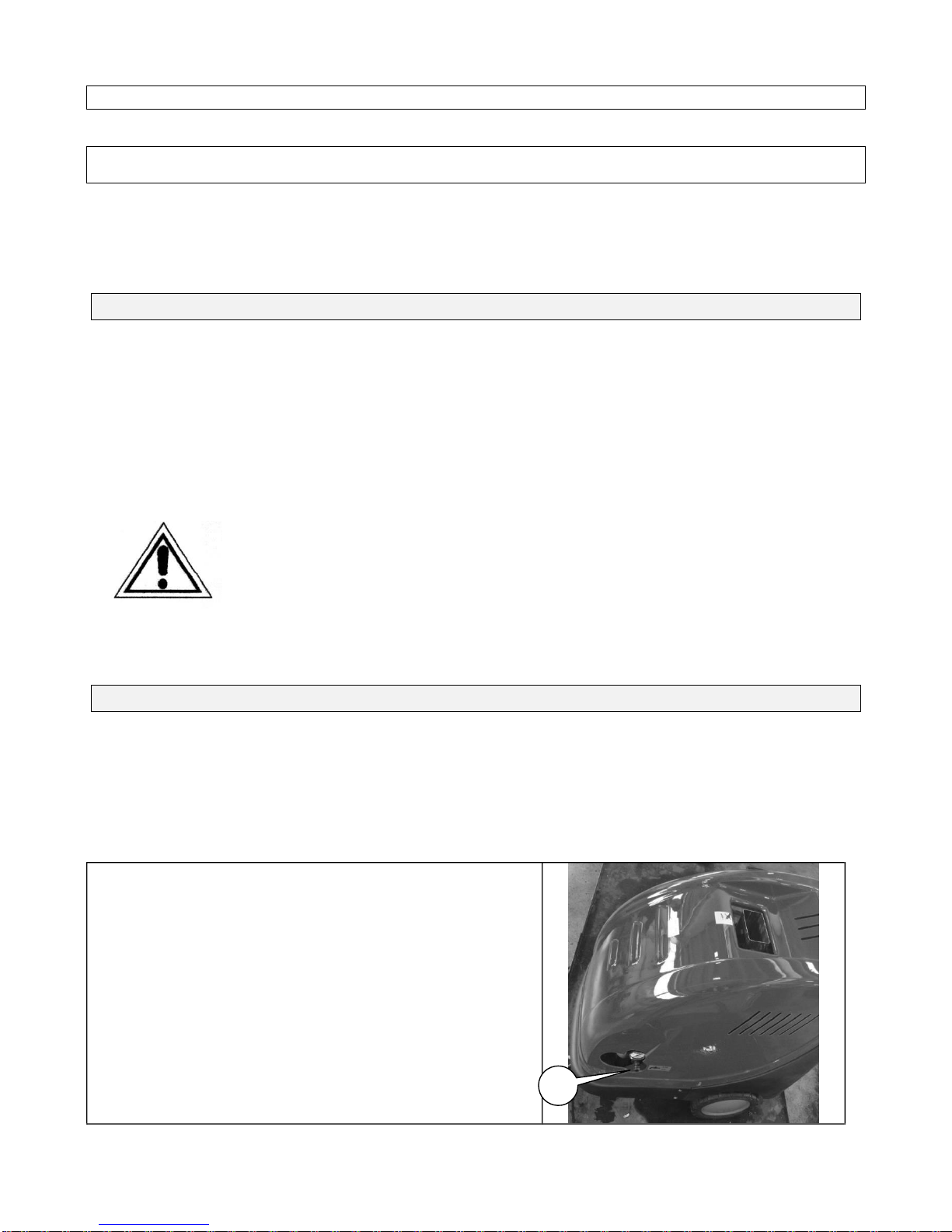

11.1 WATER SUPPLY

Connect the water supply hose to the inlet fitting

E

(

See

fig

. We suggest to use a reinforced anti

)

-

torsion

antifreeze hose having an inne

r diameter at least equal

to Ø 16

÷

Ø 18 mm. The water delivery shall be at least

equal to 15 l/min, have an inlet temperature equal to

°C, a minimum pressure equal to 2 bar and a

60

maximum pressure being approximately equal to 3.5 bar

E

_____________________________________________________________________________________

USE AND MAINTENANCE MANUAL page 10

WWW.CLENA.NL SPICEJET

Connect the water supply hose to the water supply

system tap.

