iKarus Profi Gyro 720613 User manual

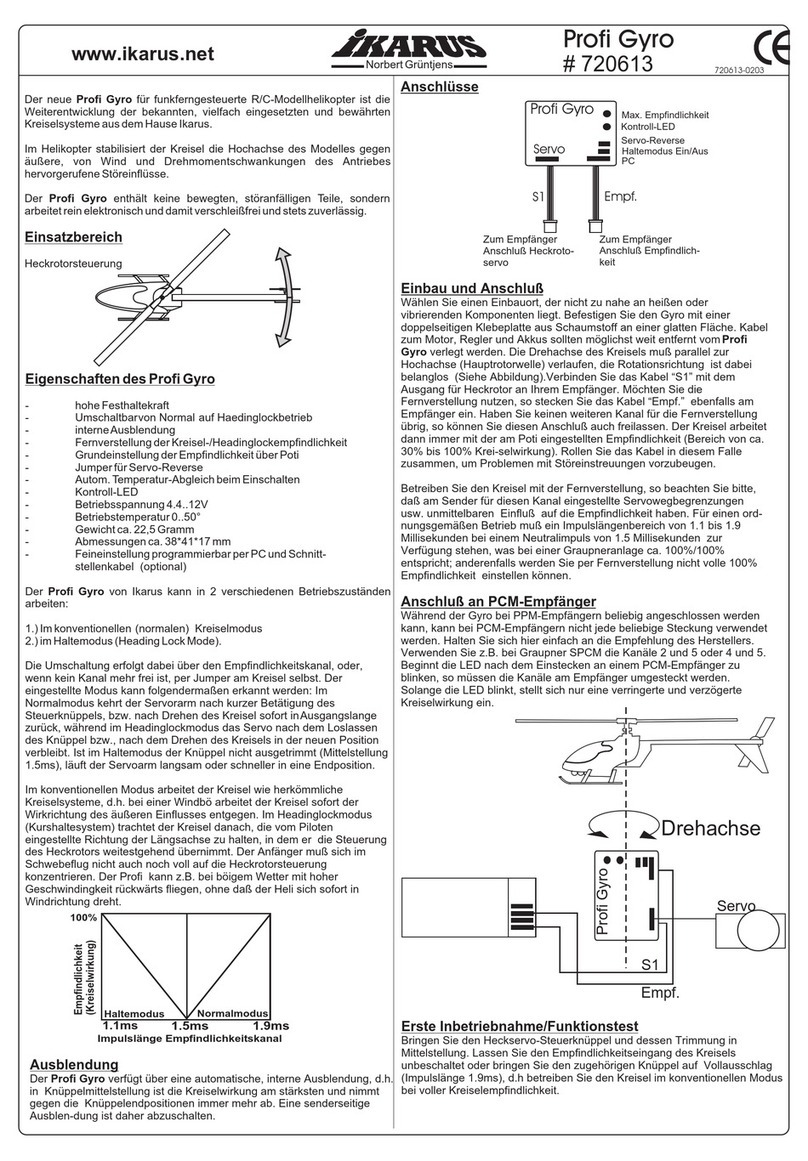

Connectors

Installation and Wiring

Initial Operation/Function Test

Choose a position away from heat and vibration. Stick the gyro with a double

sided foam tape to a smooth surface. The cables of motor, speed controler

and battery should be routed as far away as possible of the . The

gyro axis of rotation must be positioned parallel to the vertical axis (main rotor

axis), the direction of rotation is irrelevant (see figure). Connect the tail rotor

gyro connector to the selected tail rotor channel output of your receiver.

If there is no further channel left for remote sensitivity

control just leave the connector open. In that case the gyro will work with the

sensitivity which has been adjusted by potentiometer (approximate gyro

effect range between 30% and 100%).

If your gyro works in the remote adjustment mode you must not forget that the

sensitivity range will also be influenced by servo travel limit adjustments of

your transmitter on the given gyro channel. If you want a regular operational

behaviour the full pulse length range of 1.0 to 2.0 milliseconds and a neutral

pulse of 1.5 milliseconds must be available, that corresponds on JR radios to

a servo travel of 150/150%, otherways you will not be able to achieve full

remote controlled sensitivity adjustments of whole 100% or 0%.

connections please see next page.

