iMettos J210S User manual

Bone Saw

Machine

Instruction Manual

i

For Your Own Safety, Read Instruction

Manual Before Operating this Equipment

- 2-

CONTENTS

1. BreifIntroduction&SafetyInstruciton

2. Charactor

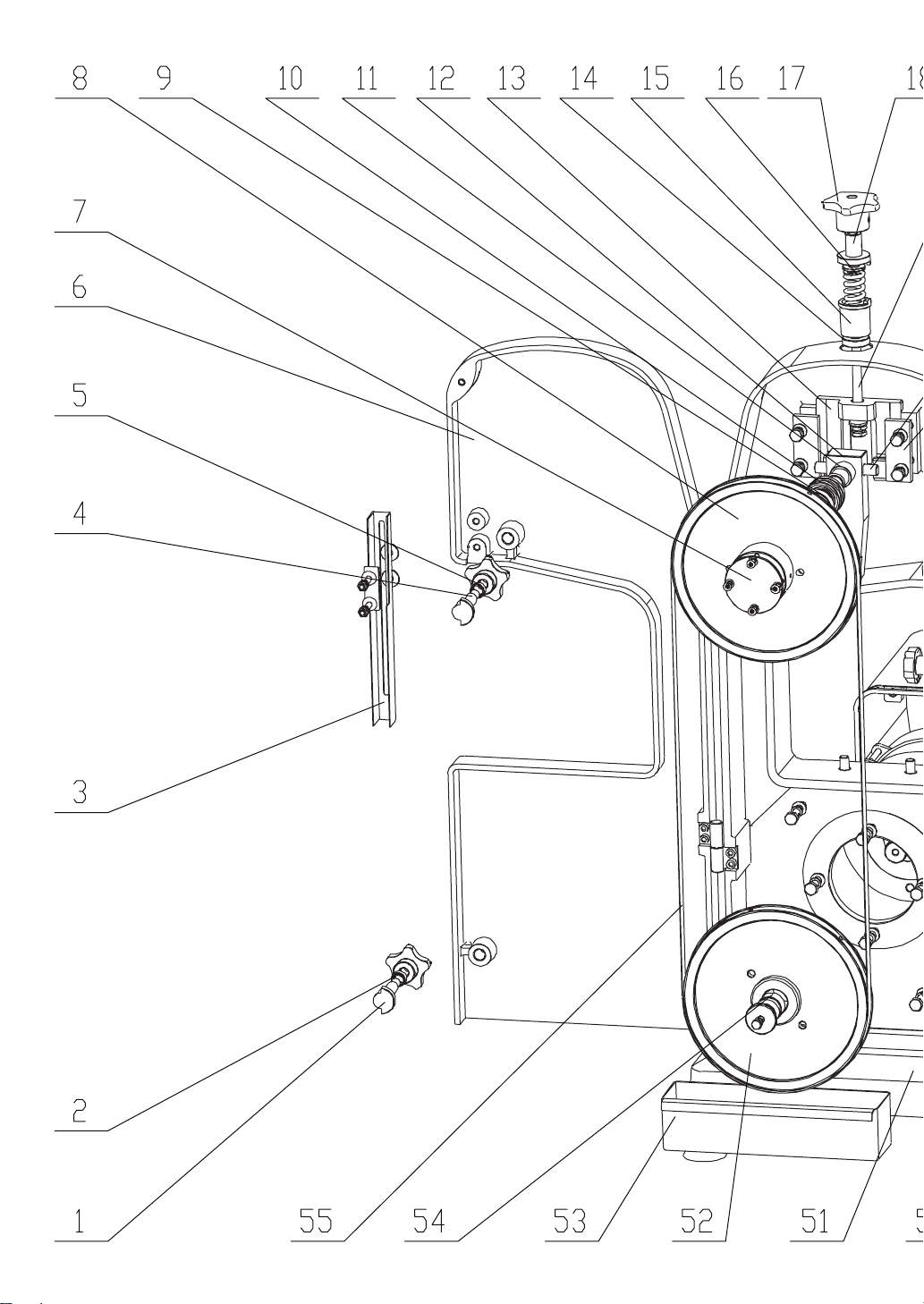

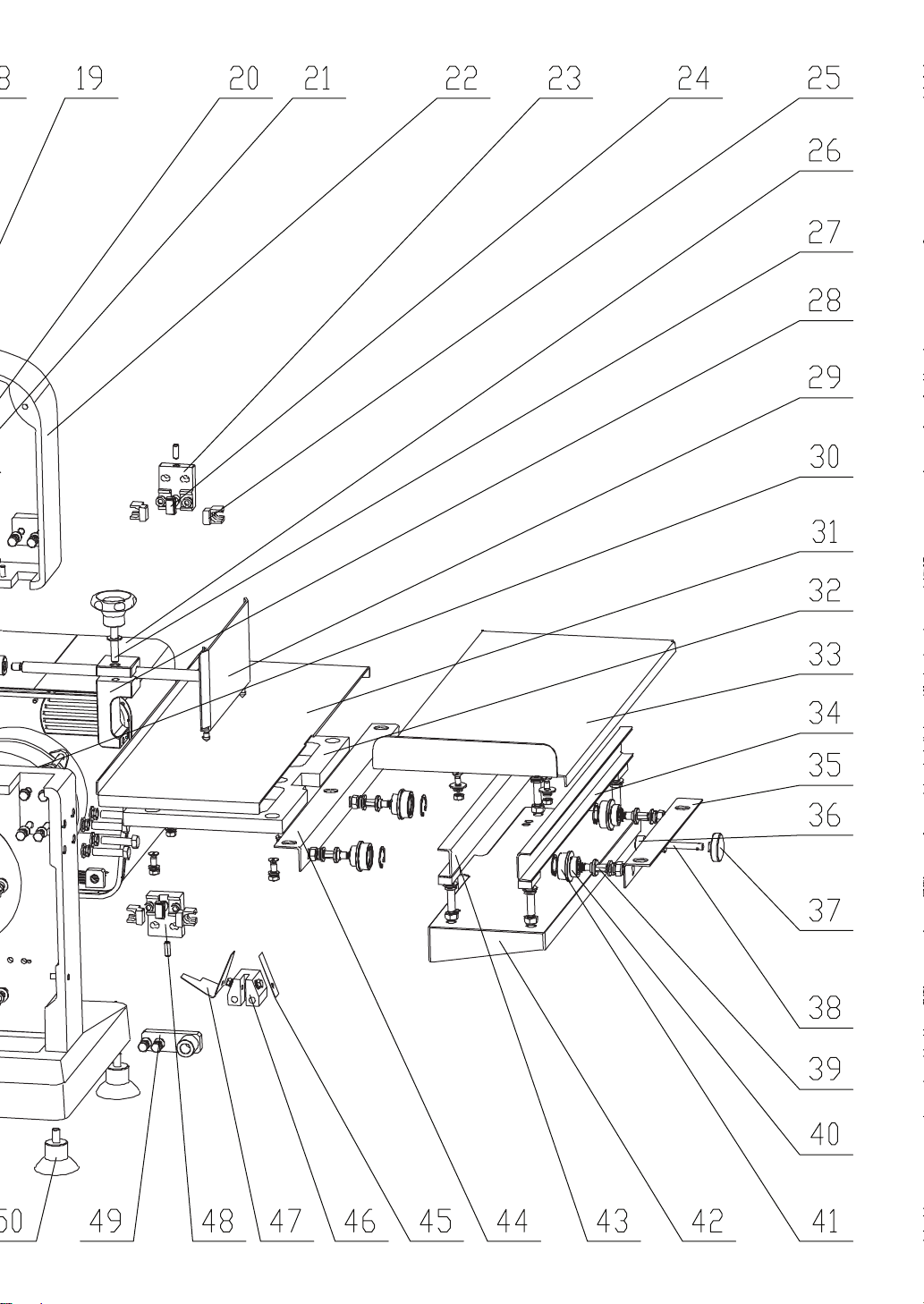

3.Components

4. PartsExplodeDiagram

5. Operation

6. Cleanning

7. PartsNameReferencetable

8. TechnicalParameters

9. PackingList

4

5

5

6-7

8

8-9

10

11

11

- 3-

- 4-

WARNING

SAFTEY INSTRUCTIONS

Brief Instruction

• Theinstructionmanualshowsthesafetyoperationforuserreference.

• Mustreadtheinstructionscarefullyandcorrectunderstandingofitsoperation

methodsandvariousconsiderations,thenoperateorrepairandmaintenance

• Keepthismanualandplacednearthemachine,sothatcancheckatany

time !

• Please wear prope working clothes、Security

posture and operate correctly !

• Before use, please check again for this machine.

Pleasebesuretocheckfortheworktableofactivitiesifitwillbechangedintransit,if

there'sanylooseforfasteningscrews,ifthereisashiftofmotorbackcover!

