Contents

Contents

1Important Information.............................................................................................................4

1.1 General Information ..................................................................................................................4

1.2 Target Groups...........................................................................................................................4

1.3 Intended Use.............................................................................................................................4

1.4 Use for an Unauthorized Purpose ............................................................................................4

1.5 Safety Devices ..........................................................................................................................5

1.6 Meaning of the Warning notes ..................................................................................................5

1.7 Product Standards, Safety Regulations....................................................................................5

2Basic Safety Instructions .......................................................................................................6

2.1 General Information ..................................................................................................................6

2.2 Electricity...................................................................................................................................6

2.3 Mechanical Systems .................................................................................................................6

2.4 Hazardous Substances.............................................................................................................7

2.5 High Temperatures ...................................................................................................................7

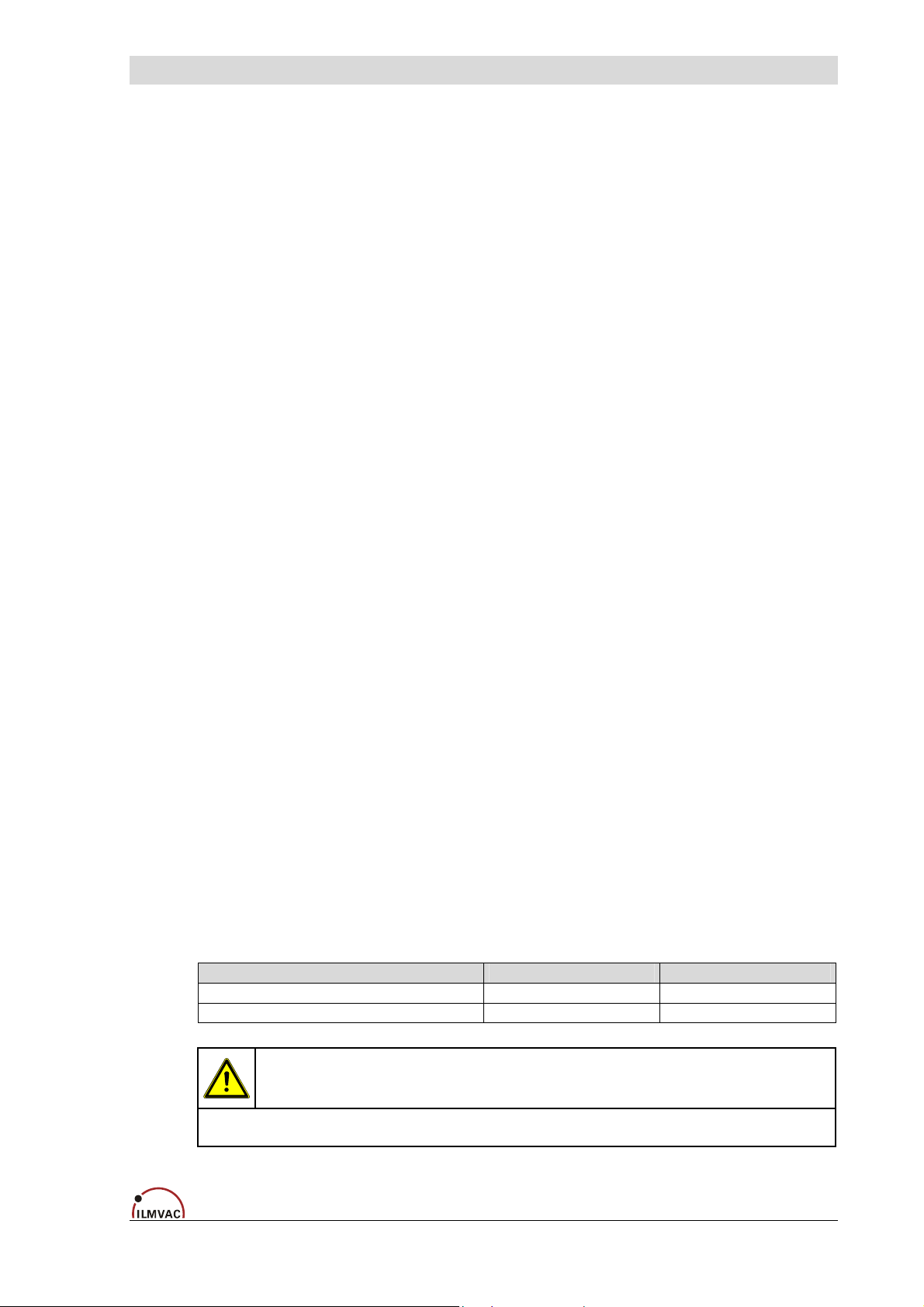

2.6 Dimensioning the fine-wire fuse................................................................................................7

