IMR 2800 P User manual

IMR 2800 P

IMR 2800 A

IMR 2800 IR

ENVIRONMENTAL EQUIPMENT, INC.

3632 Central Ave.

St. Petersburg, FL 33711

USA

Phone: 727-328-2818

E-Mail: info@imrusa.com

Web: WWW.IMRUSA.COM

IMR® 2800

2 IMR Environmental Equipment, Inc.

TABLE OF CONTENTS

INTRODUCTION __________________________________________________________ 4

SAFETY INSTRUCTIONS___________________________________________________ 4

1 DESCRIPTION __________________________________________________________ 5

1.1 FUNDAMENTALS __________________________________________________________ 6

2 SYSTEM DESCRIPTION ______________________________________________________ 7

2.1 OVERVIEW________________________________________________________________ 7

2.2 FUNCTION OVERVIEW_____________________________________________________ 8

2.3 TECHNICAL DATA - STANDARD RANGES ___________________________________ 9

TG Flue gas temperature _________________________________________________________ 9

2.4 SYSTEM CONNECTIONS __________________________________________________ 11

2.4.1 Probe ________________________________________________________________________ 11

2.4.2 Ambient air temperature plug ____________________________________________________ 13

2.4.3 Gas fitting_____________________________________________________________________ 13

2.4.4 Draft fitting ___________________________________________________________________ 13

2.4.5 LED _________________________________________________________________________ 13

2.4.6 Differential pressure fitting (if equipped) ___________________________________________ 13

2.4.7 RS232 interface ________________________________________________________________ 14

2.5 POWER __________________________________________________________________ 15

2.6 BUTTON FUNCTIONS _________________________________________________ 16

3 OPERATION ___________________________________________________________ 17

3.1 OVERVIEW_______________________________________________________________ 17

3.2 TURNING ON _____________________________________________________________ 18

3.3 FUEL TYPE SELECTION___________________________________________________ 19

3.4 MEASUREMENT MENU ___________________________________________________ 20

3.4.1 Main menu____________________________________________________________________ 21

3.4.2 Store a measurement____________________________________________________________ 22

3.4.3 Printout ______________________________________________________________________ 23

3.4.4 Feed _________________________________________________________________________ 23

3.5 SUBMENUS OF THE MAIN MENU __________________________________________ 24

3.5.1 Choice ppm/mg ________________________________________________________________ 25

3.5.2 Config. printer_________________________________________________________________ 26

3.5.3 Statistics ______________________________________________________________________ 27

3.5.4 Memory ______________________________________________________________________ 29

3.5.5 Pressure ______________________________________________________________________ 30

3.5.6 Standby ______________________________________________________________________ 31

3.5.7 Select fuel _____________________________________________________________________ 31

3.5.8 Organization __________________________________________________________________ 32

3.5.8.1 Device status_____________________________________________________________ 32

3.5.8.2 Set date / time ____________________________________________________________ 33

3.5.8.3 Interface ________________________________________________________________ 34

3.5.8.4 Configuration ____________________________________________________________ 37

3.5.8.5 Change fuel parameters_____________________________________________________ 38

3.5.8.6 Station__________________________________________________________________ 38

3.5.8.7 Select language (if equipped) ________________________________________________ 38

IMR® 2800

3 IMR Environmental Equipment, Inc.

3.5.8.8 Switch Gas 1 / Gas 2 (if equipped) ____________________________________________ 39

3.5.9 Soot detection (if equipped) ______________________________________________________ 39

3.5.10 Recalibration _________________________________________________________________ 39

4 CALCULATIONS________________________________________________________ 40

4.1 EXCESS AIR ______________________________________________________________ 40

4.2 CARBON DIOXIDE CO2____________________________________________________ 40

4.3 HEAT LOSSES ____________________________________________________________ 41

4.4 CONVERTING PPM INTO VOLUME/WEIGHT RATIO ________________________ 44

4.5 CONVERTING PPM INTO VOLUME/WEIGHT RATIO WITH REF. O2 __________ 44

4.6 NOx (NO+NO2) ____________________________________________________________ 44

5 UNIT MAINTENANCE___________________________________________________ 45

6 ERROR MESSAGES _____________________________________________________ 46

7 WARRANTY____________________________________________________________ 48

8 SPARE PARTS__________________________________________________________ 49

9 IMR ___________________________________________________________________ 50

IMR® 2800

4 IMR Environmental Equipment, Inc.

IMR reserves the right to adopt technical modifications without prior notice.

