Operation Manual TCS-01CA-PMI Sensor

12.02.2021

Page 2 of 21

1 Important information __________________________________________________ 3

1.1 Use of the operator manual __________________________________________________ 3

1.2 Copyright ________________________________________________________________ 3

1.3 Warning Notices ___________________________________________________________ 3

1.4 Address of the manufacturer ________________________________________________ 4

1.5 Obligations of the operator __________________________________________________ 5

2 Safety ________________________________________________________________ 5

2.1 Intended use ______________________________________________________________ 5

2.2 Safety notes _______________________________________________________________ 6

3 Transportation and packaging ____________________________________________ 6

3.1 Safety notes for transportation _______________________________________________ 6

3.2 Scope of delivery __________________________________________________________ 7

3.3 Packaging ________________________________________________________________ 7

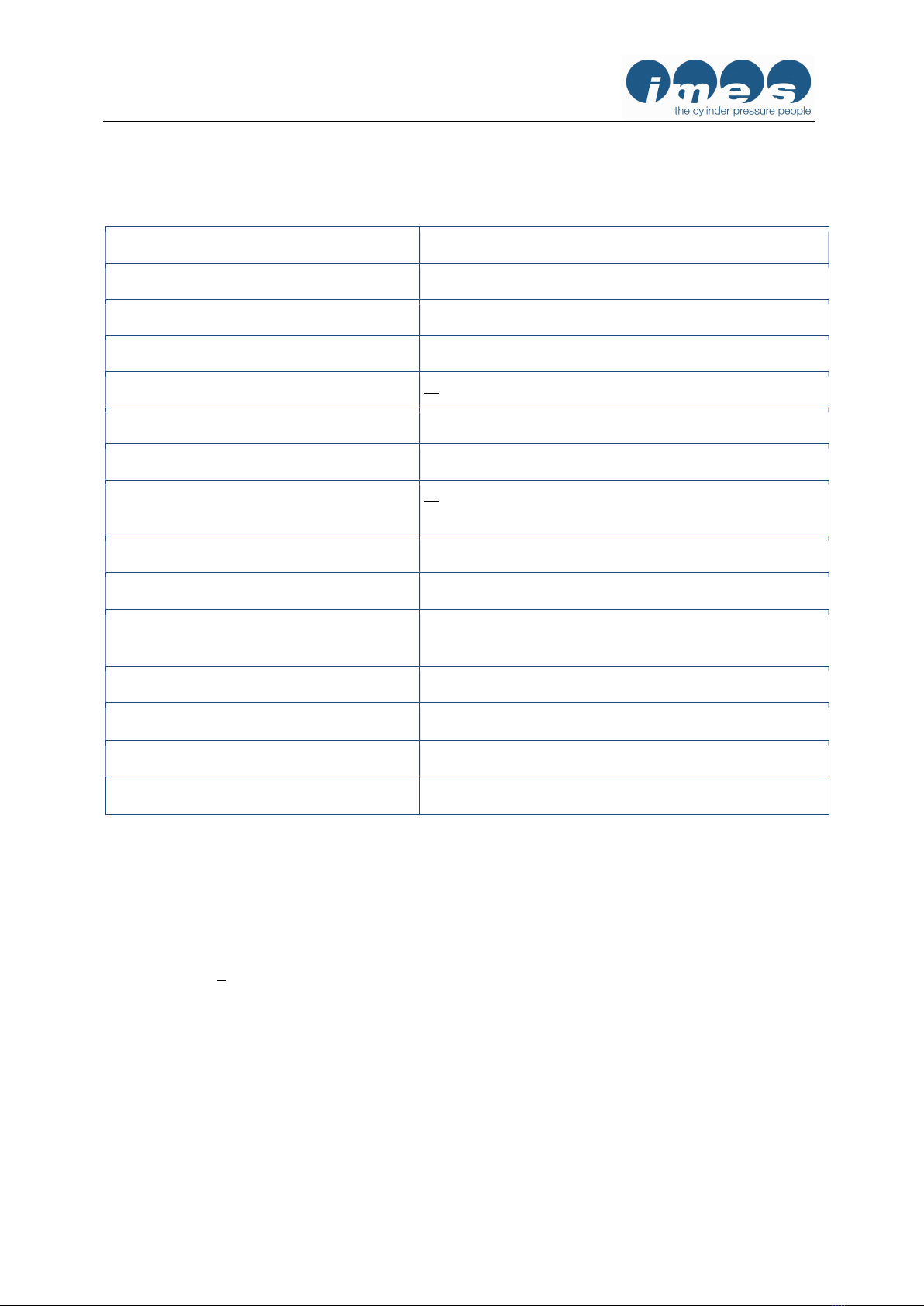

4 Technical data TCS-01CA-PMI sensor _____________________________________ 8

4.1 Fault indication ___________________________________________________________ 8

4.2 Drawing __________________________________________________________________ 9

5 Installation instructions of TCS-01CA-PMI sensor __________________________ 10

5.1 Pressure sensor with adaptor and indicator valve ______________________________ 10

5.2 Disconnection of existing ABB sensor ________________________________________ 11

5.3 Mounting of IMES adaptor_________________________________________________ 11

5.4 Mounting of indicator cock on IMES adaptor _________________________________ 12

5.5 Mounting TCS-01CA-PMI sensor on adaptor _________________________________ 12

5.6 Fixing connection cable to SCU and female connector __________________________ 13

5.7 Fixing protection cover ____________________________________________________ 14

6 Advice actions ________________________________________________________ 15

6.1 Use of indicator valve______________________________________________________ 15

7 Drawings ____________________________________________________________ 16

7.1 Overview sensor components (IW-9100) ______________________________________ 16

7.1 TCS-01CA sensor (IW-6105) _______________________________________________ 17

7.2 MAN Autotuning connector (IW-4116) _______________________________________ 18

7.3 Adaptor (IW-8005)________________________________________________________ 19

7.1 Protection cover (IW-6211) _________________________________________________ 20

8 EU Declaration of Conformity ___________________________________________ 21