• Please make sure to install leakage protection

devices, must be connected with the earth wire! !

• Wore Gloves when replacing the Saw Band !

• Never Position Fingers or thumbs in line with the cut!

Seriouspersonalinjurycouldoccur.

• DO NOT BACK MEAT AWAY fromthebladewhilethesawisrunning.

Planyourcutssoyoualwayscutthroughthemeat.Ifyouneedtobackthemeatout,

turnthebandsawoffandwaitforthebladetocometoacompletestop.Donottwistor

putexcessivestressonthebladewhilebackingmeataway

• Donot operate the emergency stop frequently In

case of damage the motor!

Charactor

1.TooTightprotectiondeviceofbandsaw!

2.Themotoroverheatingprotectiondevice.

3.Poweroffwhendooropenningsafetyprotectiondevice.

4.0.2secondsfortheemergencybrakeprotectiondevice,10timesbeyondtheEuropeanUnion's

safetystandards.(eustandards:EN60335-2-6420tharticle111)

5.Largeworkingtable,workmoresecure,moreeasily.

6.Drivenwheeldetachablewash,nohealthcorner.

7.Machinescanbedirectlysprayirrigation,clearnmoreeasilyandhealth.

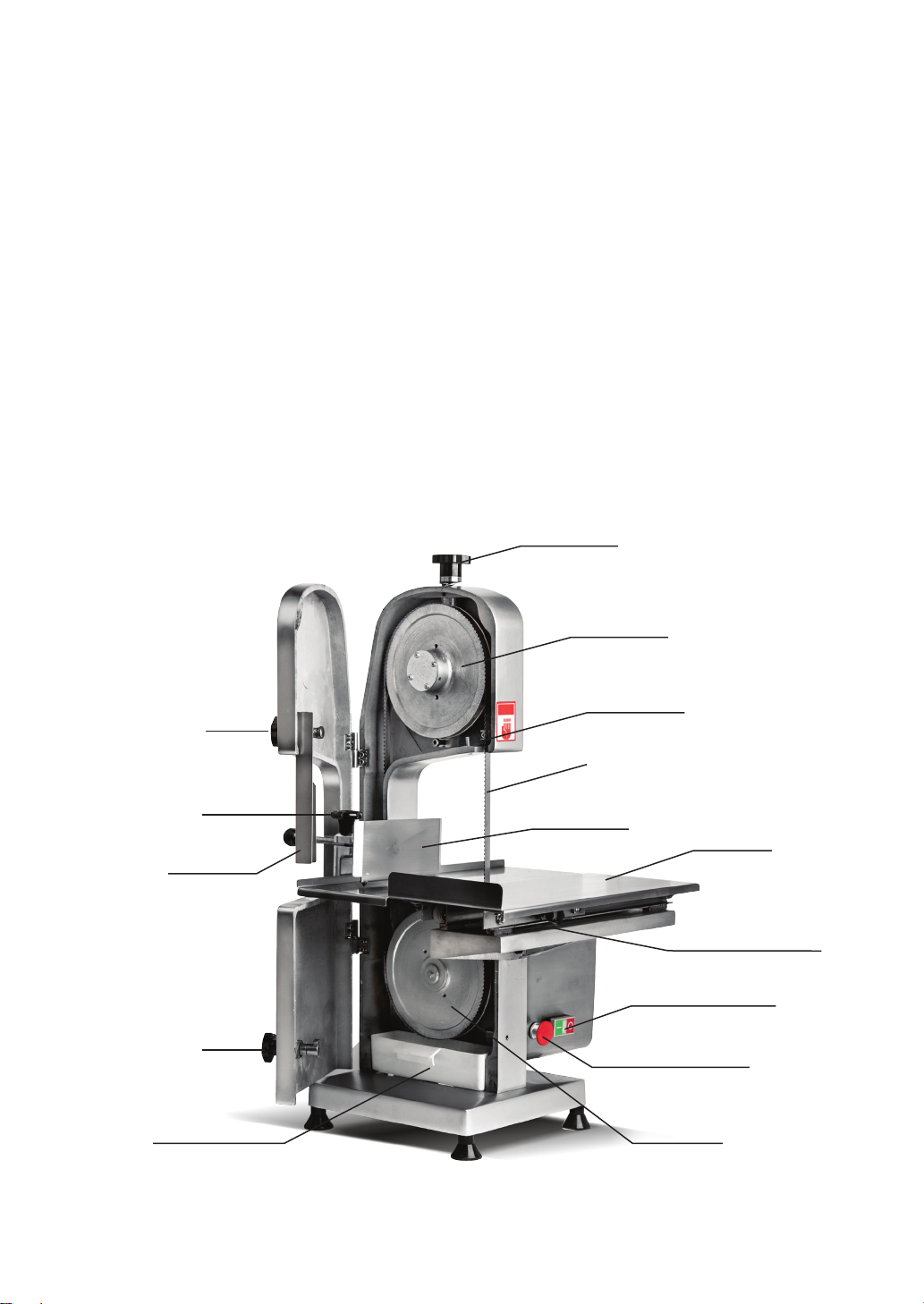

Components

SawBandtensioningKnob

DrivenWheel

VerticalClampingdevice

Sawband

Meatstopper

Carryingtable

TableSlider

DrivingWheel

MeatResidue

CollectingPan

BottomDoor

Locker

TopDoorLocker

SawProtecting

Cover

MeatStopperFixer

EmergencyStop

ON/OFFSwitch

- 5-

- 6-

- 7-

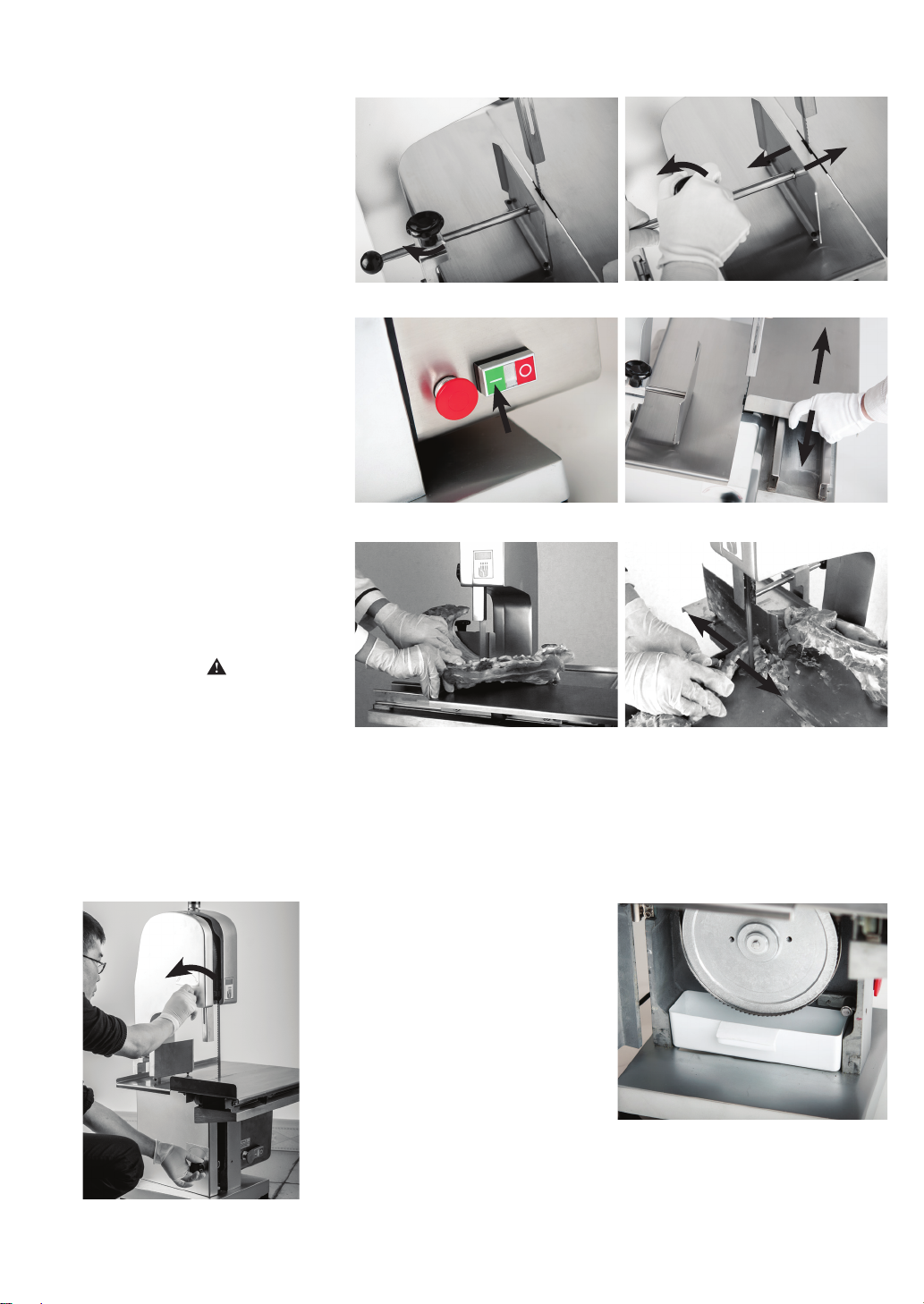

Operation

