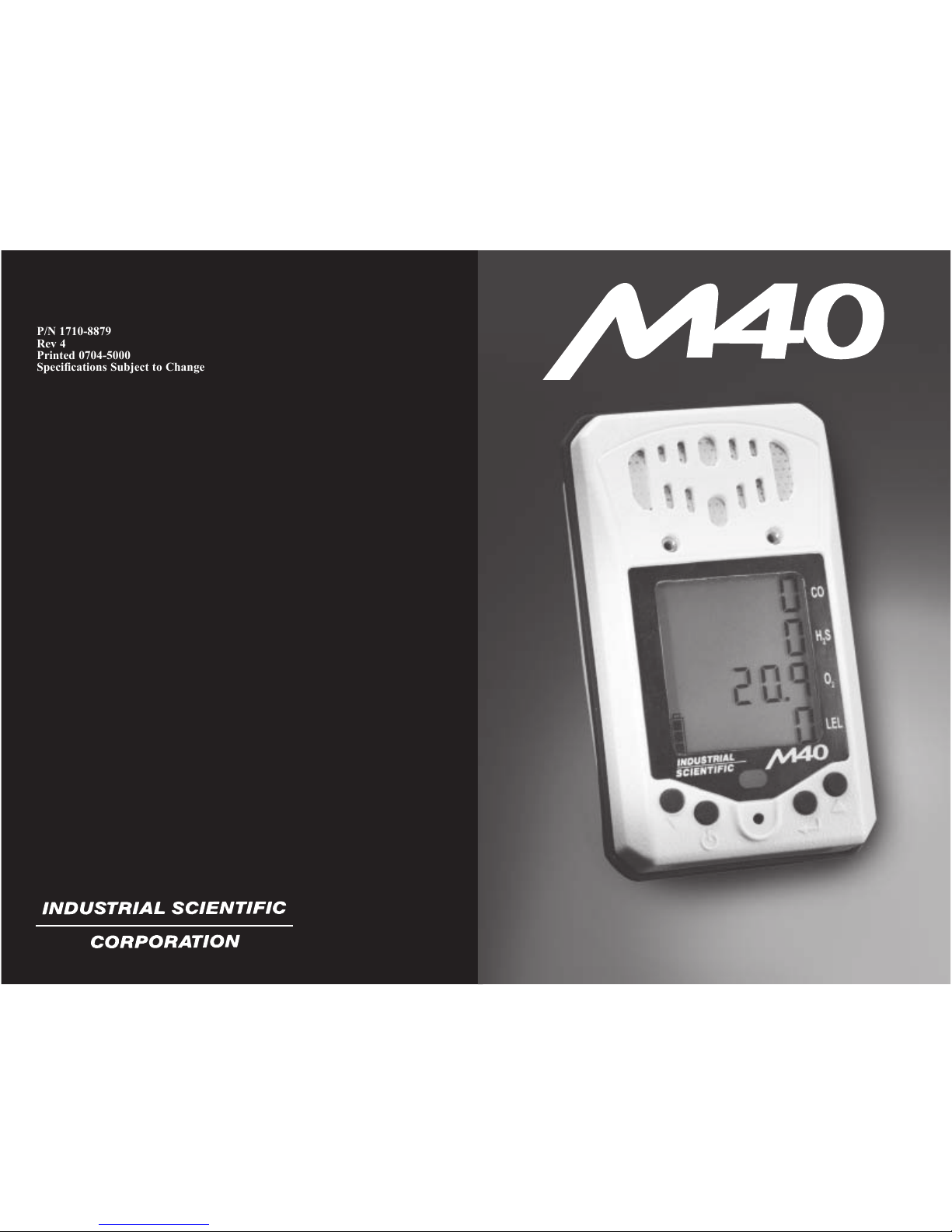

Industrial Scientific M40 User manual

9788

-0171

N

/

P

4 veR

0005-4070

det

n

i

r

P

eg

nah

C o

t t

cej

b

uS

s

no

ita

c

i

fi

c

ep

S

0051-17051 AP,

e

la

d

ka

O,

daoR

e

la

d

kaO 1001

ST

CETED

-008

-1

e

er

F

l

loT

• 35

34-887

)214(

3534-887

-888

-1 .t

p

eD

e

c

ivr

e

S • 3

538-887

-214 X

AF

no

i

tcurtsnI

la

u

naM

.

DEE

TN

A

R

AUG

ROTINOM SAG-ITLUM

OUR MISSION

Design - Manufacture - Sell:

Highest quality products

for the preservation of

life and property.

Provide:

Best customer service

available.

Dear Valued Customer,

Thank you for buying and using Industrial Scientific’s

M40 Multi-Gas Monitor.

Your M40 can be relied upon for dependable service, day

after day. It has been designed, manufactured, tested and

proven under the most scrutinizing conditions possible.

With the minimal care and maintenance described in this

Instruction Manual, it will provide you with years of

reliable monitoring.

I am most concerned that you be pleased with the

performance of your M40 in the months and years ahead.

I urge you to call us with any questions or comments you

may have. Often times a phone call and a question can

save you hours of frustration. Please never hesitate to

contact me at 1-800-DETECTS (338-3287).

All of us at Industrial Scientific appreciate the opportunity

to serve you.

Sincerely,

Kent D. McElhattan

President & CEO

Industrial Scientific Corporation

3

W

ARNINGS AND

C

AUTIONARY

S

TATEMENTS

Failure to perform certain procedures or note certain conditions

may impair the performance of the instrument. For maximum

safety and performance, please read and follow the procedures

and conditions outlined below.

Oxygen deficient atmospheres may cause combustible gas

readings to be lower than actual concentrations.

Oxygen enriched atmospheres may cause combustible gas

readings to be higher than actual concentrations.

Verify the calibration of the combustible gas sensor after any

incident where the combustible gas content has caused the

instrument to display an OVER-RANGE condition.

Silicone compound vapors or other known contaminants may

affect the combustible gas sensor and cause readings of combustible

gas to be lower than actual gas concentrations. If the instrument has

been used in an area where silicone vapors were present, always

calibrate the instrument before next use to ensure accurate

measurements.

Sensor openings and water barriers must be kept clean.

Obstruction of the sensor openings and/or contamination of the water

barriers may cause readings to be lower than actual gas

concentrations.

Sudden changes in atmospheric pressure may cause temporary

fluctuations in the oxygen reading.

Charge battery, service unit, and use its communication port only

in non-hazardous locations. Not for use in oxygen enriched

atmospheres.

WARNING: SUBSTITUTION OF COMPONENTS MAY IMPAIR

INTRINSIC SAFETY AND MAY CAUSE AN UNSAFE CONDITION.

AVERTISSEMENT: LA SUBSTITUTION DE COMPOSANTS PEUT

COMPOMETTRE LA SECURITE INTINSEQUE!

CAUTION: FOR SAFETY REASONS, THIS EQUIPMENT MUST BE

OPERATED AND SERVICED BY QUALIFIED PERSONNEL ONLY. READ

AND UNDERSTAND THE INSTRUCTION MANUAL COMPLETELY

BEFORE OPERATING OR SERVICING.