INTRODUCTION

Thank you for purchasing the IMR® 2800 combustion gas analyzer.

Please read the following instructions before operating the unit for the first time.

Proper handling is necessary to make full use of the outstanding performance and features of

this combustion gas analyzer.

IMPORTANT INFORMATION:

Use the instrument just within the recommended temperature range.

Never measure without the dust filter and condensation trap.

The dust filter must be cleaned/replaced when dirty.

The c8ondensation trap must be checked and the condensed water removed if necessary.

IMR or an authorized service facility must re-calibrate the IMR 2800 once a year to

ensure accuracy and performance.

SAFETY INSTRUCTIONS

Please make sure that you read this section carefully for use of your new combustion gas

analyzer.

Follow all warnings and instructions marked on the product or displayed on the screen.

The AC inlet should only be connected to a socket with a protective earth contact.

Any adjustment or maintenance of the analyzer under voltage should be avoided.

The maintenance of the analyzer should be done by qualified personal and the instrument

must be turned off and unplugged.

Do not take the analyzer out of the box during the warranty period. If you do so, then the

warranty is null and void.

Do not use this analyzer in water.

Never spill water or any liquid on the analyzer.

IMR® 2800

5 IMR Environmental Equipment, Inc.

1 DESCRIPTION

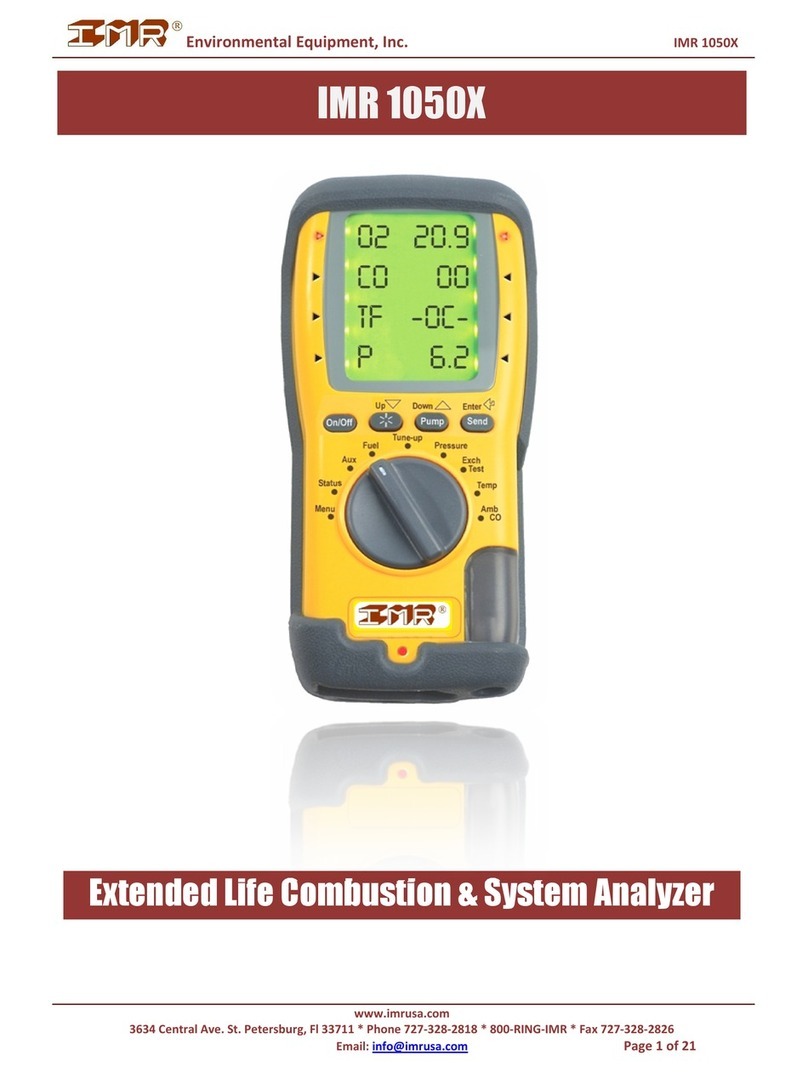

The IMR 2800 is a state of the art combustion gas analyzer.

Table 1: IMR 2800

O2

CO

NO

NO2

SO2

Additional

Sensor(s)

Printer

Memory

RS232

Interface

Ambient

Temp.