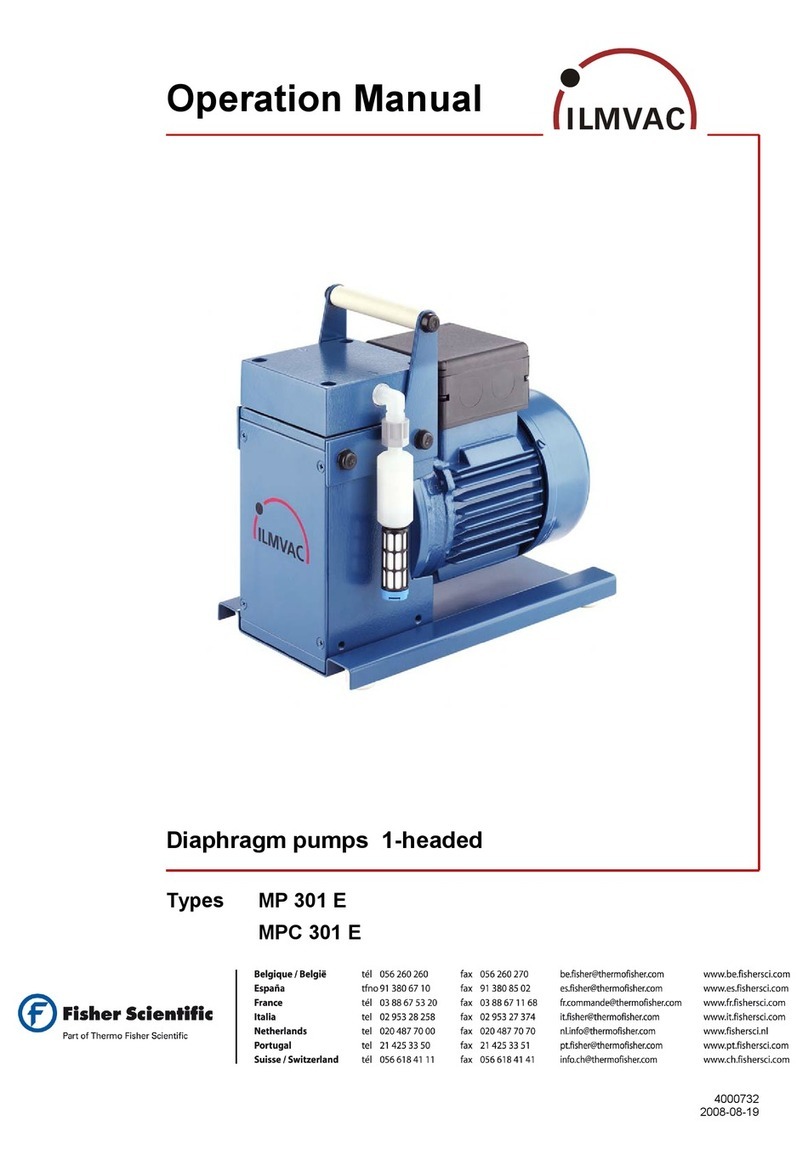

3Description ..............................................................................................................................8

3.1 Design .......................................................................................................................................8

3.2 Areas of Application ..................................................................................................................8

3.3 Principle of Operation ...............................................................................................................8

3.3.1 Pump head circuitry ..................................................................................................................9

3.3.2 Materials of the medium-affecting pump parts..........................................................................9

3.4 Scope of Delivery......................................................................................................................9

3.5 Accessories (optional)...............................................................................................................9

4Technical Data.......................................................................................................................10

4.1 View of device and dimensions...............................................................................................10

