CLA-VAL X144D e-FlowMeter Owner's manual

A view inside the X144D e-FlowMeter

Plug-and-Play Metering:Cla-Val X144D e-FlowMeter

Proven Technology from

the Industry Leader

Laboratory Tested • Field Proven • Performance Assured

Log-on to

www.cla-val.com and click Electronic

Products to learn more about our

complete line of e-products.

flow direction

X144D e-FlowMeter Installation,

Operation and Maintenance

Table o Contents

Topic Page #

ntroduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Section1:System Components and How They Work:

1.1 - Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 - Supplied Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3 - Non-Supplied Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

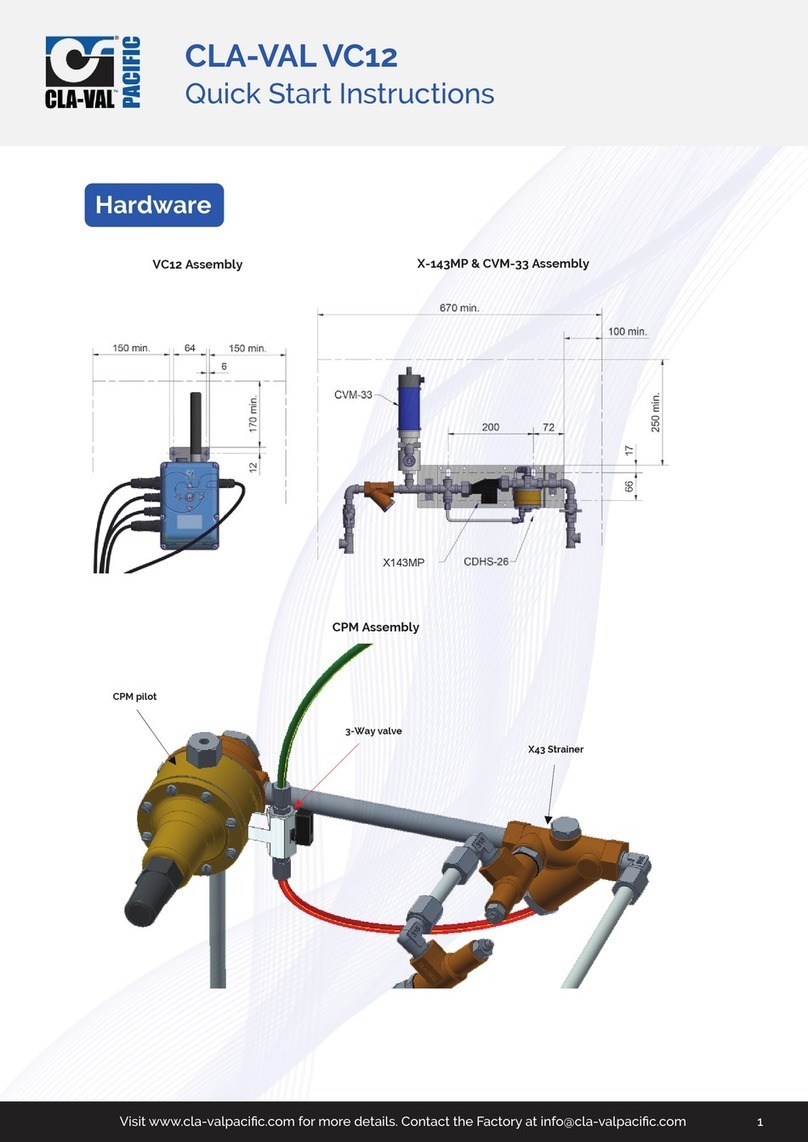

Section 2: nstallation & Removal of the X144D e-FlowMeter

2.1 - Installation Location Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 - Materials Required for Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 - Mounting the X144D e- lowMeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.4 - Step-By-Step Instructions: Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . 11-14

2.5 - Step-By-Step Instructions: Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-17

2.6 - VC-22D Wiring Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Section 3: X144D e-FlowMeter Configuration and Startup

3.1 - Startup Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2 - Shutdown / Removal of the X144D e- lowMeter. . . . . . . . . . . . . . . . . . . . . . . . . . . 20-21

3.3 - Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-24

Section 4: Maintenance and Repair

4.1 - Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2 - Cleaning Debris from Measurement Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.3 - Dealing with Sensor Tip Damage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Section 5:Specifications