Put the tail servo stick and its trim tab into neutral position. Leave the

sensitivity input of the gyro open or deflect the relevant stick to its end

position (pulse length 2 ms), that is operate the gyro in normal mode at its full

sensitivity.

Now switch on the transmitter and subsequently the receiver power supply.

The will now carry out the automatic temperature calibration.

During this process the gyro be moved. After termination of the

calibration (approx.3-5sec.) the LED lights up permanently and the

connected tail servo executes a short twitch. The gyro is now ready for

operation.

In the conventional gyro mode the servo now reacts to angular movements of

the helicopter about the axis of rotation of the gyro with corresponding

counter-movements of the servo, while steering commands of the tail servo

stick are correspondingly obeyed by the servo.

Between disconnection of the receiver power supply and repeated

switching-on you should pause for at least 10 sec. The gyro should not be

exposed to violent temperature fluctuations; you can give rise to a repeated

temperature calibration process by switching the power supply off and on.

Profi Gyro

Profi Gyro

must not

If you

intend to utilize the remote sensitivity adjustment, plug the gyro sensitivity

connector into a PPM-receiver output with a higher channel number, that is

for instance into channel 2 or higher if the tail rotor connector has been

plugged into channel 1.

PCM receiver

The new is the improved RC - helicopter gyro, developed on the

basis of the well-known and reliable Ikarus gyro family.

In a helicopter the gyro stabilizes the model about its vertical axis against

external disturbances caused by wind and torque fluctuations of the drive.

The contains no wear susceptible moving parts, it works always

reliable and without wear on pure electronic basis.

Tail rotor control

- high holding power

- switchable from normal to heading lock operation

- internal stick authority system (also "stick priority")

- remote adjustable gyro/heading lock sensitivity

- basic sensitivity adjustment by potentiometer

- jumper for servo reversal

- after switching-on automatic temperature self

calibration

- control LED

- operating voltage range + 3.5... 12 V

- temperature range 32...122°F

- weight approx. 0.8 oz.

- outside dimensions approx. 1.5" x 1.6" x 0.7”

- fine adjustment via PC interface and interface cable

(optional)

The can work in 2 different operational modes:

1.) Conventional (normal) gyro mode.

2.) Holding mode (Heading Lock Mode).

The mode switching is accomplished via the sensitivity channel or, if no

channel available, by a jumper directly on the gyro. The selected mode can

be recognized as follows: Under normal mode conditions the servo arm

returns after a short command with the joystick or after rotation of the gyro

immediately back to its original position, in the Heading Lock Mode the servo

remains in its new position after the joystick has been released or the gyro

rotation has stopped. If in the holding mode the stick channel is not properly

trimmed (neutral position 1.5 ms) the servo arm will slowly or even faster drift

towards one of its end positions.

Under normal mode the gyro works like conventional gyro systems, that is it

immediately counteracts disturbances caused for instance by wind gusts. In

the Heading Lock Mode (heading hold system) the gyro tries to hold the

heading of the longitudinal axis determined by the pilot by nearly fully

adopting the tail rotor control. Hence when hovering the beginner must not

additionally concentrate on tail rotor control. A professional pilot can for

instance fly in gusty weather fast back-wards without the helicopter turning

immediately into wind direction.

The comprises an internal automatic stick authority system, that

is the gyroscopic effect is highest at stick neutral position and decreases

gradually when the stick deflection approaches maximum (also called "stick

priority"). Any contingent stick authority system on the transmitter (ATV)

must be switched off.

