INDELAC CONTROLS NEMA 4 Instruction manual

Electric Fail-Safe Device

Battery Backup System

Installation, Operation & Maintenance

Manual

For Use with:

115vac & 230vac Units

5 Amp, 7 Amp, 10 Amp, 15 Amp & 30 Amp

TELEPHONE: +1-859-727-7890

TOLL FREE: +1-800-662-9424

FAX: +1-859-727-4070

SHIPPING ADDRESS: 6810 POWERLINE DR.-FLORENCE, KY. 41042

For a digital copy of this manual, access to training videos, access to 3D product renderings,

or to request additional support

VISIT OUR WEBSITE AT WWW.INDELAC.COM

REVISED: SEPT 2021

Electric Fail-Safe Device Installation, Operation & Maintenance Manual

Page 2

INTRODUCTION:

Thank you for selecting Indelac Controls, Inc. (ICI) for your UPS / Battery Backup System needs. We at ICI are

proud of our products and feel confident they will meet or exceed your expectations of quality and reliability.

Every precaution has been taken to insure that your equipment will arrive undamaged; however, accidents do

occur. Therefore, the first thing you must do upon receipt of your package is to inspect it for damage. If the

box is damaged there is a possibility that the equipment inside the box may be damaged as well. If this is the

case YOU MUST FILE A CLAIM with the delivering CARRIER. All shipments are F.O.B. our factory and it is

YOUR RESPONSIBILITY to file a claim for damages.

NOTE: ICI’S ELECTRIC FAIL-SAFE DEVICE MAY BE USED WITH OTHER BRANDS

OF ELECTRIC ACTUATORS - ACTUATOR TERMINAL CONNECTIONS WILL NOT

BE THE SAME. CONTACT SALES TO VERFY APPLICATION FIT.

STORAGE:

If the Fail-Safe Device is scheduled for installation at a later date:

1. Store off the floor protect with unsealed cover allowing for side and bottom ventilation. In the

event that the unit is going to be stored where there is insufficient temperature control internal

heaters must be installed and energized to protect the unit from condensation and extreme

temperature variations.

2. Store in a climate controlled building.

3. Store in a clean and dry area.

4. See the Maintenance Section in this Manual for Proper Care of the Battery.

FOR FUTURE REFERENCE RECORD:

1. Fail-Safe model number

2. Fail-Safe enclosure type NEMA 4_____, NEMA 4X_____, NEMA 7_____.

3. Fail-Safe output Voltage

4. Fail-Safe serial number

5. Date of installation Put into operation

Electric Fail-Safe Device Installation, Operation & Maintenance Manual

Page 3

TABLE OF CONTENTS:

PRODUCT DESCRIPTION: 4

UNIT SPECIFICATIONS: 5

WIRE SIZING AND LENGTHS: 5

CUSTOMER ELECTRICAL CONNECTIONS &WIRING DIAGRAMS: 6

SET-UP AND OPERATION: 16

BATTERY RUN TIMES: 18

MAINTENANCE: 18

BATTERY MAINTENANCE LOG: 19

FUSES &DESCRIPTION: 20

FAIL SAFE PART NUMBER CHART &SPECIFICATIONS: 21

SPARE PARTS: 22

NEMA 7ENCLOSURES: 22

MANUAL REVISIONS: 23

TROUBLESHOOTING: 24

Electric Fail-Safe Device Installation, Operation & Maintenance Manual

Page 4

PRODUCT DESCRIPTION:

The Indelac Controls Electric Fail-Safe Device provides battery backup power to your actuator in the

unlikely event that the Factory or Facility Mains Power should go down. These devices are designed to

seamlessly convert 12vdc, 24vdc or 36vdc battery standby power to 115vac or 230vac to power your

actuator. The battery power supplies an internal Power Inverter that converts the DC to AC to run the

actuator to the user wired Fail Position when the Mains Power fails. When normal Mains Power is present,

it powers the actuator and provides a maintenance charge to the backup battery. When the Mains Power

fails or drops out momentarily, the Power Inverter will automatically switch over to battery power and

supply a PWM sine wave AC to the actuator. When the Mains Power comes back online, the Power

Inverter will immediately transfer Mains Power back to the actuator and proceed to re-charge and maintain

the battery.

