Contents

Contents

1Important Information .......................................................................................................................................4

1.1 General Information.............................................................................................................................................4

1.2 Target Groups......................................................................................................................................................4

1.3 Intended Use .......................................................................................................................................................4

1.4 Use for an Unauthorized Purpose .......................................................................................................................4

1.5 Safety Devices.....................................................................................................................................................5

1.6 Meaning of the Warning notes.............................................................................................................................5

1.7 Product Standards, Safety Regulations ..............................................................................................................5

2Basic Safety Instructions..................................................................................................................................6

2.1 General Information.............................................................................................................................................6

2.2 Electricity .............................................................................................................................................................6

2.3 High Temperatures..............................................................................................................................................6

2.4 Mechanical Systems............................................................................................................................................7

2.5 Hazardous Substances .......................................................................................................................................8

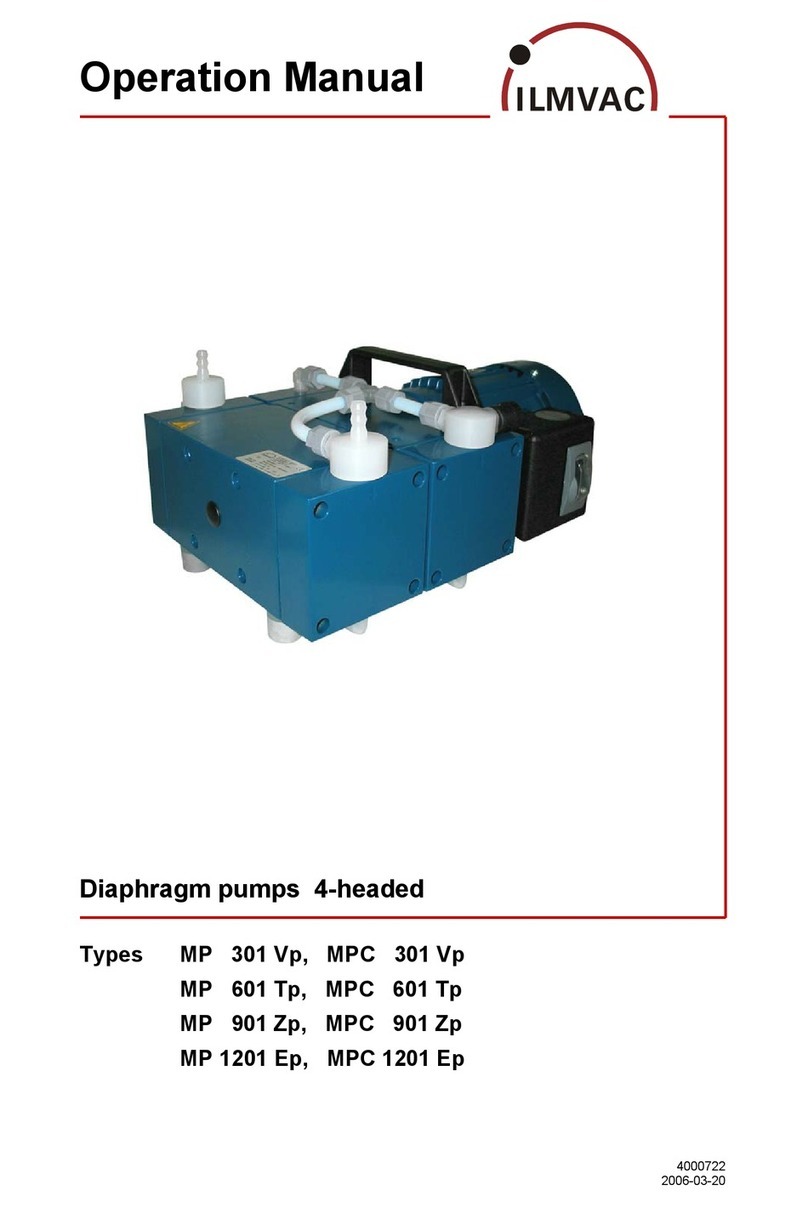

3Description .........................................................................................................................................................9

3.1 Design..................................................................................................................................................................9

3.2 Function .............................................................................................................................................................10

3.2.1 Diagram of the layout of a chemvac pump system ...........................................................................................10

3.3 Applications .......................................................................................................................................................11

3.4 Scope of Delivery...............................................................................................................................................11

4Technical Data .................................................................................................................................................12

4.1 Dimensions ........................................................................................................................................................12

4.2 Intake Pressure / Pumping Speed - Diagram....................................................................................................12

4.3 Device data - chemvac Combination Pump Systems .......................................................................................13

4.3.1 Device data - Rotary vane pump .......................................................................................................................14

4.3.2 Device data - Diaphragm pumps.......................................................................................................................15

5Installation and Operation ..............................................................................................................................16

5.1 Unpacking..........................................................................................................................................................16

5.2 Installation and Connection ...............................................................................................................................16

5.3 Operation ...........................................................................................................................................................16

5.4 Storage ..............................................................................................................................................................17

5.5 Scrap Disposal...................................................................................................................................................17

6Maintenance and Servicing ............................................................................................................................18

6.1 General Requirements ......................................................................................................................................18

6.2 Maintenance Performed by the User.................................................................................................................18

6.2.1 Maintenance of the rotary vane pump...............................................................................................................19

6.2.1.1 Oil check ............................................................................................................................................................19

6.2.1.2 Oil change..........................................................................................................................................................20

6.2.1.3 Changing the oil type.........................................................................................................................................21

6.2.2 Maintenance of the diaphragm pump................................................................................................................21

6.2.2.1 Disassembly - MPC 101 Zp...............................................................................................................................22

6.2.2.2 Assembly - MPC 101 Zp....................................................................................................................................22

6.2.2.3 Disassembly - MPC 301 Zp...............................................................................................................................23

6.2.2.4 Assembly - MPC 301 Zp....................................................................................................................................23

6.2.2.5 Test....................................................................................................................................................................23

6.3 Maintenance by the Manufacturer.....................................................................................................................24

6.3.1 Servicing ............................................................................................................................................................24

6.4 Damage Report .................................................................................................................................................24

7Troubleshooting ..............................................................................................................................................25

8Overview of spare parts..................................................................................................................................26

8.1 Gasket set - rotary vane pumps ........................................................................................................................26

8.2 Maintenance kit - rotary vane pumps ................................................................................................................27

8.3 Maintenance kit - diaphragm pumps .................................................................................................................27

8.4 Complete view - chemvac combination pump system ......................................................................................28

8.4.1 List of spare parts - chemvac combination pump system .................................................................................29

8.5 Spare part view - P 6 Z......................................................................................................................................30

8.5.1 List of spare parts - rotary vane pump P 6 Z .....................................................................................................31

8.6 Spare part view - P 12 Z, P 23 Z .......................................................................................................................32

8.6.1 List of spare parts - rotary vane pump P 12 Z ...................................................................................................33

8.6.2 List of spare parts - rotary vane pump P 23 Z ...................................................................................................34

8.7 Spare part view - MPC 101 Zp ..........................................................................................................................35

8.7.1 List of spare parts - diaphragm pump MPC 101 Zp ..........................................................................................35

8.8 Spare part view - MPC 301 Zp ..........................................................................................................................36

8.8.1 List of spare parts - diaphragm pump MPC 301 Zp ..........................................................................................36

109025 3