Profi Gyro

Profi Gyro

Profi Gyro

Wing Gyro

Application

Properties of the Profi Gyro

Stick Authority System

Profi Gyro

Servo Servo reversal

Maximum sensitivity

Control LED

PC

Holding mode on/off

To receiver

Tail rotor connector

To receiver

Sensitivity connector

Page 1

Impuls length of sensitivity channel

1ms

100%

Sensitivity

(Gyro effect)

Holding mode Normal mode

1.5ms

2ms

Profi Gyro

Servo

3

2

1

Corrective axis

04/99 Best. Nr. 720613

Profi Gyro

IKARUS Modellflugsport, Inh. Norbert Grüntjens, Brambach 36, 78 713 Schramberg / Germany, Tel. 07422 / 54001 Fax. 07422 / 54005

Angle of

incidence

Slide

Approx. 0.08 in.

in clearance

90°

After switching-on the gyro requests availability of a signal at the sensitivity

channel. If there is no signal the gyro works untill to next switching-on with the

sensitivity which has been adjusted by potentiometer. The jumper "Heading

Lock Mode" on/off decides whether the gyro will operate in the normal or

holding mode. If at the moment of switching-on the jumper was not set the

gyro will work till to the next switching-on in holding mode, if the jumper is set

the gyro works in normal mode.

With the aid of the reverse jumper the direction of gyro action can be

reversed, the processor again sends a query at the moment of switching on

and the state of operation is valid till to the next switching-off. You can

alternatively reverse the servo travel by means of turning the gyro axis of

rotation by 180 degrees.

After installation the tail servo must be mechanically aligned first.

For this purpose switch to normal gyro mode. The joystick and trim tab of the

transmitter must be in middle position. Corresponding to the stick and trim

tab middle position the servo arm must be exactly perpendicular to the tail

boom in order to achieve exactly the same travel to both directions. The arm

of the tail tie rod must also be perpendicular to the tail boom.

In order to achieve this you will either have to shift the servo longitudinally

(ECO-heli), or adjust the tie rod so far untill the tail rotor blades will attain the

desired angle of incidence (approx. 3..7°) as recommended by the manu-

facturer. Watch out for rod binding and keep backlash at a minimum. Also

watch out that the tail rotor slide does not hit the mechanical stops at both

end positions.

Reverse Operation

Basic Mechanical Adjustment

Page 2

Attention: Before first flight attempts check the direction of the gyro

effect. In case of a reversed direction of gyro effect your model may

crash due to uncontrollable pirouettes.

If you rotate the helicopter about its main rotor axis to the left the

gyro must produce a tail rotor deflection which in flight would have

the effect of a right rotation of the model about its rotor axis and vice

versa. Gyro beginners better ask an experienced clubmate for help.

Adjustment/Trimming

We recommend to find first the adjustment of the necessary maximum

sensitivity. This corresponds with the point at which the tail stops wagging

(swinging) and the gyro develops its highest effect, that is when it shows best

holding ability.

To the purpose of adjustment turn the gyro potentiometer clockwise to 100%

till to its travel stop corresponding to full sensitivity. Then adjust at your

transmitter approximately 2/3 of maximum servo travel, which approximately

corresponds to 100% (from 0...150%) on a JR radio. Higher values mean

higher sensitivity and also a higher inclination to oscillations, lower values

mean lower oscillation tendency.

Switch the gyro to the holding mode by remote control or by application of the

jumper and apply full stick travel at the sensitivity channel. Still on ground trim

to an extent until the servo does not show any recognizable tendency to run

into one of its end positions. Then lift slightly off and check again the correct

direction of gyro effect. Then lift off fully into hovering and trim until the

helicopter shows no tendency to turn in any direction. This requires a lot of

patience. In order to go safe do not lift off too high and if any oscillation occurs

land immediately.

Warranty

Safety directions

Operating directions

This quality product has been thoroughly checked before delivery. Nevertheless, in case of complaints your

warranty claims will be handled in accordance with our current General Sales Conditions. If equipment

returned for warranty repair shows full functionality during the entry inspection, handling charge will be

DM40,-. According to our experience the product works well with all current R/C systems. On the other hand

we cannot grant functionality with a specific R/C system due to the fact that control pulse conditions of

receivers are not liable to standardization. We must as well reject any responsibility for consequential

damage arisen from the use of our products since we are not able to supervise their appropriate

application.

The CE-label is no allowance for negligent handling of the equipment. Avoid dangerous areas of motors,

propellers, gears and rotor blades. Always consider electric systems as potentially dangerous. Always

remove the battery if you intend to work on the system. Avoid direct and condensed humidity. The product is

not protected against reversal of polarity. Reversing polarity or cables can entail irreparable damages.