Table 2: Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 3: Mechanical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Dimensional Drawing: X144D e- lowMeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 4: X144D e- lowMeter Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Dimensional Drawing/Data: Insertion Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 5: Insertion Tool Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 6: low Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 7: X144D e- lowMeter Analog Range (4-20mA Scaling):. . . . . . . . . . . . . . . . . . . . . 29

actory Settings

Appendix

Quick Start Installation and Removal Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-33

Quick Start Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34-37

Menu Structure Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Troubleshooting Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39-41

X144 to X144D Retrofit Kit Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42-46

www.cla-val.com

4

NTRODUCT ON:

X144D e-FlowMeter nstallation, Maintenance and Operation

The X144D is an insertion flow meter designed to provide flow information from inside a Cla-Val Control

valve.This innovative device measures flow information using standard Cla-Val control valve bodies at locations

where typical flow meters cannot provide accurate measurements. As opposed to industry standard insertion

flow meters, the X144D e- lowMeter can be installed directly into the inlet side of a Cla-Val Control Valve,

eliminating the need for costly downtime and pipe work. The X144D can also be inserted in valves at piping

locations not usually permitted for flow measurement, such as directly downstream of a flow disturbance such

as elbows, valves or reducer within just a few pipe diameters (see installation recommendations for conditions.)

This manual will help you install, operate, and maintain the X144D e- lowMeter.

mportant Safety nformation

The following safety notices are used in this manual:

• CAUT ON: indicates that minor personal injury, product or property damage may occur if

the notice is ignored.

• NOTE: indicates special instructions that are important but are not related to hazards.

Please see examples shown below:

NOTE:The X144D e- lowMeter may

be installed in inlet tap of either side of

the Cla-Val Automatic Control Valve.

CAUT ON: ailure to install the unit

correctly could result in faulty operation

and/or damage to the unit.

CAUT ON:

Valve in which X144D e- lowMeters

are installed MUST have upstream

and downstream Isolation Valves to

ensure that the line is locked out and

not under pressure during

installation, maintenance or removal

of the X144D e- lowMeter.

CAUT ON:

In all cases, installation should be done by

qualified mechanical or electrical

personnel.

CAUT ON: BEFORE removing pipe plug,

make sure that the pressure in the valve

has been bled off to prevent injury to

personnel or damage to non-waterproof

equipment.

