TABLE OF

CONTENTS

..................................

GENERAL INFORMATION

1

1.1

INTROCUCTICN

.....................................

1

.................................

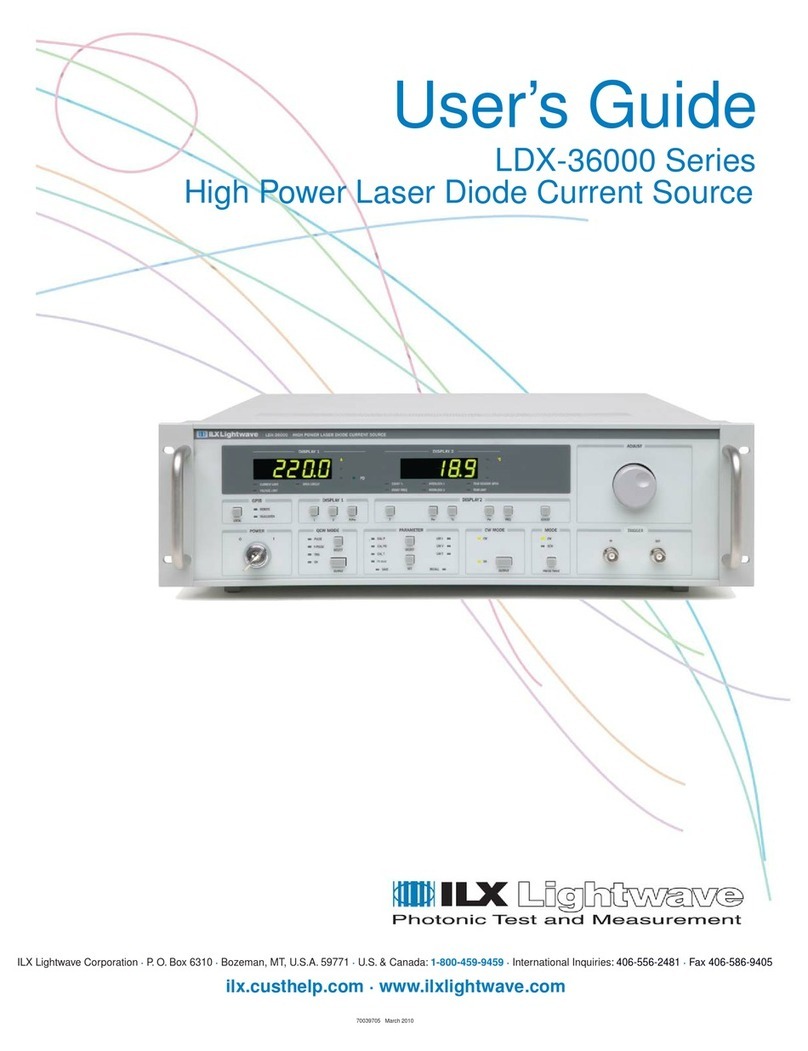

1.2 PROCUCT OVERVI

EN

1

....................

1.3 AVAILABLE OPTICNS AND ACCESSORIES

1

...................................

1.4 SPECIFICATIONS 2

1.5 YOUR COMMENTS

...................................

3

OPERATION

...........................................

4

2.1 INSTALLATION

.....................................

4

2.2 AC Power Considerations

..........................

4

2.3 TiIt-Foot Adjustments

............................

4

..................................

2.4 Rack Mount

i

ng 4

2.5 LDX-3207 FAMILIAR1ZATICN

...........................

4

....................................

2.6 Front Panel 4

..............................

2.7 Power-Up Seque.nce. 6

.........................

2.8 Current Limit Adjustment 6

........................

2.9 Output Cur rent Adjustment 6

2.10 Output Connectors

...............................

7

2.11 Output Off/On Button

............................

7

2.12 ModuIation/AnaIogControl Port

.....................

8

................................

2.13 Fault Indicators 8

2.14 GPlB Rernote/Local Switch

.........................

9

2.15 Rear Panel

.....................................

9

2.16 WARM-UP

AND

ENVIRONMENTAL CCNSIDERATICNS

..............

9

2.17 OPERATING INSTRUCTICNS

.............................

9

2.18 Connecting toYourDevice

........................

9

........................

2.19 Grounding Consideration

r.

10

.......................

2.20 General Operating Procedure

11

REMOTE

PROCRAMMIM;

...................................

11

3.1 INTROUXTICN

.....................................

I1

.....................................

3.2 CAPABILITIES

11

........................

3.3 PREPARATICN FOR BUS CCNTROL

11

.......................

3.4 REMOTE PROCRAMMING PROCEWRE 13

.......................

3.5 DEVICE-DEPENDENT COMMAND SET 13

3.6 B1 (Beep Comnand)

...............................

14

3.7 Cn (Current Set Command)

.........................

14

3.8 GO (Get Instrument Status Comnand)

.................

14

3.9 On (Output Off/On Comnand)

.......................

15

3.10 INPUT SYNTAX

.....................................

15

....................................

3.11

CUTPUT

SYNTAX 16

................................

3.12 INTERFACE MESSAGES 16

.................................

3.13 EXAMPLE PROGRAMS 16

..................................

THEORY

OF OPERATION

24

4.1 OVERVIEW

........................................

24

............................

4.2 INTERNAL POWER SUPPLIES 24

...................................

4.3 CURRENT XWRCE 26

4.4 PRECISICNCURRENT SINK

.............................

26

4.5 OUTPUTOFF/CN SWITCH

..............................

27