4.2 Intake Pressure / Pumping Speed – Diagram ........................................................................10

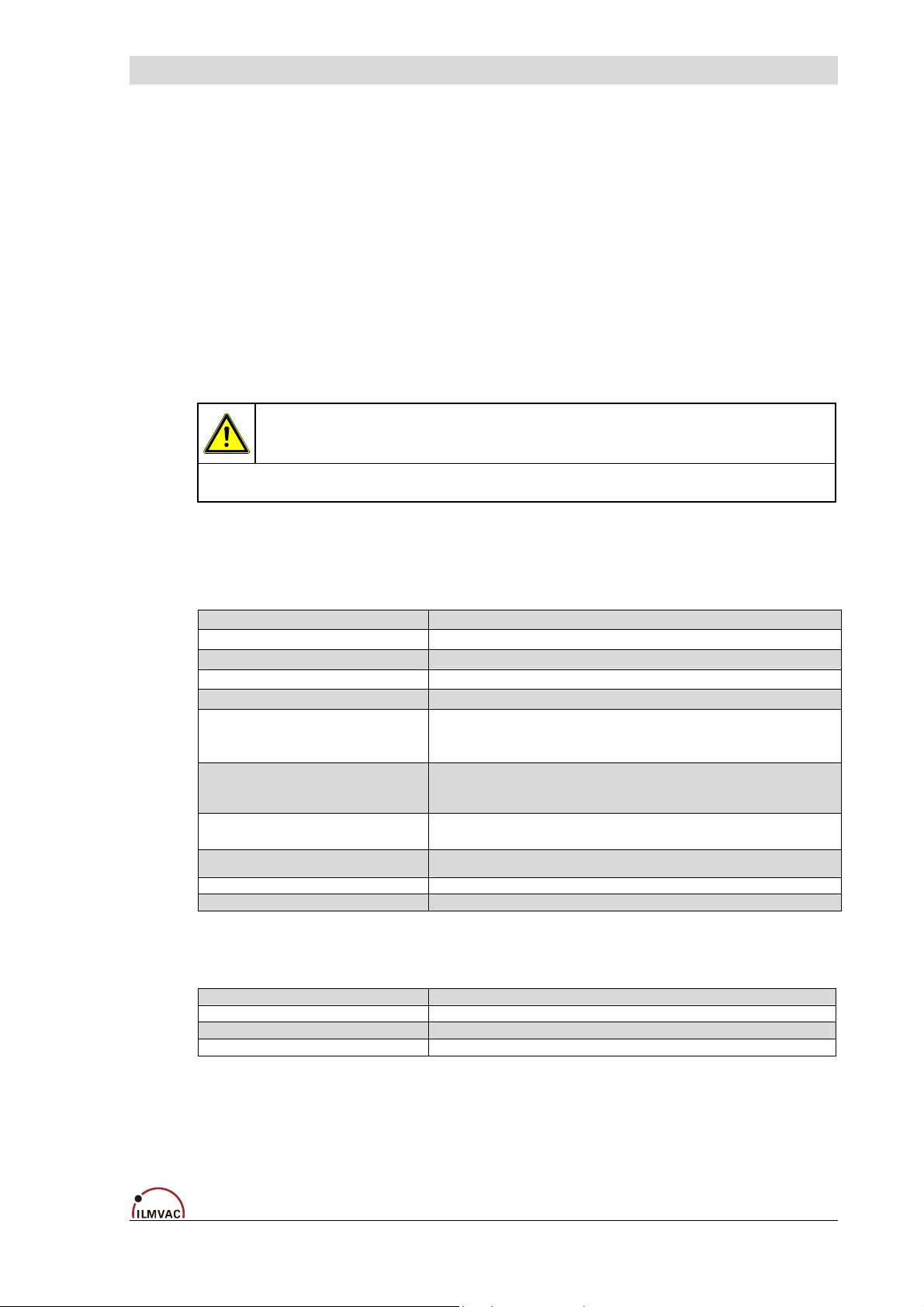

4.3 Device data .............................................................................................................................11

5Installation and Operation....................................................................................................12

5.1 Unpacking ...............................................................................................................................12

5.2 Installation and Connection.....................................................................................................12

