Industrial Scientific MX4 iQuad User manual

Part Number: 17140724-1

Revision: 2.0

Release Date: April 26, 2009

Operation Guide

Table of Contents

WARNINGS AND CAUTIONARY STATEMENTS----------------------------4

INTRODUCTION----------------------------------------------------------------------7

HARDWARE OVERVIEW ----------------------------------------------------------8

UNPACKING THE INSTRUMENT -----------------------------------------------9

DISPLAY OVERVIEW ---------------------------------------------------------------9

TURNING THE MX4 ON AND OFF ---------------------------------------------10

GENERAL OPERATION -----------------------------------------------------------11

DAYS SINCE CALIBRATION SCREEN------------------------------------------------12

BUMP TEST SCREEN (IF ENABLED)--------------------------------------------------12

ZERO SCREEN (IF ENABLED)---------------------------------------------------------13

PEAK READINGS SCREEN ------------------------------------------------------------13

TIME WEIGHTED AVERAGE (TWA) READINGS SCREEN -------------------------14

SHORT TERM EXPOSURE LIMIT (STEL) READINGS SCREEN---------------------14

CHARGING SCREEN (FROM ON STATUS) ------------------------------------------15

CHARGING SCREEN (FROM OFF STATUS) -----------------------------------------15

IRDA COMMUNICATIONS SCREEN--------------------------------------------------15

MISSING SENSOR/NO SENSORS INSTALLED SCREEN -----------------------------16

LOW BATTERY LIFE SCREEN --------------------------------------------------------16

OVERRANGE ALARM SCREEN -------------------------------------------------------16

CAL DUE ALARM SCREEN -----------------------------------------------------------17

LOW ALARM SCREEN ----------------------------------------------------------------17

HIGH ALARM SCREEN----------------------------------------------------------------17

TWA ALARM SCREEN ---------------------------------------------------------------17

STEL ALARM SCREEN ---------------------------------------------------------------18

CALIBRATION -----------------------------------------------------------------------19

CONFIGURATION MODE---------------------------------------------------------22

INTRODUCTION------------------------------------------------------------------------22

SECURITY CODE ----------------------------------------------------------------------22

COMBUSTIBLE GAS OPERATING MODE SCREEN ----------------------------------23

ENTER ZERO SCREEN-----------------------------------------------------------------24

CALIBRATION MODE SCREEN -------------------------------------------------------24

LOW ALARM SET POINT -------------------------------------------------------------24

HIGH ALARM SET POINT-------------------------------------------------------------25

Operation Guide

Rev 2.0 (p/n: 17140724) INDUSTRIAL SCIENTIFIC 3

TWA ALARM SET POINT (OPTIONAL) ---------------------------------------------25

TWA TIME BASE SCREEN (OPTIONAL) --------------------------------------------26

STEL ALARM SET POINT (OPTIONAL) ---------------------------------------------26

CAL GAS SETPOINT SCREEN---------------------------------------------------------27

CLOCK SETTING SCREEN ------------------------------------------------------------27

DATE SETTING SCREEN --------------------------------------------------------------28

DISPLAY MODE SETTING SCREEN --------------------------------------------------28

CONFIDENCE INDICATOR SCREEN --------------------------------------------------29

FIELD BUMP TEST OPTION-----------------------------------------------------------29

BUMP OVERDUE ALARM ENABLE --------------------------------------------------29

BUMP TEST INTERVAL SCREEN -----------------------------------------------------30

BUMP TEST THESHOLD SREEN ------------------------------------------------------30

BUMP TEST TIMEOUT SCREEN ------------------------------------------------------31

ALARM LATCH SET SCREEN---------------------------------------------------------31

ZERO ENABLE SCREEN---------------------------------------------------------------32

CAL ENABLE SCREEN ----------------------------------------------------------------32

CAL DUE ALARM OPTION SCREEN -------------------------------------------------32

CAL DUE SETPOINT SCREEN---------------------------------------------------------33

CODE SET SCREEN--------------------------------------------------------------------33

DATA LOGGING -----------------------------------------------------------------------34

MAINTENANCE----------------------------------------------------------------------35

CLEANING -----------------------------------------------------------------------------35

CHARGING THE BATTERIES----------------------------------------------------------35

BATTERY REPLACEMENT ------------------------------------------------------------35

SENSOR AND FILTER REPLACEMENT -----------------------------------------------36

SPECIFICATIONS -------------------------------------------------------------------37

PHYSICAL SPECIFICATIONS ----------------------------------------------------------37

SENSOR SPECIFICATIONS-------------------------------------------------------------37

ENVIRONMENTAL SPECIFICATIONS -------------------------------------------------38

BATTERY SPECIFICATIONS-----------------------------------------------------------38

REPLACEMENT PARTS -----------------------------------------------------------39

EXPLODED VIEW DIAGRAM----------------------------------------------------40

WARRANTY---------------------------------------------------------------------------41

LIMITATION OF LIABILITY-----------------------------------------------------------41

Operation Guide

Warnings and Cautionary Statements

IMPORTANT: Failure to perform certain procedures or note certain

conditions may impair the performance of this product. For maximum

safety and optimal performance, please read and follow the procedures

and conditions listed below.

