Indol 200A++ User manual

Operation & Installation Manual

Operation & Installation Manual

Air source hot water heat pump

Air source hot water heat pump

COMPACT

COMPACT

INDOL

INDOL

Preface

The installer shouldexplain to theuser how tooperate and maintainthe unit accordingto

the manual, whenthe unit isinstalled. Andask the userto read themanual carefully, keep

the manual anddo the operationin strict accordancewith the Manual.

This manual includesall the necessaryinformation about installation,debugging,

discharging and maintenance. Please read thismanual carefully beforeyou open or

maintain the unit.

When install theunit and connectthe pipe, pleasecarry it outstrictly according tothe

manual.

Once finish theinstallation and connection,please make everythingok before poweron the

unit.

The manufacture ofthis product willnot be heldresponsible if someoneis injured orthe unit

is damaged, asa result ofimproper installation, debugging,unnecessary maintenance

which is notin line withthis manual.

It is vitalthat the belowinstructions are adheredto at alltimes to keepthe warranty.

---Maintenance and operation must be carriedout according tothe recommended timeand

frequency, as stated inthis manual.

---Failure to complywith these recommendationswill invalidate thewarranty.

The manual willbe changed ifthere is anyimprovement on theunit, there willnot be

advance notice.

1. Safety Precaution

2. Specs

2.1) Appearance

2.2) Characteristic

2.3) Principle

2.4) Dimensions

2.5) Performance Parameter

3. Function Presentation

4. Installation

4.1) Installation Sketch Map

4.2) Choose the Suitable Unit

4.3) Deposited and Transportation

4.4) Installation Position

4.5) Water Loop Connection

4.6) Wire Connection

4.7) Trial Running

5. Usage

5.1) Icons Introduction

5.2) Operation

5.3) Parameter

6. Maintenance and Repair

6.1) Maintenance

6.2) Trouble Shooting

7.Appendix

7.1) Appendix 1

Content

Content

1

3

3

3

4

5

6

7

8

8

8

9

9

10

12

12

13

13

15

26

27

27

28

28

28

1

1.Safety Precaution

1.The hurt means no need to be in hospital and cure for a long time, it's

injury, burn and get an electric shock.

2.The material lost means property and datum lost.

Concentration

limits

Toprevent the usersand others fromthe unpredictable/unexpected hurtof this unit,and

avoid damage onthe unit orother property, please usethe heat pumpproperly, please read

this manual carefullyand understand thefollowing information correctly.

Safety Precaution

Installation warning

The heat pump must be installed by qualified personnel,

to avoid improper installation which can lead to water

leakage, electrical shock or fire.

Professional installer

is required

Earthing is required

Please make sure that the unit and power connection

have good earthing, otherwise may cause electrical

shock.

When install theunit in a small room, please take some

measures to prevent the asphyxia caused by the leakage

of refrigerant. Pleaseconsult the dealerfor concrete

measures.

Icon

Compulsory implement. The listed action need to be taken.

ATTENTION (include WARNING)

Please pay attention to what is indicated.

Prohibition. What is prohibited will be nearby this icon.

Mark Meaning

A wrongoperation may lead to death or heavy injury on people.

A wrongoperation may lead to hurt on people or loss of

material.

WARNING

ATTENTION

Meaning

2

Installation place

Fix the unit

Need circuit

breaker

The unit CANNOTbe installed nearthe flammable gas.Once there is

any leakage ofthe gas, firecan be occur.

Make sure thatthe basement ofthe heat pumpis strong enough,to

avoid any declineor fall downof the unit.

Make sure thatthere is circuitbreaker for theunit, lack ofcircuit breaker

can lead toelectrical shock orfire.

Prohibition

Entrust

Entrust

Check the install

placement

Prohibit

Shut off the power

Prohibit

Shut off the power

Do not putfingers or othersinto the fans.Children should besupervised

to ensure thatthey do notplay with theappliance.

When there issomething wrong orstrange smell, thepower supply need

to be shutoff to stop the unit.

Operation warning

Move and repair

Prohibition

When the heatpump need tobe moved orinstalled again, please

entrust dealer orqualified person tocarry it out.Improper installation

will lead towater leakage, electricalshock, injury orfire.

It is prohibitedto repair theunit by theuser himself, otherwiseelectrical

shock or firemay be occur.

When the heatpump need tobe repaired, pleaseentrust dealer or

qualified person tocarry it out.Improper movement orrepair on theunit

will lead towater leakage, electricalshock, injury orfire.

Operation attention

The unit mustbe installed indoor, and the ambient temperature must be

over 0¡æ,if do notuse the unitfor a longtime and theenvironment

temperature is below0¡æ, please drainthe water inthe tank toprevent

When do theclean, must stopthe unit andshut off the power, if do not

stop the unit,it will causehurt by thehigh speed runningfan.

Please use thesuitable fuse.

If use copperor iron, itwill cause failure,even the fire.

Forbid spraying theflammable aerosols tothe unit, otherwiseit will cause the fire.

Usage warning

1.Safety precaution

Usage warning

This appliance canbe used by children aged from8 years and above and persons

with reduced physical,sensory or mental capabilities or lackof experience and

knowledge if theyhave been given supervision or instructionconcerning use of the

appliance in asafe way and understand the hazardsinvolved. Children shall not

play with theappliance .Cleaning and user maintenance shallnot be made by

children without supervision.

