0 – 2

SAFETY INFORMATION

We offer you basic and important rules and precautions for safe operations.

Read, understand, and observe them before starting operation. This is the most essential

way to prevent accidents.

Wrong operation, inspection, or maintenance can cause personal injury or death.

Throughout this manual and on the machine, precautions are provided with marks

and classified by the words “DANGER”, ‘’WARNING”, and “CAUTION” according to

their extent of danger.

The classification is as follows :

Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could

result in minor or moderate injury. It may also be used to alert against

possible damage to the machine and its components.

We have made every effort for you to prevent accidents during operation, however, we

cannot be held responsible for predicting every kind of danger in all operating conditions.

It is the owner or user of the machine who is responsible for ALWAYS paying attention to

operate the machine; as well as reading and understanding this manual enough to obtain

the essential knowledge and skills fundamental to correct machine operation.

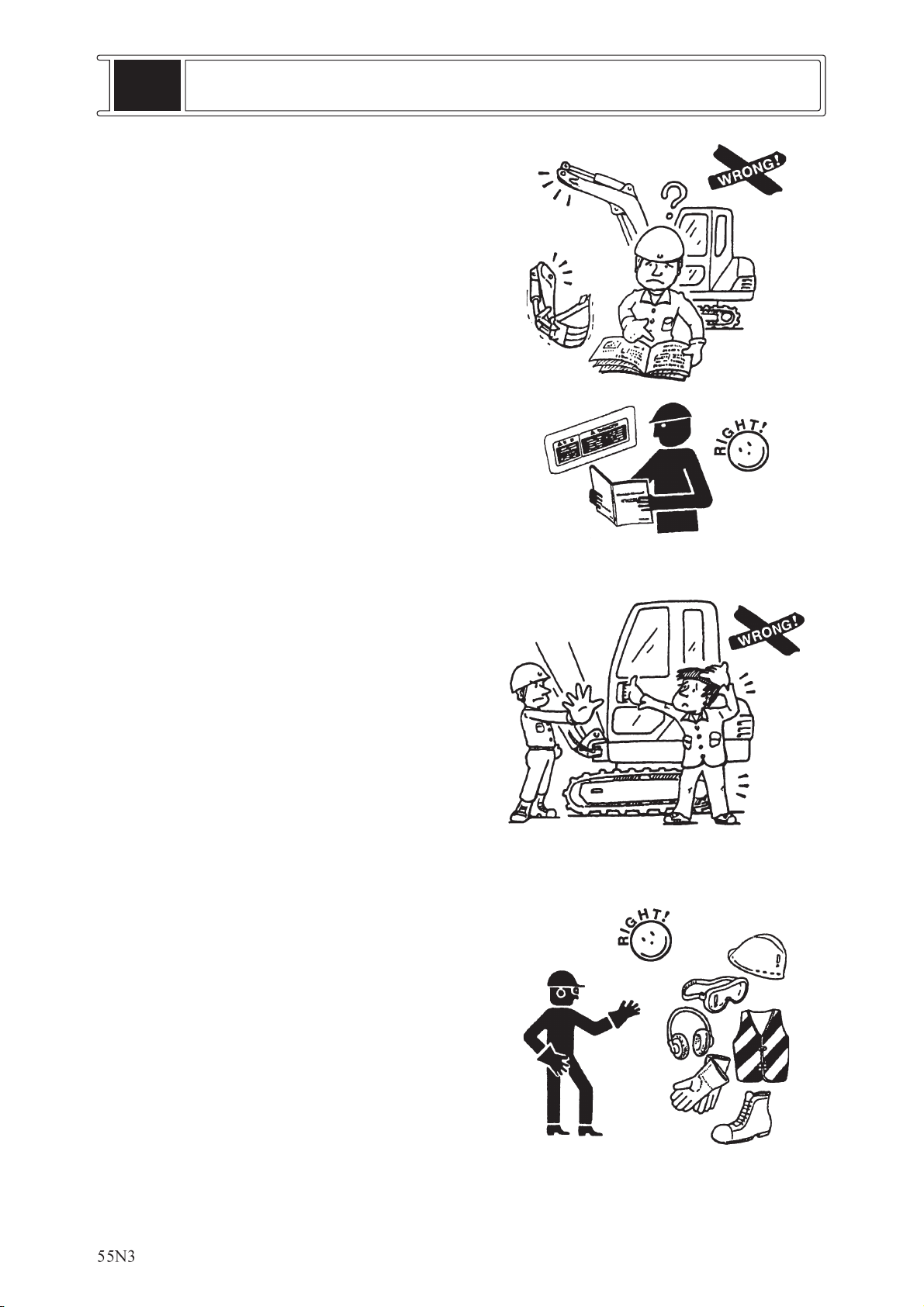

•BEFORE inspection, operation, or maintenance of the machine, be sure to

read and understand this manual.

• Incorrect operation or maintenance of the machine can cause the accident

and serious injury or death.

• Keep this manual on hand during operation so that you can immediately

consult it when necessary. If it should be missing or damaged, place an order

from lHI distributor for a replacement.

• There are various kinds of federal, state, and local regulations that effect

construction and industrial machinery. Since the regulations are subject to

change, and differ from one locale to another, it is impossible for us to provide

such information in this manual.

It is the responsibility of the owner or user to be familiar with the regulations.

• Specifications and materials of the machine are subject to change without

any obligation on the part of the manufacturer.

DANGER

WARNING

CAUTION

WARNING