6 7

Safety instructions

/// General information

›

Read the operating instructions completely before starting up and follow the safety

instructions.

› Keep the operating instructions in a place where it can be accessed by everyone�

› Ensure that only trained staff work with the device�

› Follow the safety instructions, guidelines, occupational health and safety and accident

prevention regulations�

›

The vessel must only be used in a technically perfect condition�

›

Refer to the operating instructions for the drive unit�

Caution!

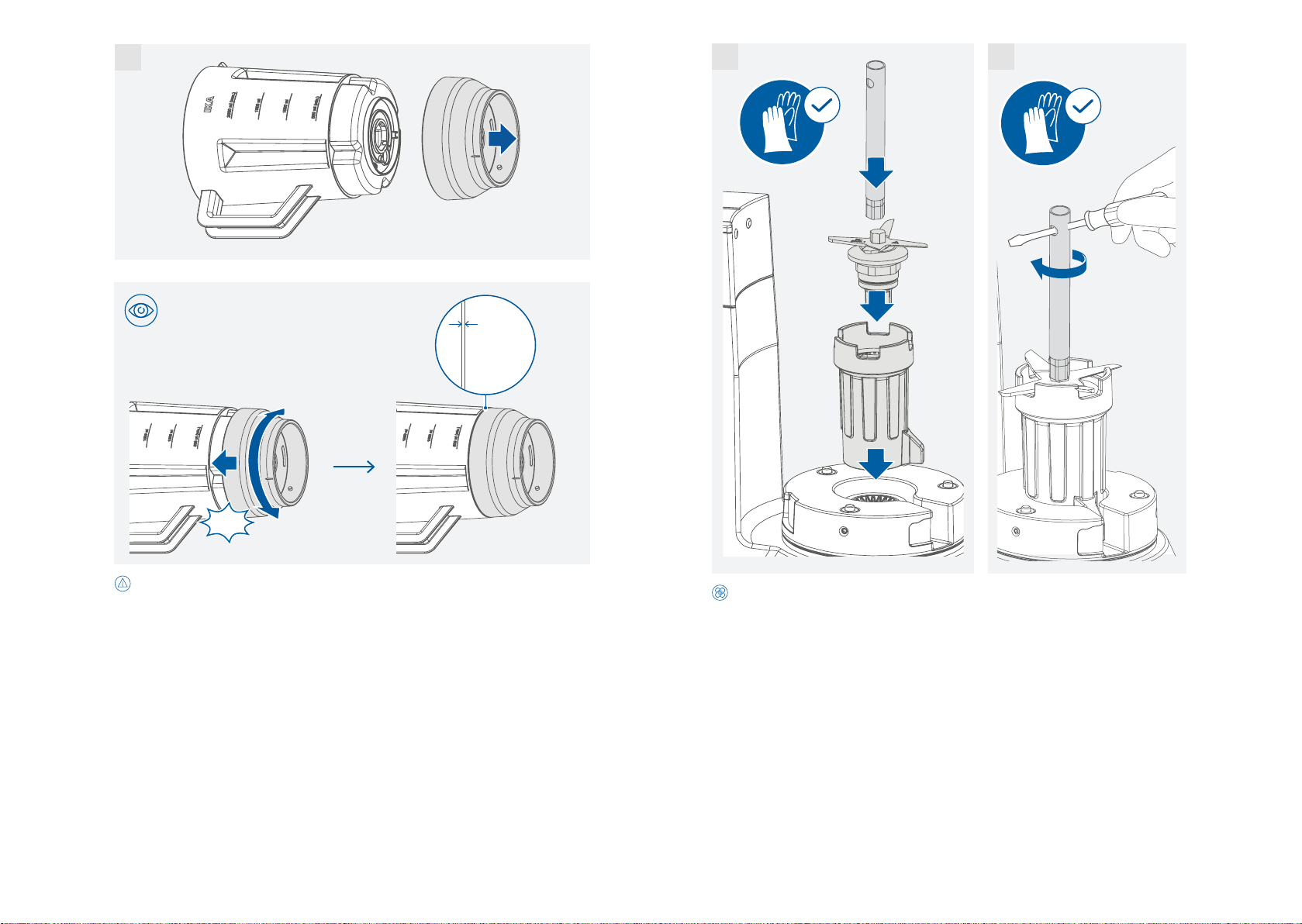

›Wear your personal protective equipment in accordance with the hazard category of the

medium to be processed, there is a risk of:

- splashing of liquids

- body parts, hair, clothing and jewellery getting caught�

- sharp blade edges�

!Notice!