ATTENTION: POUR DES RAISONS DE SÉCURITÉ, CET ÉQUIPMENT

DOIT ÉTRE UTILESÉ ENTRETENU ET RÉPARÉ UNIQUEMENT PAR UN

PERSONNEL QUALIFIÉ. ÉTUDIER LE MANUEL D'INSTRUCTIONS EN

ENTIER AVANT D'UTILISER, D'ENTRETENIR OU DE RÉPARER

L'ÉQUIPEMENT.

!

!

!

!

!

!

!

!

!

2

WARNINGS AND CAUTIONARY STATEMENTS.....................................3

UNPACKING THE INSTRUMENT ........................................................5

VIEW OF INSTRUMENT ....................................................................6

INTRODUCTION................................................................................7

INSTRUMENT OPERATION.................................................................7

M40 Gas Reading Mode......................................................7

Operating Modes .................................................................8

Zero/Calibration Mode........................................................9

Display Peaks Mode............................................................9

View TWA Mode...............................................................10

View STEL Mode..............................................................10

CONFIGURATION MODE.................................................................10

Low Alarm Set Points........................................................11

High Alarm Set Points.......................................................11

TWA Alarm Set Points ......................................................12

STEL Alarm Set Points......................................................13

Clock Setting......................................................................13

Calendar Setting.................................................................14

Security Code Setting........................................................14

LEL Setting........................................................................15

Protected Zero/Cal Setting.................................................15

ZERO/CALIBRATION.......................................................................16

DATA LOGGING .............................................................................17

LEL OVER RANGE........................................................................17

MAINTENANCE..............................................................................18

Cleaning.............................................................................18

Charging the Batteries .......................................................18

SP40 SAMPLING PUMP..................................................................18

M40 SPECIFICATIONS....................................................................19

REPLACEMENT PARTS LIST............................................................20

WARRANTY...................................................................................21

EC DECLARATION.........................................................................23

TABLE OF CONTENTS

MULTI-GAS MONITOR

CAUTION: HIGH OFF-SCALE READINGS MAY INDICATE

EXPLOSIVE CONCENTRATION.

ATTENTION: DES LECTRURES SUPÉRIEURES A L'ÉCHELLE PEUVENT

INDIQUER DES CONCETRATOINS EXPLOSIVES.

CAUTION: ANY RAPID UP-SCALE READING FOLLOWED BY A

DECLINING OR ERRATIC READING MAY INDICATE A GAS

CONCENTRATION BEYOND THE UPPER SCALE LIMIT WHICH MAY BE

HAZARDOUS.

CANADIAN STANDARDS ASSOCIATION (CSA) HAS ASSESSED

ONLY THE COMBUSTIBLE GAS DETECTION PORTION OF THIS

INSTRUMENT FOR PERFORMANCE ACCORDING TO CSA STANDARD

C22.2 NO. 152.

WARNING: THE ALARMS ON THE MODEL M40 ARE NON-

LATCHING ALARMS.

CAUTION: BEFORE EACH DAY’S USAGE, SENSITIVITY MUST BE

TESTED ON A KNOWN CONCENTRATION OF PENTANE OR METHANE

EQUIVALENT TO 25%-50% OF FULL SCALE CONCENTRATION.

ACCURACY MUST BE WITHIN +/- 20% OF ACTUAL CONCENTRATION.

ACCURACY MAY BE CORRECTED BY REFERRING TO THE

ZERO/CALIBRATION SECTION OF THE INSTRUCTION MANUAL.

THE MODEL M40 IS CERTIFIED FOR USE WITHIN AN AMBIENT

TEMPERATURE RANGE OF -20°C TO 40°C ONLY.

THE MODEL M40/SP40 COMPLIES WITH RELEVANT PROVISIONS

OF EUROPEAN ATEX DIRECTIVE 94/9/EC AND EMC DIRECTIVE

89/336/EEC, AMENDED BY DIRECTIVES 92/31/EEC AND 93/68/EEC.

THE EC TYPE EXAMINATION CERTIFICATE IS DEMKO 03 ATEX

0324154X; WITH MARKING CODE EEx ia d IIC T4; FOR EQUIPMENT

GROUP AND CATEGORY II 2G.

THE MODEL M40 MULTI-GAS MONITOR (P/N 1810-5437) AND

MODEL SP40 SAMPLING PUMP (P/N 1810-5460) ARE CONSTRUCTED

WITH REFERENCE TO PUBLISHED STANDARDS OF DIRECTIVE

72/23/EEC, TO ELIMINATE ELECTRICAL RISKS AND FULFILL 1.2.7 OF

ANNEX II OF DIRECTIVE 94/9/EC.

THE MODEL M40 MUST BE USED ONLY WITH MODEL SP40

EXTERNAL SAMPLING PUMP.

FOR EUROPE ONLY, MODEL M40 AND M40/SP40 COMBINATION

REQUIRE EXTERNAL PROTECTIVE MEARSURES TO PREVENT

INADVERTENT ELECTROSTATIC DISCHARGE INTO EXPOSED METAL

SURFACES TO MAINTAIN PERFORMANCE CRITERIA AS SPECIFIED IN

EN50270 TABLE 1.4. THE M40 INSTRUMENT AND M40/SP40

COMBINATION MUST BE OPERATED WITHIN THE SUPPLIED

LEATHER CASE.

!

!

!

!

!

!

!

!

!

!

!

U

NPACKING THE

I

NSTRUMENT

The shipping box should contain the following items. Account for

each item before discarding the box.

QUANTITY PART NUMBER DESCRIPTION

1 1810-5437-XXXXX M40

1 1710-8630 Swivel Belt Clip (Plastic)

1 1710-8879 Manual

1 1710-8622 Cal-Cup

1 1710-2005 Urethane Tubing

1 1710-7582 Suspender Clip

1 1810-5981 Carrying case

1 1810-5460* SP40 sampling pump

1 1810-5999* Carrying case

1 1711-6096* T-Fitting Assembly

* Items are only included in 1810-5437-1XXXX part numbers.

After unpacking, if any listed item is missing, contact either your local

distributor of Industrial Scientific products or call Industrial Scientific

Corporation at 1-800-DETECTS (338-3287) in the United States and

Canada, or 412-788-4353.

