Industrial Data Systems 160 User manual

THE IDS 160 ROLL TAPE PRINTER

Rev. C 03/09/04

Industrial Data Systems Inc. 590 W. Freedom Ave. Orange, CA 92865

WARRANTY INFORMATION

INDUSTRIAL DATA SYSTEMS, INC. LIMITED WARRANTY.

Industrial Data Systems, Inc., warrants that the products furnished are free from defects in material and workmanship and perform to

applicable, published Industrial Data Systems, Inc., specifications for one (1) year from the date of shipment.

THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTY EXPRESSED OR

IMPLIED. IN NO EVENT SHALL INDUSTRIAL DATA SYSTEMS, INC. BE LIABLE

FOR LOSS OF PROFITS, OR INDIRECT, SPECIAL OR CONSEQUENTIAL DAMAGES,

OR FOR OTHER SIMILAR DAMAGES ARISING OUT OF ANY BREACH OF THIS

WARRANTY PROVISION.

The liability of Industrial Data Systems, Inc. shall be limited to repairing or replacing, WITHOUT CHARGE, any defective products

which are F.O.B Industrial Data Systems, Inc. Plant. Equipment or parts which have been subject to abuse, misuse, accident,

alteration, neglect, unauthorized repair or installation are not covered by warranty. Industrial Data Systems, Inc. shall have the right

of final determination as to the existence and cause of defect. As to items repaired or replaced, the warranty shall continue in effect

for the remainder of the warranty period, or for ninety (90) days following date of shipment by Industrial Data Systems, Inc. of the

repaired or replaced product, whichever period is longer. No liability is assumed for expendable items such as lamps and fuses. No

warranty is made with respect to customer equipment or products produced, to Buyer's specifications except as specifically stated in

writing by Industrial Data Systems, Inc. and contained in the contract. In no case is product to be returned without first obtaining

permission and a Customer Return Authorization Number (RMA) from Industrial Data Systems, Inc. Product being returned during

or after the original warranty period should be carefully packed and sent prepaid and insured along with an explanation of the

problem. Customer shall be responsible for all damages resulting from improper packaging or handling, and for loss in transit. If it

is found that Industrial Data Systems, Inc. product has been returned without cause and is still serviceable, customer will be notified

and Product returned at customer's expense. Repairs or replacements made by Industrial Data Systems, Inc. on Products under

warranty will be returned, shipped at NO CHARGE by method of shipment Industrial Data Systems, Inc. deems most advantageous.

EXCEPT AS SPECIFICALLY PROVIDED HEREIN, THERE ARE NO OTHER

WARRANTIES EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE.