11.2 POWER SUPPLY

The machine shall be connected to a fixed power supply point being equipped with an effective

earthing contact, as well as controlled by cut off devices acting as protection from overload and

power leak.

The connection to the power supply system shall be carried out by a qualified electrician. Make

sure the power supply point is protected as provided for by the legislation in force. In case an

extension lead is used, both the plug and the socket shall be immersion proof.

WARNING!

Non suitable extension leads could represent a danger.

11.3 PREARRANGEMENT OF ACCESSORIES

Connect the high pressure hose Ato the gun Band

the other end of the hose to the inlet fitting, by

tightening the fixing ring nut C(See fig 4).

Fig 4

11.4 TANK FILLING

A

B

C

Fill

F

fuel tank (see fig. 5) with (Diesel) gas oil.

_____________________________________________________________________________________

USE AND MAINTENANCE MANUAL page 11

WWW.CLENA.NL SPICEJET

12. STARTING

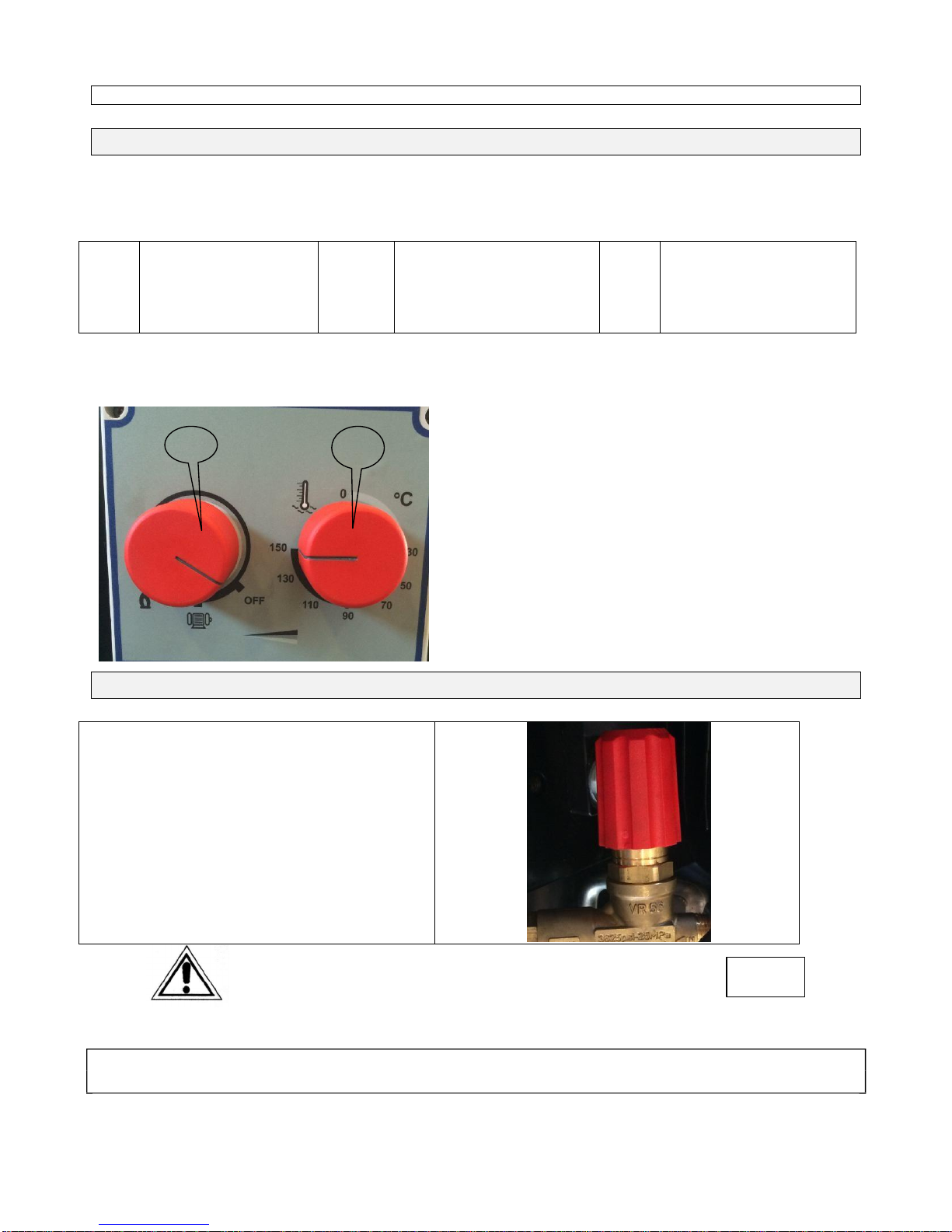

The control board managing the operations to be carried out is very simple. Aknob has three

positions:

Pos.1

OFF indicates that

the machine is off.

Pos.2

The intermediate

second position

indicates that the motor

pump is on.

Pos.3

The third ON position

indicates that the

burner is on.

Bknob turns the thermostat on and by a scale of values it allows a temperature from 0 to 150°C.