IMPORTANT: Read and understand this manual before

operating.

AVERTISSEMENT: Lire attentivement les instructions avant de

mettre en marche.

WARNING: SERVICING THE UNIT, REPLACING THE

RECHARGEABLE BATTERY PACK, OR CHANGING THE

ALKALINE BATTERIES MUST ONLY BE DONE IN AN AREA

KNOWN TO BE NONHAZARDOUS.

WARNING: INSERT THE ALKALINE BATTERIES WITH THE

CORRECT POSITIVE “+” AND NEGATIVE “-“ ORIENTATION.

FAILURE TO FOLLOW PROPER BATTERY ORIENTATION

WILL RESULT IN DAMAGE TO THE INSTRUMENT.

WARNING: THE MX4 IS ONLY APPROVED FOR USE WITH

AAA BATTERY TYPES ENERGIZER EN92 AND DURACELL

MN2400. DO NOT MIX BATTERY TYPES.

A functional bump test of the instrument should be performed

before each day’s use. If the instrument does not pass the bump

test, a full instrument calibration should be performed prior to

use.

The MX4 is CSA certified according to the Canadian Electrical

Code for use in Class I, Division 1 and Class I, Zone 1

Hazardous Locations within an ambient temperature range of

Tamb: -20°C to +50°C. CSA has assessed only the %LEL

combustible gas detection portion of this instrument for

performance according to CSA Standard C22.2 No. 152,

applicable only when the instrument is used in the diffusion

mode and has been calibrated to 50% LEL CH4.

Oxygen deficient atmospheres may cause combustible gas

readings to be lower than actual concentrations.

Oxygen enriched atmospheres may cause combustible gas

readings to be higher than actual concentrations.

Operation Guide

Rev 2.0 (p/n: 17140724) INDUSTRIAL SCIENTIFIC 5

Verify the calibration of the combustible gas sensor after any

incident where the combustible gas content has caused the

instrument to display an over-range condition.

Silicone compound vapors or other known contaminants may

affect the combustible gas sensor and cause readings of

combustible gas to be lower than actual gas concentrations. If

the instrument has been used in an area where silicone vapors

were present, always calibrate the instrument before next use to

ensure accurate measurements.

Sensor openings and water barriers must be kept clean.

Obstruction of the sensor openings and/or contamination of the

water barriers may cause readings to be lower than actual gas

concentrations.

Sudden changes in atmospheric pressure may cause temporary

fluctuations in the oxygen reading.

Charge battery, service unit, and use its communication port

only in non-hazardous locations. Not for use in oxygen-enriched

atmospheres.

WARNING: Substitution of components may impair intrinsic

safety and may cause an unsafe condition.

AVERTISSEMENT: La substitution de composants peut

compomettre la securite intrinseque.

CAUTION: For safety reasons, this equipment must be operated

and serviced by qualified personnel only. Read and understand

the instruction manual completely before operating or servicing.

ATTENTION: Pour des raisons de sécurité, cet équipment doit

étre utilesé entretenu et réparé uniquement par un personnel

qualifié. Étudier le manuel d'instructions en entier avant d'utiliser,

d'entretenir ou de réparer l'équipement.

CAUTION: High off-scale readings may indicate explosive

concentration.

ATTENTION: Des lectrures supérieures a l'échelle peuvent

indiquer des concentrations explosives.

Operation Guide

6 INDUSTRIAL SCIENTIFIC Rev 2.0 (p/n: 17140724)

CAUTION: Any rapid up-scale reading followed by a declining or

erratic reading may indicate a gas concentration beyond the

upper scale limit which may be hazardous.

CAUTION: CSA C22.2 No. 152 requires before each day’s

usage, sensitivity must be tested on a known concentration of

pentane or methane equivalent to 25% or 50% of full scale

concentration. Accuracy must be within -0% to +20% of actual

concentration. Accuracy may be corrected by referring to the

zero/calibration section of the instruction manual.