CAUT ON 1: ailure to use the

provided Insertion Tool W LL result

in damage to the e- lowMeter

CAUT ON2: To avoid injury, isolate

the valve and bleed pressure prior

to removing the e- lowMeter

for assistance, call

800.942.6326

5

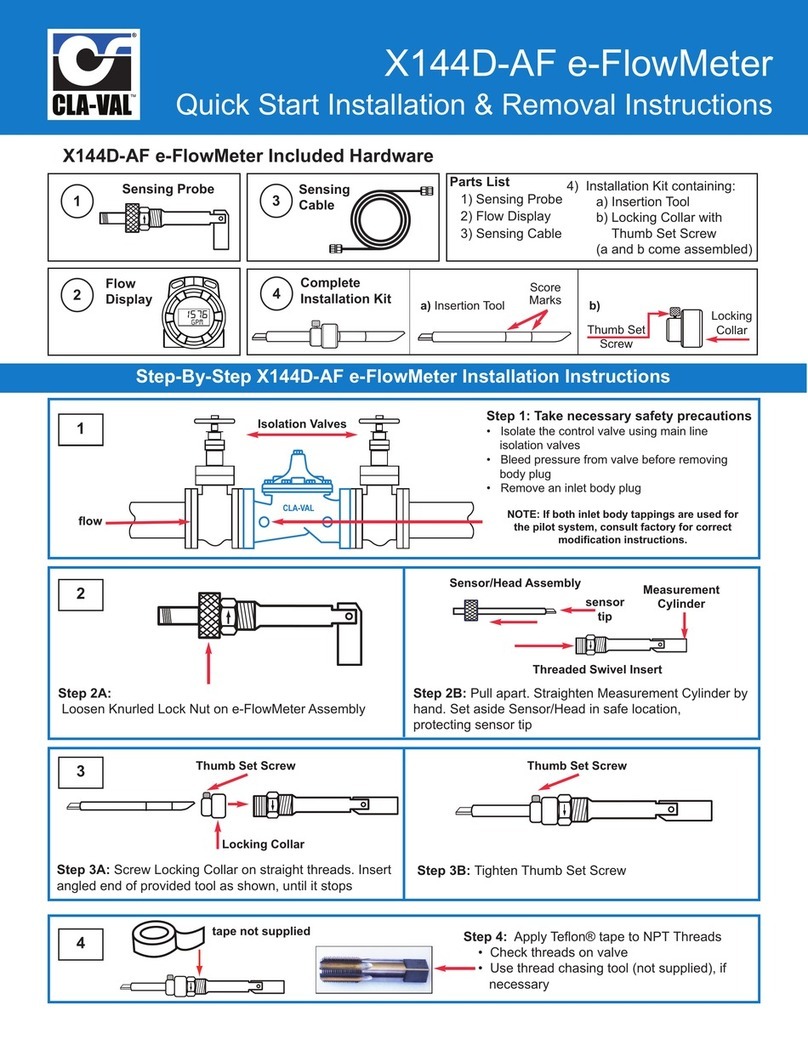

SECT ON 1: System Components and How They Work

1.1 - Theory of Operation

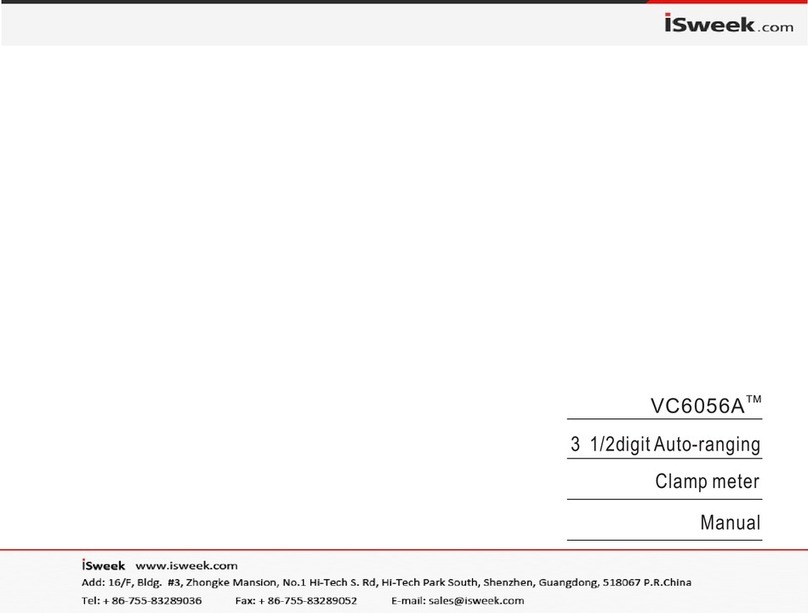

The X144D e- lowMeter is an insertion vortex flowmeter based on a phenomenon which generates of a

succession of alternating swirls called Karman vortex street ( igure 1-1).

When the fluid meets an obstacle (called a bluff body) which is placed in parallel with the flow of the fluid it

divides the flow and generates small swirls or vortices alternately on both sides downstream of the obstacle.

The generation of the swirls is directly proportional to the speed of the fluid. The detached swirls generate

zones of variable pressure that are detected by the forces acting on a small piezoelectric crystal