A. Loosenthemeatstopper

C.Startthemachine

DEF.Putthefoodonmovable

worktingtable,thenTake

sawguardontheright

protectionlevel,promotejob

boards,tobringfoodtothe

saw(Thedrivingspeed

differsaccordingtothe

differentfood,andbaseson

thenormalrunningofsaw

bandasalimition.Repeat

theoperationfortimesuntil

thecuttingoperationis

completed,thentrunoffthe

powersupply! Never

Position Fingers or

thumbs in line with the

cut!

B. Confirmthecuttingthickness

byadjustingthedistance

betweenfrontandrearmeat

stoppersandbandsaw

- 8-

(A)

(C)

(E)

(B)

(D)

(F)

Cleaning

A. Opentheprotectiondoor B. Takeouttheresiduepan

(A) (B)

Notice:

- 9-

CDE.LossenthetensioningKnobtorelaxthebandsawthendemountthesaw(Wearinggloves

before)。Onehandpressdownthetensioningknob,onehandupwardlifttheDrivenwheel

outandclean

F. Pleaseuselowpressuresquirtgunto

spraytheinteriormincedmeat,then

reinstallmentinorder. Electrical

parts(as exterior control

knob,switch....) can't be directly

sprayed by squirt gun.

1)Duringremountingthesawband,

checkthetoothdirection,positionand

makesurethatthesawbandshall

beclosetothebackingwheelfaceof

lowerclampingdevice(Theposition

ofbackingwheelhasbeenpresetat

delivery)

2)Rotatetopwheelwithhandandmake

surethatitrunssmoothlyandthe

sawteethstandoutonthewheel(if

necessary,itcanberealizedtoadjust

theregulatingdeviceontthetopwheel)

(C) (D) (E)