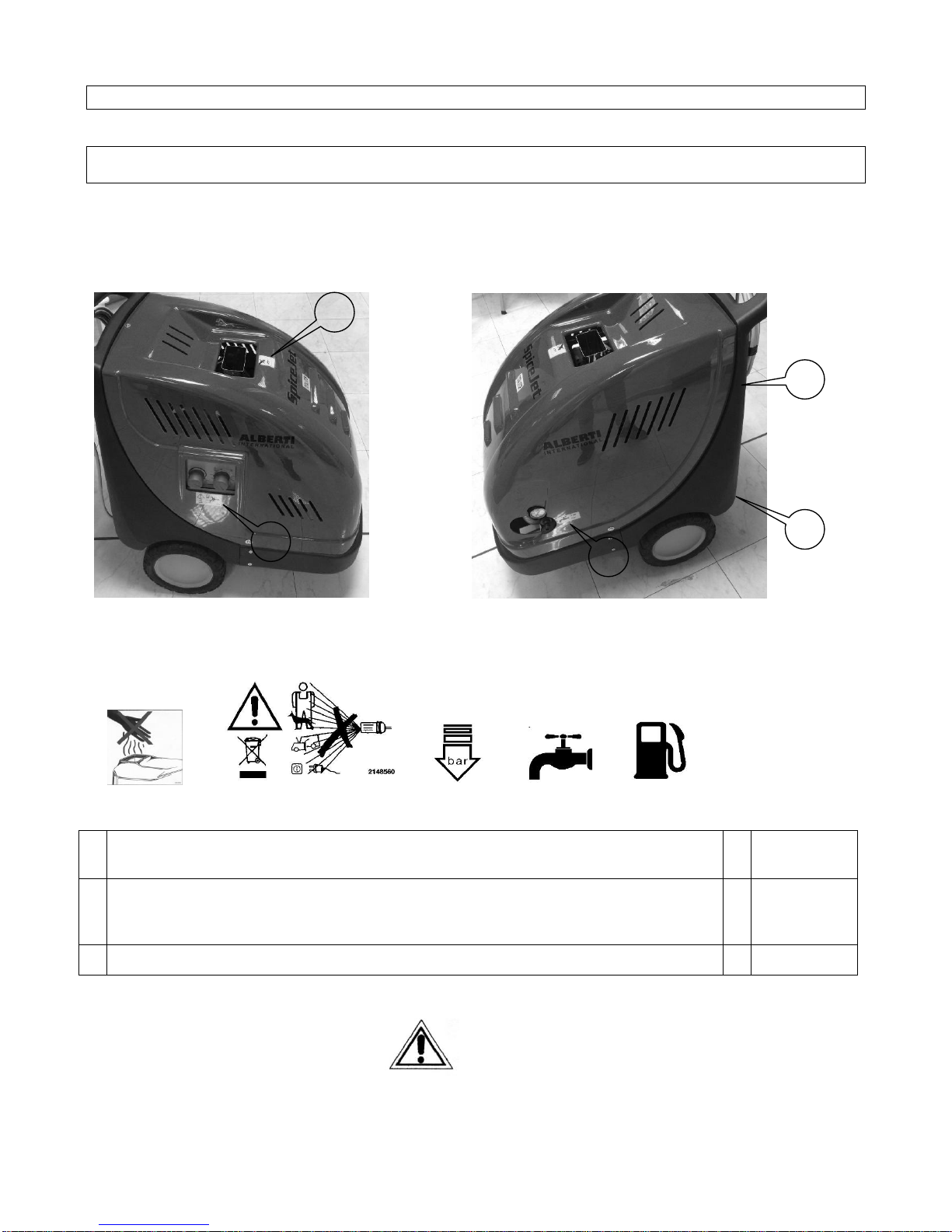

13. REDUCTION OF WORKING PRESSURE

The machine is supplied with the correct

nominal pressure, therefore it is not

possible to increase the pressure, in order

to avoid serious damages to the pump.

B

A

IMPORTANT! The pressure of utilization shall not be higher than the

pressure indicated in the table

. (Paragraph 5 TECHNICAL DATA)

The hydraulic system is equipped with a safety valve that intervenes

in case of pressure higher

than the calibration value.

Fig 6

_____________________________________________________________________________________

USE AND MAINTENANCE MANUAL page 12

WWW.CLENA.NL

SPICEJET

14. STORAGE

At the end of the work, after discharging the residual hose pressure and inserting the safety catch

in the gun, rewind the electric cable and the high pressure hose in such a way that it is not

possible for them to get damaged. Store the water pressure cleaner in a place being protected

from frost, where there is no possibility for non-authorized persons to use the latter. The machine

shall neither be stored on a ground which could jeopardize its stability nor on a sloping surface.

15. ACCESSORIES

ALBERTI INTERNATIONAL can by customer's request supply useful accessories as per the

following pictures, which allow different works very easily to be done.

ROTARY BRUSH

Used to clean

vehicles, surfaces,

tiles, etc …

HYDRO-

SANDBLASTING KIT

ROTARY-JET

NOZZLE It

allows even the most

tenacious dirt to be

removed.

16. RESIDUAL RISKS

The machine has been designed and produced to ensure highest safe operating conditions to

users, under any circumstances; anyway, there are some potential ineliminable risks.

WARNING!

To limit this possibility of risk, we remind to follow all instructions described in this

manual, neither to tamper with nor to inhibit the machine safety devices, as well as always use