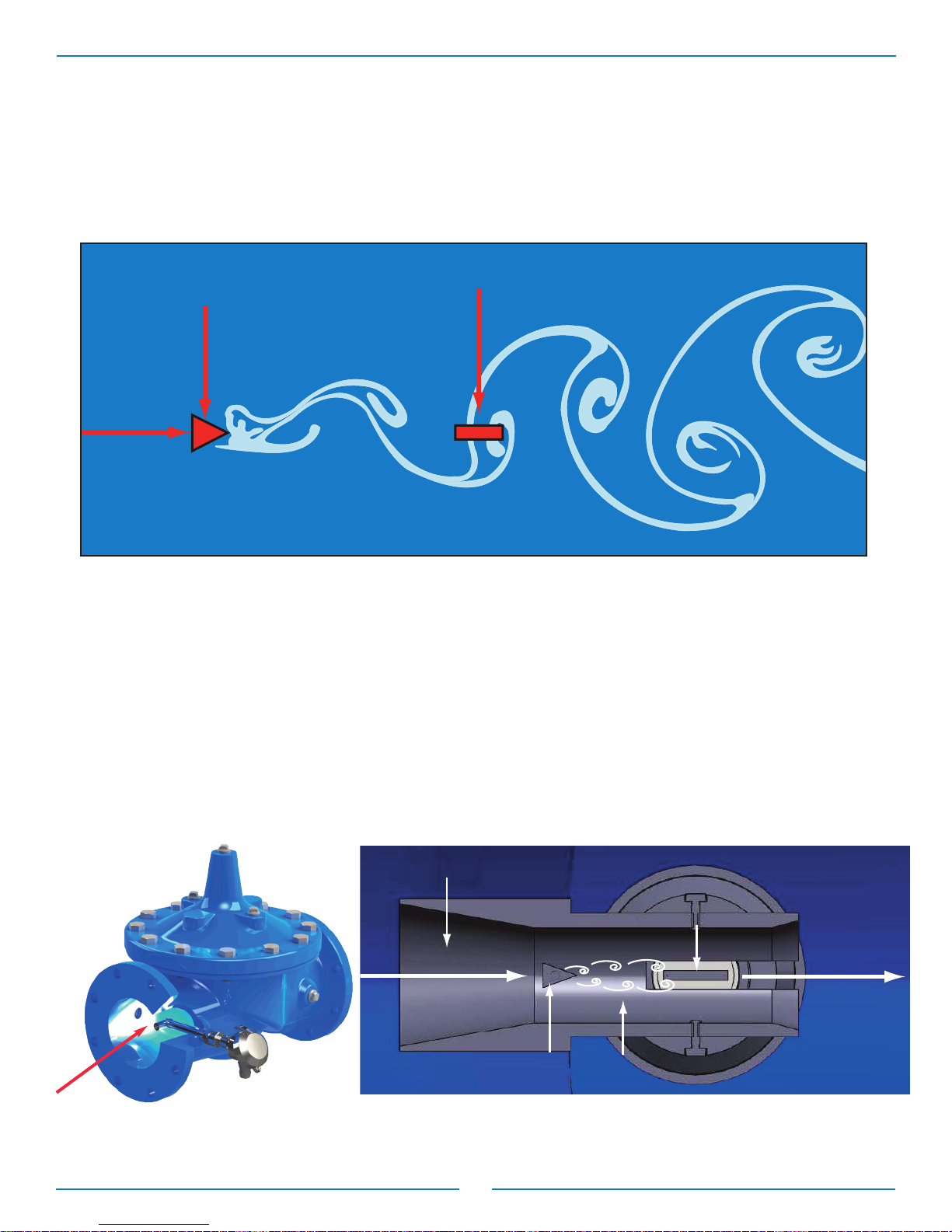

encapsulated in the transmitter ( igures 1-2 and 1-3).

The X144D e- lowMeter employs an innovative feature called the Swivel Measurement Cylinder which

allows for the proper distance between the bluff body and the sensor, while still retaining the capability of

being inserted into a tapping as small as 1/2-inch NPT.

Bluff Body

Sensor

Karman

Vortex

Street

Flow

Direction

Figure 1-1: Karman Vortex Street

Meter Bluff Body

Flow

Direction

Integral Sensor

Flow

Direction

Vortices

Measurement Cylinder

Figure 1-3

Figure 1-2

flow direction

6

Figure 1-4: e-FlowMeter

X144D e-FlowMeter Parts

1) IP68 Submersible Electronics Housing 2) Knurled Lock 3) Centering Pin

4) O-Ring 5) Shaft 6) Sensor

1

2

6

53

Swivel Threaded nsert Parts

1) Straight Threads

2) Centering Groove

3) Tapered Threads

4) Sleeve

5) Swivel Measurement Cylinder

SECT ON 1: System Components and How They Work (continued)

1.2 – Supplied Parts List

X144D Equipment - Supplied by Cla-Val

1) e- lowMeter with Swivel Threaded Insert

( igures 1-4 and 1-5)

2) Insertion Tool ( igure 1-6)

3) 20 feet of Electrical Cable (See Section 2.5)

Figure 1-5: e-FlowMeter Swivel Threaded Insert Detail

X144D e- lowMeter

Swivel

Threaded Insert

4

1

3

4

2

5

Figure 1-6: Insertion Tool Kit

nsertion Tool Kit Parts

1) Bevel

2) Tool

3) Score Marks

4) Thumb Set Screw

5) Tool Lock

6) lat Tipped End

7) Locking Collar

1

4

2

53

6

7

7

SECT ON 1: System Components and How They Work (continued)

1.3 – Non-Supplied Parts List

The following parts are necessary for installation and operation but not included with the e- lowMeter:

• Cla-Val Automatic Control valve in which to insert the e- lowMeter - Globe or Angle Pattern, 2" - 36".