TABLE OF CONTENTS

1. INSTALLATION

1.1 UNPACKING THE IDS 160 PRINTER.

1.2 COVER INSTALLATION FOR DUSTY ENVIRONMENTS.

1.3 MAKING THE IDS 160 READY TO PRINT.

2. DESCRIPTION OF THE IDS 160 FUNCTIONS AND CAPABILITIES

2.1 THE IDS 160 CONNECTORS, SWITCHES AND LEDS.

2.2 PRINT FEATURES.

2.3 BATTERY BACKUP FEATURES.

2.4 THE BASIC PRINTER MODE.

2.5 THE SPECIAL APPLICATION MODES.

2.5.1 PRINT WEIGHT ONLY.

2.5.2 PRINT WEIGHTS WITH GROSS, AND TARE LABELS.

2.5.3 GROSS, TARE, NET PRINTING.

2.5.4 PRINT AND TOTAL.

2.5.5 PRINT, SUBTOTAL, AND TOTAL.

2.5.6 PRINT AND TOTAL ( AXLE WEIGH ).

2.5.7 WEIGH-IN, WEIGH-OUT.

2.5.8 AUTO AXLE WEIGH

3. CONFIGURATION OF THE IDS 160

3.1 CONFIGURE SERIAL COMMUNICATIONS PORT.

3.2 CONFIGURE PRINT FEATURES.

3.2.1 AUTOMATIC LINE-FEED AFTER CARRIAGE RETURN.

3.2.2 AUTOMATIC FORM FEED.

3.2.3 AUTOMATIC PRINT WRAP.

3.2.4 BOTTOM MARGIN.

3.2.5 PRINT SIZE (Normal, Enhanced, Mixed).

3.2.6 STATION NUMBER.

3.2.7 ENTER PRINT ONLY HEADING.

3.3 CONFIGURE BATTERY-BACKUP OPTIONS

3.3.1 BATTERY ENABLE.

3.3.2 SET TIME.

3.3.3 SET DATE.

3.3.4 SET TIME AND DATE PRINT FORMAT.

3.3.5 SET SEQUENCE NUMBER.

3.4 CONFIGURATION OF WEIGHING APPLICATION OPTIONS.

3.4.1 SELECT SCALE INTERFACE TYPE

3.4.2 CONFIGURE SCALE UNITS.

3.4.3 CONFIGURE DECIMAL POINT.

3.4.4 CONFIGURE COUNT/PULSE.

3.4.5 CONFIGURE TRIP LEVEL.

3.4.6 CONFIGURE TIMEOUT TIME.

3.4.7 CONFIGURE SETTLE TIME.

3.5 INITIALIZE PRINTER TO FACTORY SETTINGS.

4. MAINTENANCE

4.1 REMOVAL OF DIRT AND STAINS.

4.2 LUBRICATION.

4.3 PRINT RIBBON REPLACEMENT.

5. TESTING AND TROUBLESHOOTING.

APPENDIX I. SERIAL COMMUNICATIONS PORT.

APPENDIX II. CONFIGURATION REFERENCE LIST

APPENDIX III. ASCII CONTROL CODES

APPENDIX IV. ASCII CHART

1.0 INSTALLATION

Installation begins with unpacking the IDS 160. Save packing materials

if the printer is to be re-shipped. Next, the IDS 160 needs to be made

ready to print. Examine the options available in the IDS 160 to

determine the best setup for your application.

1.1 UNPACKING THE IDS 160 PRINTER.

Remove the printer from the shipping container and verify all items

listed below are included.

Install printer ribbon.

PACKING LIST CHECK OFF

IDS 160 PRINTER ______

PRINTER MANUAL ______

POWER LINE CORD ______

MATING CONNECTOR/CABLE ______

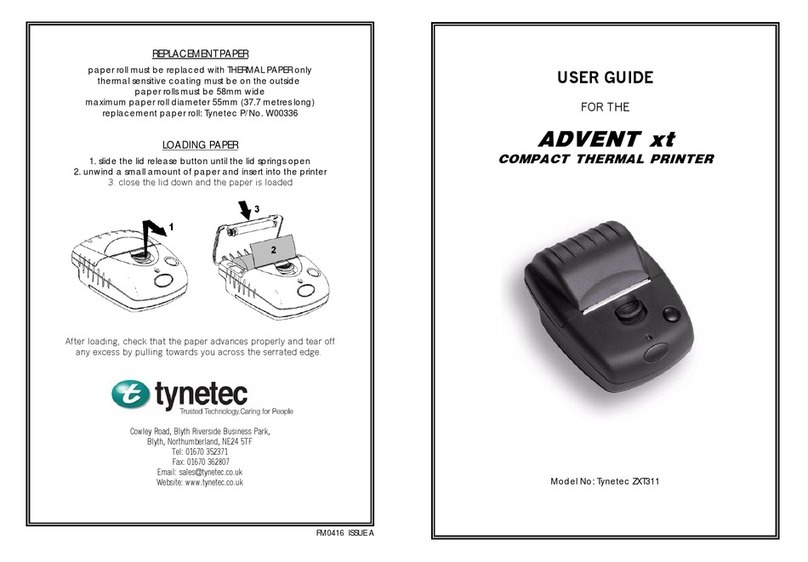

1.2 COVER INSTALLATION FOR DUSTY ENVIRONMENTS.

The cover over the print mechanism can be set in two positions. It is

set at the factory for paper to exit out of the top. For dusty

environments the access hole can be covered. Remove the two screws

which secure the hinged cover and reposition the cover forward. Use the

take up reel to take up the paper roll inside the cover.

1.3 MAKING THE IDS 160 READY TO PRINT.

1. Set the serial communications parameters (baud rate, data bits, etc.)

See Section 3 for directions.

2. Connect the IDS 160 to the 'host' device via the 25 pin 'D' connector

at the back of the printer.

See Appendix I for communication port wiring information.