54

76

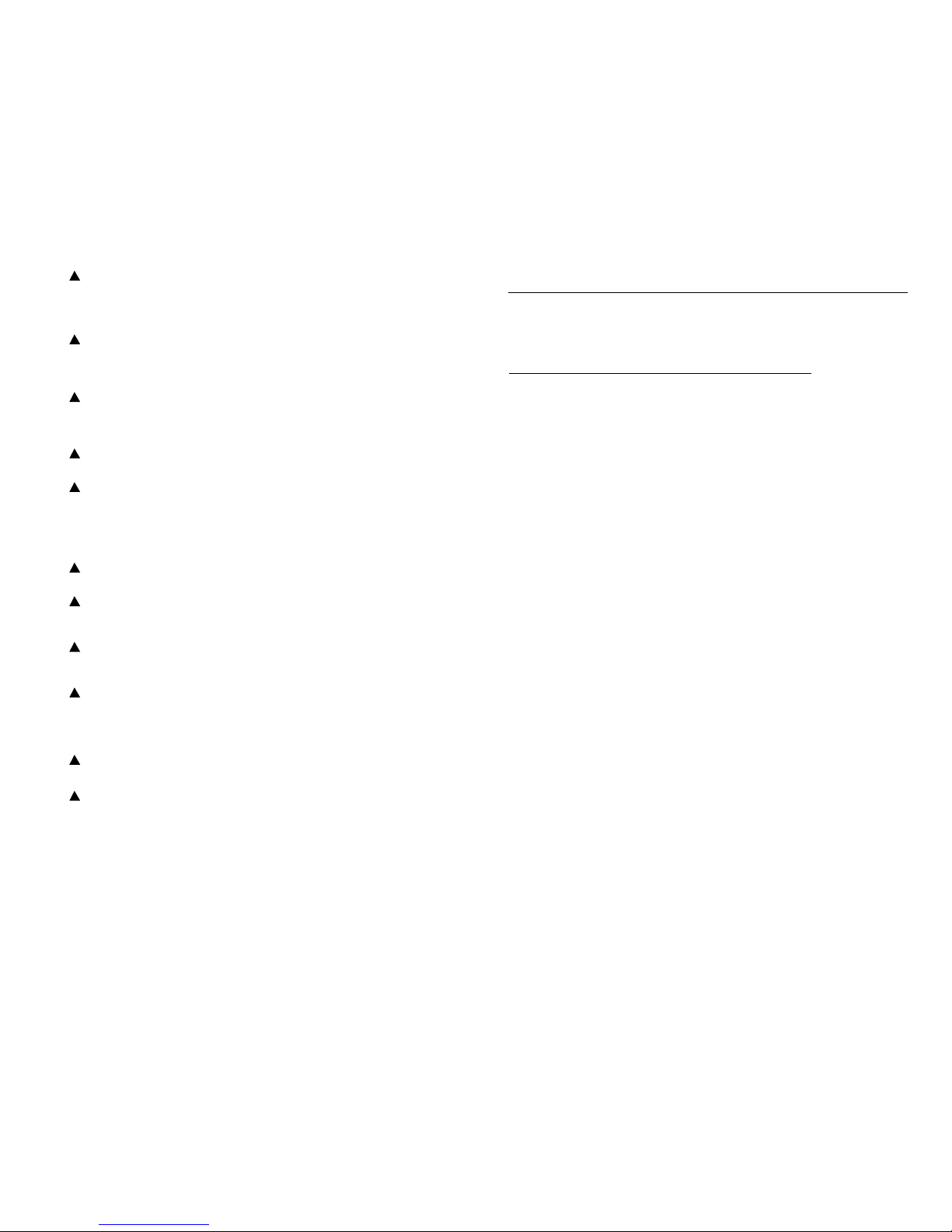

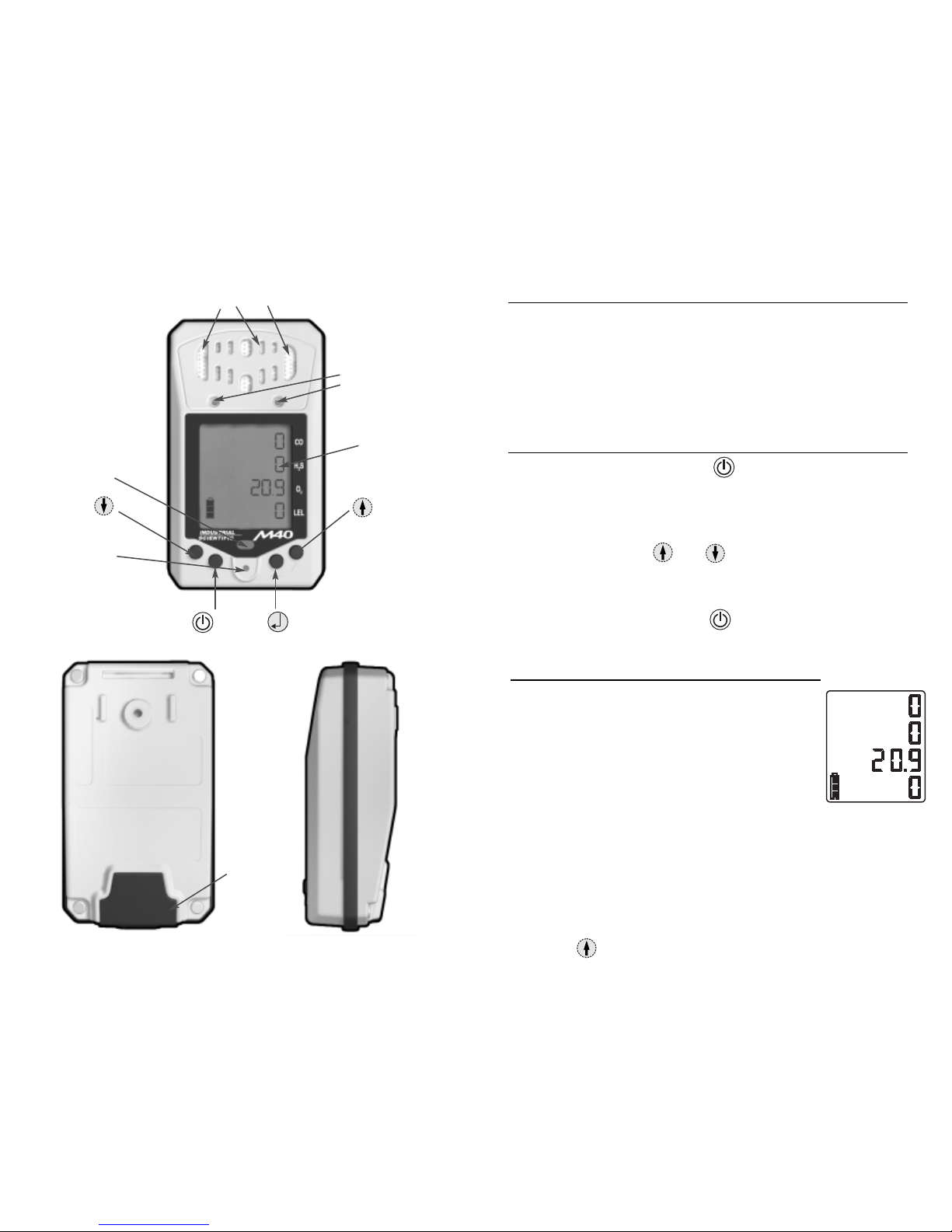

Key

Key

Visual Alarm

Audible Alarm

KeyKey

Sensor Openings

Display

Charger/

Datalink

Port

SP40

Contacts

FRONT

BACK SIDE

I

NSTRUMENT

O

PERATION

To turn on the M40, press and hold the button for 1

second. The unit will emit a single beep and go into a

display test. All icons and segments on the LCD will light.