- 10-

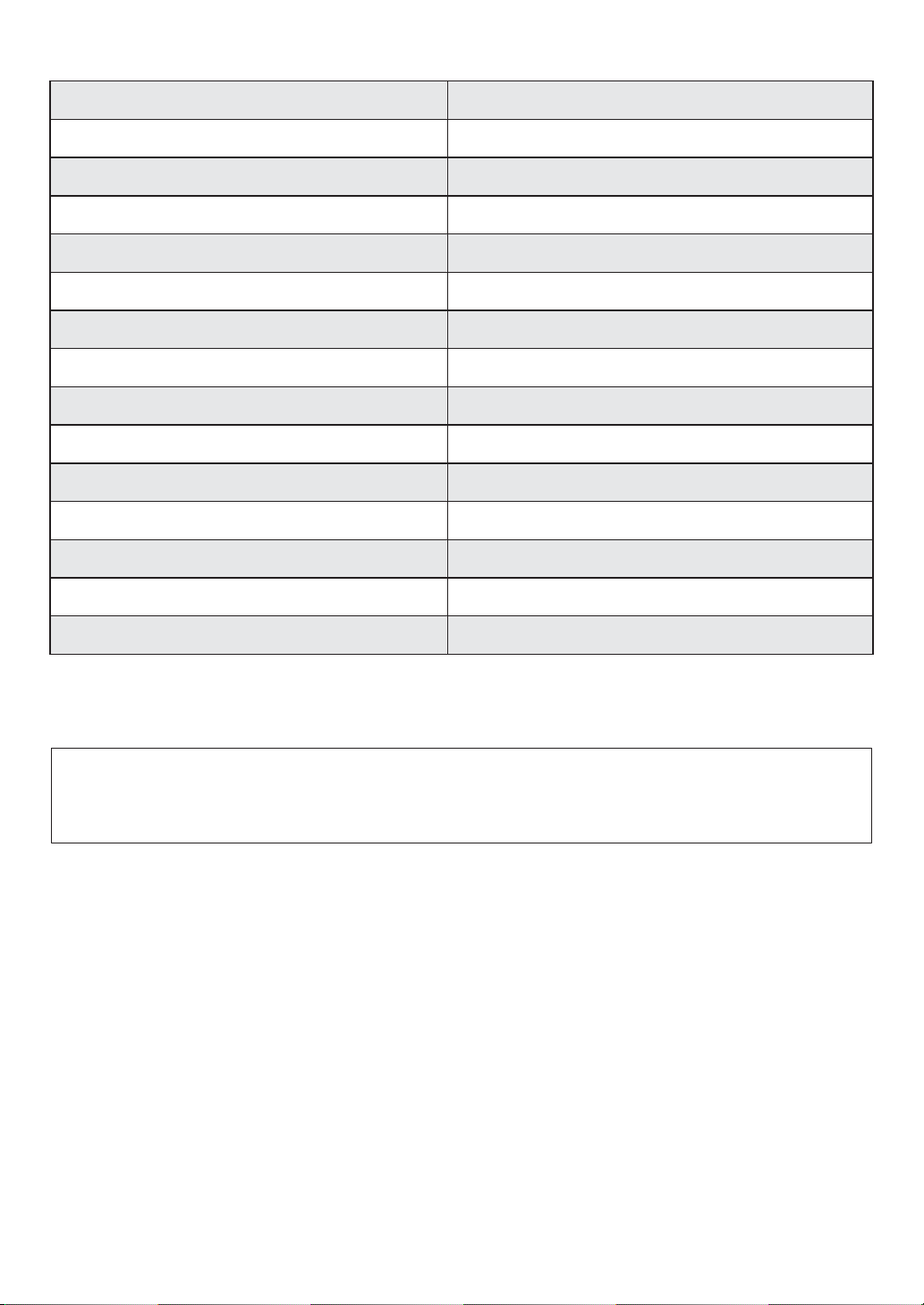

SN PartsDescription SN PartsDescription

1 BottomLockingBlock 29 MeatStopper

2 BottomDoorlockerseat 30 Motor

3 SawProtectingCover 31 CarryingPlate

4 TopLockingBlock 32 CarryingPlateSeat

5 TopDoorlockerseat 33 Movableworkingtable

6 Door 34 RightSlideRail

7 DrivenwheelCover 35 TherightwheelFrame

8 Drivenwheel 36 LockingBlock

9 DrivenwheelBearing(6004) 37 Lockinghandle

10 Sealingring 38 Lockingbolt

11 Drivenwheelaxle 39 Rollershaft

12 Drivenwheelstand 40 Rolleraxle(627)

13 Drivenslidecarriage 41 Roller

14 Adjustingnut 42 Railcarriageframe

15 Springseat 43 LeftSlideRail

16 Spring 44 LeftRollerframe

17 TensioningKnob 45 MeatScrappingPlate

18 tensioningnut 46 MeatScrappingseat

19 tensioningshaftscrew 47 MeatScrappingPlate

20 Framebolt 48 BandSawGuideSeat

21 SlideCarriagePressingPlate 49 DoorSwithseat

22 Enclosure 50 Footpad

23 BandSawGuideSeat 51 Baseseat

24 BandSawBlocker 52 DrivingWheel

25 BandSawGuidePlate 53 ResidueCollectingPan

26 MotorCover 54 DrivingWheelaxleSleeve

27 MeatStopperLockerBolt(M8) 55 BandSaw