The model MX4 complies with relevant provisions of European

ATEX directive 94/9/EC and EMC directive 89/336/EEC,

amended by directives 92/31/EEC and 93/68/EEC.

The EC type examination certificate is DEMKO 09 ATEX

0854530 ; with marking code Ex ia d I/IIC T4; for equipment

group and category II 2G and I M2.

The MX4 iQuad Multi-Gas Monitor is constructed with reference

to published standards of directive 72/23/EEC, to eliminate

electrical risks and fulfill 1.2.7 of ANNEX II of directive 94/9/EC.

Contact your service representative immediately if you suspect

that the MX4 is working abnormally.

Specifications subject to change without notice.

Operation Guide

Rev 2.0 (p/n: 17140724) INDUSTRIAL SCIENTIFIC 7

Introduction

The MX4 is a light-weight, portable gas monitor capable of continuously

and simultaneously monitoring 4 gases:

Oxygen (O2)

Combustible (LEL and CH4)

Two interchangeable toxics (CO, H2S, NO2)

The sensors are easily replaced. Gas readings from the installed sensors

are displayed on a custom graphic LCD. Peak readings are also available

for each sensor, and can be cleared by the user.

The instrument provides alarms for the following conditions:

low limit (user adjustable)

high limit (user adjustable)

STEL (user adjustable)

TWA (user adjustable)

overdue for calibration (user selectable).

Overdue for bump test (user selectable)

When alarm conditions are exceeded, the MX4 has an audible, visual and

standard vibrating alarm to alert the user.

The MX4 is compatible with the MX•Cal™ calibration station, the DS2

Docking Station™, and its own cradle-style charger. It communicates to

the Charger/Datalink via infrared communications (IrDA). MX4 is also

compatible with Industrial Scientific’s automated and comprehensive gas

monitor management solution, iNet™.

The MX4 performs continuous data logging at 10 second intervals and

can hold approximately three month’s of data for the four-sensor

configuration. Readings are time-stamped and are stored in a first-in-first-

out (FIFO) queue that is overwritten when full. In addition to data logging,

the MX4 has an event log that records the last 15 alarm events.

Operation Guide

8 INDUSTRIAL SCIENTIFIC Rev 2.0 (p/n: 17140724)

Enter

Button

On/Off/Mode

Button

Audible

Alarm Port

Charging

Contacts IrDA Interface

Instrument

Display

Visual Alarm

Indcators

Sensor

Ports

Hardware Overview

Operation Guide

Rev 2.0 (p/n: 17140724) INDUSTRIAL SCIENTIFIC 9

Unpacking the Instrument

The shipping box should contain the following items. Account for each

item before discarding the box.

Quantity Description

1 MX4 iQuad Multi-Gas Monitor

1 Manual

1 Battery Pack (installed as ordered)

1 Cradle-style Charger with Power Cord

1 Calibration Cup and Tubing

After unpacking, if any listed item is missing, contact either your local

distributor of Industrial Scientific products or call Industrial Scientific

Corporation at 1-800-DETECTS (338-3287) in the United States and

Canada, or 412-788-4353.