personal protective equipment as required.

We also remind that the personnel involved in use, maintenance and cleaning of the machine,

shall be aware of the relevant safety rules.

Therefore, pay attention to the following danger situations:

HIGH TEMPERATURE

There is a burn risk due to a combustion gas outlet at high temperature. All the parts subject to

high temperature are protected by a special plastic covering, but there is still a risk near the

combustion gas outlet and such risk has been emphasized by a label.

_____________________________________________________________________________________

USE AND MAINTENANCE MANUAL page 13

WWW.CLENA.NL SPICEJET

EMISSION OF DANGEROUS MATERIAL AND SUBSTANCES

It is suggested not to use powder-based detergents, but to utilize liquid-based products. Moreover,

the latter shall be biodegradable as provided for by the relevant rules in force.

Do not use the machine to wash animals and/or persons, or the machine itself. Do not direct the

machine jet toward yourself or other persons to clean your/their clothes and/or shoes. Only adults

being in good psychophysical condition may use the machine.

POWER SUPPLY

The machine is electrically supplied by the power supply grid.

To reduce the risks arising from this kind of power supply, the following devices have been

included:

•the power supply network connection terminals contain a connector ensuring the earth

connection;

•choice of the devices in compliance with the rules being in force;

•the power devices (having inside parts being connected to the supply voltage) are placed

inside a plastic body having a suitable IP degree (degree of protection); in no case, the user

is entitled to operate in that area;

•the user may only intervene during the installation and/or maintenance phase.