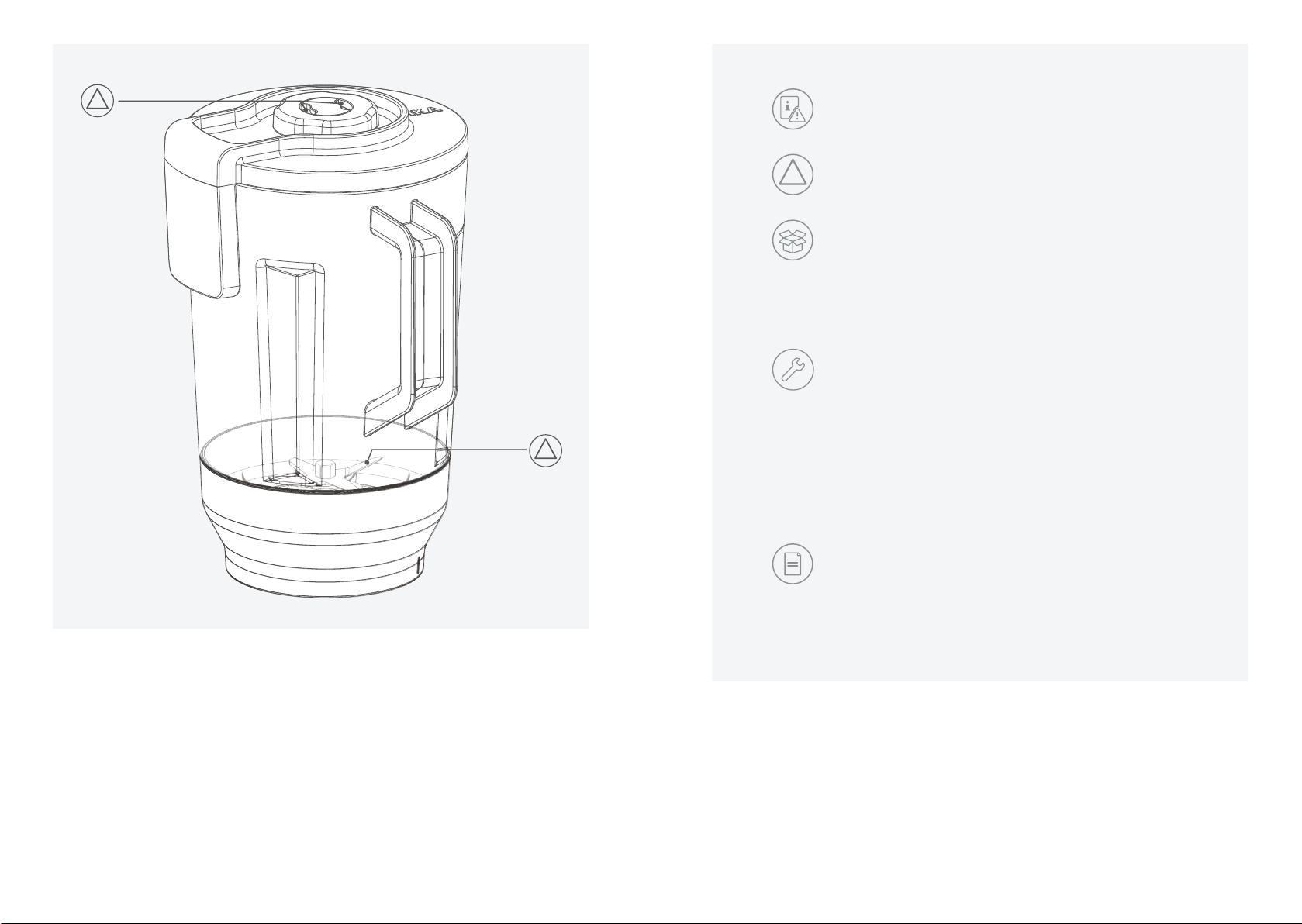

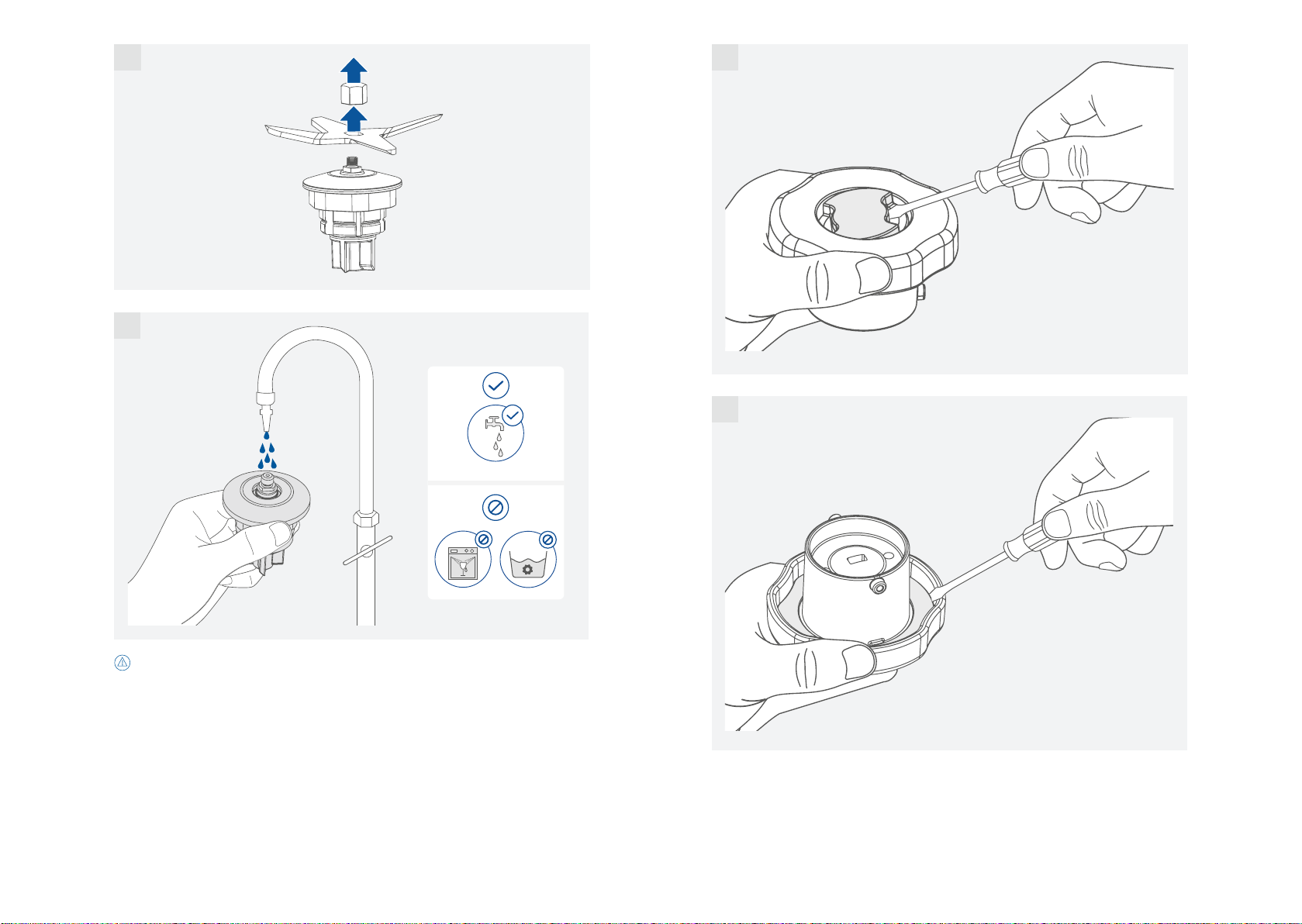

› Pay attention to the marked sites in Fig� 1�

› Protect the vessel from bumping and impacting�

›

Do not use any damaged vessel e�g� with hairline cracks or splits�

› Check the vessel beforehand for damage each time when you use them� Do not use dam-