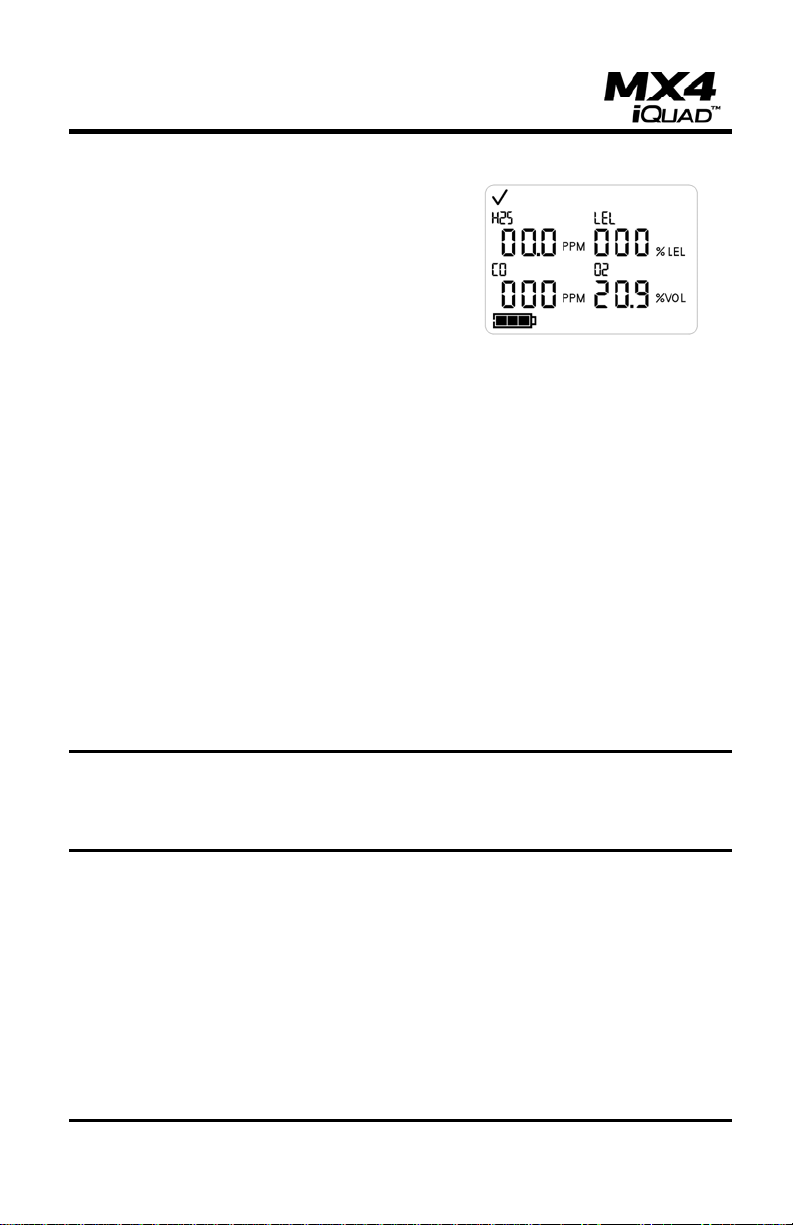

Display Overview

LCD Display Panel Overview

Operation Guide

10 INDUSTRIAL SCIENTIFIC Rev 2.0 (p/n: 17140724)

Turning the MX4 ON and OFF

To turn on the MX4, press and hold the On/Off/Mode button ( ) until the

unit emits a single beep (approximately 3 seconds). All icons and

segments on the LCD display as shown in the graphic above. Next, the

software version is displayed. After this, the instrument performs a 20

second countdown, during which the user has the option to enter the

configuration mode (by pressing and holding both the On/Off/Mode ( )

and Enter ( ) buttons simultaneously). If this configuration mode option is

bypassed, the MX4 enters the normal operating mode and displays the

normal monitoring screen. Sequential presses of the On/Off/Mode button

will cycle the user through the Days Since Calibration Screen, Zero

Screen (if enabled), Peak Readings Screen, Time Weighted Average

(TWA) Screen (if toxic sensors are installed) and the Short Term

Exposure Limit (STEL) Screen (if toxic sensors are installed). Another

press of the On/Off/Mode button returns the user to the normal monitoring

screen. Each screen is explained individually in the sections that follow.

To turn off the MX4, press and hold the

On/Off/Mode button for 5 seconds. During

the shutdown process, the displayed value

will change from “5” to “1” and the MX4 will

beep five times.

NOTE: Any button press activates the backlight for a period of 30 seconds.