The Electric Fail-Safe Devices come in a variety of styles and sizes to fit the smallest to largest of

actuators. Indelac provides these Devices in NEMA 4, NEMA 4X or NEMA 7 enclosures to provide 5, 7,

10, 15 or 30 Amps of output power. Each Fail-Safe Device is designed to supply the actuator’s continuous

Full Load Ampere draw to drive the Actuator to the Fail-Safe position. The Power Inverter can also supply

the additional current required for start-up / Locked Rotor Ampere Torque for up to the initial 1-2 second

turn on.

The internal Power Inverter has a built in 3 Stage Battery Charger for the on-board Sealed Lead Acid

Battery. Depending on the size & age of the battery used in each Fail-Safe Device, battery charge time

can vary from hours to overnight for a full charge.

Optional features, such as Emergency Disconnect Switches, Internal Heaters and Internal Relays to run

more than 1 actuator to Fail Position may be ordered –Consult the Factory for available SPECIAL

Options.

5 Amp NEMA 4X Version Shown

Electric Fail-Safe Device Installation, Operation & Maintenance Manual

Page 5

UNIT SPECIFICATIONS:

Enclosure rating: NEMA 4; NEMA 4X & NEMA 7

Operating Voltages: 115vac or 230vac

Fail-Safe Device Fuses: See the Maintenance Section for Fuse Values

Light Indicators: Green = Power; Yellow = Battery; Red = Mains ON

Battery: 12vdc or 2/3-12vdc (24vdc & 36vdc for 230vac units)

ALL OTHER SPECIFICATIONS ARE DEPENDENT ON THE STYLE AND CURRENT OUTPUT OF THE

FAIL-SAFE DEVICE. SEE THE STANDARD PART NUMBER SPECIFICATION CHART.

WIRE SIZING AND LENGTHS:

Indelac recommends the Installer follow the wire gauge chart shown below when connecting the Fail-Safe

Device to the actuator. The Fail-Safe Device should be mounted at the shortest distance possible to the

actuator to assure best possible performance. Indelac DOES NOT recommend that the Fail-Safe Device

be mounted any further than 100 feet from the actuator.

Fail-Safe Device

18

16

14

12

10

Amperage

MAXIMUM Distance in Feet From Fail-Safe

5 Amp

100

100

-

-

-

7 Amp

50

100

100

-

-

10 Amp

-

50

100

100

-

15 Amp

-

-

50

100

100

30 Amp

-

-

-

50

50

WARNING!

WIRING MUST CONFORM TO ALL STATE AND LOCAL ELECTRICAL WIRING CODES.

THIS DEVICE SHOULD BE INSTALLED BY A LICENSED ELECTRICIAN.

IMPROPER POWER CONNECTION CAN RESULT IN DAMAGE TO THE COMPONENTS OR SERIOUS

INJURY TO THE INSTALLER.

VERIFY THAT ALL WIRES ARE DE-ENERGIZED BEFORE MAKING ELECTRICAL CONNECTIONS!

WIRE GAUGE

NOTE: For all wiring, make sure the connectors and wires are fully seated after making all wiring

Connections and Screw Terminals are tight!