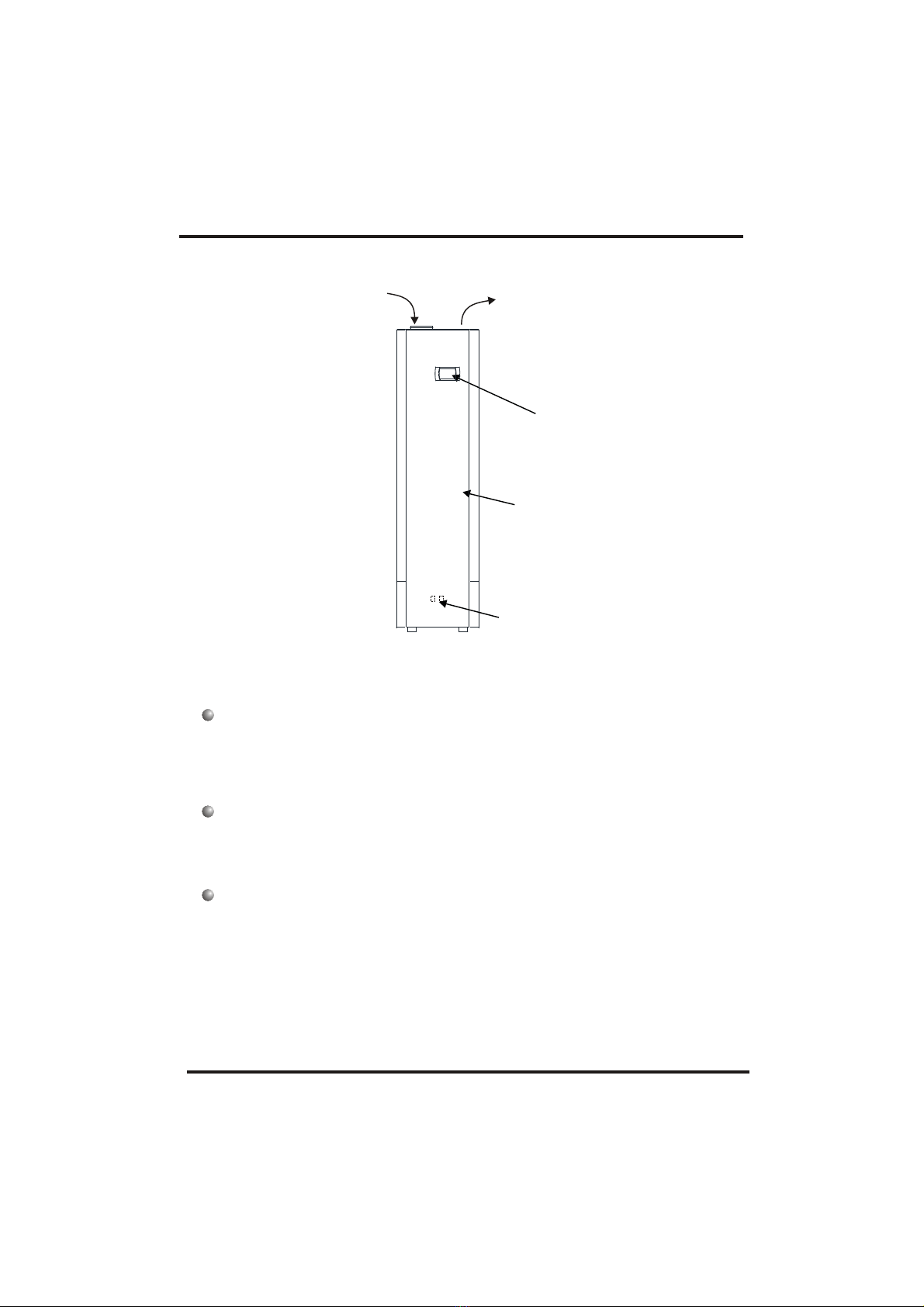

2.1 Appearance

3

2.Specs

good looking and efficient

Attractive design allows the unit to be placed in the open in finished utility spaces and

basements, reducing the cost of remodelling; depending on external condition the cost of

operation can be 25% of that of an electric water heater, and can be used in locations

unsuitable for solar hot water heating.

2.2 Characteristic

easy to operate and multiple heat sources

Contains a timer for start and stop, and an adjustment dial for easy setting of the water

temperature; depending upon the location of the air exchanger , heat may be taken from the

outside environment , from a sun porch or attic space, or from hot areas in light industrial

environments.

environmentally friendly and safer

Produces no harmful gas locally from the combustion of oil, coal, or natural gas; free of

potential hazards from carbon monoxide, it also can avoid electrical contact with water, and

does not provide an open flame, making the device more suitable for installation.

Air inlet Air outlet

Controller

Tank

Compressor

Water connections

2.3 principle

2. Specs

4

1Refrigerant is compressed into vapor with high temperature and high pressure when

it goes through the compressor.

On the discharge side of the compressor, the now hot and highly pressurized vapor

is cooled down through the heat exchange with the water in the tank until it

condenses into a high pressure, moderate temperature liquid.

Then the pressure of the liqiud refrigerant drops as it passes throttling device.

Finally, refrigerant absorbs heat from the surrounding air and evaporates into

vapor with low temperature and low pressure and then it goes into compressor

again.

The cooled surrounding air could be blew to the rooms which needs fresh cooled air.

2

3

4

5

System Principle:

Air from

outside

Hot water

Low temp.

Compressor

Compressor

Compressor

Throttling

device

Water supply

Tank

Air

exchanger Water

exchanger

High temp.

A

B

D

C

Removeable knocking down hole (when

you need to use this hole, as soon as the

center of the round is knocked, the hole

will be opened) 3 on the left and right

sides and 1 at the back, 7 in total.