Operation Guide

Rev 2.0 (p/n: 17140724) INDUSTRIAL SCIENTIFIC 11

General Operation

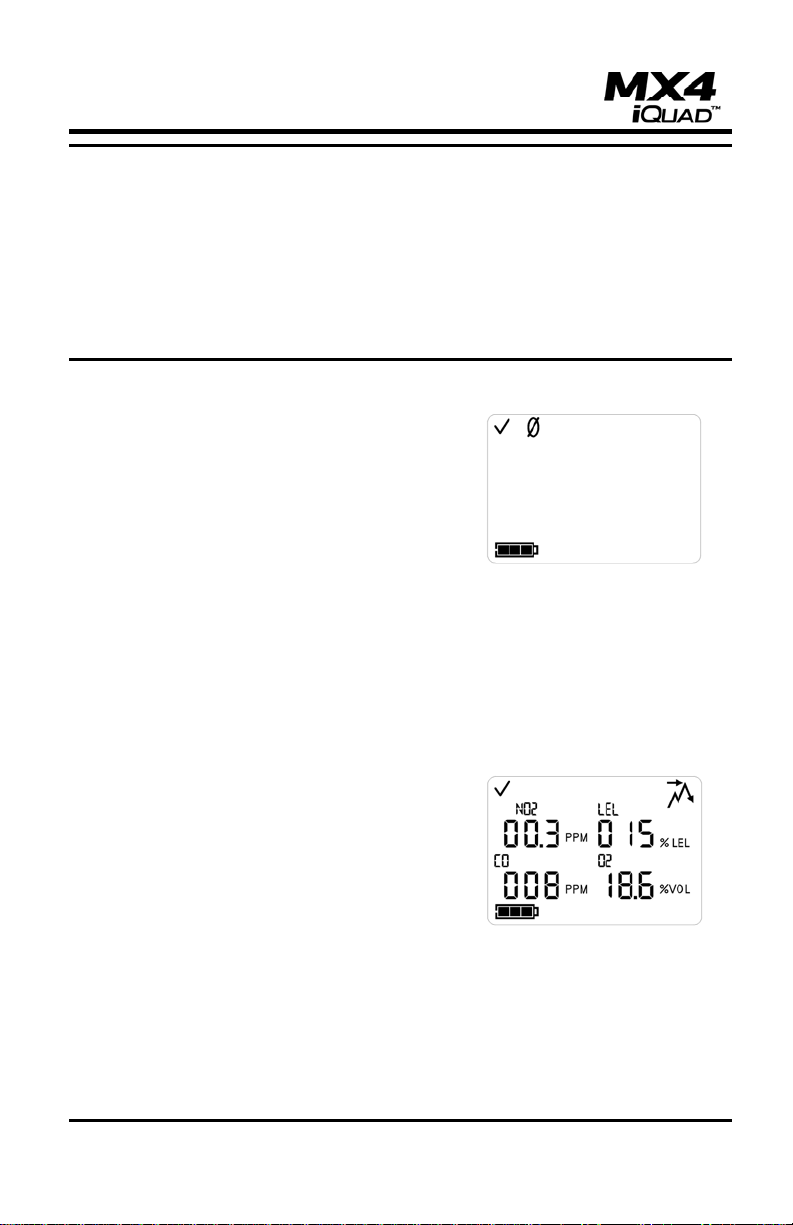

The normal monitoring screen in numeric

mode contains the abbreviated names and

concentrations of all 4 gases. In text mode,

the sensor names are displayed instead of

the numerical values. The gasses are

continuously monitored and the readings

updated on the LCD. If any of the gas

concentrations exceed the low or high

alarm limits (as well as STEL/TWA), the

MX4 will go into alarm. When in alarm, the

audible and visual alarms will beep and

flash at set frequencies, and the vibrating

alarm will be pulsed.

When the gas concentrations return to normal values (for example, drop

out of the range that will cause an alarm condition), and the alarm latching

feature is not set, the MX4 will go back to the normal monitoring screen.

The normal monitoring screen may appear differently based on which

sensors are installed and which display mode is selected.

A battery life indicator is displayed in the lower left corner of the LCD. As

battery life decreases, the shaded area of the battery icon decreases.

Pressing the On/Off/Mode button from the Normal Monitoring screen

displays the Days Since Calibration screen.

NOTE: In an over-range condition, the display will show a blinking “OR”,

in a negative over-range condition “-OR” will be shown. Any over-range

values in the event log or peaks will be truncated at the measurement

range of the sensor.

Operation Guide

12 INDUSTRIAL SCIENTIFIC Rev 2.0 (p/n: 17140724)

Days Since Calibration Screen

The Days Since Calibration screen displays

the calibration bottle icon, the calendar

icon, the names of the four installed

sensors, and the corresponding number of

days since each sensor was last calibrated.

Pressing the On/Off/Mode button from the Days Since Calibration screen

displays the Bump Test screen (if enabled in the configuration mode).

Bump Test Screen (if enabled)

The bump test screen allows the user to

initiate and perform a manual bump test of

the instrument using calibration gas. (This

screen will only be seen if the bump test

option is enabled in the configuration

mode.)

After initiating the bump test by pressing the Enter button at this screen,

the user will apply the calibration gas to the instrument as described under

Calibration. If the sensor responds to the percentage of the calibration gas

value programmed in the configuration mode within the timeout specified

in the configuration mode, the instrument will pass the bump test. If the

sensor does not respond to the programmed percentage of the gas

concentration within the timeout period, the instrument will fail the bump

test and require calibration. A failed sensor will show “b F” on the display

instead of the gas reading for that particular sensor. If the bump overdue

alarm is enabled in the configuration mode, “b” will be shown for the gas

reading and the sensor name will flash when the bump test is overdue.

This screen will appear when the instrument is turned on and remain until

a bump test of the instrument is completed successfully.

Pressing the On/Off/Mode button from the Bump Test screen displays the

Zero screen (if enabled in the configuration mode).