aged components�

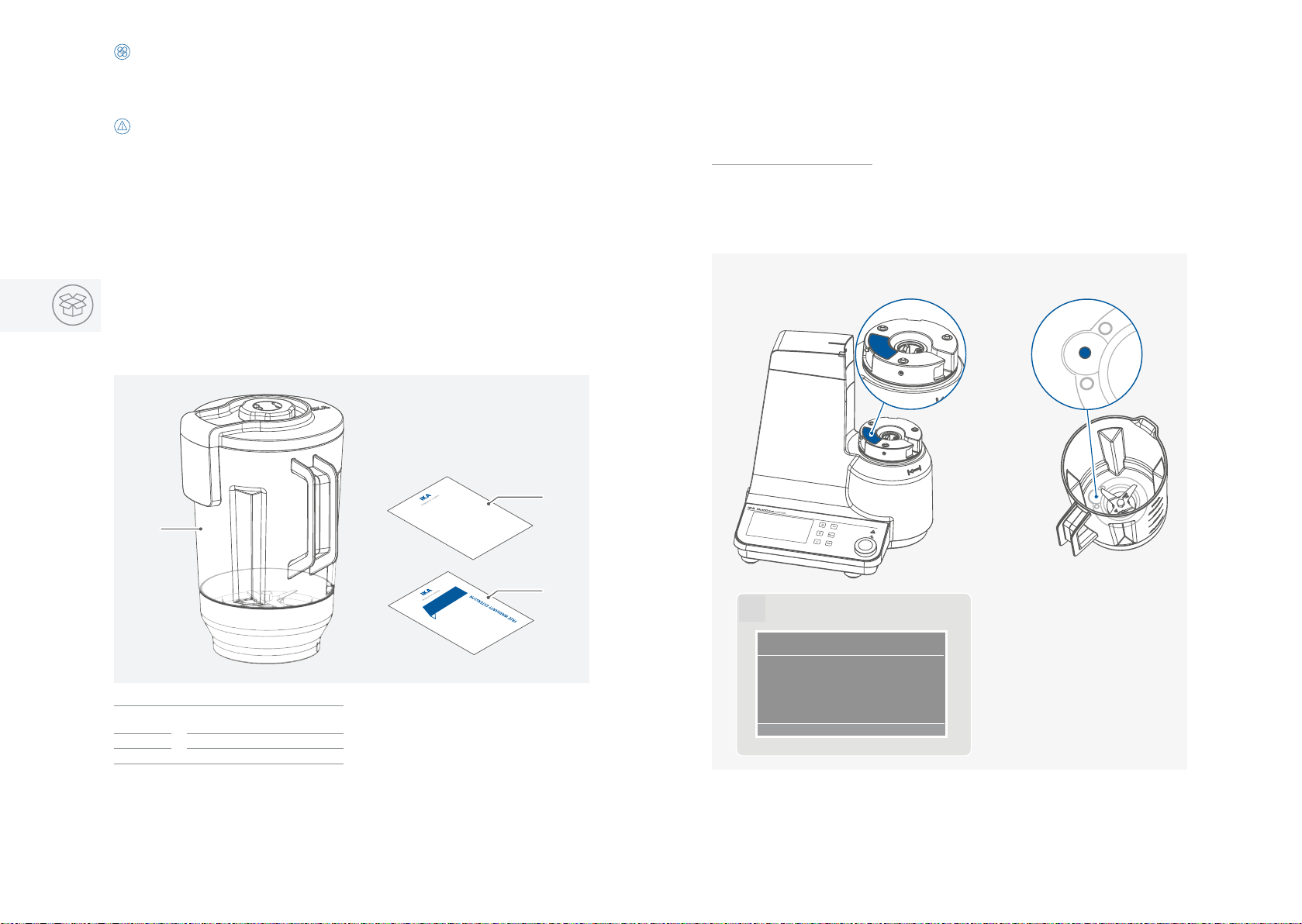

/// Device setup

!Notice!

› Ensure that the vessel

and the cover

is firmly attached to the drive unit prior to operating the

device�

› The drive unit cannot be operated without a closed vessel�

Source language: German

Explication of warning symbols

/// Warning symbols

Indicates an (extremely) hazardous situation, which, if not avoided, will

result in death, serious injury�

Danger!

Indicates a hazardous situation, which, if not avoided,

can result in

death, serious injury�

Warning!

Indicates a potentially hazardous situation, which, if not avoided, can

result in injury�

Caution!

!

Indicates practices which, if not avoided, can result in equipment damage�

Notice!