5

2.Specs

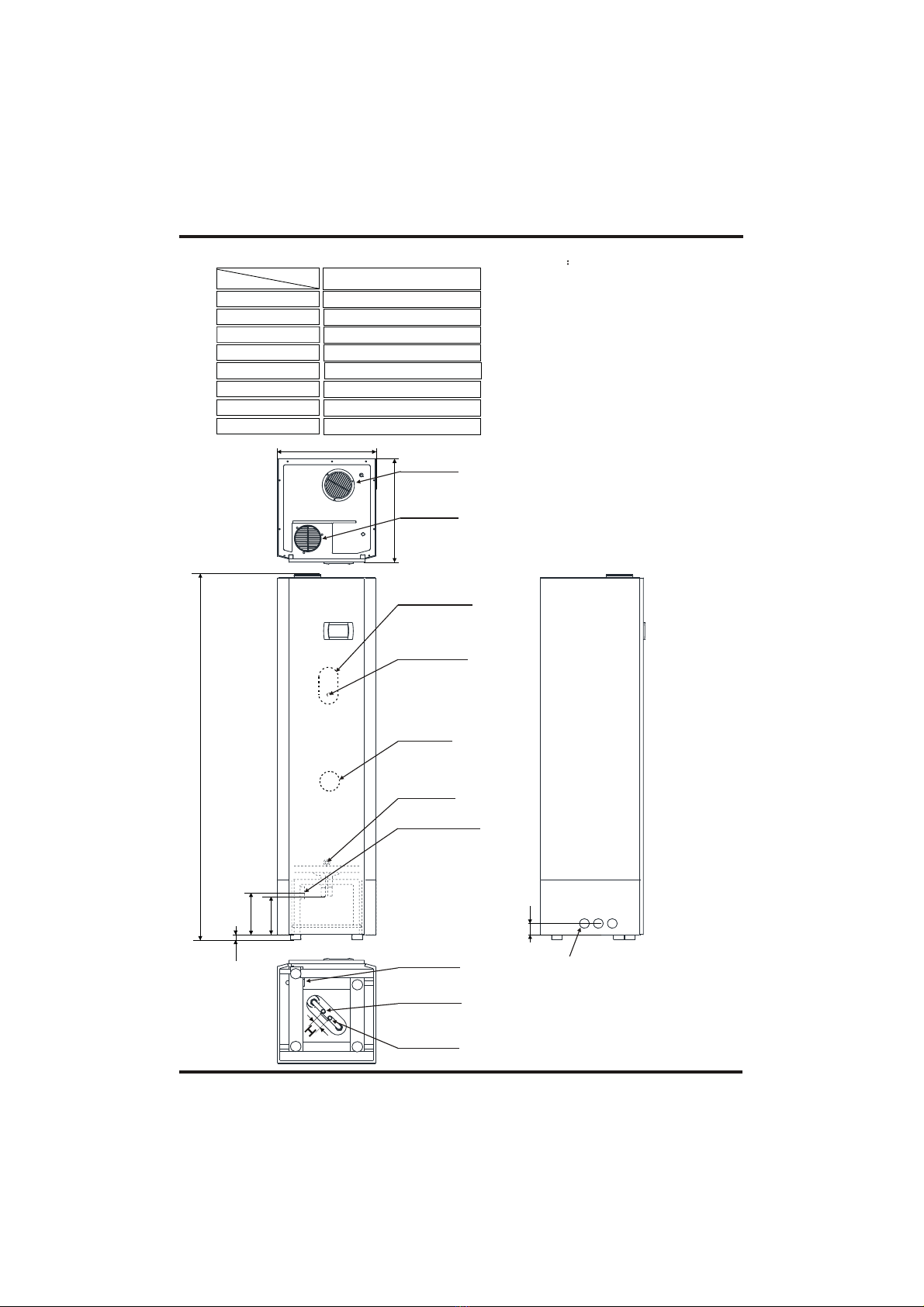

2.4 Dimensions Unit mm

DimentionModel Indol Compact 200A++

C

B

Condensation

water outlet

A

Overheating

protector

Eletricity

heater

Drainage

E

F

D

G

Condensation

water outlet

Hot water

outlet

Cold water

inlet

2100

566

590

30

230

240

65

55

A

B

C

D

E

F

G

H

Magnesium

anode

Air outlet

Air inlet

6

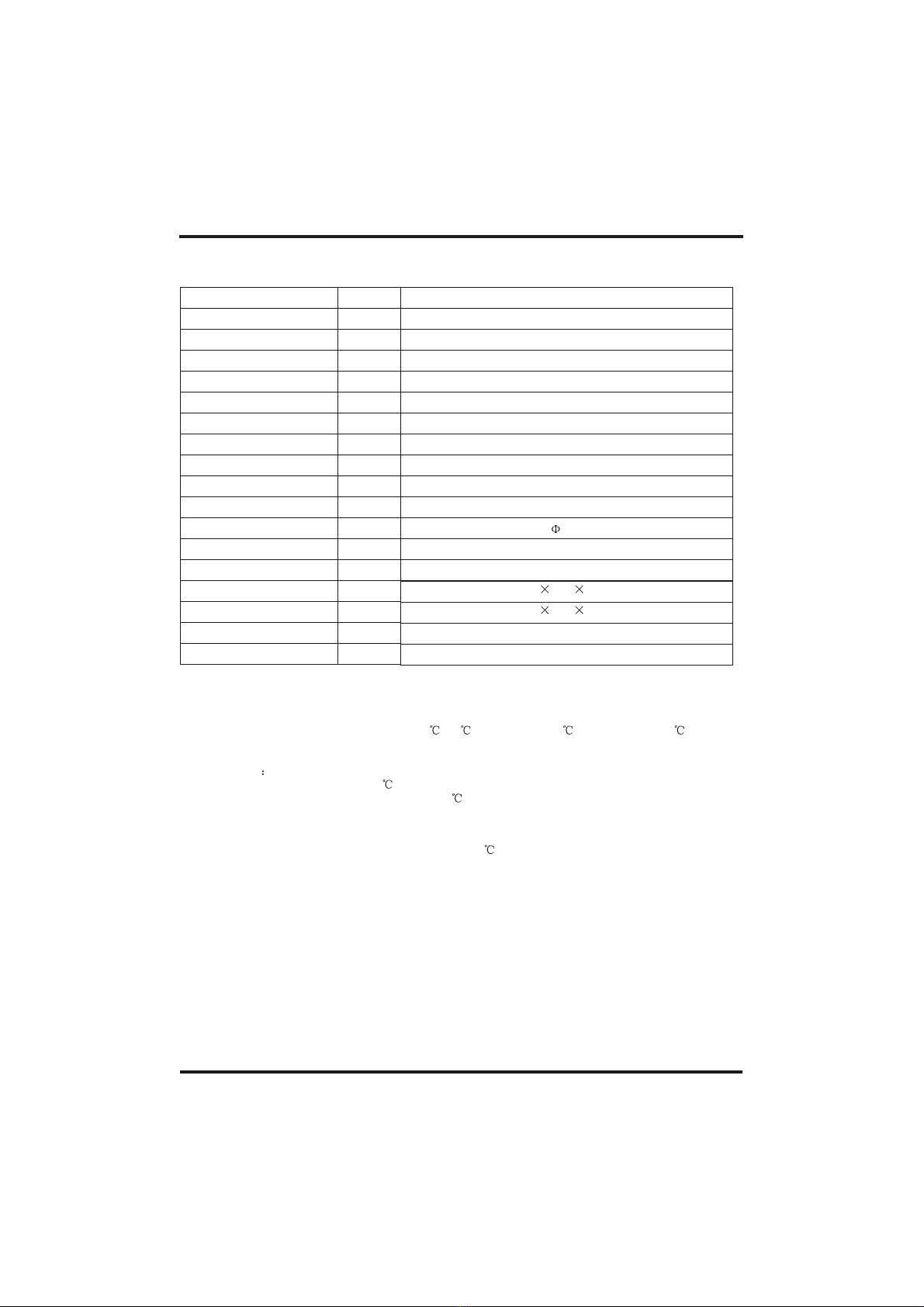

2.5 Performance Parameter

Work range

(1) Ambienttemperature is 0-40

(2) The max temperature ofwater tank is 60

Measurement conditions:

Instant heating:Ambient temperature15 /13 ,Water inlet 15 , Water outlet.45

Operating parameters

The range of the operating water temperatures: 9~60

The range of the operating water pressures: 0.15~0.7MPa

Model

Heating capacity

Water tank capacity

Power input

Running current

Power supply

Compressor Number

Compressor

Rated outlet waterTemp.

Air volume

Air pressure

Duct diameter

Water inlet/outlet size

*Auxiliary E-heater

Net dimensions

Shipping dimensions

Net weight

Shipping weight

kW

L

kW

A

¡æ

m3/h

Pa

mm

inch

kW

mm

mm

kg

kg

566 590 2100

640 680 2100

126

142

2.Specs

Indol Compact 200A++

1.8

200

0.46

2.0

1

rotary

55

350

40

150

3/4

1.5

230V~/50Hz

7

3.Function Presentation

1.Function Presentation

The unit absorbsenergy from outsideand releases the heat according to the heat

exchanger, ifthe environment temperatureis low, the heating capacity will be

attenuation.

Heating capacity

3 minutes protection

When the unitstop, if yourestart the unit or turn on the manual switch, the unit will not run

in 3 minutes,it's the protectionfor the compressor.

Defrosting

Under the heatingmode, the unitwill defrost automatic to make sure the heating

efficiency (it will last 2-10minutes).

Working condition

In order touse the unitcorrectly, please run the unit at environment temperature 0-40 .

The unit includessophisticated electronic devices,prohibited to use water from lake,

untreated river waterand groundwater!

Power off