3. Connect the IDS 160 to AC power.

CAUTION: To avoid contact with moving parts which could cause injury,

do not open printer cover while unit is in operation.

4. Turn power on. The print head should cycle 1 time.

5. Activate the TEST mode and print the configuration parameters

(Section 6).

6. Reset the printer to normal by turning power off and then back on.

Send data from the 'host' device to the IDS 160.

The IDS 160 is pre-configured at the factory for use as a BASIC 'Slave'

printer. The IDS 160 has a wide range of features that can be activated

as needed. If your application requires something beyond the

capabilities of a BASIC printer then read Section 2. Choose the

functions that you need and then use Section 3 for directions on

activating the functions.

2. DESCRIPTION OF THE IDS 160 FUNCTIONS AND CAPABILITIES

This section is divided into 5 parts:

2.1 THE IDS 160 CONNECTORS, SWITCHES AND LEDS.

The physical characteristics of the IDS 160.

2.2 PRINT FEATURES.

Ticket formatting features.

2.3 BATTERY BACKUP FEATURES.

Ticket numbering and the clock functions.

2.4 THE BASIC PRINTER MODE.

General purpose ticket printer mode.

2.5 THE SPECIAL APPLICATION MODES.

Weighing applications.

2.1 THE IDS 160 CONNECTORS, SWITCHES AND LEDS.

The front of the printer has 3 switches (PRINT, AUX and PAPER FEED) and

2 light emitting diodes (READY and PAPER).

The PRINT switch activates a Print Request signal that can be sent to

the host device. Also an inquire character (ASCII 05) is transmitted

when the PRINT switch is activated.

The AUX switch is used in some of the special application modes.

The PAPER FEED switch advances the paper. Holding the switch in

advances the paper continuously.

The functions of the PRINT and AUX switches will change if any of the

Special Application modes are selected.

The READY light indicates that the printer is ready for receiving print

commands. It turns off when the printer is busy. It FLASHES on and off

when the printer is in the test mode or if an error is detected.

The PAPER light indicates that there is no paper in the printer. It

turns OFF when paper is properly in place.

On the rear of the printer is the Line connector, the DATA I/O

connector, and the Power Switch.

Behind the access panel are a thumbwheel switch, a push button switch

(ENTER SWITCH), and an LED(ENTER LIGHT). The switches are used to

select print features and the printer's mode of operation.

2.2 PRINT FEATURES.

The Print Features are used to customize the print format of the IDS 160

and to match the requirements of the 'host' device.

1. AUTOMATIC LINE-FEED AFTER CARRIAGE RETURN (Default = ON)

The printer inserts a line feed command whenever it receives a carriage

return command. Turn this feature on if your 'host' device does not

send a line feed after a carriage return.

2. AUTOMATIC FORM FEED (Default = ON)

Used by the Special Application modes. A bottom margin command is

issued after each print if auto form feed is on.

3. AUTOMATIC PRINT WRAP (Default = ON)

If more than 26 characters (13 char Enhanced) are printed a line feed is

performed, the overflow data is automatically printed on the next line.

If automatic print wrap is turned off, the overflow data is lost.

4. BOTTOM MARGIN. (Default = 0)

The bottom margin is used to advance the paper from 2 to 18 line feeds

after printing.

5. PRINT SIZES. (Normal, Enhanced, Mixed). (Default = Norm)

The Normal is 12 char/in (typewriter size). The Enhanced print is 6

char/in (double width). The Mixed size prints text in normal size and

numbers in enhanced size.

6. STATION NUMBER (Default = OFF)

The station number is used print a station ID on each ticket. Station

numbers range from 1 to 9.

7. HEADER LABEL. (Default = OFF)

The header label is used to print the company name or other information

on each ticket. The header label is up to 30 characters long.

2.3 THE BATTERY BACKUP FEATURES.

The battery is used for the following functions:

1. TIME AND DATE CLOCK. The battery keeps the clock running when power

is turned off.

2. TICKET NUMBERING. Automatically prints a ticket number on each

transaction. The battery keeps the number in memory when power is

turned off.

3. TOTALS. The battery permits storage of the subtotal and total in

memory when power is turned off.

Configure the BATTERY BACKUP option to ON if any of the battery backup

functions are used.