Operation Guide

Rev 2.0 (p/n: 17140724) INDUSTRIAL SCIENTIFIC 13

IMPORTANT: A function or “bump” test, using a known concentration of

calibration gas, should be performed periodically based on instrument use,

exposure to gas, and environmental conditions. The frequency is best

determined by company policy or local regulatory agencies. If an

instrument fails a function or “bump” test, or, if it is dropped, submerged,

or appears damaged, a full calibration is recommended. The safest

approach is to perform a function or “bump” test prior to each day’s use.

Industrial Scientific is not responsible for establishing customer safety

practices and policies.

Zero Screen (if enabled)

If zeroing is enabled (via the Zero Enable

screen in the Configuration section), then

the Zero screen is displayed. From this

screen the user initiates the zeroing process

of the sensors by pressing the Enter button.

The zeroing process should only be initiated

when the instrument is in clean ambient air.

If clean air is not available, a cylinder of

zero grade air should be used. (Refer to the

Zeroing and Calibration processes later in

this manual).

Pressing the On/Off/Mode button from the Zero screen displays the Peak

Readings screen.

Peak Readings Screen

The Peak Readings screen displays the

peak icon, the names of the four installed

sensors, and the corresponding peak

values for each since the last time the peak

value(s) were cleared.

Pressing the Enter button resets all of the

peak values to the current reading.

If one or more toxic gas sensors are installed, then pressing the

On/Off/Mode button from the Peak Readings screen displays the TWA

Readings screen.

If no toxic gas sensors are installed, then pressing the On/Off/Mode

button from the Peak Readings screen returns the user to the Normal

Monitoring screen.

Operation Guide

14 INDUSTRIAL SCIENTIFIC Rev 2.0 (p/n: 17140724)

Time Weighted Average (TWA) Readings Screen

The TWA Readings screen is only

displayed if one or more toxic gas sensors

are installed.

The TWA Readings screen displays the

TWA icon, the names of the installed toxic

sensor(s), and the corresponding time

weighted average gas concentration for

each.

Pressing the Enter button while on this screen resets the TWA and STEL

values. The time base for TWA calculation may be set in the configuration

mode. The default time base is set for 8 hours.

Pressing the On/Off/Mode button from the TWA Readings screen displays

the STEL Readings screen.

Short Term Exposure Limit (STEL) Readings Screen

The STEL Readings screen is only

displayed if one or more toxic gas sensors

are installed.

The STEL Readings screen displays the

STEL icon, the names of the installed toxic

sensor(s), and the corresponding short-term

exposure limit for each.

The STEL (Short Term Exposure Limit) for the toxic sensors is reset every

time the unit is powered down. In addition, pressing the Enter button while

on this screen resets the STEL values, but not the TWA values. The STEL

readings are calculated as a running average of readings over the last 15

minutes.

Pressing the On/Off/Mode button from the STEL Readings returns the

display to the Normal Monitoring screen.

Operation Guide

Rev 2.0 (p/n: 17140724) INDUSTRIAL SCIENTIFIC 15

While in the normal operating mode, the MX4 display will vary depending

on current monitoring conditions. Variations of the display indicating the

charging, battery, calibration, sensor, communication and alarm status are

shown below.

Charging Screen (From ON Status)

When the MX4 is turned on and the Normal

Monitoring screen is displayed, docking the

instrument to charge it will cause the

instrument to turn off, and move to the

normal charging state. The battery icon will

cycle from empty to full to empty to indicate

that charging is taking place. The names of

any installed sensors are also shown. (The

battery indicator will show full when the

instrument battery is fully charged.) If the

unit is using an alkaline battery, the battery

icon will reflect the amount of battery life

left.

Charging Screen (From OFF Status)

When the MX4 is turned off, and then

docked, the battery life icon will be

displayed and will cycle from empty to full to

empty if the unit is being recharged. The

names of any installed sensors are also

shown. If the unit is using an alkaline

battery, the battery icon will reflect the

amount of battery life left.

IrDA Communications Screen

During IrDA communications, the IrDA

communications icon is displayed. This

happens only when the instrument is

docked.

Operation Guide

16 INDUSTRIAL SCIENTIFIC Rev 2.0 (p/n: 17140724)

Missing Sensor/No Sensors Installed Screen

If a sensor is not detected or is missing from

the instrument, the corresponding sensor

position on the display will be blank. If no

sensors are installed in the instrument the

display will be blank as shown and the

warning icon will flash.

Low Battery Life Screen

When battery power is nearly exhausted,

the battery icon will begin to flash. It will

continue to flash until the unit shuts down

due to insufficient power.