Next the software revision will be displayed. After this, the

instrument will go into a 20 second countdown. During the

countdown sequence, if the and arrow keys are

pressed simultaneously, the user will enter into the

Configuration Mode. When the countdown is complete, the

M40 will be in its normal Gas Reading Mode. To turn off

the M40 instrument press and hold the button for 5

seconds. The instrument will beep 5 times and then shut off.

M40 GAS READING MODE

Once the M40 enters into the Gas Reading Mode, all 4 gases

(O2, LEL, CO and H2S) will be continuously monitored and

the readings updated on the liquid crystal display. As gas

levels increase, the corresponding reading will reflect the

current gas concentrations. A battery life indicator is also

displayed in the lower left corner. As battery life decreases,

the shaded area of the battery icon decreases. If any of the

gas concentrations exceed the low or high alarm limits (as

well as STEL/TWA), the M40 will go into alarm. When in

alarm, the audible and visual alarms will beep and flash at

set frequencies, and the vibrating alarm will be pulsed.

When the gas concentrations drop below the alarm set

points, the M40 will go back to the Gas Reading Mode.

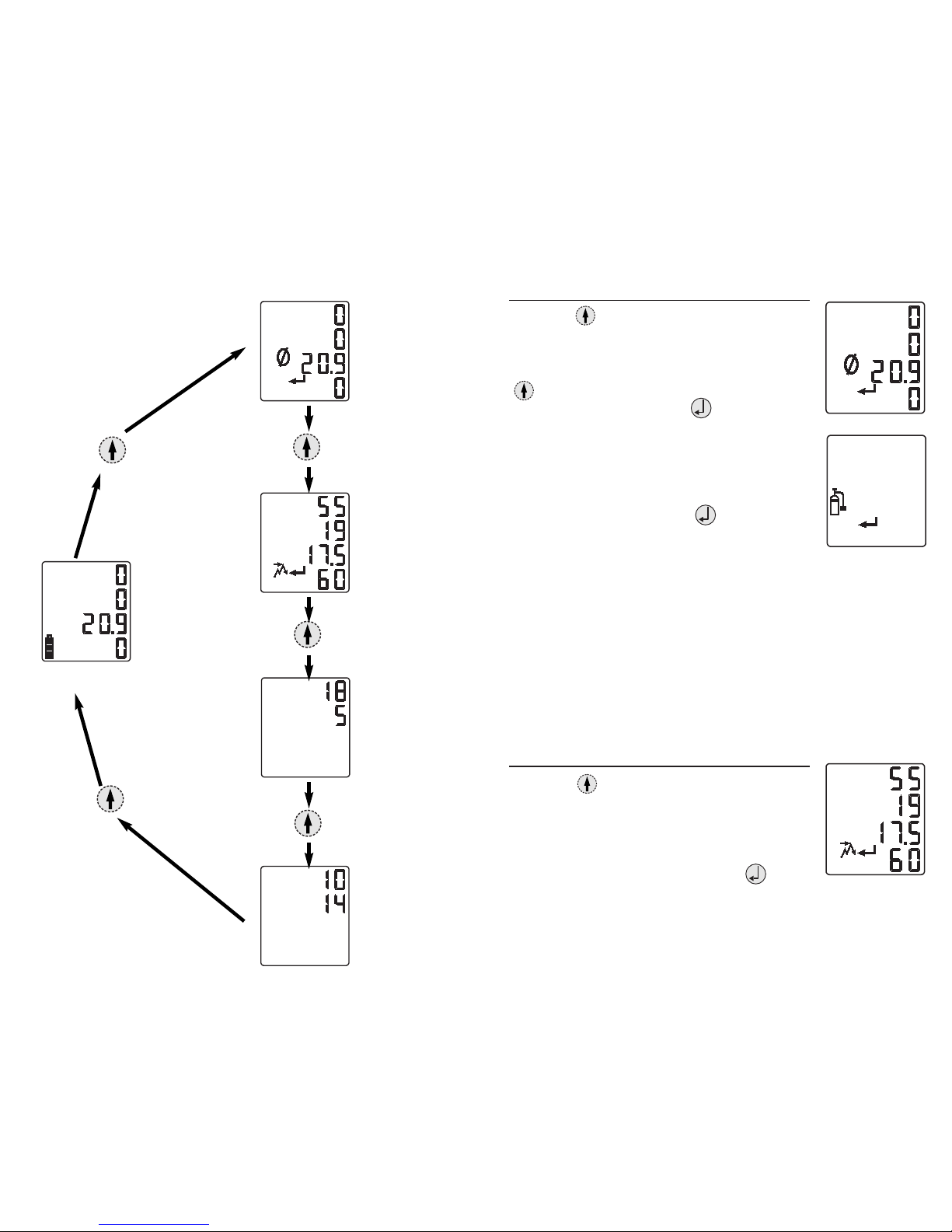

From the Gas Reading Mode, there are four other modes

that can be accessed. These other modes are reached by

pressing the arrow key.

I

NTRODUCTION

The M40 is a portable gas monitor capable of continuously

and simultaneously monitoring 4 standard gases; O2, LEL,

CO and H2S. Each gas reading is displayed on a custom

graphic LCD. The instrument provides user configurable

low and high alarms as well as STEL and TWA alarms.

When alarm conditions are exceeded, the M40 has audio,

visual and a standard vibrating alarms to alert the user.

98

ZERO/CALIBRATION MODE

Pressing the arrow key once from the Gas Reading

Mode will put the M40 in the Zero/Cal Mode. When this

mode is entered, the "Zero" icon and the "Enter" icon will

be displayed along with all four gas readings. Pressing the

arrow key a second time will advance you to the

Display Peaks Mode. Pressing the key will start the

zeroing process. When the CO, H2S, and LEL sensors

have finished the zeroing process, the oxygen sensor will

start to span. During this process, the "Clock" icon and

oxygen full span value will be displayed. When this

process is complete, the instrument will display the "Span"

icon and "Enter" icon. Pressing the key at this time

will cause the M40 to begin calibration for the remaining

sensors. For more information, reference the calibration

section on page 15.

The M40 calibration gases are fixed values. You must

calibrate the instrument on a blended cylinder containing

25 ppm H2S, 100 ppm CO, 25% or 50% LEL Methane or

Pentane, and 19% Oxygen at 0.5 LPM flow.

Note: CSA International compulsory calibration is 50%

LEL Methane.

DISPLAY PEAKS MODE

Pressing the arrow key from the Zero/Calibration

Mode will advance the M40 to the Display Peaks Mode.

When in this mode, the M40 will display the peak gas

readings seen by the toxic and combustible sensor as well

as the lowest reading for the oxygen sensor. The "Peak"

and "Enter" icons are displayed. Pressing the key

will reset all the peak values to the current reading.

TWA

STEL

Gas Reading Mode

Zero/Callibration

Mode

Display Peaks

Mode

View TWA

Mode

View STEL

Mode

O

PERATING

M

ODES

Pressing the and arrow keys simultaneously

during the twenty second countdown will put the M40 into

the Configuration Mode. The Configuration Mode allows

the user to change the Low, High, TWA, and STEL alarm

levels, as well as set the time, date and security code (if

desired). Once the Configuration Mode is entered, a

Security Code screen will be displayed. If no security

code has been set ( 000 ), the M40 will go directly to the

low alarm setpoints. If a security code has been set, use

the and arrow keys to change the value of the

flashing digits to match the code. Once the desired

number is reached for the first digit, press the key to

select the next digit. Continue this process until all three

digits are correct, then press the key. For any

changes made in the Configuration Mode to take affect,

the instrument must be turned off and restarted.