• Power supply

- 6-30 VDC, 0.7 Watts minimum

- Can be powered with batteries or AC/DC Converter

• Power supply/battery housing

with optional equipment to pair with

the X144D e-FlowMeter™

X144D e-FlowMeter Schematic

X144D

e-FlowMeter

Cla-Val Automatic Control Valve

6 - 30 VDC

Battery

SCADA

System

8

Section 2: nstallation of the X144D e-FlowMeter

2.1 - nstallation Locations:

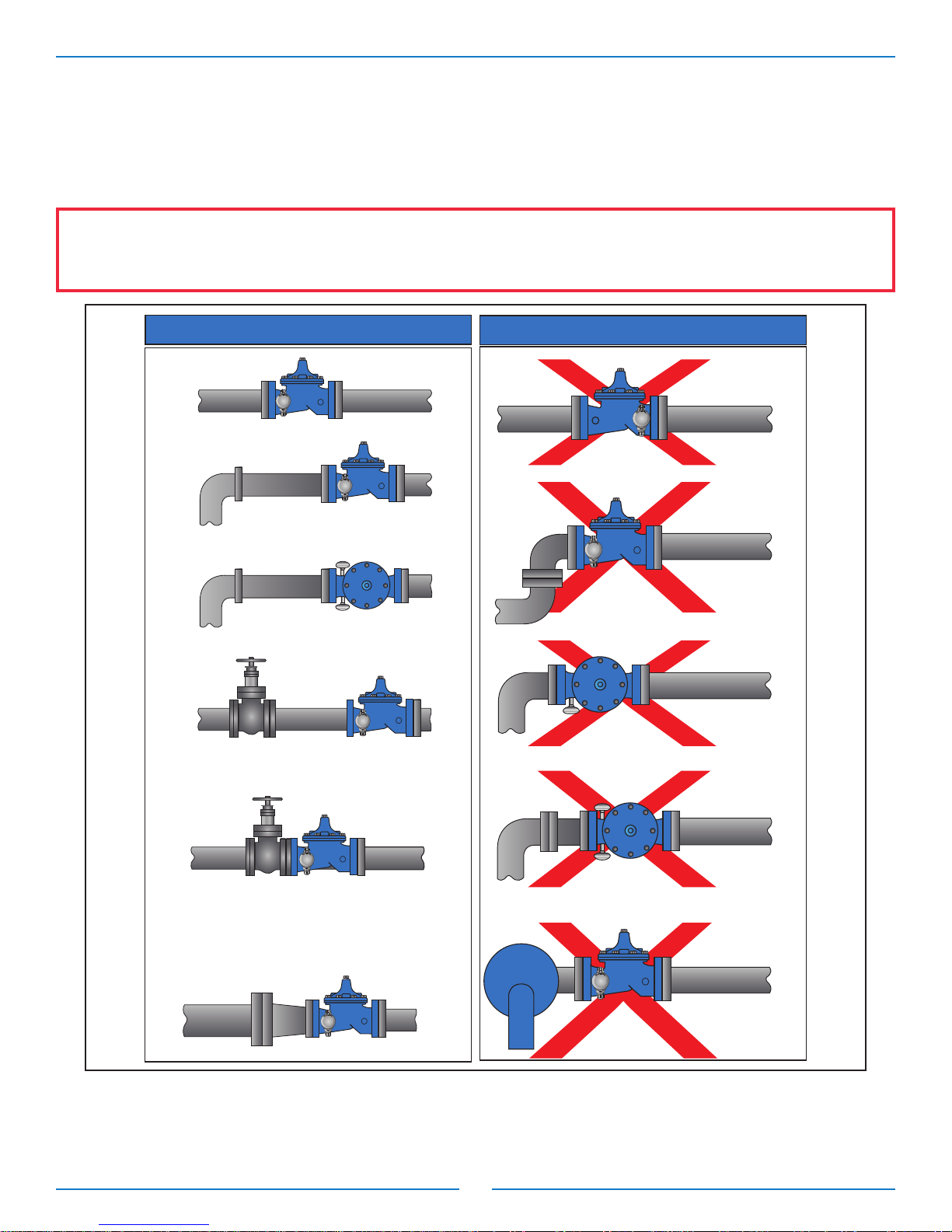

or optimum performance, it is recommended that the valve in which the X144D e- lowMeter is installed be

located as shown in the “Optimum Installations” illustration below, igure 2-1.