Over Range Alarm Screen

An over range condition occurs when the

gas concentration value read by the sensor

is above its specified measuring range.

During an over range condition, the “Or”

(Over Range) icon flashes in place of the

numerical value for the sensor that is in

over range.

For toxic sensors and/or the oxygen sensor, the over range alarm will

normally reset itself when the gas concentration returns to a level within

the sensor measuring range. However, if the LEL sensor reaches an over

range condition, the alarm will latch and the instrument must be turned off

and then on again to clear the over range condition.

The instrument should always be recalibrated after any over range

condition occurs.

Operation Guide

Rev 2.0 (p/n: 17140724) INDUSTRIAL SCIENTIFIC 17

Cal Due Alarm Screen

When a sensor calibration is due, the gas

bottle icon and the associated sensor icon

flash. In addition, the MX4 beeps every five

seconds to alert the user that calibration is

past due.

Low Alarm Screen

When a low alarm condition occurs (based

on the low alarm limit settings in the

configuration menus), the alarm icon and

the down arrow (low limit) icon are

displayed. Depending on the display mode

that is selected, either the gas reading value

will flash or the alarming gas type text will

flash (Text display mode).

High Alarm Screen

When a high alarm condition occurs (based

on the high alarm limit settings in the

configuration menus), the alarm icon and

the up arrow (high limit) icon are displayed.

Depending on the display mode that is

selected, either the gas reading value will

flash or the alarming gas type text will flash

(Text display mode).

TWA Alarm Screen

When a TWA alarm condition occurs (based

on the TWA alarm limit settings in the

configuration menus), the alarm icon and

the TWA icon are displayed. Depending on

the display mode that is selected, either the

gas reading value will flash or the alarming

gas type text will flash (Text display mode).