5.3 Operation ................................................................................................................................13

5.4 Storage....................................................................................................................................13

5.5 Scrap Disposal ........................................................................................................................13

6Maintenance and Servicing..................................................................................................14

6.1 General Requirements............................................................................................................14

6.2 Maintenance Performed by the User ......................................................................................14

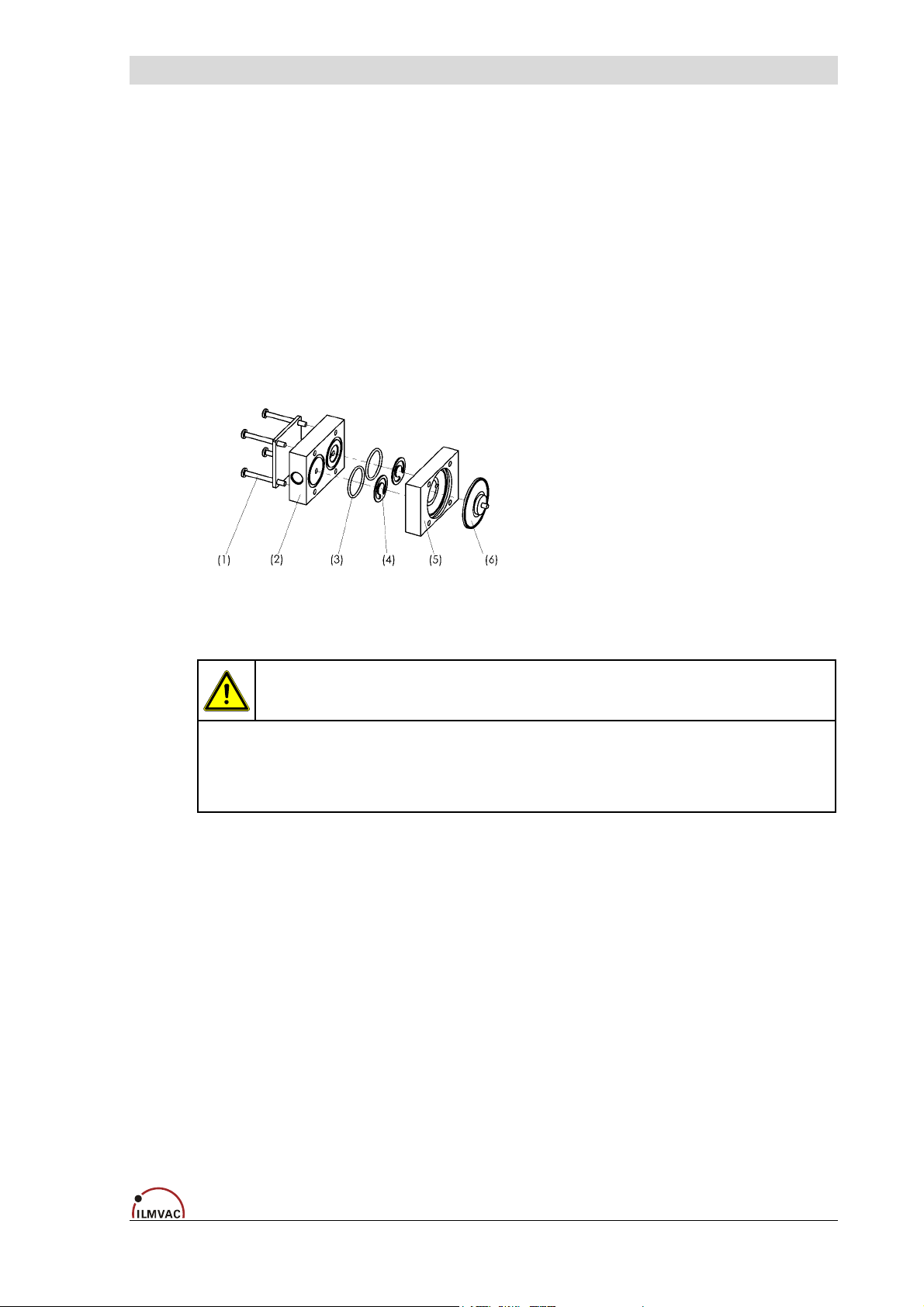

6.2.1 Disassembly............................................................................................................................15