C

ONFIGURATION

M

ODE

1110

VIEW TWA MODE

Pressing the arrow key a third time will put the M40

in the View TWA Mode. The TWA screen will show the

"TWA" icon along with the TWA (Time Weighted

Average) values for the two toxic sensors. TWA values

are reset every time the instrument is powered down, and

the time base is set for 8 hours.

VIEW STEL MODE

Pressing the arrow key a fourth time from the Gas

Reading Mode will put the M40 in the View STEL Mode.

The STEL screen with display the "STEL" icon along

with the STEL values for the two toxic sensors. STEL

(Short Term Exposure Limit) for the toxic sensors will be

reset every time the unit is powered down. The time base

for the STEL is set for 15 minutes.

LOW ALARM SET POINTS

This is the first of the configuration screens. The display

will show the "Buzzer", "Low", "Enter", and

"Up/Down/Enter" icons along with the four low alarm set

points. If no changes are needed, press the arrow

key to move to the next screen. If changes are desired,

press the key. The first low alarm value will be

flashing. To adjust this value, use the and

arrow keys. Once the desired value is met, press the

key to select the next low alarm value. Continue

this process until all four low alarm set points have been

set. Once all four values are set, the display will again

show the "Buzzer", "Low", "Enter", and "Up/Down/Enter"

icons along with the four low alarm set points. Pressing

the key will re-enter the mode and let you set the low

alarm levels again; pressing the arrow key will move

you to the High Alarm Set Points screen. Pressing the

key at any time will take you back to initial Low Alarm

screen, and no changes will be saved. Pressing the

key a second time will take you to the normal Gas

Readings screen. The low alarm is a non-latching alarm.

HIGH ALARM SET POINTS

This is the second of the configuration screens. The

display will show the "Buzzer", "High", "Enter", and

"Up/Down/Enter" icons along with the four high alarm set

points. If no changes are needed, press the arrow

key to move to the next screen. If changes are desired,

press the key. The first high alarm value will be

flashing. To adjust this value, use the and

arrow keys. Once the desired value is met, press the

key to select the next high alarm value.

TWA

STEL

STEL ALARM SET POINTS

The fourth of the configuration screens is the STEL alarm

values. The display will show the "STEL", "Buzzer",

"Low", "Enter", and "Up/Down/Enter" icons along with

the two STEL alarm set points. If no changes are needed,

press the arrow key to move to the next screen. If

changes are desired, press the key. The first STEL

alarm value will be flashing. To adjust this value, use the

and arrow keys. Once the desired value is met,

press the key to select the next STEL alarm value.

Continue this process until both STEL alarm set points

have been set. When both values are set, the display will

again show the "STEL", "Buzzer", "Low", "Enter", and

"Up/Down/Enter" icons along with the two STEL alarm

set points. Pressing the key will re-enter the mode

and let you set the STEL alarm levels again; pressing the

arrow key will move you to the Clock Setting

screen. Pressing the key at any time will take you

back to initial STEL Alarm screen, and no changes will be

saved. Pressing the key a second time will take you

to the normal Gas Readings screen.

CLOCK SETTING

Setting the clock is the next configuration screen. The

display will show the "Clock", "Enter", and

"Up/Down/Enter" icons along with two rows of digits. If

no changes are needed, press the arrow key to move

to the next screen. If changes are desired, press the

key. The first value that will be flashing is the hours

setting of your clock. To adjust this value, use the

and arrow keys. Once the desired value is met, press

the key to select the minutes value. Continue this

process until both hours and minutes have been set. When

both values are set, the display will again show the

"Clock", "Enter", and "Up/Down/Enter" icons along with

the two rows of digits. Pressing the key will re-enter 13

12

Continue this process until all four high alarm set points

have been set. Once all four values are set, the display will

again show the "Buzzer", "High", "Enter", and

"Up/Down/Enter" icons along with the four high alarm set

points. Pressing the key will re-enter the mode and

let you set the high alarm levels again; pressing the

arrow key will move you to the TWA Alarm Set Points

screen. Pressing the key at any time will take you

back to initial High Alarm screen, and no changes will be

saved. Pressing the key a second time will take you

to the normal Gas Readings screen. The high alarm is a

non-latching alarm.

TWA ALARM SET POINTS

This is the third of the configuration screens. The display

will show the "TWA", "Buzzer", "Low", "Enter", and

"Up/Down/Enter" icons along with the two TWA alarm set

points. If no changes are needed, press the arrow key

to move to the next screen. If changes are desired, press

the key. The first TWA alarm value will be flashing.

To adjust this value, use the and arrow keys.

Once the desired value is met, press the key to select

the next TWA alarm value. Continue this process until

both TWA alarm set points have been set. When both

values are set, the display will again show the "TWA",

"Buzzer", "Low", "Enter", and "Up/Down/Enter" icons

along with the two TWA alarm set points. Pressing the

key will re-enter the mode and let you set the TWA alarm

levels again; pressing the arrow key will move you to

the STEL Alarm Set Points screen. Pressing the key

at any time will take you back to the initial TWA Alarm

screen, and no changes will be saved. Pressing the

key a second time will take you to the normal Gas

Readings screen.

TWA

TWA

STEL

STEL

15

14

the mode and let you set the hours and minutes again;

pressing the arrow key will move you to the

Calendar Setting screen. Pressing the key at any

time will take you to the normal Gas Readings screen.

CALENDAR SETTING

Setting the calendar is the configuration screen after the

clock set up. The display will show the "Calendar",

"Enter", and "Up/Down/Enter" icons along with three rows

of digits. If no changes are needed, press the arrow

key to move to the next screen. If changes are desired,

press the key. The first value that will be flashing is

the month setting of your clock. To adjust this value, use

the and arrow keys. Once the desired value is

met, press the key to select the day value. Continue

this process until the month, day and year have been set.

When all three values are set, the display will again show

the "Calendar", "Enter", and "Up/Down/Enter" icons

along with three rows of digits. Pressing the key will

re-enter the mode and let you set the calendar again;

pressing the arrow key will move you to the Security

Code Settings screen. Pressing the key at any time

will take you to the normal Gas Readings screen.

SECURITY CODE SETTING

The next setting is the Security Code Settings. The

display will show the "Closed Lock", "Enter", and

"Up/Down/Enter" icons along with the top row of digits

displaying the current security code. If no changes are

needed, press the arrow key to move to the LEL

settings. If changes are desired, press the key. The

current security code will be flashing. To adjust the first

value, use the and arrow keys. Once the

desired value is met, press the key to select the next

digit. Continue this process until all three digits have been

set. When all three values are set, the display will again

show the "Closed Lock", "Enter", and "Up/Down/Enter"

icons along with the top Security Code. Pressing the

key will re-enter the mode and let you set the security

code again; pressing the arrow key will move you to

LEL Settings. Pressing the key at any time will take

you back to the initial Security Code screen, and no

changes will be saved. Pressing the key a second

time will take you to the normal Gas Readings screen. If a

security code is set, the user will not be able to calibrate

the instrument in the field or make any changes to the

instruments settings without entering the proper code. To

Calibrate the instrument when a security code is set, the

user must turn on the instrument and enter the

Configuration Mode. Once the proper password is

entered, the user can select the Protected Zero/Cal Setting

to zero and calibrate the instrument.