CAUT ON: Valves in which X144D e- lowMeters are installed MUST have upstream and downstream

Isolation Valves to ensure that the line is locked out and NOT under pressure during installation, maintenance

or removal of the X144D e- lowMeter.

pump

Unacceptable Installations

CLA-VAL

CLA-VAL

In Outlet Tapping

Downstream of

Double Elbow

Inside of

an Elbow

(top view)

1 to 5 Pipe

Diameters

Outside

or Inside

(top view)

On Discharge

of a Pump

CLA-VAL

pump

Optimum Installations

Downstream

of an Elbow

Pipe Reducer Upstream

> 5 Pipe Diameters

Either Inlet Tapping (top view)

(vertical rise)

CLA-VAL

CLA-VAL

In Inlet Tapping

CLA-VAL

CLA-VAL

Install Isolation Valve (any style) a minimum

of 5 pipe diameters upstream of the control valve

For installation directly onto the inlet flange of the

control valve or where less than 5 pipe diameters

upstream is the only option, an Isolation Valve MUST

be a ful ported, wide open Gate or Sluice style valve.

In this scenario, the Isolation Valve MUST NOT

be a Butterfly style valve.

CLA-VAL

Note: Do not use with 40 Series Rate-of- low Controllers with orifice on inlet

Do not use butterfly valves adjacent to X144D installations

Figure 2-1: nstallation Guidelines

9

Section 2: nstallation of the X144D e-FlowMeter (continued)

2.2 - Materials Required for nstallation

nsertion tool

• Tool allows the proper installation and alignment of the

bluff body to be parallel to upstream flow, ( igure 1-5).

Power Supply

• 6-30 VDC, 0.7 Watts minimum. If more than one piece of equipment will be connected to

this power supply, you must verify that the power supply is large enough to handle all the power needs of

the entire system, not just the X144D e- lowMeter.

• You will also need the appropriate equipment to connect the X144D to each the power supply. See your

local electrical specifications to determine the appropriate wire and connection hardware.

Pipe and Fittings Mounting Hardware

• The X144D connects directly into the control valve on an inlet port and the size of the thread is dependent

on the specific valve size for which it it has been calibrated - no additional fittings are required.

Cabling

• The X144D has 30 feet cable supplied and attached as a factory standard. If additional lengths of cable

are

needed, the connections should be made with #22 AWG or larger cable and may need to be shielded in

some environments where high electrical noise may exist. If using shielded cable, one end of the shielding

should be connected to an earth ground, such as a piping system fitting, etc.

CAUT ON:

• In all cases, installation should be done by qualified mechanical or electrical personnel.

Figure 1-5: Insertion Tool

Log-on to www.cla-val.com

and to learn more about Cla-Val’s

complete line of automatic control valves

10

Section 2: nstallation of the X144D e-FlowMeter (continued)

2.3 - Mounting the X144D e-FlowMeter

Mount the X144D e- lowMeter in a proper orientation as shown in igure 2-2.

NOTE:The X144D e- lowMeter may be installed in inlet tap of either side of the

Cla-Val Automatic Control Valve.

CAUT ON: ailure to install the unit correctly could result in faulty operation and/or damage

to the unit.

Figure 2-2: X144D e-FlowMeter correctly installed in a Cla-Val Control Valve

11

Section 2: nstallation of the X144D e-FlowMeter (continued)

2.4 - Step-by-Step nstructions: Mechanical nstallation

CAUT ON: BE ORE removing pipe plug, make sure that the pressure in the valve has been bled

off to prevent injury to personnel or damage to non-waterproof equipment

1) Isolate valve/pipe from pressure and flow.

2) Remove pipe plug on INLET boss of valve.

3) Remove sensor/head unit from threaded pipe insert

by unscrewing the knurled lock and sliding the sensor

out of the threaded insert ( igure 2-3).

Set aside sensor head, making sure to protect the

sensor tip

4) Apply Teflon®thread tape and/or pipe thread compound to tapered threads on pipe insert,

shown below ( igure 2-4):

5) Straighten the Measurement Cylinder by hand to create a slight angle ( igure 2-5); Tighten the

locking collar on the straight threads of the insert (2); and tighten the thumb

set screw (3); to maintain the slight angle of the Measurement Cylinder.