6.2.2 Montage .................................................................................................................................15

6.2.3 Test .........................................................................................................................................16

6.3 Maintenance by the Manufacturer ..........................................................................................17

6.4 Damage Report.......................................................................................................................17

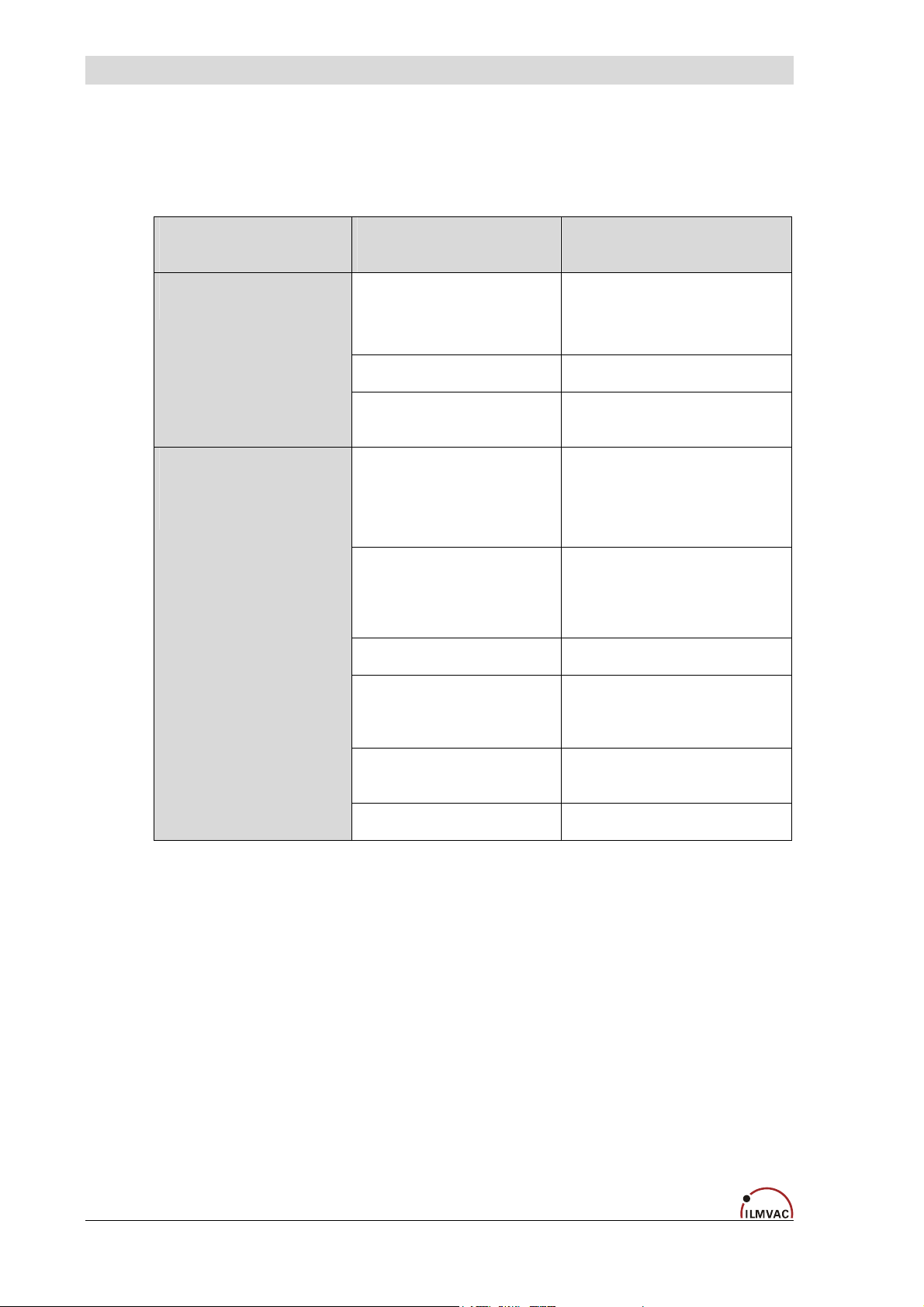

7Troubleshooting....................................................................................................................18