HIGH PRESSURE WATER AND STEAM

The existing hydraulic circuit is fed by water from the water network. To reduce the existing risk,

the following has been included:

•in the hydraulic circuit, a valve limits the maximum pressure according to the values which

have been determined in the design phase;

•choice of the components in compliance with the rules being in force or, anyway, being

properly oversized;

•use and maintenance handbook containing all instructions regarding a proper maintenance

of the circuit, as well as the precautions to be taken;

•use and maintenance handbook containing instructions concerning a proper management

of the hydraulic circuit (for example: connection to the water supply network, cable

characteristics).

NOISE AND VIBRATIONS

At the light of the existing noise level (as mentioned in this use and maintenance handbook), the

residual risk level is low.

The evaluation of a risk level to users (which also depends upon the duration of exposure) shall be

carried out by the employer, as provided for by the rules related to Health and Safety at Work.

SLIPPING, STUMBLING, FALL

The machine can create areas pools of water or other liquid can form in, and this represents a risk

of falls. Therefore, the user shall utilize protective shoes and before using the machine, he shall

make sure the area the machine shall be used in has a water/liquid drain.

THUNDERBOLTS

The machine wheels ensure a very good electric insulation, so that there is a low degree of

probability that thunderbolts are attracted by the machine. Moreover, the machine can be utilized

under cover (having at least a roofing) in case of bad weather conditions, which could jeopardize

its functioning.