LEL SETTING

The LEL Setting Configuration screen allows the user to

select the LEL calibration gas concentration. After

pressing the key, the LEL and the concentration will

start to flash. Use the to toggle between 25% LEL

and 50% LEL. When the desired concentration is

selected, press the key. Pressing the key will

take you out of the Configuration Mode and into the

normal Gas Reading Mode. Pressing either of the arrow

keys will scroll you through the configuration menus.

PROTECTED ZERO/CAL SETTING

The final configuration screen is a protected zero and

calibration screen. This setting allows the user to zero and

calibrate the instrument when a security code is set. For

more information on how to calibrate the M40, please see

the Zero/Calibration section.

17

16

The M40 comes standard with a continuous loop data logger. The

data logger has enough memory to store 50 hours of data for all four

sensors as well as the temperature. When the 50 hours is exceeded,

the data logger will go back and start overwriting the oldest data in

memory. Data is logged in one minute intervals and can be

downloaded to a PC via the software package and Datalink Module.

Data is extracted from the M40 via a Datalink Module (1810-5528).

To purchase a Datalink Module please contact either you local

distributor of Industrial Scientific Products, or call Industrial

Scientific Corporation at 1-800-DETECTS. To use the Datalink

Module, you must first install the setup software located on the CD

(comes with Datalink). Also make sure there is a fresh battery in the

Datalink Module. Once the Datalink is connected to the M40, and to

the COM port on your PC, click on the "Connect" button to establish

communication. Once communication is established, data can be

downloaded or cleared from the interface menu. To view data, select

"File Open", and to view graphics, select "Graphics" from the

spreadsheet menu. To disconnect at anytime, click on the

"Disconnect" button and unplug the M40.

Note: When a sensor is in an over range condition, a value of 1000

will be logged into the datalog memory for that sensor.

D

ATA

L

OGGING

LEL O

VER

R

ANGE

Z

ERO

/C

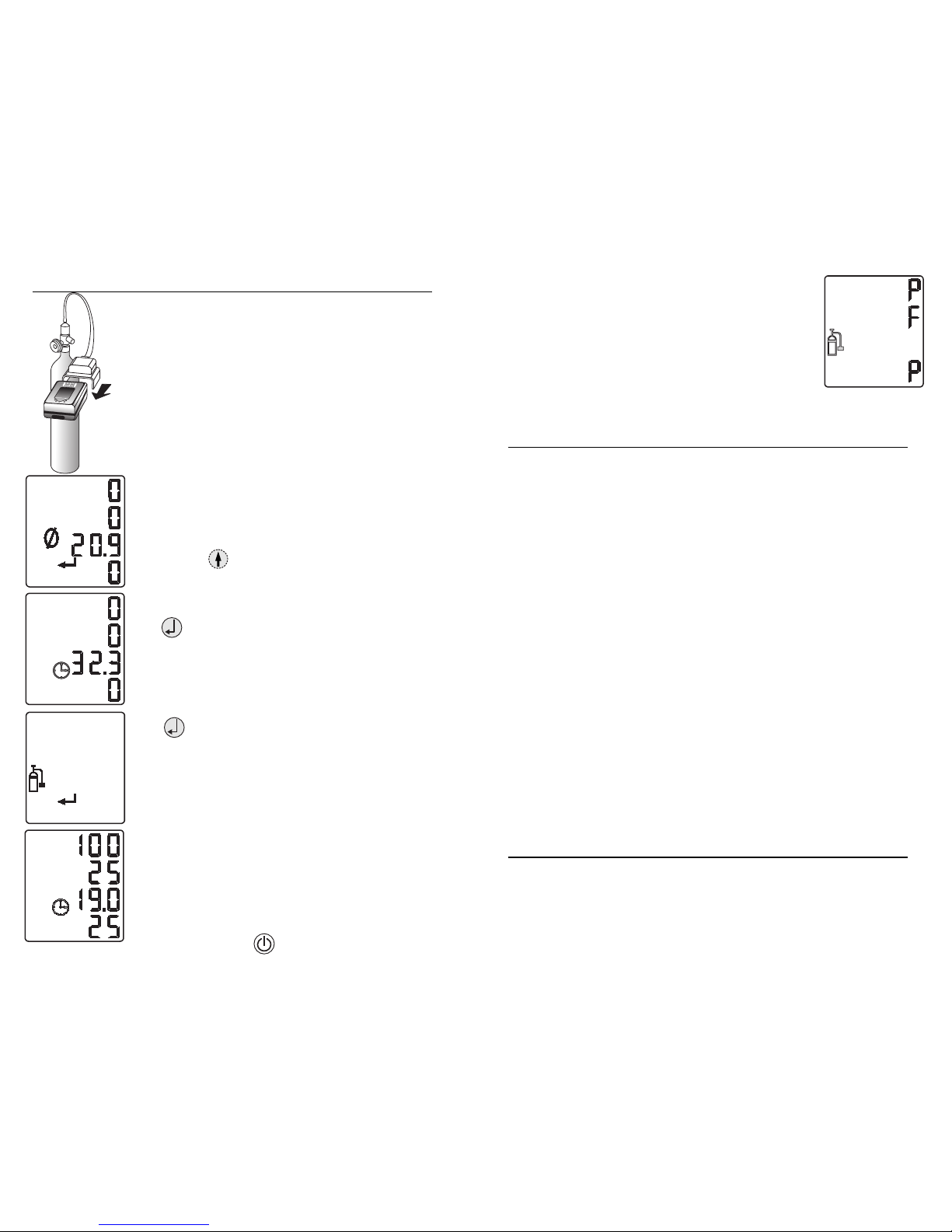

ALIBRATION

The M40's calibration procedure is a ‘Quick-Cal’

procedure that will calibrate all four sensors

simultaneously with a single blended cylinder of gas. The

‘Quick-Cal’ feature offers calibration times of <60

seconds. The M40 can be calibrated with or without the

external pump. If calibrating with the SP40 pump on the

instrument, please attatch a piece of tubing from the end

of the pump to the demand flow regulator on the blended

gas cylinder. When using a pressure regulator to calibrate

with the SP40 pump, attach the supplied T-fitting/tubing

assembly to the pressure regulator and SP40 pump. If

calibrating without the SP40, securely place the M40 cal-

cup over the sensors. With a piece of tubing, connect the

cal-cup to the regulator on the blended gas cylinder.