Figure 2-3

Figure 2-4

Figure 2-5

1 2 3

12

Section 2: nstallation of the X144D e-FlowMeter (continued)

2.4 - Step-by-Step nstructions Mechanical nstallation

6) Screw threaded insert into the inlet tap of the control valve, tighten properly and align so that the

arrow points to downstream flow making sure that the wrench flat with arrow is level with the

valve cover,and the measurement cylinder is facing (parallel to) upstream flow. ( igure 2-6).

7) Measurement Cylinder Swivel Procedure

a) Position of Threaded Insert + Insertion Tool, just prior to installation into valve, ( igure 2-7).

b) Slide Insertion Tool straight out, then insert the opposite side flat tipped end into the

threaded insert.

c) Insert tool, flat tipped end first, making sure to feel for the Insertion Tool to engage the

measurement cylinder, then push straight into the insert until the tool seats, which puts

the measurement cylinder to roughly 90° to the sleeve of the threaded insert (see igure 2-8).

d) It may help to wiggle the tool slightly while pushing firmly.

Figure 2-6

Figure 2-7

Please note that the flat with the engraved arrow must be positioned so that arrow

is in line with the flow direction. Failure to do so will result in inaccurate readings.

13

Section 2: nstallation of the X144D e-FlowMeter (continued)

2.4 - Step-by-Step nstructions Mechanical nstallation

8) Once the measurement cylinder rotates, remove the tool lock then use the score marks on

the Insertion Tool to verify measurement cylinder is locked in 90° orientation, ensure that

the tool seated to appropriate ½” or ¾” score marks, ( igure 2-9).

9) Insert sensor into threaded pipe insert. Ensure that the centering pin is aligned

with the centering groove on the threaded insert, ( igure 2-10). Push firmly to

seat the o-ring.

Figure 2-9

Figure 2-10

pressure

Measurement

Cylinder swivels

to proper

position

Figure 2-8

replace this

photo with one

showing pin &

groove

14

Section 2: nstallation of the X144D e-FlowMeter (continued)

2.4 - Step-by-Step nstructions Mechanical nstallation

10) Ensure that the e- lowMeter is properly seated and tight using the knurled lock, hand tight only,

( igure 2-11). Tighten M3 Allen set screw to lock orientation of head.

Figure 2-11

Log onto www.cla-val.com

and click on the X144D e-FlowMeter icon to

learn more

CAUT ON: If the e- lowMeter is not properly seated, it will not hold pressure and will leak. To avoid

potential damage from water leaking at the tap, be sure that the e- lowMeter is tight and

seated.

15

Section 2: nstallation of the X144D e-FlowMeter (continued)

2.5 - Step-By-Step nstructions: Wiring Diagrams

X144D

e-Flow Meter

Required:

6 - 30 VDC,

Power Supply

Optional:

Pulse

grey

pink

red

blue

Pulse Output

Circuit Wiring

white

brown

4-20mA Loop

Power

Circuit Wiring

Optional:

4-20mA signal is passive.

Must be powered by 6-30 VDC

power supply/battery.

Figure 2-12:

X144D e-FlowMeter Wiring Overview

16

Section 2: nstallation of the X144D e-FlowMeter (continued)

2.5 - Step-by-Step nstructions: Wiring Diagrams

1) Connect V+ and V- wires to 6-30 VDC power source

2) Connect the wires marked 4-20mA (+/-) to the proper recording/measurement device. Connect device

per manufacturer’s recommendations.

3) If possible, use handheld multi-meter to verify mA readings prior to leaving installation.

a) When there is no flow present, the X144D e- lowMeter should read very close to 4.0 mA.

Note: AC/DC converters must be properly grounded in order to prevent electronic noise.

6-30 VDC

white wire

4-20mA

brown wire

4-20mA signal is passive.

Must be powered by 6-30 VDC

power supply/battery.

Note: When connecting 4-20mA

circuit, place all reading/ logging

equipment (if any) in series

X144D e-FlowMeter™

SCADA

System

Key: accessory equipment not supplied with e-FlowMeter

red

blue

grey

pink

white

brown

6 - 30 VDC

Power Supply/Battery

Figure 2-13: X144D e-FlowMeter

using 4-20mA Output

17

Section 2: nstallation of the X144D e-FlowMeter (continued)

2.5 - Step-by-Step nstructions: Wiring Diagrams

1) Connect V+ and V- wires to 6-30 VDC power source

2) Connect the wires marked pulse (+/-) to the proper recording/measurement device. Connect device per

manufacturer’s recommendations.