Soot

Draft

IMR 2800

X

X

X

X

X

O

X

X

X

X

O

X

X - standard O - optional

Maximum 8 electrochemical sensors

The IMR 2800 calculates the parameters below:

- Excess air / Lambda

- Heat losses / Efficiency

- Carbon dioxide CO2

Optional features: - Differential draft measurement

- Gas Flow measurement (m/s) with Pitot tube

- HCl, N2O, CL2, H2, NH3, HC, H2S measurement

- CO2, CH4/HC and N2O NDIR sensors available

- Speed RPM

- Soot Measurement

- High temperature gas sampling probes (ceramic, PT-RhPT)

(up to 1500C / 2732F)

- Gas-sampling probes with different lengths

- NOx (NO + NO2)

- Additional Instruments: RPM Meter, Soot Meter

IMR® 2800

6 IMR Environmental Equipment, Inc.

1.1 FUNDAMENTALS

Gas flow

A built-in sampling pump is drawing the flue gas through the gas-sampling probe into the

analyzer.

1. The gas flows through the gas-sampling probe to the condensation trap.

2. Then the gas passes through a particle filter where dust particles are removed.

3. Then the gas enters the sensor chamber.

Gas temperature

The gas temperature is measured by a thermocouple located at the tip of the gas-sampling

probe.

Electrochemical sensors

Each electrochemical sensor measures the concentration of a specific gas.

Electrochemical sensors can be damaged

-if exposed to small particles - never measure without a dust filter

-if water / condensation comes in contact with the sensors - empty condensation

trap

Service / Calibration

A “Service” message will be displayed after 1000 hours or after one year of operating time.

IMR Environmental Equipment, Inc. recommends checking the calibration once a year.

Operating Temperature

50oF..104oF / 10oC..40oC

If the unit is brought in from the cold, then it should be allowed to warm up for a few minutes.

Storage Procedures: IMPORTANT!

Storage Temperature

-4oF..122oF / -2oC..50oC

When not in use or in storage, please make sure to keep the analyzer plugged into a wall outlet

(AC).

This ensures that the analyzer maintains a constant battery charge and function properly if

needed.

Prolonged periods of disuse without charging the battery may result in a weak battery and the

battery can lose its ability to hold the charge.

IMR® 2800

7 IMR Environmental Equipment, Inc.

2 SYSTEM DESCRIPTION

2.1 OVERVIEW

Please check now if the unit is equipped with all the ordered features and accessories.

Features and Accessories (if equipped):

-Backlit LCD

-Keypad

-Gas sampling probe

-Ambient temperature probe

-Thermal printer

-RS232 interface

-Rechargeable battery

-Draft measurement

-Soot measurement w/ soot filter paper and comparison scale

-Memory

-O2 electrochemical sensor

-CO electrochemical sensor

-NO electrochemical sensor

-NO2 electrochemical sensor

-SO2 electrochemical sensor

-Additional sensor(s)

-Case

-Manual

-Power Cord

-Calibration certificate

IMR® 2800

8 IMR Environmental Equipment, Inc.

2.2 FUNCTION OVERVIEW

Measurements

Gas Temperature

Ambient Temperature

Draft

Soot

O2

CO, NO, SO2, NO2, HC

(max. 7 more sensors)

Calculations

CO2

Losses

Excess Air

NOx (NO+NO2)

I

n

p

u

t

s

FUNCTIONS

IMR 2800

Gas Temperature

Ambient Temperature

Gas sensors

Draft

Soot

Printer

RS232

Calculations

OUTPUTS

IMR® 2800

9 IMR Environmental Equipment, Inc.

2.3 TECHNICAL DATA - STANDARD RANGES

Other measurement ranges and probe lengths are optional available.