Electric Fail-Safe Device Installation, Operation & Maintenance Manual

Page 6

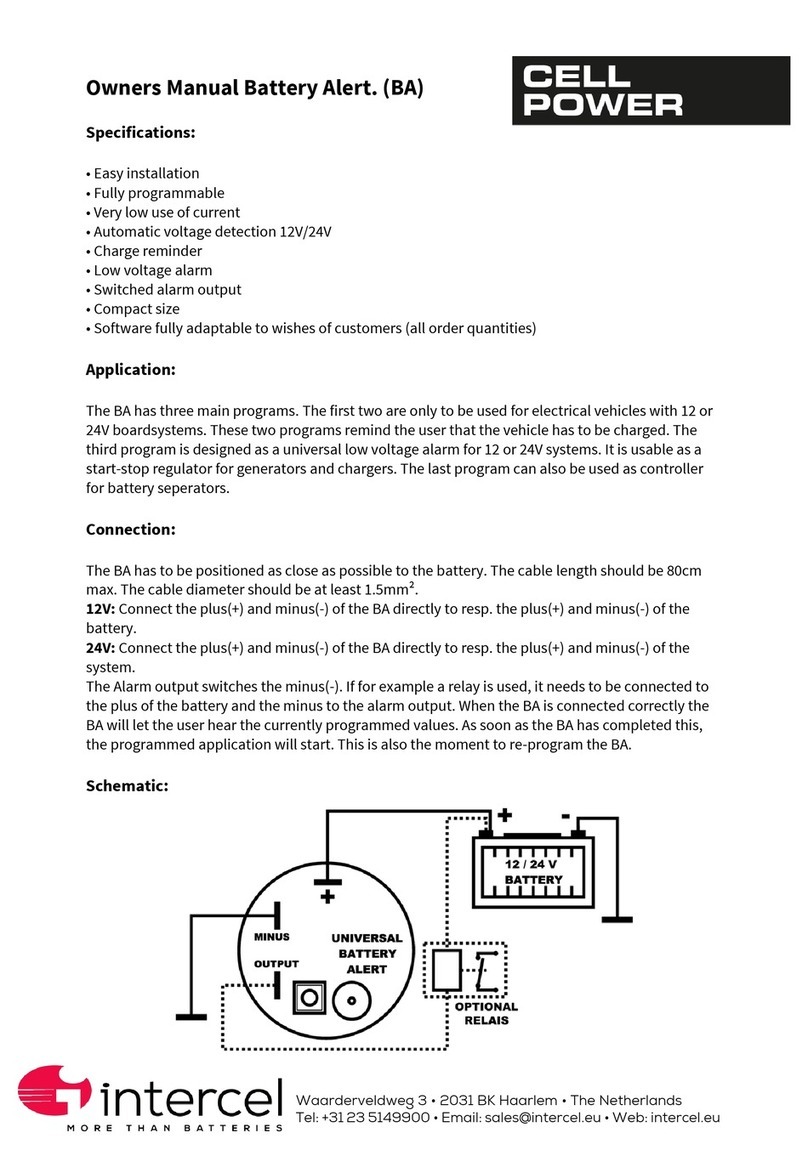

ELECTRICAL CONNECTIONS & WIRING DIAGRAMS:

All wiring is to be completed through the conduit openings using the appropriate conduit –Refer to your

local electrical codes. Open the Fail-Safe Device door by turning the latch counter-clockwise using a flat

head screwdriver. To Open the Door on the NEMA 7 enclosure, ALL of the outer Door bolts need to be

removed before Opening at the hinge. Connect the Main Power to the Fail-Safe Device & connect the Fail-

Safe Device to the actuator per the appropriate wiring diagram below. Assure that the power wires are DE-

ENERGIZED!

Mount the Fail-Safe Device to a solid surface using the appropriate hardware. These units are heavy and

using hardware that is not appropriate or too small may cause the Fail-Safe Device to separate from its

mounting and become damaged. See the Part Number Specifications Section for dimensions and weights.

NOTE: Two (2) conduit openings are supplied in the cabinet housing of the Fail-Safe Device.

One opening is for the incoming AC power wires and the other is for the Outgoing Power wires

to the actuator. All wires are to be securely tightened into the Customer Connections Terminal

Block.

5 Amp NEMA 4X Version Shown, Internal Connections View

CAUTION: Make sure that the wires are DE-ENERGIZED BEFORE making any electrical

connections. Serious damage to the components or serious injury/death may occur.

Also verify that the proper voltage and wiring is being connected to the Fail-Safe Device and

matches the required input of BOTH the Device and the Actuator.

Customer Connections

Terminal Block

Electric Fail-Safe Device Installation, Operation & Maintenance Manual

Page 7

5AMP 120VAC FAIL-SAFE DEVICE WIRING/CONNECTION DIAGRAM

Wiring diagram shows the Actuator wired for FAIL CLOSE –the Fail Terminal #7 is wired to the CLOSE Terminal on the

Actuator. When the incoming Mains Power Fails or is shut OFF, Terminal #7 will be energized HOT to drive the

Actuator to the CLOSE Position. This Terminal #7 may also be connected to the OPEN Terminal on the Actuator to

drive the Actuator OPEN when power fails.

Electric Fail-Safe Device Installation, Operation & Maintenance Manual

Page 8

7AMP 120VAC FAIL-SAFE DEVICE WIRING/CONNECTION DIAGRAM

Wiring diagram shows the Actuator wired for FAIL CLOSE –the Fail Terminal #7 is wired to the CLOSE Terminal on the

Actuator. When the incoming Mains Power Fails or is shut OFF, Terminal #7 will be energized HOT to drive the

Actuator to the CLOSE Position. This Terminal #7 may also be connected to the OPEN Terminal on the Actuator to

drive the Actuator OPEN when power fails.