/// General Symbols

Position number

A–––

Correct / Result

Shows the correct execution or the result of an action step�

Wrong

Shows the incorrect execution of an action step�

Note

Displays action steps that require particular attention to detail�

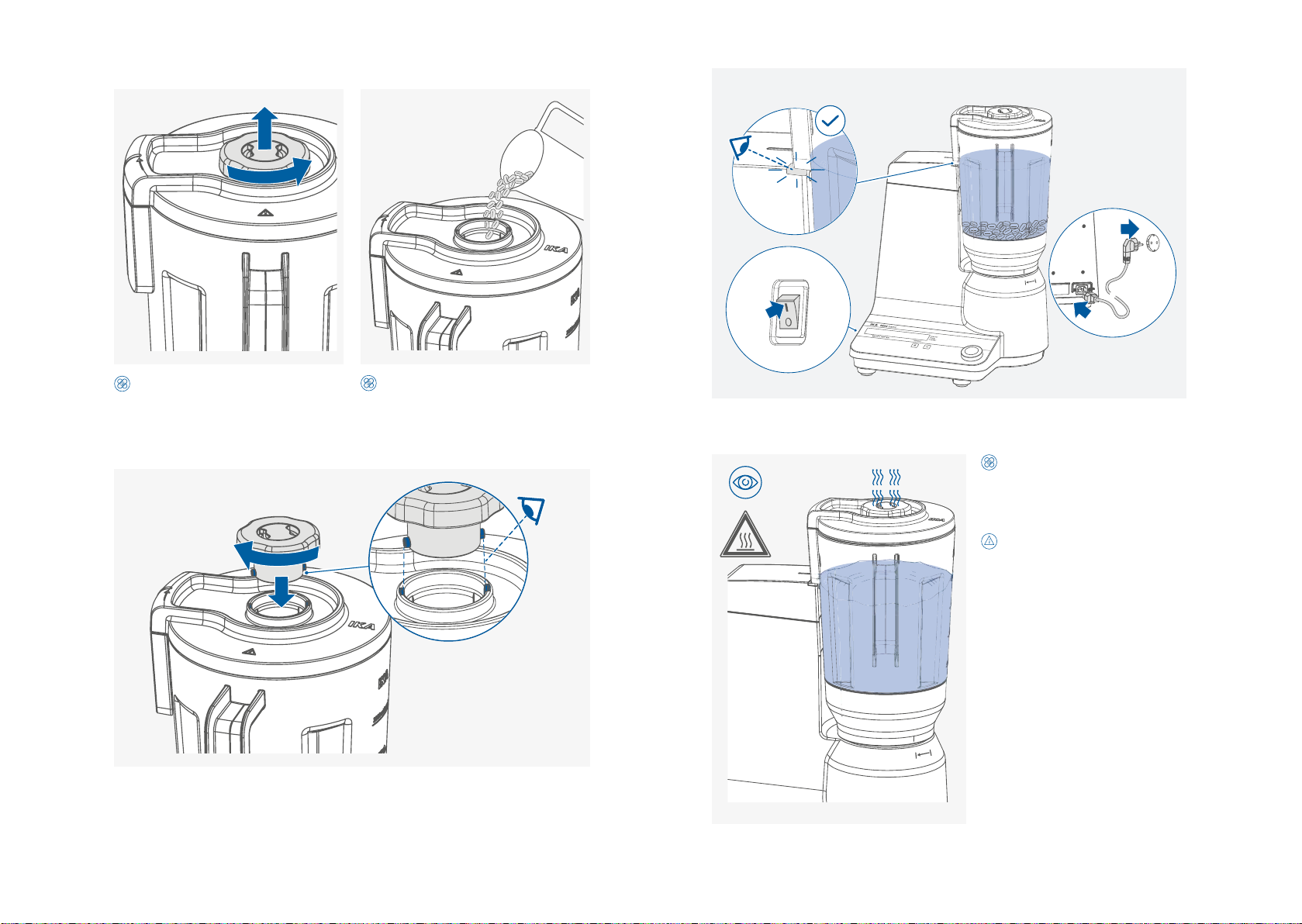

/// Working with the vessel

Danger!

› With substances capable of forming an explosive mixture, appropriate safety measures must

be applied, e�g� working under a fume hood�

› To avoid body injury and property damage, observe the relevant safety and accident preven-

tion measures when processing hazardous materials�

Warning!

› Only process samples that will not react dangerously to the extra energy produced through

processing� This also applies to any extra energy produced in other ways, e�g� through light

irradiation�

!