Table 2: Technical Data

PARAMETER

PRINCIPLE

RESOLUTION

ACCURACY

RANGE**

STANDARD

O2Oxygen

Electro-chemical

cell

0.1 Vol.%

0.2 Vol. %

0-20.9 Vol. %

CO Carbon

monoxide

Electro-chemical

cell

NDIR

1 ppm

0.001 Vol.%

Z

0-

2000/4000ppm

0-10/20 Vol.%

NDIR

Optional

NO Nitric oxide

Electro-chemical

cell

1 ppm

Z

0-2000 ppm

NO2Nitrogen

dioxide

Electro-chemical

cell

0.1 ppm

Z

0- 100 ppm

SO2Sulfur

dioxide

Electro-chemical

cell

1 ppm

Z

0-4000 ppm

H2S Hydrogen

Sulfide

Electro-chemical

cell

0.1 ppm

Z

0- 200 ppm

HC/CH4

Hydrocarbons

Pellistor or NDIR

0.1 %

Z

0-100% LEL

TG Flue gas

temperature

NiCr-Ni

thermocouple

1°C/1°F

2 %

-4F - 2192F

0C - 1200C

TA Air

temperature

Semiconductor

1°C/1°F

2 %

-4F / 248F

0C - 120C

P Draft

Solid state

0.01 hPa

2 %

40 hPa

NOxNitrogen

oxides

Calculation

1 ppm

Z

0-NOxmax

CO2Carbon

dioxide

Calculation

0.1 Vol.%

0.2 Vol. %

0- CO2 max

CO2Carbon

dioxide

NDIR

0.01 Vol.%

0.2 Vol. %

0-20 Vol. %

NH3Ammonia

Electro-chemical

1 ppm

Z

0-1000/5000

ppm

N2O Nitrous Oxide

NDIR

0.001 Vol. %

Z

0-1 Vol. %

HCl Hydrogen

Chloride

Electro-chemical

1 ppm

Z

0-200 ppm

Cl2Chlorine

Electro-chemical

1 ppm

Z

0-5000 ppm

H2Hydrogen

Electro-chemical

1 ppm

Z

0-10000 ppm

Losses / Efficiency

Calculation

0.1 %

0.1 %

0-99.9 %

Excess Air /

Lambda

Calculation

0.1 %

0.1 %

1.0-9.99

Soot

Filter paper

method

0-9

Velocity with Pitot

tube

Solid state

0.01 m/s

2 %

0-80 m/s

RPM Meter

Solid state

100 RPM

2 %

180-10000

RPM

** Different/customized ranges available. Equipped with a maximum of 8 gas sensors

Z = 0 - 20 % of whole measurement range ± 5 % of maximum measurement

21 - 100 % of whole measurement range ± 1 % of displayed measurement

IMR® 2800

10 IMR Environmental Equipment, Inc.

Power Inlet 110VAC/60Hz or 230VAC/50Hz

Battery Sealed lead acid 12VDC- Five-hour charge time

Display 4-line, 20-character illuminated LCD

Printer Thermal printer - paper width 58mm - built-in

Gas sampling probe If the unit is equipped with soot measurement

- Type S, probe length 10.6" / 270mm, hose 11.5' / 3.5m

If the unit is not equipped with soot measurement

- Type E, probe length 9.8" / 250mm, hose 8.2' / 2.5m

Ambient air probe Ambient air temperature plug

Condensation Trap Inline with integrated filter

Filter In-line - four micron - washable

Case Rugged wood/aluminum case with compartment for gas sampling

probe, power cord and accessories.

Operating temperature 50oF..104oF / 10oC..40oC

Storing temperature -4oF..122oF / -20oC..50oC

Calibration Automatic 3-minute zero calibration

Fuels USA

Natural gas, Propane, Kerosene, Distillate #1, Anthracite coal,

Bituminous coal, Fuel #2, Fuel #5, Fuel #6, Bagasse, Wood, Bark,

Special fuel A, Special fuel B, Special fuel C, Special fuel D

European

Fuel oil extra light, Natural gas, Town gas, Coalgas, Liquid gas,

Hard coal hb 1950, Wood (air dry), Fuel oil light, Fuel oil heavy,

Coaltar oil, Liquid gas air ventil., Liquid gas air, Propane ventil.,

Propane, Butane ventil., Butane, Propane / Butane ventil.,

Propane / Butane, Biogas ventil., Biogas, Hard coal hb 7450,

Hard coal hb 7170, Hard coal hb 2230, Special fuel A, Special fuel

B, Special fuel C, Special fuel D

IMR® 2800

11 IMR Environmental Equipment, Inc.

2.4 SYSTEM CONNECTIONS

2.4.1 Probe

The gas-sampling probe plug and hose has to be connected to the analyzer before it can be

turned on and must stay connected during the whole measurement.

If the gas-sampling probe is not connected, then the analyzer cannot perform an accurate

calibration and an error message will be displayed.

Type S (if equipped with soot measurement)

The probe S has two hoses. One for the flue gas measurement and one for the draft

measurement. Both hoses must be connected to their fittings at all time.