2.4 THE BASIC PRINTER MODE (SLAVE PRINTER).

The basic printer mode is for general purpose applications. In this

mode the printer prints what is sent. This permits the IDS 160 to be

used with a wide range of devices, including most weigh-meters. The

Basic Mode can be combined with the Print Features for applications that

require more than your average basic printer. The print features are

set with the thumbwheel switch (see section 3.2) or they can be set by

sending control codes (see appendix III).

The Print switch is used to output a data request signal. This is used

to activate data transmission from the 'host'.

2.5 THE SPECIAL APPLICATION MODES.

The special modes are used for weighing applications. They are used in

those cases where the weigh-meter is not capable of producing the

required print data.

The mode options are selected by setting the thumbwheel switch to the

option number. The following is a list of the modes and their option

numbers:

0 BASIC PRINTER MODE (Slave Printer).

1 PRINT WEIGHT ONLY.

2 PRINT WEIGHTS WITH GROSS, AND TARE LABELS.

3 GROSS, TARE, NET PRINTING.

4 PRINT AND TOTAL.

5 PRINT, SUBTOTAL, AND TOTAL.

6 PRINT AND TOTAL ( AXLE WEIGH ).

7 WEIGH-IN, WEIGH-OUT.

8 AUTOMATIC AXLE WEIGHING.

If you use one of the special modes be sure to configure the scale

options:

Section 3.4.1 SELECT SCALE METER TYPE

Section 3.4.2 CONFIGURE SCALE UNITS.

If pulse input is being used then also configure:

Section 3.4.3 DECIMAL POSITION.

Section 3.4.4 COUNT/PULSE FACTOR.

2.5.1 PRINT WEIGHT.

Print the weight on the scale in the form:

WEIGHT 12345 LB

2.5.2 PRINT WEIGHTS WITH GROSS, AND TARE LABELS.

The Print Switch prints the weight on the scale in the form:

GROSS 12345 LB

The Aux Switch prints the weight on the scale in the form:

TARE 2000 LB

2.5.3 GROSS, TARE, NET PRINTING.

This feature provides gross, tare, and net printing in 2 weighments.

The Aux Switch instructs the printer store the weight on the scale into

the tare register. The printer cycles to signal that tare weight is

read.

The Print Switch causes the printer to print the GROSS, TARE, and NET

weights.

2.5.4 PRINT AND TOTAL.

This feature provides a total register for summing weighments.

The Print Switch prints the weight on the scale. The printer adds the

weight to the total register.

The Aux Switch prints the total.

Press the Aux Switch twice within 10 seconds to clear the total

register. The print head will cycle at the end of 10 seconds to signal

that the printer is ready for new commands.

2.5.5 PRINT, SUBTOTAL, AND TOTAL.

This feature provides a subtotal and a total register for summing

weighments.

The Print Switch prints the weight on the scale. The printer adds the

weight to the subtotal and total registers.

The Aux Switch prints the subtotal and clears the subtotal register.

Press the Aux Switch again to print the total.

Press the Aux Switch twice within 10 seconds to clear the total

register.

2.5.6 PRINT AND TOTAL ( AXLE WEIGH ).

This feature is for printing a list of weights with the total at the

end.

The Print Switch prints a sequence number and the weight on the scale.

The printer adds the weight to the total register.

The Aux Switch prints the total.

2.5.7 WEIGH-IN, WEIGH-OUT.

This feature allows a truck (container, etc) to weigh-in either empty or

full, and then weigh-out after filling or unloading.

Pressing the PRINT switch stores the weigh-in weighment, and pressing

AUX switch stores the weight-out weighment and causes the GROSS, TARE

and NET weight to be calculated and printed.

2.5.8 AUTOMATIC AXLE WEIGHING.

Automatic axle weighing allows unattended weighing for short scale

platforms. The program will activate TTL outputs for a red and green

traffic light. The automatic axle program uses a combination of a

weight trip level a timing delay to determine axles weights on the

scale.

The trip level is the weight that each axle must exceed to be a valid

axle. You can configure the trip level to be 500, 1000, 2000 or 5000

(default).

The Time out time the amount of time that needs to elapse before

printing the total weight of the axles.

The Settle time is the amount of time that the scale needs for it to

settle.