If the powersupply is off, the unitwill stop running.If the running unit is disturbed by

lightening, car radio,power grid fluctuationsplease cut off the manualpower switch , and

then power on,press the on/ off button.

Water pressure protection

In the water system will be installed the Pressure release valve.When the tank pressure reach

0.7MPa,The Pressure release valve to open sluice

Keep power on

Always ensure thatthe unit ispowered on, you can turn off the unit, but can not power

off. If you want topower off the unit, must drain out the water in the tank.

8

4. Installation

4.1 Installation Sketch Map

Air inlet

160mm pipe

Drainage

Cold water inlet

Manual

valve

Air outlet

Condensation

water outlet

Hot water outlet

NOTE! Asafety valve MUST be installed onwater inlet!

9

4.Installation

4.2 Choose the Suitable Unit

Notice: The choice is justfor reference, pleasechoose the unitaccording to native

environment and custom.

4.3 Deposited and Transportation

As arule, the unitis to be stored and/or transported in its shipping container in upright

position and withoutwater charge. Fora transport over short distance, and provided due

care is exercised,an inclination angleof up to 30 degree is permitted. Both during

transport and storage, ambient temperatures of0 to +43 are permissible.

4.4.1 Transport using a forklift

When transported bya fork lift,the unit must remain mounted on the pallet. The lifting

rate should bekept to aminimum. Due to its top-heaviness, the unit must be secured

against tipping over. To prevent any damage, the unit must be placedon a levelsurface!

4.4.2 Manual transport

For the manualtransport, the woodenpallet can be used for bottom part. Using ropes or

carrying straps, asecond or thirdhandling configuration is possible. With this type of

handling, care mustbe taken thatthe max. Permissible inclination angle of 60 degree is

not exceeded. Iftransport in aninclined position cannot be avoided, the unit should be

taken into operationone hour afterit has been moved into final position.