It also has a connection line to connect the thermocouple with the analyzer.

a) Thermocouple - Connect the thermocouple plug (5-pos) with the

'flue gas temp' socket of the analyzer

b) Flue gas - Connect the hose, which has the condensation trap

inline to the barbed fitting 'gas input'

c) Draft - Connect the second hose to the barbed fitting

'draft'

Type E

The probe E has one hose for the flue gas measurement and the draft measurement.

It also has a connection line to connect the thermocouple with the analyzer.

a) Thermocouple - Connect the thermocouple plug (5-pos) with the

'flue gas temp' socket of the analyzer

b) Flue gas - Connect the hose to the barbed fitting 'gas input'

The hose must be connected to the 'gas input' fitting for the flue gas measurement.

The hose must be connected to the 'draft' fitting only for the draft measurement and it must be

connected back to the 'gas input' fitting after the draft measurement is completed.

Type C (if equipped)

The probe C is a ceramic probe with a Pt-RhPt thermocouple and it is used for high

temperatures. The temperature range is 302F-2732F / 150C-1500C.

It has the same connections as the probe E.

IMR® 2800

12 IMR Environmental Equipment, Inc.

Gas sampling probe (type S) connection:

IMR® 2800

13 IMR Environmental Equipment, Inc.

2.4.2 Ambient air temperature plug

The ambient air temperature plug must be connected to the instrument at all time.

If the ambient air temperature plug is not connected, then the unit shows an error message.

The ambient air temperature plug measures the temperature of the air that is used for the

combustion process.

The measured temperature is needed for various calculations.

Connect the plug (4-pos) with the 'air temp' socket of the analyzer.

2.4.3 Gas fitting

The gas hose of the gas-sampling probe must be connected to the gas fitting.

2.4.4 Draft fitting

The draft hose of the gas-sampling probe must be connected to the draft fitting.

2.4.5 LED

The LED shows the power status of the unit.

RED: battery powered

GREEN: AC connected and turned off (charging the battery)

YELLOW: AC connected and turned on

2.4.6 Differential pressure fitting (if equipped)

The analyzer is equipped with a third barbed fitting for a differential pressure measurement.

The differential pressure is the pressure that is measured between the 'draft' fitting and this 3rd

fitting.

Connect a hose to this fitting and insert it into the medium and start the regular draft

measurement. The draft measurement measures now the differential pressure from the

medium to the flue gas, where the gas-sampling probe is inserted.

IMR® 2800

14 IMR Environmental Equipment, Inc.

2.4.7 RS232 interface

The RS232 serial interface can be used to transfer data from the analyzer to a PC.

Real time data or stored data can be transferred (ASCII signs are getting transferred).

The serial connection to a PC must be a 'Null-modem connection'.

The IMR 2800 has a 9-pos. female D-Sub connector on the front panel.

RS232 female connector 9-pos.

1-

2-

3- TXD transmit data

4-

5- GND ground

6-

7-

8- CTS clear to send

9-

5 1

9 6

Connection to a PC (null-modem connection):

IMR 2800

PC 9-pos

PC 25-pos

3 TXD

2 RXD

3 RXD

5 GND

5 GND

7 GND

8 CTS

7 RTS

4 RTS

Serial data format

A character has 8 data bits; no parity and 2 stop bits.

ASCII "Computer" format:

Start ()

Station

Fuel

Units (ppm, etc.)

NOx (according TA-Luft)(1)

Date

Time

No. of samples

Time of samples

Room Temperature

O2

CO

HC

SO2

NO2

NO

Draft

Gas Temperature

CO2

Losses

Excess Air

Stop ()

IMR® 2800

15 IMR Environmental Equipment, Inc.

2.5 POWER

The IMR 2800 works on 230VAC/50Hz or 110VAC/60Hz. A fuse selector next to the AC

inlet sets the voltage.

The analyzer is able to work without being connected to the AC by using the power of the

internal rechargeable battery lead acid battery.

However IMR recommends connecting the analyzer always to the AC during a measurement

or during storage.