Electric Fail-Safe Device Installation, Operation & Maintenance Manual

Page 9

10 AMP 120VAC FAIL-SAFE DEVICE WIRING/CONNECTION DIAGRAM

Wiring diagram shows the Actuator wired for FAIL CLOSE –the Fail Terminal #7 is wired to the CLOSE Terminal on the

Actuator. When the incoming Mains Power Fails or is shut OFF, Terminal #7 will be energized HOT to drive the

Actuator to the CLOSE Position. This Terminal #7 may also be connected to the OPEN Terminal on the Actuator to

drive the Actuator OPEN when power fails.

Electric Fail-Safe Device Installation, Operation & Maintenance Manual

Page 10

15 AMP 120VAC FAIL-SAFE DEVICE WIRING/CONNECTION DIAGRAM

Wiring diagram shows the Actuator wired for FAIL CLOSE –the Fail Terminal #7 is wired to the CLOSE Terminal on the

Actuator. When the incoming Mains Power Fails or is shut OFF, Terminal #7 will be energized HOT to drive the

Actuator to the CLOSE Position. This Terminal #7 may also be connected to the OPEN Terminal on the Actuator to

drive the Actuator OPEN when power fails.

Electric Fail-Safe Device Installation, Operation & Maintenance Manual

Page 11

30 AMP 120VAC FAIL-SAFE DEVICE WIRING/CONNECTION DIAGRAM

Wiring diagram shows the Actuator wired for FAIL CLOSE –the Fail Terminal #7 is wired to the CLOSE Terminal on the

Actuator. When the incoming Mains Power Fails or is shut OFF, Terminal #7 will be energized HOT to drive the

Actuator to the CLOSE Position. This Terminal #7 may also be connected to the OPEN Terminal on the Actuator to

drive the Actuator OPEN when power fails.

Electric Fail-Safe Device Installation, Operation & Maintenance Manual

Page 12

5AMP 230VAC FAIL-SAFE DEVICE WIRING/CONNECTION DIAGRAM

Wiring diagram shows the Actuator wired for FAIL CLOSE –the Fail Terminal #7 is wired to the CLOSE Terminal on the

Actuator. When the incoming Mains Power Fails or is shut OFF, Terminal #7 will be energized HOT to drive the

Actuator to the CLOSE Position. This Terminal #7 may also be connected to the OPEN Terminal on the Actuator to

drive the Actuator OPEN when power fails.

Electric Fail-Safe Device Installation, Operation & Maintenance Manual

Page 13

7AMP 230VAC FAIL-SAFE DEVICE WIRING/CONNECTION DIAGRAM

Wiring diagram shows the Actuator wired for FAIL CLOSE –the Fail Terminal #7 is wired to the CLOSE Terminal on the

Actuator. When the incoming Mains Power Fails or is shut OFF, Terminal #7 will be energized HOT to drive the

Actuator to the CLOSE Position. This Terminal #7 may also be connected to the OPEN Terminal on the Actuator to

drive the Actuator OPEN when power fails.

Electric Fail-Safe Device Installation, Operation & Maintenance Manual

Page 14

10 AMP 230VAC FAIL-SAFE DEVICE WIRING/CONNECTION DIAGRAM

Wiring diagram shows the Actuator wired for FAIL CLOSE –the Fail Terminal #7 is wired to the CLOSE Terminal on the

Actuator. When the incoming Mains Power Fails or is shut OFF, Terminal #7 will be energized HOT to drive the

Actuator to the CLOSE Position. This Terminal #7 may also be connected to the OPEN Terminal on the Actuator to

drive the Actuator OPEN when power fails.

Electric Fail-Safe Device Installation, Operation & Maintenance Manual

Page 15

15 AMP 230VAC FAIL-SAFE DEVICE WIRING/CONNECTION DIAGRAM

Wiring diagram shows the Actuator wired for FAIL CLOSE –the Fail Terminal #7 is wired to the CLOSE Terminal on the

Actuator. When the incoming Mains Power Fails or is shut OFF, Terminal #7 will be energized HOT to drive the

Actuator to the CLOSE Position. This Terminal #7 may also be connected to the OPEN Terminal on the Actuator to

drive the Actuator OPEN when power fails.

Electric Fail-Safe Device Installation, Operation & Maintenance Manual

Page 16

FAIL-SAFE SET-UP & OPERATION:

SET-UP:

When the Fail-Safe Device is mounted and all wiring has been completed to the proper wiring diagram, the

final Set-Up steps can be completed. The Fail-Safe unit is internally wired and ready to be enabled.