Plugs and sockets must always fit perfectly. Improvisations can give rise to damages. Care about the power

consumption of the power supply, especially with regard to the gyro. A higher power consumption than

assigned for can damage the power supply and other equipment connected to it. Never disconnect an

electrical appliance from the battery as long as it is operating.

The transmitter must always be switched on first and subsequently the receiver. Make sre that the throttle

stick is in the low throttle position. In any case verify that you are exclusive user of the selected frequency

and nobody else is using it. Pay attention to the CE-labels of other components. Provide motors with at least

2 noise suppressing ceramic capacitors 10 - 100 nF/63 - 100 V and optional with further noise suppressing

means (filters, chokes). Route the antenna at least 1" away of motor, battery, speed controller and their

cables. Install the receiver as far away as possible of motor, battery and speed controller. Keep cables as

short as possible. Motor and battery cables should be twisted. For the purpose of storing your model remove

the batteries and store it at a dry place with normal air humidity. Should the system act erratically, disconnect

the flight battery from the system and reconnect it again after a waiting period of5-10s.

Specifications are subject to change without prior notice.

Change the servo travel at the transmitter up or down until the tail in flight arrives

at the verge of oscilation or just stops oscillating.

If the adjusted value on a JR radio becomes lower than 80% you must decrease

the servo travel mechanically.To that purpose insert the tie rod at the servo arm

one hole closer toward the servo axis, at the ECO-heli you may additionally

move the rear hinge (at the tail) one hole further outward. There are, of course,

other factors which influence the flight behaviour, especially linkage play, a heli

design configuration which is too flexible or too stiff, or the gyro support itself

may influence the flight characteristic of the whole system.

Now land the helicopter.

If your transmitter contains a memory save the trim adjustments or the complete

program.

Switch to normal mode and start again. Retrim until your model stops turning

away and store the new trim values or the complete adjustment under a new

program.

Watch out that the tail rotor slide does not hit the mechanical stops at both end

positions, on both sides of the slide there should remain a clearance of at least

0.08 in.

Programming of your transmitter should ensure switching of the trim value

memory or of the complete programs if you switch from holding mode to normal

mode.

In this mode the gyro for the most part holds the longitudinal heading of the

helicopter, there is no tendency to turn into wind direction as in conventional

mode. Now you can without the problem of weathercocking fly backwards and

sideways even in gusty weather. But in holding mode you are obliged to control

turns about the vertical axis more consciously as the gyro tries to keep the

heading of the longitudinal axis constant.

If you own a PC you can carry out further fine adjustments with the aid of an

optional PC-interface cable.

Particularly the flight characteristics can be optimized if you were not successful

enough when following our above advices.

In the holding mode there is no additional mixing of tail equalizing or gas allowed,

in normal mode you still can use mixers as before. Stick authority mixing in the

transmitter is unnecessary as the provides a built in automatic stick

authority system ("stick priority").

The gyro connections to JR PCM-receivers are as follows

ZPCM: Channel 4 and channel 7

SPCM: Channel 4 and channel 7 or 8

PCM20: Channel 4 and channel 9

(Channel 4: servo, channel 7/8/9: sensitivity)

The gyro can be connected to Futaba-PCM-receivers after modification of

parameters saved in the gyro EEPROM. At the moment it is necessary to send

the gyro for reprogramming to the manufacturer.

Flight Behaviour in Heading Lock Mode

PC-Interface

Mixers/Transmitter Stick Authority

Connections to PCM receivers

Profi Gyro

Other iKarus Drone & Quadcopter Accessories manuals

Popular Drone & Quadcopter Accessories manuals by other brands

dji

dji PHANTOM 2 VISION PLUS manual

Airpixel

Airpixel AIR Commander Entire user manual

Dronefly

Dronefly Inspire 1 v2.0 FPV installation guide

Foxfury Lighting Solutions

Foxfury Lighting Solutions D10 PARROT ANAFI product manual

dji

dji Ronin Series Battery Power Distributor quick start guide

DRS

DRS DRS-M600 manual