Pressing the arrow key once from the Gas Reading

Mode will put the M40 in the Zero/Cal Mode. When this

mode is entered, the "Zero" icon and the "Enter" icon will

be displayed along with all four gas readings. Pressing

the key will start the zeroing process. When the CO,

H2S, and LEL sensors have finished the zeroing process,

the oxygen sensor will start to span. During this process,

the "Clock" icon and oxygen full span value will be

displayed. When this process is complete, the instrument

will display the "Span" icon and "Enter" icon. Pressing

the key at this time will cause the M40 to begin

calibration for the remaining sensors. If this occurs, the

display will flash the "Clock" icon along with the span

values of the sensors. When gas is detected, the display

will show the span readings as well as the "Calibration"

icon. This is a quick calibration (‘Quick-Cal’) process,

and should take no longer than 60 seconds. At the end of

the calibration, the display will flash between the span

readings and a pass/fail indication for ten seconds. Full

span values between 50 and 70 percent are considered

marginal calibrations, and the sensor may soon need

replaced. Full span values less than 50 percent will result

in a failed calibration. To abort calibration at any point in

the process, press the key.

CO

H2S

O2

LEL

The M40 calibration gases are fixed values. You must

calibrate the instrument on a blended cylinder containing

25 ppm H2S, 100 ppm CO, 25% or 50% LEL Methane or

Pentane, and 19% Oxygen at 0.5 LPM flow.

Note: CSA International compulsory calibration is 50%

LEL Methane.

Note: If a security code is set, user will not be able to

calibrate instrument in the field. Please refer to Security

Code Setting for more information.

When an LEL over range condition occurs, the M40 instrument will

enter into an LEL over range condition. This condition is identified

as a continous high alarm. To clear the LEL over range, power down

the M40 and restart it. After any over range it is good practice to

verify the calibration of the combustible gas sensor.

19

18

SP40 S

AMPLING

P

UMP

The SP40 external sampling pump is available for the M40. The SP40 is a parasitic

pump that draws its power from the M40's battery pack. The pump attaches to the

M40 via two captive screws on the face of the M40. The SP40 has a flow rate of .5

SCFH (0.25 LPM), and can draw up to a 50 foot sample. If flow is restricted to the

pump, the M40 will go into a low flow alarm to alert the user.

If the M40 gets a low flow alarm, make sure there are no visible restrictions in the

sampling line. If the unit stays in alarm, the internal dust/water filter should be

replaced. To replace the filter, power down the M40 and remove the end nozzle of the

SP40. Once the nozzle is removed, replace the internal filter. With the new filter in

place, screw the end nozzle back onto the SP40 and power up the M40.

Note: Proper verification of the SP40 flow alarm is recommended before each days

use. To verify operation, restrict flow to the SP40 by blocking the inlet with a finger

and making sure the M40 goes into a flow alarm. A flow alarm is indicated by a high

alarm with a flashing fan icon on the screen.

CHARGING THE BATTERIES

The lithium-ion (Li-ion) battery pack should be fully charged before using the

M40. To charge the internal battery, plug the flying lead of the M40 battery

charger into the charging port located at the bottom of the instrument. This port

is protected with a rubber flap. To ensure proper connection, line up the arrow on

the charger plug with the arrow on the label located on the bottom of the M40.

The battery pack should be fully charged in 5 hours. With a fully charged battery

pack, the M40 typically will run 18 hours in the diffusion mode, or 12 hours with

the SP40. As the battery life decreases, the shaded area of the battery icon will

also decrease. With a maximum of 10 minutes left in the life of the battery, the

M40 will emit a periodic tone alerting you to charge the unit.

M

AINTENANCE

With normal routine maintenance the M40 can be relied upon to provide years of

dependable service. The following guidelines should be followed when performing

maintenance on the M40.

CLEANING

When necessary, wipe the outside of the M40 with a soft, clean cloth. Never

use solvents or cleaning solutions of any type. Make sure the sensor diffusion

membrane is free of debris. Clean sensor openings with a soft, clean cloth or

soft brush.

M40 S

PECIFICATIONS

Size: 4.30" x 2.45" x 1.27" (109mm x 62mm x 35mm)

Weight: 8.6 oz. without SP40 (243 grams)

11.5 oz. with SP40 (326 grams)

Display: Custom Grahic LCD with Backlight

SENSOR SPECIFICATIONS:

Gas Range Resolution T90

Carbon Monoxide (CO) 0-999 ppm 1 ppm 48 sec

Hydrogen Sulfide (H2S) 0-500 ppm 1 ppm 30 sec

Oxygen (O2) 0-30% 0.1% 10 sec

Combustible (LEL) 0-100% LEL 1% 35 sec

TEMPERATURE AND HUMIDITY RANGE:

Operating Temperature: -20ºC to +50ºC (-4ºF to 122ºF),

all sensors

per CSA standard C22.2 No. 152,

LEL sensor tested to 0ºC to 40ºC

(32ºF to 104ºF)

Operating Humidity: 15-95% RH, typical

0-99%, intermittent, non-condensing

Storage Temperature: 0 to 20ºC (32º to 68ºF)

BATTERY SPECIFICATIONS:

Rechargeable Lithium-Ion battery

3.6 Volts, 1.8 Amp/hr.

CHARGER SPECIFICATIONS:

Runtimes:

18 hours diffusion, 12 hours with pump

Runtimes are specified at room temperature with no alarm conditions.

21

20

PART NO. DESCRIPTION

Accessories 1810-5460 SP40 Sampling pump

1810-5528 Datalink

1810-5478 M40 Nylon Carrying Case

1810-5486 M40/SP40 Combination Carrying Case

1810-5494 Compact Charger 120 VAC

1810-5668 Compact Charger 230 VAC

1810-5890 Compact Charger 230 VAC (UK)

1810-5908 Compact Charger 230 VAC (Aus)

1810-5502 12 VDC Automotive Charger

1810-5510 6 Unit Charger

1710-8895 Swivel Belt Clip (standard)

1709-2941 Metal Belt Clip

1710-7582 Suspender Clip

1810-5981 M40 Leather Case

1810-5999 M40/SP40 Combination Leather Case

Calibration Stations

M-CAL 401: Single Unit M40 calibration station:

18105965-10X X = 0 (US plug)

= 1 (UK plug)

= 2 (European plug)

= 3 (Australian plug)

M-CAL 401: Single Unit M40/SP40 combination calibration

station:

18105965-01X X = 0 (US plug)

= 1 (UK plug)

= 2 (European plug)

= 3 (Australian plug)

M-CAL 406: Six Unit Configurable Calibration Station

18105973-ABC A = # of M40 bays (0-6)

B = # of SP40 bays (0-6)

C = 0 (US plug)

= 1 (UK plug)

= 2 (European plug)

= 3 (Australian plug)