CAUTION High center ofgravity, low overturning moment!

60

10

4.Installation

4.5 Installation Position

(1) Waste heat is useful heat (see picture below)

The standard heat exchanger ofthe hot-water heatpump enables directconnection to a

second heat generator, e.g. a solar heating system or a boiler.

(2) Dehumidification in the recirculating air mode (see picture below)

Dehumidified air inthe laundry roomsupports laundry drying and prevents moisture-

induced damage.

11

4.Installation

(3) Cooling in the recirculating air mode (see picture below)

The room air is extractedfrom the storage room or a wine cellar, subsequently cooled and

dehumidified in theheat pump andfinally re-introduced into the room. Recreation rooms,

boiler rooms orutility rooms areideal installation sites. The air ducts leading through warm

sections must beinsulated to preventthe formation of condensation.

1. Choose theright path tomove the unit;

2. Tryto move theunit as original case;

3. If theunit installed inthe building of the metal part, it must work for electrical

insulation and complywith the relevanttechnical standards of electrical equipment.

4.The unit doesnot include anyduct pipe, the customer also can install the duct pipe

during the installationif needed.

(4) variable change over of intake air (see picture below)

Aduct system withintegrated bypass flaps allows for variable utilization of the heat

contained in theoutside air orroom air for the production of hot water.

Installation attentions

12

4.Installation

4.5 Water Loop Connection

4.6 Wire Connection

4.7 TrialRunning

Pay attention tothese points whenconnect the water loop pipe:

Try to reduce the water loop resistance

There is wireat the bottomof the unit, it's for power supply of the unit. The spec of the wire

2

is 1.5mm .

4.8.1 Inspection beforetrial running

4.8.2 Trialrunning

The water maydrip from thedischarge pipe ofthe pressure-relief device and that this pipe

must be leftopen to theatmosphere.

Make sure thereis nothing inthe pipe andthe water loop is smooth, check the pipe

carefully to seeif there isany leak, thenpack the pipe with the insulation.

Install the oneway valve andsafety valve inthe water circulation system. The one way

valve is tobe operated regularlyto remove limedeposits and to verify that it is not blocked.

The nominal pipewidths of thefield-installed sanitary installationsmust be selectedon the

basis of theavailable water pressureand the expectedpressure drop within the piping

system. The water-side installation hasto be executedin compliance withDIN 1988(in

case of excessivewater pipe pressure,a pressure reliefvalve is to be provided!)

The water pipesmay be ofthe rigid offlexible type to prevent corrosion damage.

When installing thepipework on thecustomer's site, anycontamination of the piping

system must beavoided(pipes may haveto be flushed prior to theconnection of theunit).

There must bea switch whenconnect the unitto power system.

If the supplycord is damaged,it must be replaced by the manufacturer or our service

agent or similarlyqualified person inorder to avoida hazard.

Check the waterin the tankand the waterpipe connection.

Check the powersystem£ºmake sure the power supply isnormal and thewire connection is

Check the unit: make sure everything is ok before power on the unit, check the light on the

wire controller whenthe unit runs.

Use the wirecontroller to startthe unit;

Listen to theunit carefully whenpower on the unit, power off the unit at once when you

heard deviant noise;

Measure the water temp. to check the undulation of the water temp.;

When the parameterhas been set,the user can't change the parameter optionally, ask for

professional person tochange the parameter.