The TTL outputs for red and green traffic lights are as follows:

Pin 25 -> Green light -> (Open collector output)

Pin 18 -> Red light -> (Pulled up output)

Pin 6 -> -> (5 volt pull up)

This feature allows the operator to start weighing the axles by pressing

the Print Switch. It provides a list of axle weights with the total at

the end.

The Aux Switch allows the operator to force the operation to end and

totalize the axles.

3. CONFIGURATION OF THE IDS 160

Remove the access panel located on the back of the printer. The 8

position 'dip' switch is used to configure the serial communications

port. The thumbwheel switch and the push-button switches are used to

configure everything else.

The ENTER light provides feedback for the entry process. If there is

paper in the printer, the results of the data entry will be printed

after it is entered.

All data entry functions begin with the ENTER light OFF.

REMEMBER: The printer's personality is determined by the position of

the thumbwheel switch (ie. Dumb printer = mode 0 = thumbwheel switch at

position 0). Return the thumbwheel switch to the correct mode position

after configuration.

Topics Covered In Section 3:

3.1 CONFIGURE SERIAL COMMUNICATIONS PORT.

3.2 CONFIGURE PRINT FEATURES.

3.3 CONFIGURE BATTERY-BACKUP OPTIONS

3.4 CONFIGURATION OF WEIGHING APPLICATION OPTIONS.

3.5 INITIALIZE PRINTER TO FACTORY SETTINGS.

3.1 CONFIGURATION OF SERIAL COMMUNICATIONS PORT.

The baud rate and data format is set by the 8 position 'DIP' switch,

located behind the access panel at the back of the printer.

Select the baud rate and data format from the table below.

Dip Switch 1: on = RS232 Input off = not selected

Dip Switch 2: on = Current Loop Input off = not selected

Dip Switch 3: on = Even Parity off = Odd Parity

Dip Switch 4: on = Disable Parity off = Enable Parity

Dip Switch 5: on = 7 Data Bits off = 8 Data Bits

Dip Switches 6,7,8: Baud Rate Select

Baud Rate sw6 sw7 sw8 NOTE: Some dip

switches use the

300 off off on following labels:

600 off on off CLOSED = on

1200 off on on OPEN = off

2400 on off off

4800 on off on

9600 on on off

3.2 CONFIGURE PRINT FEATURES.

The following list shows how the print features are set at the factory.

3.2.1 AUTO LINE-FEED AFTER CR = ON

3.2.2 AUTO FORM FEED = ON

3.2.3 AUTOMATIC PRINT WRAP = ON

3.2.4 BOTTOM MARGIN = 8

3.2.5 PRINT SIZE = NORMAL

3.2.6 STATION NUMBER = DISABLED

3.2.7 PRINT ONLY HEADING = DISABLED

Use the following sections to change the settings.

3.2.1 CONFIGURATION: AUTOMATIC LINE FEED AFTER CARRIAGE RETURN.

1. Begin with the ENTER light OFF.

2. Turn the thumbwheel switch to position 1.

3. Press the ENTER switch. The ENTER light begins flashing.

4. Turn the thumbwheel switch to position 1.

5. Press the ENTER switch. The ENTER light turns on.

6. Turn the thumbwheel switch to position:

0 for AUTO LF --- OFF

1 for AUTO LF --- ON

7. Press the ENTER switch. The ENTER light turns off.

---------- SET AUTO LF AFTER CARRIAGE RETURN ---------

FLASH ON OFF (Enter Light)

Auto lf OFF 1 1 0 (Thumbwheel Switch)

Auto lf ON 1 1 1 (Thumbwheel Switch)

3.2.2 CONFIGURATION: AUTOMATIC FORM FEED.

1. Begin with the ENTER light OFF.

2. Turn the thumbwheel switch to position 1.

3. Press the ENTER switch. The ENTER light begins flashing.

4. Turn the thumbwheel switch to position 2.

5. Press the ENTER switch. The ENTER light turns on.

6. Turn the thumbwheel switch to position:

0 for AUTO FORM FEED --- OFF

1 for AUTO FORM FEED --- ON

7. Press the ENTER switch. The ENTER light turns off.

--------------- SET AUTO FORM FEED ---------------

FLASH ON OFF (Enter Light)

Auto Form Feed OFF 1 3 0 (Thumbwheel Switch)

Auto Form Feed ON 1 3 1 (Thumbwheel Switch)

REMEMBER: Return the thumbwheel switch to the correct mode position after configuration.