Note: AC/DC converters must be properly grounded in order to prevent electronic noise.

X144D e-FlowMeter™

Key: accessory equipment not supplied with e-FlowMeter

red

blue

grey

pink

white

brown

6 - 30 VDC

Power Supply/Battery

SCADA

System

Figure 2-14: X144D e-FlowMeter

using Pulse Output

18

Section 2: nstallation of the X144D e-FlowMeter (continued)

2.6 - Wiring nstallation

Power

Connections

4-20mA

Connections

Red

6-30 VDC

Blue

0 VDC

DIP

Switch 2

ON

White

PO1

Brown

AI2+

4-

Figure 2-15:

Wiring Diagram: X144D e-FlowMeter

with VC-22D Controller (4-20mA Output)

Power

Connections

Pulse

Connections

Red

6-30 VDC

Blue

0 VDC

Pink

0V

Gray

DI1

Figure 2-16:

Wiring Diagram: X144D e-FlowMeter

with VC-22D Controller (Pulse Output)

19

SECT ON 3: X144D e-FlowMeter Operation

3.1 – Startup Checklist

ollow this procedure when starting the installation for the first time or after shutting the system down for

maintenance of the Control Valve.

1) Check all connections to power supply and other User Devices (data loggers, telemetry, etc.)

2) Ensure all wiring is properly connected per wiring diagrams.

3) Open shut-off valves and allow water into the system.

4) Check the system for water leaks, at both the tapered threads, as well as the straight threads

with knurled lock.

5) Check surrounding piping and auxiliary equipment for leaks.

6) Verify X144D is configured to correct valve size.

7) Verify mA scaling between X144D and PLC/display match. (per table 1):

Table1: X144D e-FlowMeter Analog Range (4-20mA Scaling)

Log onto www.cla-val.com

and click on the X144D e-FlowMeter

icon to learn more

*2" X144D e- lowMeter may be installed on new valves only

Note: Consult actory for Angle Pattern Applications

Port Style Line Size

inches (mm)

**2"

(50)

(100-49

Body)

2-1/2"

(65)

3"

(80)

4"

(100)

6"

(150)

8"

(200)

10"

(250)

12"

(300)

14"

(350)

16"

(400)

18"

(450)

20"

(500)

24"

(600)

30"

(750)

Full Port

Valves

4mA = 0

(GPM -

l/s)

20mA Range

(GPM) 260 375 575 1000 2250 3900 6000 8750 10500 14000 17500 22000 31000 52000

20mA Range

(l/s) 16.4 23.7 36.3 63.1 142 246 379 552 663 883 1104 1388 1956 3281

Full Port

Pulse

Weight*

Gal/Pulse 1 1 1 1 1 1 1 2 2 3 3 4 6 9

l/Pulse 0.63 0.63 0.63 0.63 0.63 0.63 0.63 0.13 0.13 0.19 0.19 0.25 0.38 0.57

Reduced

Port

Valves

4mA = 0

(GPM-

l/s)

20mA Range

(GPM)

not available

675 1600 2900 4500 5650 7750 9350

Consult Factory

20mA Range

(l/s) 42.5 101 183 284 356 489 590

Reduced

Port

Valves

Pulse

Weight*

Gal/Pulse 1 1 1 1 1 2 2

l/Pulse 0.63 0.63 0.63 0.63 0.63 0.13 0.13

20

SECT ON 3: X144D e-FlowMeter Operation

3.2 – Shutdown/Removal of X144D e-FlowMeter

1) Close the shut-off valves to stop the flow of water, bleed pressure.

2) Disconnect all wiring.

3) ollow the steps below to remove the X144D e- lowMeter

from the Control Valve.

a) Unscrew knurled lock and remove the sensor from the

threaded insert and set aside, making sure to protect the sensor tip.

b) Orient the Insertion Tool so that the bevel is facing downstream, away from the centering groove,

and insert into the threaded insert.

c) The tool will engage the top face of the measurement cylinder and force it to the 45° position,

as shown below.

CAUT ON 1: ailure to use

the provided Insertion Tool

W LL result in damage to

the e- lowMeter

CAUT ON2: To avoid injury,

isolate the valve and bleed

pressure prior to removing

the e- lowMeter

remove

insert and apply light force

Figure 3-1

Figure 3-2

Figure 3-3

Other manuals for X144D e-FlowMeter

2

Table of contents

Other CLA-VAL Measuring Instrument manuals