13

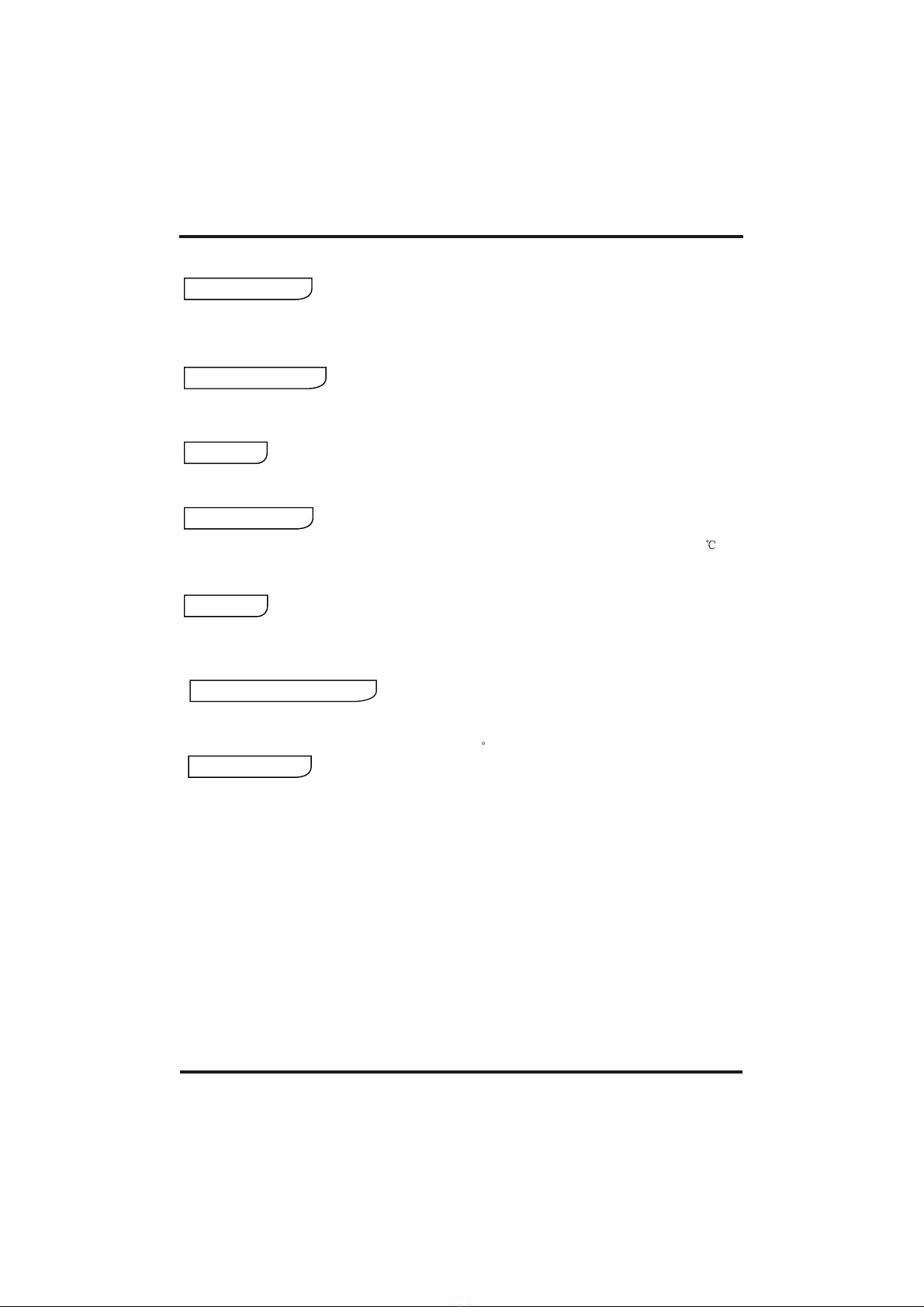

5. Usage

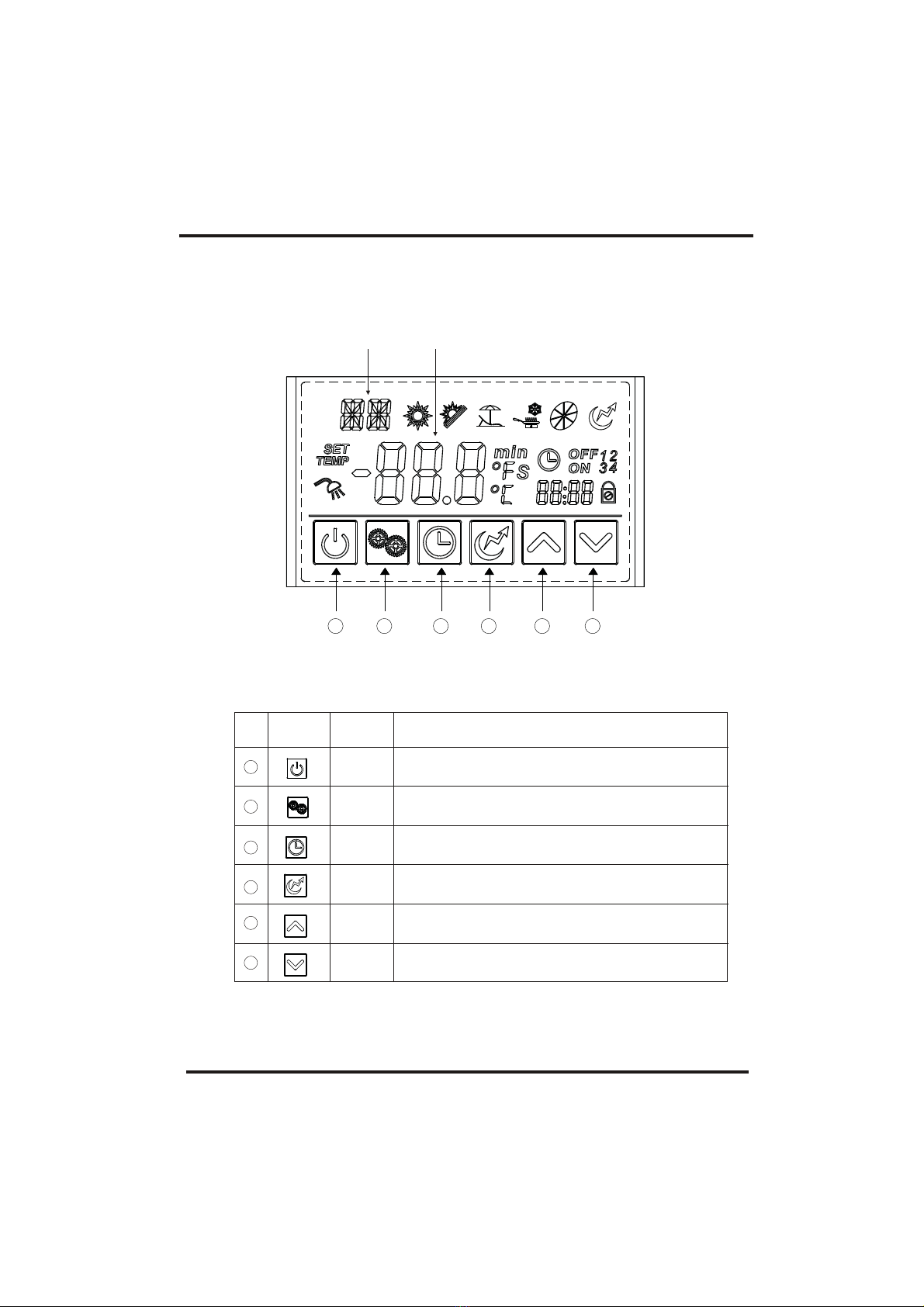

5.1 The function diagram of the wire controller

1.Function of wire controller

1£©Function ofkey

NO. Button Name Function

1

2

3

4

5

6

ON/OFF

Mode

Electric

Heater

Up

Down

Turn on/offthe unit.