3.2.3 CONFIGURATION: PRINT WRAP.

1. Begin with the ENTER light OFF.

2. Turn the thumbwheel switch to position 1.

3. Press the ENTER switch. The ENTER light begins flashing.

4. Turn the thumbwheel switch to position 3.

5. Press the ENTER switch. The ENTER light turns on.

6. Turn the thumbwheel switch to position:

0 for PRINT WRAP --- OFF

1 for PRINT WRAP --- ON

7. Press the ENTER switch. The ENTER light turns off.

------------------ SET PRINT WRAP ------------------

FLASH ON OFF (Enter Light)

Print Wrap OFF 1 3 0 (Thumbwheel Switch)

Print Wrap ON 1 3 1 (Thumbwheel Switch)

REMEMBER:Return the thumbwheel switch to the correct mode position

after configuration

3.2.4 CONFIGURATION: BOTTOM MARGIN.

1. Begin with the ENTER light OFF.

2. Turn the thumbwheel switch to position 2.

3. Press the ENTER switch. The ENTER light begins flashing.

4. Turn the thumbwheel switch to position 1.

5. Press the ENTER switch. The ENTER light turns on.

6. Turn the thumbwheel switch to position:

0 for BOTTOM MARGIN = 0 line feeds.

1 for BOTTOM MARGIN = 2 line feeds.

2 for BOTTOM MARGIN = 4 line feeds.

3 for BOTTOM MARGIN = 6 line feeds.

.

.

.

9 for BOTTOM MARGIN = 18 line feeds.

7. Press the ENTER switch. The ENTER light turns off.

NOTE: The factory setting of the bottom margin is 8 line feeds. This

setting feeds the paper 1 space past the tear bar.

------------------ SET BOTTOM MARGIN -----------------

FLASH ON OFF (Enter Light)

Bottom Margin: OFF 2 1 0 (Thumbwheel Switch)

Bottom Margin: Clear 2 1 4 (Thumbwheel Switch)

Tear Bar (8 line feeds)

REMEMBER:Return the thumbwheel switch to the correct mode position

after configuration

3.2.5 CONFIGURATION: PRINT SIZE.

1. Begin with the ENTER light OFF.

2. Turn the thumbwheel switch to position 2.

3. Press the ENTER switch. The ENTER light begins flashing.

4. Turn the thumbwheel switch to position 3.

5. Press the ENTER switch. The ENTER light turns on.

6. Turn the thumbwheel switch to position:

0 for Host Control of Print Size.

1 for NORMAL SIZE PRINT.

2 for ENHANCED SIZE PRINT (double width).

3 for MIXED SIZE PRINT (numbers large,

letters small).

7. Press the ENTER switch. The ENTER light turns off.

---------------- PRINT SIZE ---------------

FLASH ON OFF (Enter Light)

Host Control of Size 2 3 0 (Thumbwheel Switch)

Normal Size Print 2 3 1 (Thumbwheel Switch)

Enhanced Size Print 2 3 2 (Thumbwheel Switch)

Mixed Size Print 2 3 3 (Thumbwheel Switch)

REMEMBER:Return the thumbwheel switch to the correct mode position

after configuration

3.2.6 CONFIGURATION: STATION NUMBER.

The station number is enabled when it is set. Setting the station

number to 0 disables it.

1. Begin with the ENTER light OFF.

2. Turn the thumbwheel switch to position 2.

3. Press the ENTER switch. The ENTER light begins flashing.

4. Turn the thumbwheel switch to position 4.

5. Press the ENTER switch. The ENTER light turns on.

6. Turn the thumbwheel switch to position:

0 for STATION NUMBER = DISABLED.

1 for STATION NUMBER = 1.

.

.

.

9 for STATION NUMBER = 9.

7. Press the ENTER switch. The ENTER light turns off.

------------------ SET STATION NUMBER -----------------

FLASH ON OFF (Enter Light)

Disable Station No. 2 4 0 (Thumbwheel Switch)

Set Station No. = 1 2 4 1 (Thumbwheel Switch)

. .

. .

Set Station No. = 9 2 4 9 (Thumbwheel Switch)

REMEMBER: Return the thumbwheel switch to the correct mode position after configuration

Table of contents