1) If the front panel door to the Fail-Safe Device is not open, open it using a flat head screwdriver to

unlock the door latch. On the NEMA 7 Device, you will need to remove ALL of the outer door bolts

to open the door!

2) Check all wiring connections again and verify that all wiring and terminals are tight.

3) Enable the Power Inverter by switching the slide switch on the rear of the unit to the

“AUTO/REMOTE” or Left position. This will involve sliding the switch towards the battery Status

LEDs.

5 Amp Rear Panel View 7 –30 Amp Rear Panel View

4) Once the Power Inverter is in the “AUTO” mode, the Inverter will turn ON and the battery will

power the Inverter to supply 120vac to the Output Terminal Block. CAUTION: Depending on the

position of the Actuator when the set-up was completed, it may start to move.

5) Apply Incoming Mains Power to the Fail-Safe Device and turn ON the front panel Power Switch.

CAUTION: This will apply Mains Power to the Actuator and depending on the position of the

Actuator, it may move again.

6) When the Front Door Power Switch is turned ON, the Front Door Power Switch should illuminate

Red, the Green POWER Light should turn ON to indicate that the Fail-Safe Device is Enabled.

7) Close and Latch (or Bolt) the Front Door securely Closed.

CAUTION: WHEN ENABLING THE POWER INVERTER AND APPLYING

MAINS POWER TO THE FAIL-SAFE DEVICE, LIVE VOLTAGE IS PRESENT!

TAKE GREAT CARE NOT TO TOUCH THE POWER TERMINAS - SERIOUS

INJURY OR DEATH MAY OCCUR!

Electric Fail-Safe Device Installation, Operation & Maintenance Manual

Page 17

OPERATION:

When the Fail-Safe Device is in the Normal Mode, the Red Front Door Power Switch will be illuminated

Red and the Green POWER Light will be ON for the NEMA 4 & NEMA 4X. On the NEMA 7 Version,

there will NOT be a Red Light on the ON/OFF Switch. If the Green POWER Light turns OFF, there is a

blown output fuse and the actuator will not run.

NEMA 4 & 4X NEMA 7

The Fail-Safe Device is designed so that when the Mains Power Fails, or the Front Door Power Switch is

turned OFF, the Red Power Switch Light and Green POWER Light will turn OFF and the Yellow

BATTERY Light will turn ON. This indicates to the User that the Fail-Safe Device is running on Battery

Power and should deliver Power to the User selected Fail Terminal on the Actuator and the Actuator will

drive to that position. This power transfer takes only milliseconds and happens automatically without any

User interface.

When the Mains Power returns, the Fail-Safe Device will automatically switch the Battery power OFF and

enable Mains Power back to the Actuator. When this happens, the Yellow BATTERY Light will turn OFF

and the Green POWER Light and Red Switch Light will both turn back ON. At this time, the battery will

be re-charged by the internal battery charger.

If the Green POWER Light does NOT turn ON, but the Mains Power has been checked and is good to the

Fail-Safe Device, it is possible that the internal Output Fuse has blown. See the Maintenance Section for

how to check this fuse.

If the Mains Power has shut down and the Yellow BATTERY Light does not come ON and there is NO AC

Power to the Actuator, the internal Battery Fuse or Output Fuse may have blown or the Power Inverter was

damaged. See the Maintenance Section for how to check these devices.

POWER

Light

BATTERY

Light

ON/OFF

Switch

Electric Fail-Safe Device Installation, Operation & Maintenance Manual

Page 18

BATTERY RUN TIMES:

Each of the Fail-Safe Devices has a minimal run time depending on the load and charge of the battery.

These Devices are calculated to have a continuous battery run time of 8 to 12 minutes under full capacity

load. For example, a 5 Amp Device will run under battery power for 9 minutes under a 5 Amp continuous

load draw. Therefore, if the load draw is less than the Device’s current rating, the battery run time will be

longer. The Fail-Safe Device is designed to run the Actuator to the wired FAIL position and hold there until

Mains Power comes back ON. All of the Indelac Actuators will complete an OPEN or CLOSE cycle in less

than the 8 to 12 minutes under full load with a fully charged battery.

If longer battery run times are required, contact Indelac Controls for special order Fail-Safe Designs.