Switch unit runningmodes or savesetting parameters.

Set the clockor the timer.

Turn on/offthe electric heateror switch fanmodes.

Move up orincrease parameter values.

Move down ordecrease parameter values.

Clock

Main display

area

Auxiliary display

area

1 2 3 4 5 6

14

5. Usage

Electric

heater

Fan

Shows that theelectric heater ison.

Shows that thefan is onand the speed of the fan.

Set temperature

achieved

Shows that thewater temperature hasreached the target

point and theunit shut off automatically.

Timer & ON

Timer & OFF Shows that theunit will beturned off by the timer

automatically.

Shows that theunit will beturned on by the timer

automatically.

Minute Shows that themain display areadisplays the minute.

Second Shows that themain display areadisplays the second.

Centigrade Shows that thetemperature in Maindisplay area or Auxiliary

display area isin .

Fahrenheit Shows that thetemperature in Maindisplay area or Auxiliary

display area isin .

Lock Shows that thekeyboard is locked.

Status

icon What it means

Heating

Vacation

Shows that theunit is inheating mode.

Heatpump+Electric heater

Shows that theunit is invacation mode.

ECO heating

Temperature Shows that thetemperature is non-adjustable

(measured value).

Name

Shows that theunit is inECO mode.

Heatpump only(saves mostenergy)

heating

5. Usage

15

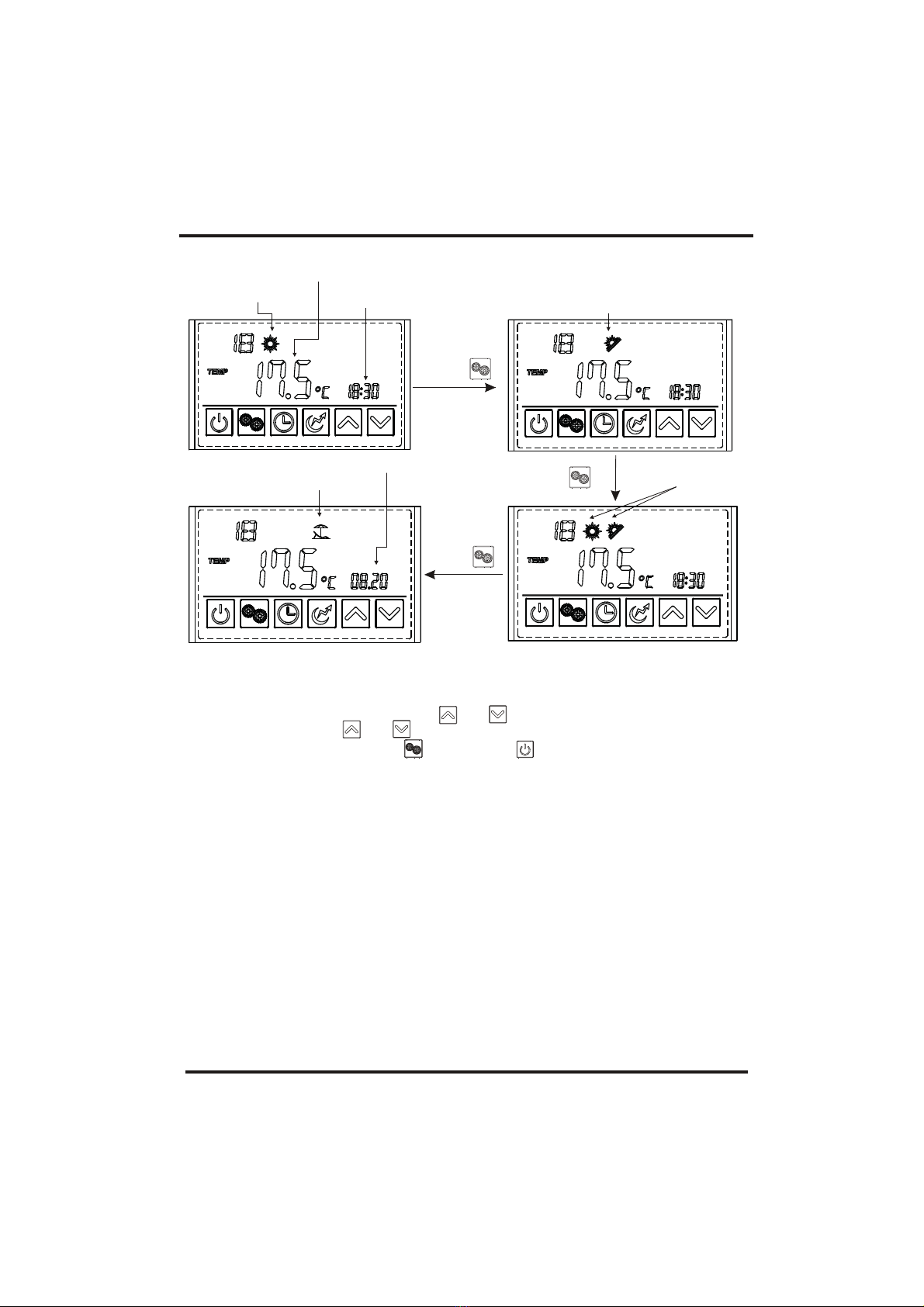

2.Usage of wire controller

Outlet water temperature

Press " " and hold for0.5s.

Inlet water

temperature

Heating mode

Standby interface

2.2 Mode selection

Press " " to select the mode from Heating ,Eco.heating , , Vacation in the

standby or runninginterface.