Confined Space Kits M40-KIT-11111 M40/SP40 - O2, LEL, CO, H2S

M40-KIT-11101 M40/SP40 - O2, LEL, H2S

M40-KIT-11110 M40/SP40 - O2, LEL, CO

R

EPLACEMENT

P

ARTS

L

IST

W

ARRANTY

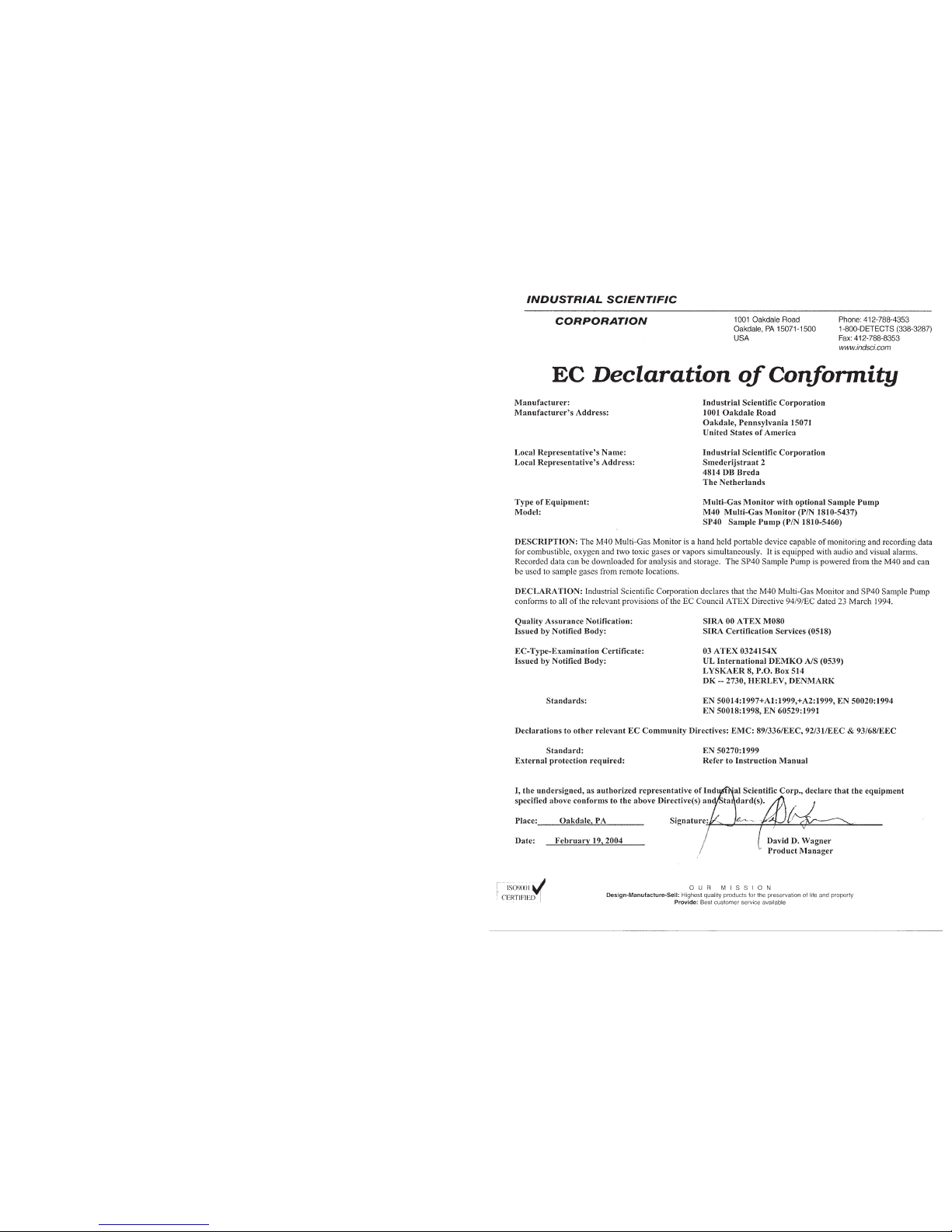

Industrial Scientific Corporation's M40 portable gas monitors are warranted to be

free from defects in material and workmanship for a period of two years after

purchase.

The above warranty includes sensors, battery pack, and sampling pump (SP40).

Filters are warranted to be free from defects in material and workmanship for 18

months from date of shipment, or 1 year from date of first use, whichever occurs

first, except where otherwised stated in writing in Industrial Scientific literature

accompanying the product.

LIMITATION OF LIABILITY

INDUSTRIAL SCIENTIFIC MAKES NO OTHER WARRANTIES, EITHER

EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR PARTICULAR

PURPOSE.

SHOULD THE PRODUCT FAIL TO CONFORM TO THE ABOVE WARRANTY,

BUYER’S ONLY REMEDY AND INDUSTRIAL SCIENTIFIC’S ONLY

OBLIGATION SHALL BE, AT INDUSTRIAL SCIENTIFIC’S SOLE OPTION,

REPLACEMENT OR REPAIR OF SUCH NON-CONFORMING GOODS OR

REFUND OF THE ORIGINAL PURCHASE PRICE OF THE NON-

CONFORMING GOODS.

IN NO EVENT WILL INDUSTRIAL SCIENTIFIC BE LIABLE FOR ANY

OTHER SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES,

INCLUDING LOSS OF PROFIT OR LOSS OF USE, ARISING OUT OF THE

SALE, MANUFACTURE OR USE OF ANY PRODUCTS SOLD HEREUNDER

WHETHER SUCH CLAIM IS PLEADED IN CONTRACT OR IN TORT,

INCLUDING STRICT LIABILITY IN TORT.

It shall be an express condition to Industrial Scientific’s warranty that all products

be carefully inspected for damage by Buyer upon receipt, be properly calibrated for

Buyer’s particular use, and be used, repaired, and maintained in strict accordance

with the instructions set forth in Industrial Scientific’s product literature. Repair or

maintenance by non-qualified personnel will invalidate the warranty, as will the use

23

22

of non-approved consumables or spare parts. As with any other sophisticated

product, it is essential and a condition of Industrial Scientific’s warranty that all

personnel using the products be fully acquainted with their use, capabilities and

limitations as set forth in the applicable product literature.

Buyer acknowledges that it alone has determined the intended purpose and

suitability of the goods purchased. It is expressly agreed by the parties that any

technical or other advice given by Industrial Scientific with respect to the use of

the goods or services is given without charge and at Buyer’s risk; therefore,

Industrial Scientific assumes no obligations or liability for the advice given or

results obtained.

Copyright

2003 © Industrial Scientific Corporation

All rights reserved.These help materials or any part thereof may not, without the

written consent of Industrial Scientific Corporation, be copied, reprinted or reproduced

in any material form including but not limited to photocopying, transcribing, transmitting

or storing it in any medium or translating it into any language, in any form or by any

means, be it digitally, electronic, mechanical, xerographic, optical, magnetic or

otherwise.

The information contained in this document is proprietary and confidential and all

copyright, trade marks, trade names, patents and other intellectual property rights in

the documentation are the exclusive property of Industrial Scientific Corporation

unless otherwise specified.The information (including but not limited to data, drawings,

specification, documentation, software listings, source or object code) shall not at any

time be disclosed directly or indirectly to any third party without prior written consent.

The information contained herein is believed to be accurate and reliable. Industrial

Scientific Corporation accepts no responsibility for its use by any means or in any way

whatsoever Industrial Scientific Corporation shall not be liable for any expenses, costs

by damage that may result from the use of the information contained within this

document.The information contained herein is subject to change without notice.

Table of contents

Other Industrial Scientific Monitor manuals