Operation Guide

18 INDUSTRIAL SCIENTIFIC Rev 2.0 (p/n: 17140724)

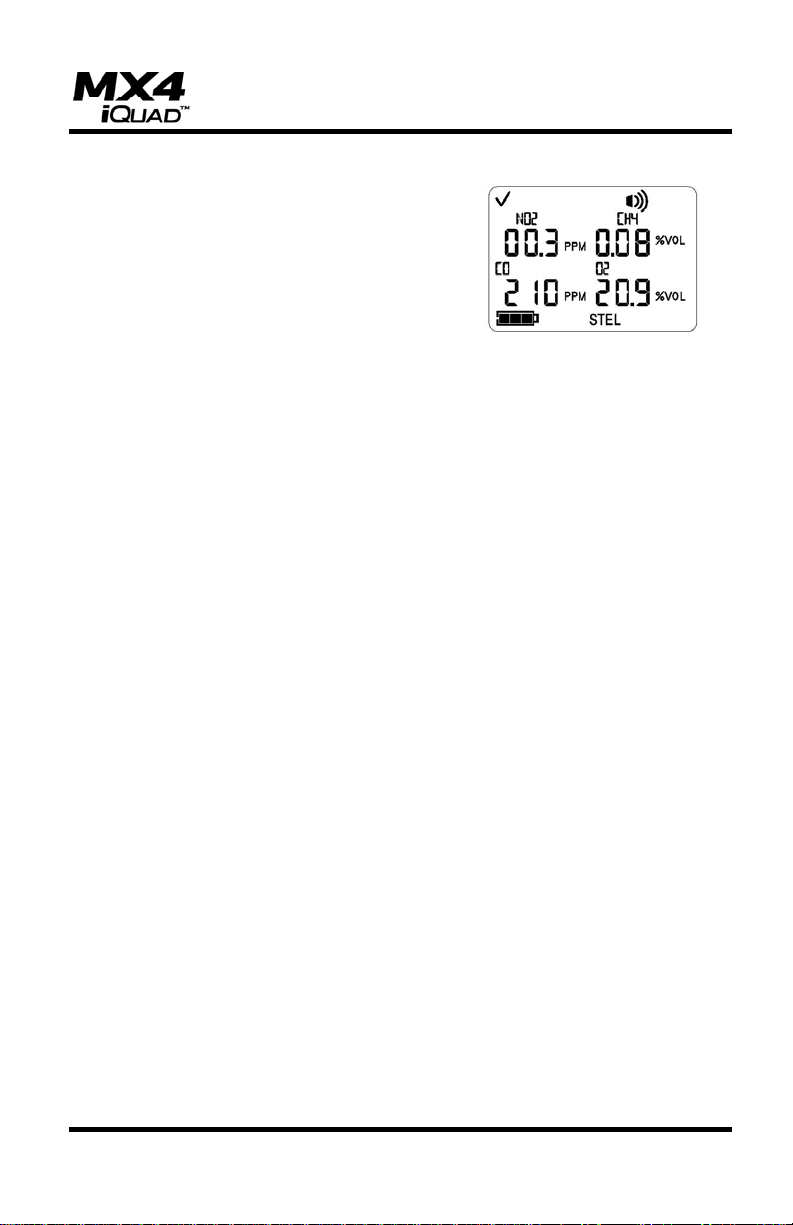

STEL Alarm Screen

When a STEL alarm condition occurs

(based on the STEL alarm limit settings in

the configuration menus), the alarm icon

and the STEL icon are displayed.

Depending on the display mode that is

selected, either the gas reading value will

flash or the alarming gas type text will flash.

Operation Guide

Rev 2.0 (p/n: 17140724) INDUSTRIAL SCIENTIFIC 19

Calibration

IMPORTANT: Industrial Scientific Corporation recommends that a

functional (“bump”) test be performed on every instrument prior to each

day’s use. A functional test is defined as a brief exposure of the monitor to

a concentration of gas(es) in excess of the lowest alarm set-point for each

sensor for the purpose of verifying sensor and alarm operation and is not

intended to be a measure of the accuracy of the instrument. If an

instrument fails to operate properly following any functional "bump" test,

full instrument calibration should be performed prior to use. If conditions

do not permit daily testing, bump tests may be done less frequently based

on instrument use, exposure to gas, and environmental conditions. The

frequency of testing is best determined by company policy or local

regulatory agencies.

Industrial Scientific further recommends that full instrument calibration be

performed using a certified concentration(s) of Industrial Scientific

calibration gas(es) monthly to ensure accuracy.

NOTE: CSA International requires the %LEL sensitivity to be tested

before each use. Any inaccuracy may be adjusted by calibration to 50%

LEL Methane.

NOTE: If the option to zero or calibrate in field is not enabled, the user will

not be able to calibrate the instrument in the field.

NOTE: If a security code is set, the user will not be able to enter the

configuration screens in the field. Please refer to Security Code Setting

section for more information.

The MX4 may be calibrated in the normal operating mode if field

calibration is enabled or in the configuration mode if field calibration is

disabled. Calibration is first initiated by advancing to the Zero screen if

calibration is to be performed in the normal operating mode or entering

the Configuration mode and then initiating the zero process. The MX4 has

two calibration options that may be selected in the Configuration mode.

The first is the Quick-Cal option in which all sensors will be calibrated

simultaneously using the appropriate blended cylinder of calibration gas.

The second option is the Standard-Cal option where sensors may be

calibrated individually using either blended or individual calibration gases.

Operation Guide

20 INDUSTRIAL SCIENTIFIC Rev 2.0 (p/n: 17140724)

The zeroing process is initiated by pressing

the Enter button when this zero screen is

being displayed. The zeroing process

should only be initiated when the instrument

is in clean ambient air. If clean air is not

available, a cylinder of zero grade air should

be used. During the zeroing process, the

toxic and combustible gas sensors are

zeroed and the oxygen sensor is calibrated

to ambient air.

When the zeroing process is completed,

calibration can be initiated by pressing the

On/Off/Mode button. The instrument display

will flash the calibration gas concentration

for the first sensor to be calibrated. The

calibration cup should be attached to the

instrument and the calibration gas applied

at a flow rate of 0.5 liters per minute.

The instrument will recognize the presence of calibration gas and begin

the calibration process. When the sensor has completed calibration, the

instrument will emit a short beep and the display will step to the next

sensor to be calibrated. If the Standard-Cal option is enabled, a sensor

may be skipped by pressing the On/Off/Mode button. If the oxygen sensor

calibration gas value is set to 20.9%, the oxygen sensor will not be

available for calibration in this mode because it was calibrated during the

zeroing process and the oxygen sensor display position will be blank.

When the calibration is complete, the

instrument will display the Pass/Fail status

of the calibration and the full span value for

each sensor. The full span value provides

an indication of the sensors operation

condition.

A full span value greater than 70% of the applied calibration gas value

indicates a healthy sensor. A full span value between 50% and 70% of the

applied gas concentration are considered to have marginal sensitivity and

limited life remaining. Sensors will fail calibration if the full span value is

less than 50% of the applied calibration gas concentration. If a sensor fails

calibration, the display reading for that sensor will be replaced by the letter

Table of contents

Other Industrial Scientific Monitor manuals