For example:

Intelligent

Running interface

2.1 TurnON/OFF the unit

Press " " and hold for 0.5s in the standby interface of the wire controllerto turn onthe

unit and atthis time themain display area shows the water outlet temperature.

Press " "and hold for 0.5s in the running interface of the wire controllerto turn off the

unit and atthis time themain display area shows OFF.

Note: The ON/OFF button canonly be used to turn on/off the unit in standby or running

interface of thewire controller.

5. Usage

16

Heating mode

Outlet water

temperature

Time

2.3 Target temperature checking and setting

In the standbyor running interface,press " " or " " once to check the target temperature

of the outletwater. Press " " or " " againto change the target temperature. After making

the changes tothe parameter,press " " to confirm or " " to cancel the changes, then

return to theprevious interface. Ifno operations are performed on the keypad for 5s, the

controller exits theparameter modification menuby timeout and the changes are confirmed.

Example: Change thetarget temperature from50 to 55.5 when the actual outlet water

temperature is 18¡æ.

Eco.heating mode

modeIntelligent

Press¡° ¡±

Vacation mode

Date

Press¡° ¡±

Press¡° ¡±

5. Usage

17

Outlet water temperature

Time

Target temperature

Press or again to change

the target temperature.

Press

to confirm

or to

cancel, then

return to the

previous

interface.

Press once

or

to check the

target

temperature.

Time

Press

twice then

press or

to change

the hour

parameter

and press

to confirm.

Press " " or " " to change the minute

parameter.

2.4 Timesetting

In the standbyor running interface, do as follows to set the time when in heating mode. When

press " "once, the timeparameter will flash. When press " " again, thehour parameter

will flash thenpress " "or " "to change it.After making the changes to the parameter,

press" " toconfirm, then changethe minute parameter as well as the date parameter in the

same way.

If no operationsare performed onthe keypad for 10s, the controller exits the parameter

modification menu bytimeout and thechanges are confirmed.

Note: Set the datein the sameway when in vacation mode.

Example: Change thetime and datefrom 18:30 on August 4th to 17:40 on September 8th.

Other manuals for 200A++

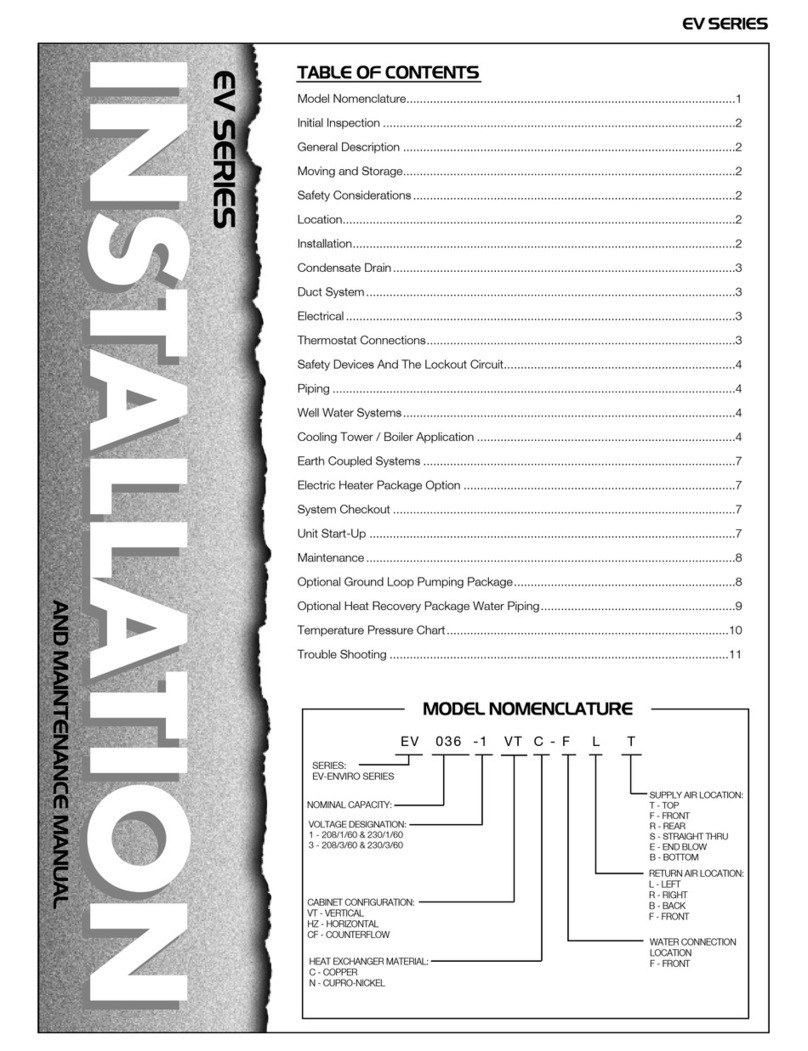

1

Table of contents

Other Indol Heat Pump manuals

Popular Heat Pump manuals by other brands

Carrier

Carrier DHMVHA Service manual

Midea

Midea V4 Plus S Series Technical & service manual

Mitsubishi Electric

Mitsubishi Electric ecodan EHPT series Operation manual for user

FHP

FHP EV Series Installation and maintenance manual

Bosch

Bosch Compress 2000 AWF Installation and operating instructions

Lennox

Lennox ELP Series user manual

Trane

Trane 4TWR3 Installer's guide

Carrier

Carrier Comfort 25HCR3C Product data

Sanden

Sanden GAUS-160FQS owner's manual

Mitsubishi Electric

Mitsubishi Electric Ecodan Homeowner quick start guide

Daikin

Daikin EHBH04CA3V Operation manual

Mitsubishi Electric

Mitsubishi Electric City Multi PUHY-P168TSJMU-A datasheet