_____________________________________________________________________________________

USE AND MAINTENANCE MANUAL page 14

WWW.CLENA.NL

SPICEJET

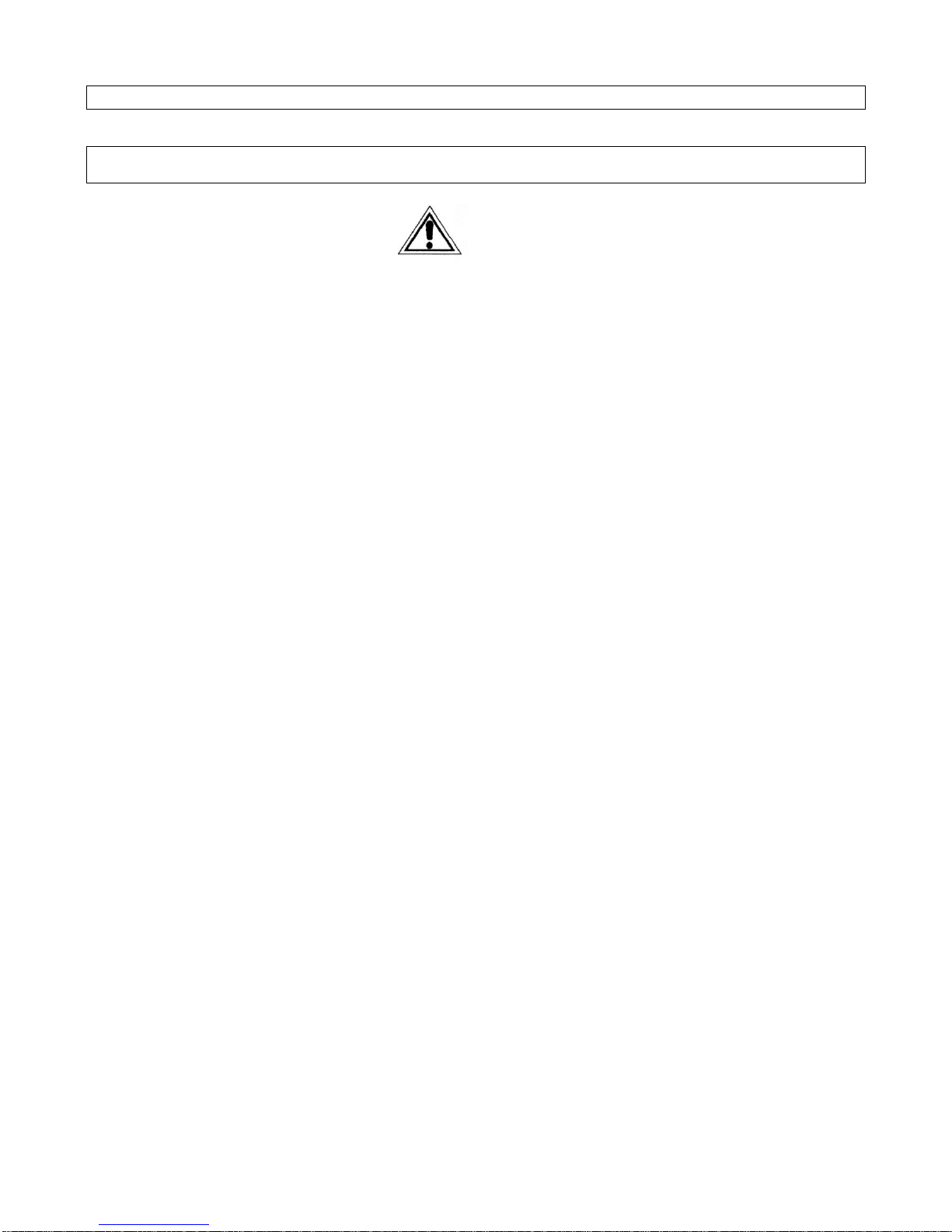

17. SYMBOLS AND LABELS UTILIZED ON THE MACHINE

The machine is supplied with safety warning notices; also any safety rules being in force in the

Country/ies the machine/s will be installed in have to be followed. Here below, you can find a table

reporting the different types of utilized labels and their meaning:

1 2 3 4 5

1

Warning! High temperature combustion gas outlet, burn risk.

4

Water

supply

2

Warning! Do not direct the high pressure jet towards persons, animals,

electric equipment, etc…

To dispose of the machine, only contact authorized waste disposal centres.

5

Fuel tank

3

Delivery to the lance.

WARNING!

Make sure the data plates are present and can easily be read; should that not be the case, apply

or replace them. To request the plates, contact the authorized dealer being nearest to you.

1

2

3

4

5

_____________________________________________________________________________________

USE AND MAINTENANCE MANUAL page 15

WWW.CLENA.NL

SPICEJET

18. MAINTENANCE

WARNING!

•All maintenance operations must be carried out when the machine is positioned on a horizontal

surface and has previously been disconnected from both the power and the water supply.

•Only skilled personnel may carry out repairs and/or maintenance operations.

•A careful maintenance and a proper use are a prerequisite to ensure effectiveness and safety of

the machine.

•To ensure a constant and regular machine functioning, only original spare parts supplied by the

manufacturer or approved by the latter must be used.

•The machine you have purchased has been submitted to an approval testing in order to ensure

a proper starting/functioning of the machine.

•In case the machine is not utilized for a long time, before restarting it, it is recommendable to let

some water go through the coil, for some time, at least until clean water comes out of the coil.

Besides the usual preliminary checks, the machine needs to be checked constantly, i.e. at the

following intervals:

1) DAILY

Check the level of the oil pump by means of the cap complete of dipstick If necessary add some

(suggested type of oil: SAE 15W/40). The first

oil top up must be done after 1 week work.

Check the working condition of the feeding hose and the extension cable.

2) EVERY 2 WEEKS AND AFTER 50 HOURS WORKING SHIFT

By means of an air jet, clean the water filter placed in the water inlet by means

of an air jet.

3) EACH MONTH OR 100 HOURS WORKING SHIFT

Clean the combustion head.

4) EACH MONTH OR 200 HOURS WORKING SHIFT

Carry out the first oil top up of the pump as described at point 1.

Replace the fuel filter.

Clean the filter of the fuel pump.

_____________________________________________________________________________________

USE AND MAINTENANCE MANUAL page 16

WWW.CLENA.NL SPICEJET

20. SPARE PARTS

Any request regarding spare parts shall be sent to ALBERTI INTERNATIONAL by mentioning:

•machine model,

•serial number,

•year of construction,

•description and quantity

21. SCRAPPING

In case the machine shall be scrapped, the rules in force in the Country the machine will be

utilized in shall be followed. The machine consists of parts containing metals as well as recyclable

plastic materials. The highly polluting oil being in the pump as well as electric and electronic

material shall not be disposed of as household waste.