MAINTENANCE:

After proper installation, the Fail-Safe Device requires no actual maintenance. This unit should operate for

4-5 years on the original battery as long as the Mains Power is applied and the power is ON to maintain the

internal battery charger. However, we do recommend a periodic battery check to assure that the battery is

retaining a charge. This can be accomplished by checking the battery LED indicators on the back panel of

the Power Inverter (see diagrams in Set-Up Section). The left-most column of LEDs gives the charge status

of the battery/battery pack. If the Green Battery Charge LED is lit, battery charge is at FULL. If the

Yellow, Red or NO LEDs are lit, the battery is less than 70-80% and should be charged or replaced.

Internal View of 5A Fail-Safe Device Shown

(Other Output Current Models will vary)

Power

Inverter

Battery

Connection

Terminal

Block

Battery Fuse

(Larger)

Output Fuse

(Smaller)

Power Inverter

LED Location

Electric Fail-Safe Device Installation, Operation & Maintenance Manual

Page 19

The following chart has been provided to log the periodic maintenance battery checks:

Battery Status LEDs

Date

Checked By:

Green

Yellow

Red

The Fail-Safe Device can be stored for 4-6 months in the “no load” condition before the battery will need to

be recharged. If these Units are stored longer than this before being installed, the customer needs to

implement a program to charge these batteries for 8-10 hours every 4 months. This will maintain the

batteries until installation. If these batteries are NOT maintained, they will be too low or dead and not

operate when installed.

If the Fail-Safe Device is installed and the Power Inverter Selector Switch in AUTO/REMOTE position, the

Mains Power needs to be turned ON to maintain the battery. The internal trickle charger will maintain the

battery for use when needed. If the Mains Power is shut OFF or the Mains Power Breaker has tripped, the

Fail-Safe will be operating under battery power an illuminates the Front Door Yellow Light. This will drain

the battery more quickly.

To charge a low battery, slide the Power Inverter Selector Switch to CHARGE position and make sure the

Mains Power and Front Door Power Switch is ON. Once the battery charge measures below 6-7vdc, it may

not take a charge due to internal cell damage. Even if the battery does take a charge, it may be unreliable

and SHOULD be REPLACED!

BATTERY MAINTENANCE LOG

ATTENTION: IF THE BATTERY IS NOT PROPERLY MAINTAINED,

THE BATTERY WILL BE TOO LOW TO DRIVE THE ACTUATOR TO

THE FAIL POSITION WHEN NEEDED!

Electric Fail-Safe Device Installation, Operation & Maintenance Manual

Page 20

OUTPUT FUSE (smaller fuse):

When the Green POWER Light on the Front Door of the Fail-Safe Device does NOT turn ON when the

Mains Power is active, the Output Fuse may be blown. This fuse value varies depending on the Output

Current Model of Fail-Safe Device you have. All of these fuses are Slow Blow Cartridge Fuses rated for

250VAC.

1) Remove ALL power from the Fail-Safe Device and remove the fuse from the holder.

2) Using an Electrical Meter, check the continuity of the fuse.

3) If it is blown, replace with the proper fuse value as listed in the chart below.

4) Turn the Mains Power back on and check to see if the Front Door Green Light is ON.

5) If the Green Light is still not ON, there may be a problem with the Power Inverter and the unit will

need to be returned to Indelac for Service.

Current Model

5 Amp

7 Amp

10 Amp

15 Amp

30 Amp

Output Fuse Value

5

8

10

15

30

Fuse Size

5x20mm

5x20mm

5x20mm

5x20mm

1 ¼”

Indelac Part Number

46044

46043

46039

46059

46081

BATTERY FUSE (larger fuse):

When the Yellow BATTERY Light on the Front Door of the Fail-Safe Device does NOT turn ON when the

Battery Power is active, the Battery Fuse may be blown. This fuse value varies depending on the Output

Current Model of Fail-Safe Device you have. All of these fuses are Slow Blow Large Cartridge Fuses rated

for 32VDC.

1) Remove ALL power from the Fail-Safe Device and remove the fuse from the holder.

2) Using an Electrical Meter, check the continuity of the fuse.

3) If it is blown, replace with the proper fuse value as listed in the chart below.

4) Turn the Inverter Power back on and check to see if the Front Door Yellow Light is ON.

5) If the Yellow Light is still not ON, there may be a problem with the Power Inverter or Battery and

the unit will need to be returned to Indelac for Service.

Current Model

5 Amp

7 Amp

10 Amp

15 Amp

30 Amp

Battery Fuse Value

125

225

225

400

225

Indelac Part Number

46077

46078

46078

46067

46078

Other manuals for NEMA 4

1

This manual suits for next models

2

Table of contents

Other INDELAC CONTROLS Camera Accessories manuals