28 MeatStopperseat

Parts Description

-

11-

Tech. Parameter

Name

Meat Bone Saw

Model

J210S/ J210

Machine Size

550×500×920mm

Packing Size

585×585×980mm

Band Saw Thickness

0.5mm

Band Saw Length

1650mm

Band Saw width

16mm

Power Supply

~110V/220V / 50/60 Hz

Power

750W

Cutting Thickness

5 ~155mm

Working table Size

505×415mm

Movable working table Range

240mm

Net Weight

≈47kg

Gross Weight

≈52kg

Brake Time

≤0.3s

-12-

Name

Meat Bone Saw

Model

J320S/ J320

Machine Size

500×470×1200mm

Packing Size

670×630×1270mm

Band Saw Thickness

0.5mm

Band Saw Length

2040mm

Band Saw width

16mm

Power Supply

~110V/220V / 50/60 Hz

Power

1100W

Cutting Thickness

5 ~200mm

Working table Size

530×430mm

Movable working table Range

300mm

Net Weight

≈63.5kg

Gross Weight

≈81kg

Brake Time

≤0.3s

PackingList

Instruction Manual*1, Band Saw*1, Driving Wheel Disassemble Tool*1

Remark: All photos just for reference, it will be adjust without any notice.

-

13-

iMettos Limited

www.imettos.co.uk

This manual suits for next models

1

Table of contents