Arcadia Fault Codes (Simple)

2/3

- If status type pressure switch, check component directly;

- Check efficiency of connector contacts on PCB;

- Check pressure switch wiring;

- Check continuity of pump on connector pins 4and 5(in case

of classic door lock), ensuring that impedance value is 170 Ω

+/- 10%;

- Check the wiring of pins 4and 5(/pump;

- Check pump filter, drain hose and wall drain outlet;

Reset the appliance with the OFF button, also after Fault resetting

with plug. Check the appliance pressure switches reaches full

without Faults at the next cycle;

- Replace the drain pump;

- Replace the linear pressure switch;

- Replace the main PCB.

- Check for water leaks that may affect connectors J004 (collector)

or J11 (three-phase) causing the relative contacts to short;

- Check the door lock terminal board (possible problems due to

aggression caused by manufacturing chemical residues that

may cause short circuits);

- Check J004/door lock wiring;

- Replace door lock;

- Replace PCB.

- Check efficiency of contacts on connector J001(commutator) or

J10 (three-phase) on PCB;

- Check continuity of wash heating element on connectors

J001(Commutator) or J10 (Three-phase), pins 3and 4. The

1700W 230V heating element impedance value is 30 Ohm

+/- 10%. If value is different renew wash heating element;

- Renew PCB.

- Check efficiency of contacts on connector J001(commutator) or

J10 (three-phase) on PCB;

- Check leakage between the two ends and ground, impedance

should be at least 2 MOhm;

- Renew heating element;

- Renew PCB.

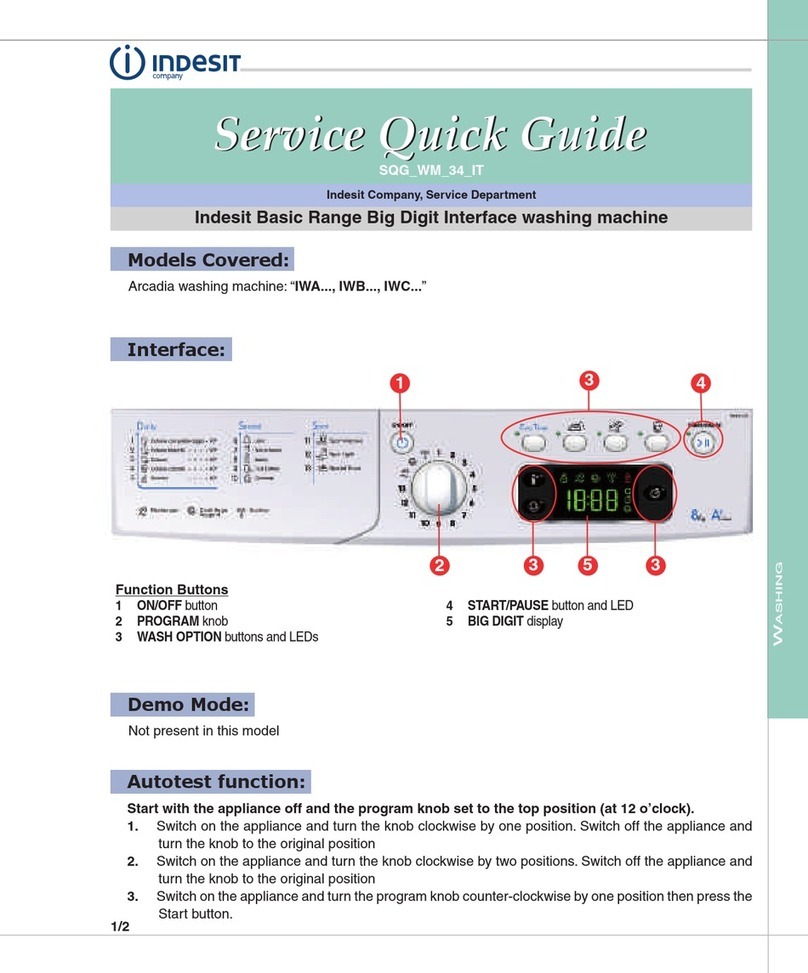

- Disconnect appliance for 2 minutes. Check that correct operation

has been restored by starting the Autotest routine;

- Reprogram Main PCB;

- Renew main PCB;

- Renew display PCB.

- Check efficiency of contacts on connector J004 (commutator)

or J11 (three-phase) on PCB;

- Check continuity on connector J004 (commutator) or J11 (three-

phase), pins 4and 5(in the case of classic door lock);

- Check continuity of pump, ensuring that impedance value is 170

Ohm +/- 10%;

- Check wiring of connector J004 (commutator) or J11 (three-

phase)/pump;

- Renew pump;

- Renew PCB.

- Check efficiency of contacts on connector J010 (Commutator)

or J16 (Three-phase) on main PCB;

- Check efficiency of contacts on Display PCB;

- Check continuity of J010 (Commutator) or J16 (Three-phase)/

Display PCB wiring;

- Disconnect appliance, wait for 2 minutes and reconnect to power

supply, then start autotest routine;

If problem persists proceed as follows:

- Renew main PCB;

- Renew display PCB.

Setting File error detected by Main PCB

or Display PCB

F09

Communication error between Main PCB

and Display PCB

F12

F08

Door lock fails to close/open, door lock

PTC triac open/closed, mains frequency

signal fault, mains power signal fault

Wash heating element relay open/diverter

relay sticking on drain pump side

Wash heating element relay earth leak-

age/wash heating element relay contacts

sticking

F07

F06

Pressure switch empty condition not

reached (valid for linear and status pres-

sure switch) or drain pump jammed (valid

for linear and status pressure switch)

F05

F11

Pump not wired or pump driving triac

short circuit

FAULT SERVICE ACTIONSCAUSE