8Spare Parts Overview ...........................................................................................................19

8.1 Maintenance kit.......................................................................................................................19

8.2 Exploded view.........................................................................................................................20

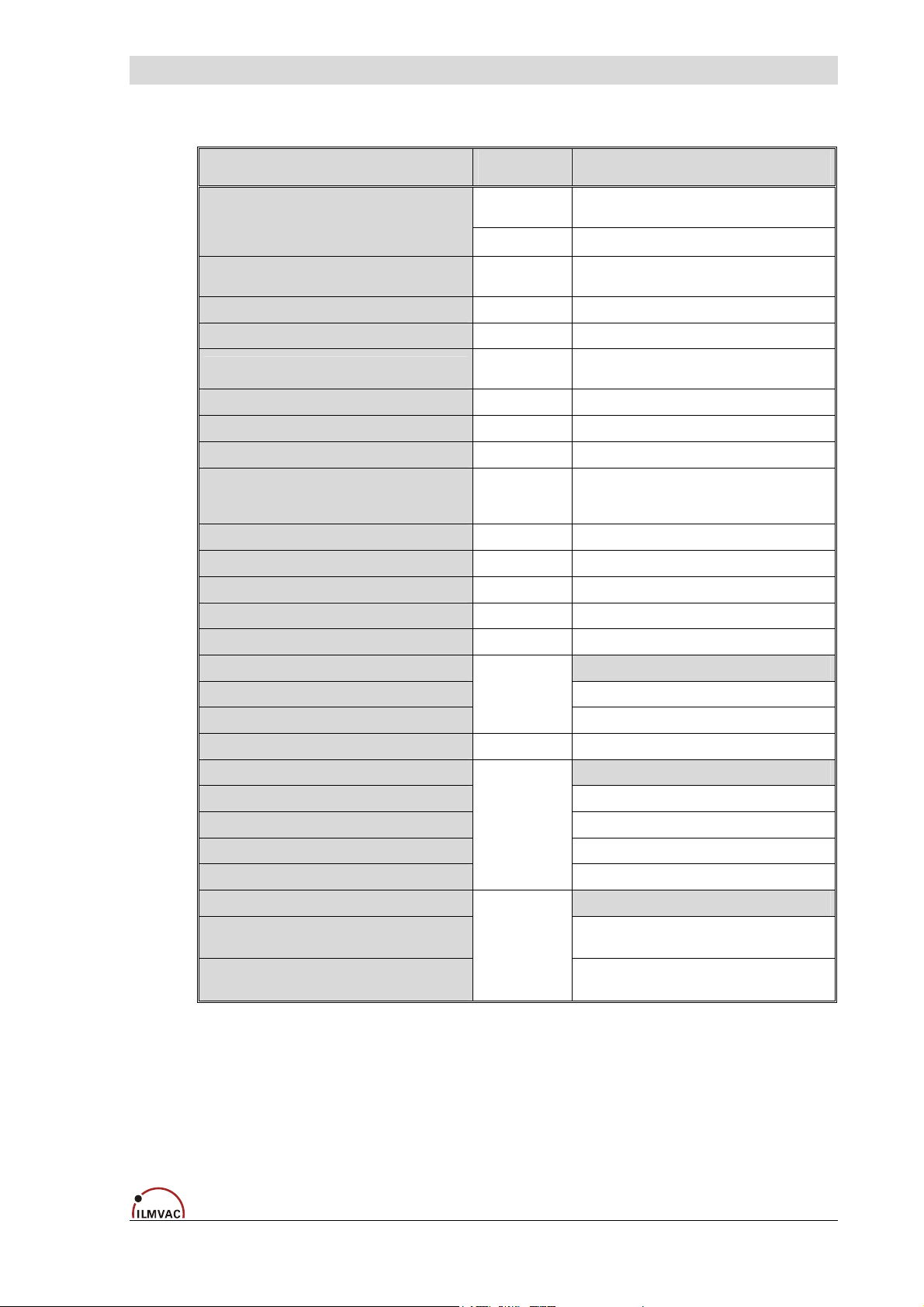

8.2.1 Spare part list..........................................................................................................................21

400082 3