For scrapping the machine and its parts, you shall turn to authorized waste disposal centres, in

particular concerning both drain oil and electric/electronic materials.

_____________________________________________________________________________________

USE AND MAINTENANCE MANUAL page 17

WWW.CLENA.NL

SPICEJET

22. SINGLE-PHASE ELECTRIC EQUIPMENT

_____________________________________________________________________________________

USE AND MAINTENANCE MANUAL page 18

WWW.CLENA.NL

SPICEJET

23. THREE-PHASE ELECTRIC EQUIPMENT

_____________________________________________________________________________________

USE AND MAINTENANCE MANUAL page 19

WWW.CLENA.NL

SPICEJET

24. TROUBLES, CAUSE AND CURE

TROUBLE

CAUSE

CURE

THE WATER DOES

NOT COME OUT

The water filter is dirty

The intake valves are jammed

The lance nozzle is clogged

Clean or replace.

Check the intake valves.

Clean the nozzle.

INSUFFICIENT OR

UNEVEN PRESSURE

The detergent valve is open and

intakes air

Lack of water

The pump intakes air

The valve is worn

The nozzle is worn or non suitable

The gaskets are worn

The water temperature is too high

The coil is scaled

Check.

Check the water

capacity.

Check the pump.

Replace.

Replace.

Replace.

Check the temperature.

Remove the scale.

THE BURNER DOES

NOT START

Too much air goes in

The gas oil filter is dirty

The pump/gas oil filter is dirty

The burner nozzle is dirty

The thermostat is faulty

The solenoid valve is clogged or

faulty

The spark to the electrodes is not

sufficient

The flowmeter and/or the

pressure controller is faulty

The pump-motor coupling is worn

Lack of voltage

Check.

Replace.

Clean or replace.

Replace.

Replace.

Replace.

Replace.

Replace.

Replace.

Check.

NOISE

Air suction

The valves are worn, dirty or clogged

The water temperature is too high

Check the air suction conduits.

WATER PRESENCE IN

THE OIL

The water/oil sealing rings ae worn

High percentage of humidity in the

air

Replace.

Check.

OIL LEAK ON THE

HEAD

The O-rings of the sealing system

are worn

Replace.

BY PRESSING THE

START BUTTON, THE

MOTOR DOES NOT

START

The plug does not work due to

overheating

Check the plug, the cable and

the switch.

THE MOTOR

SUDDENLY STOPS

Thermal protection intervention due

to overheating

Make sure the voltage is as

provided for.

WWW.CLENA.NL SPICEJET

_____________________________________________________________________________________

USE AND MAINTENANCE MANUAL page 20

25. WARRANTY

Concerning the machine warranty, please refer to the conditions in the paragraph WARRANTY

RULES being validated by a WARRANTY CERTIFICATE, which is issued on the date of the

purchase of the machine.

26. PHONOMETRY AND VIBRATIONS

This manual describes the machine being tested, the measurement methods as well as the results

aimed at determining the sound power level according to UNI EN ISO 3744:2009.

During the test, the source has been started to simulate a normal machine running.

The sound level measurements have been taken at 2 mtrs from the source and a height from the

ground as provided for by UNI EN ISO 3744:2009 - Appendix C.

The background sound level measurement has been taken when the water pressure cleaner was

not working.

26.1 PRESSURE LEVEL AND SOUND POWER

Results

Obtained from taken measurements and calculations (according to UNI EN ISO 3744:2009)

26.2 EMITTED VIBRATIONS

By taking the relevant measurements, the following results have been obtained:

Water cleaner description

Lance

handgrip [see

fig 1]

Vibrations transmitted to

the hand-arm system

Awsum [m/s2]

Action level

(see

Decree Law

81/08)

[m/s2]

Sound pressure level at user's place Lp [dBA]

80.1

Sou

nd power level Lw [dBA]

90.3

1

1.45

Machine model:

SPICEJET

2

1.10

2.5

This manual suits for next models

2

Table of contents