IMR® 2800

16 IMR Environmental Equipment, Inc.

2.6 BUTTON FUNCTIONS

"0" - "9" - Numeric buttons for numbers

"P" - Prints a measurement

"measurement menu" - complete measurement

submenu "pressure" - draft measurement

"M" - Stores a measurement

"F" - Feed

"^" - Scroll up

"v" - Scroll down

"ESC" - Back to the measurement menu

"" - Enter / confirm

IMR® 2800

17 IMR Environmental Equipment, Inc.

3 OPERATION

3.1 OVERVIEW

Connect gas sampling probe and

ambient air plug

(Do not put the gas sampling

probe into the flue gas at this

time)

"On/Off" - Turn the unit on

3 min Calibration and self check

Press any key after calibration is

Finished

Fuel type selection

"^", "v" - Select fuel type

"" - Confirm selected fuel type

Measurement menu

"P" - print measurement

"^", "v" - scroll first line

"M" - store measurement

""

Main menu

-Choice ppm / mg

-Config. Printer

-Statistics

-Memory

-Pressure

-Standby

-Select fuel

-Organization

-Soot detection

-Recalibration

"^", "v" - Select submenu

"" - Confirm and enter submenu

"ESC" - Back to measurement menu

IMR® 2800

18 IMR Environmental Equipment, Inc.

3.2 TURNING ON

Make sure to connect the gas sampling probe and the ambient air temperature plug to the

analyzer and do not insert the gas-sampling probe into the flue gas.

IMR 2800P

FLUE GAS

ANALYZING COMPUTER

Turn the "On/Off"- button to "On" and the unit starts with the

zero calibration.

IMR 2800P

Calibration 2:00 PM

174 seconds

The zero calibration takes 180 seconds and the unit is checking

all sensors and sets all the values to its zero point.

IMR 2800P

Calibration done.

Press any key

Press any key after the calibration is finished.

IMR® 2800

19 IMR Environmental Equipment, Inc.

3.3 FUEL TYPE SELECTION

The IMR 2800 has most common fuels programmed and 4 more fuel types are programmable

by the user.

After the calibration is finished the analyzer needs to know, which fuel is used by the

combustion process. This information is necessary to calculate the combustion parameters.

===Select fuel===

fuel oil. ex. lgh.

natural gas

town gas

Select the fuel with the "^" or "v" button.

Confirm the selection by pressing the "" button.

The analyzer enters the measurement menu after the

confirmation.

Active buttons

Move arrow selector up

^

Back to measurement menu

ESC

Move arrow selector down

v

Confirm selection

Fuel types:

USA: - Natural gas

- Propane

- Kerosene

- Distillate #1

- Anthracite coal

- Bituminous coal

- Fuel #2

- Fuel #5

- Fuel #6

- Bagasse

- Wood

- Bark

European: - Fuel oil extra light

- Natural gas

- Town gas

- Coalgas

- Liquid gas

- Hard coal hb 1950

- Wood (air dry)

- Fuel oil light

- Fuel oil heavy

- Coaltar oil

- Liquid gas air ventil.

- Liquid gas air

- Propane ventil.

- Propane

- Butane ventil.

- Butane

- Propane / Butane ventil.

- Propane / Butane

- Biogas ventil.

- Biogas

- Hard coal hb 7450

- Hard coal hb 7170

- Hard coal hb 2230

Programmable fuel:

If the used fuel type is not programmed, then a special fuel type can be entered with its

parameters.

IMR® 2800

20 IMR Environmental Equipment, Inc.

Editing the fuel parameters for the special fuel type has to be done in the submenu

"organization".

3.4 MEASUREMENT MENU

Measurement

- Put the gas sampling probe into the flue gas and check for the highest temperature. Lock the

probe tube with the cone at this point.

- The sensors need approximately 3 minutes for an accurate and stable reading.

The measurement menu shows all measured and calculated parameters as well as the fuel

type.

The first line scrolls automatically every 10 seconds. However one value can be selected by

using the "^" and /or "v" button.

CO2 0.0%

T-gas 75.2oF O2 20.9%

CO ppm NO ppm SO2ppm

0 0 0

The first line shows these different values:

CO2, T-room, losses, excess air, fuel type

Active buttons

Scroll first line

^ , v

Print measurement

P

Store measurement

M

Line feed

F

Enter main menu

This manual suits for next models

3

Table of contents

Other IMR Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

ARAG

ARAG orion 462A Series Installation, use and maintenance

MPH

MPH Sure Shot user manual

Vulcan-Hart

Vulcan-Hart V320 Setup and Calibration Instructions

YSI

YSI 2900 series Operation and maintenance manual

CLA-VAL

CLA-VAL X144D e-FlowMeter Installation operation & maintenance

Pittsburgh

Pittsburgh 63711 Owner's manual & safety instructions