Industrial Scientific T40 II User manual

Portable Single Gas Monitor

Product

Manual

The Essential Guide for

Safety Teams and

Instrument Operators

Edition: 2.3

Sep 27, 2022

Part Number: 17160575-1

1

Content

1. Certifications................................................................................................................. 2

2. Warnings and cautionary statements........................................................................ 3

3. Product Overview......................................................................................................... 3

3.1 Product Specifications......................................................................................... 4

3.2 Hardware Overview............................................................................................. 5

4. Operation and Instructions ......................................................................................... 6

4.1 Display Overview................................................................................................. 6

4.2 Start-up, Shutdown and Always on..................................................................... 8

4.3 Configuration mode ............................................................................................. 8

4.4 Operation mode................................................................................................. 13

4.5 Bump test (or "functional test").......................................................................... 15

4.6 Zeroing............................................................................................................... 16

4.7 Calibration.......................................................................................................... 17

5. Alarms and Notifications.......................................................................................... 18

6. Replace the battery .................................................................................................... 19

7. Warranty Policy .......................................................................................................... 20

8. Limitation of Liability ................................................................................................. 20

2

1. Certifications

Directive

or CB

Area Classifications

Approved

Temperature

Range

Standards

IECEx

Ex ia IIC T4 Ga

Ex ia I Ma

-40 ° C to +50 ° C

-40 ° F to +122 ° F

IEC 60079-0:2017 Ed.7.0

IEC 60079-11:2011 Ed.6.0

ATEX

Ex ia IIC T4 Ga

Ex ia I Ma

-40 ° C to +50 ° C

-40 ° F to +122 ° F

EN IEC 60079-0:2018

EN 60079-11:2012

UL

Class I, Division 1,

Groups A, B, C, D T4

Class I, Zone 0, AEx ia

IIC T4 Ga

-40 ° C to +50 ° C

-40 ° F to +122 ° F

ANSI/UL 60079-0-2020 Ed.7

ANSI/UL 60079-11-2018 Ed.6

ANSI/UL 913-2019 Ed.8

UL 61010-1 3rd Edition (2012),

AMD1: 2018

CSA

Ex ia IIC T4; Class I,

Division 1, Groups A,

B, C, D T4

-40 ° C to +50 ° C

-40 ° F to +122 ° F

CAN/CSA C22.2

No. 60079-0:19

CAN/CSA-C22.2

No. 60079-11:14 (r2018)

CAN/CSA C22.2 No.61010-1-12,

UPD1: 2015, UPD2: 2016,

AMD1: 2018

China

Ex

Ex ia IIC T4 Ga

-40 ° C to +50 ° C

-40 ° F to +122 ° F

GB/T 3836.1- 2021

GB/T 3836.4- 2021

GB/T 4208-2017

China

CPA

Metrological

-10 ° C to +40 ° C

14 ° F to +104 °F

JJF 1363-2019

JJF 1421-2013

China

MA

Ex ia I Ma

-20 ° C to +40 ° C

-4 ° F to +104 °F

MT 703-2008

GB/T 3836.1-2021

GB/T 3836.4-2021

3

2. Warnings and cautionary statements

For maximum safety and optimal performance, read and understand the manual

before operating or servicing the unit. Failure to perform certain procedures or note

certain conditions may impair the performance of this product.

For safety reasons, this equipment must be operated and serviced by qualified

personnel only. Customer site assembly is not recommended, improper disassembly

may reduce the performance of the instrument.

Substitution of components may impair intrinsic safety and may cause an unsafe

condition.

DO NOT REPLACE BATTERY WHEN AN EXPLOSIVE ATMOSPHERE IS

PRESENT. USE ONLY RAMWAY ER14335 BATTERIES.

Before use, ensure that the ESD film on the LCD display and label is not damaged or

peeling.

Obstruction of sensor openings–due to dust, dirt, water, or another cause–can inhibit

the unit’s ability to measure gas concentrations accurately. When this occurs,

readings may appear lower than the actual gas concentration. Keep sensor openings

clean, dry, and properly exposed to the ambient air.

Obstructed, contaminated, or damaged sensor water barriers (or their gaskets) can

inhibit the unit’s ability to measure gas concentrations accurately. When this occurs,

readings may appear lower than the actual gas concentration. Contact after-sales

service to replace the sensor water barriers and gaskets as needed.

Service the unit, use its communications port, and change its battery cell only in

nonhazardous locations. Not for use in oxygen-enriched atmospheres.

Contact your service representative immediately if you suspect that the unit is working

abnormally.

3. Product Overview

T40 II single gas monitor is compact, easy to carry and use. It is specially designed to detect the

concentration toxic gases, and mainly used in Petrochemical industry and coal mine. The monitor can

continuously monitor the concentration of harmful gas in the surrounding environment, once the gas

concentration reaches the low and high alarm and TWA/STEL alarm preset values, T40 II will produce

sound, light and vibration alarms

4

3.1 Product Specifications

Item

Description

Display

Segment LCD

Keypad buttons

Two buttons

Technology

Electrochemical

Battery Pack

Replaceable RAMWAY ER14335 3.6 V Primary Lithium-thionyl chloride

(Li-SOCl2) battery cell, 1.65AH, 2/3AA. Two-yearsarun time

Case materials

polycarbonate with a protective rubber over-mold

Alarms

Visual alarm (two red LEDs). Audible alarm(95 dB). Vibration alarm

Ranges

Carbon Monoxide (CO)

0-1000 ppm

0-2000 ppm

Hydrogen Sulfide(H2S)

0-100 ppm

0-200 ppm

0-500 ppm

Display resolution

1 ppm

0.1 ppm

Calibration gas and

concentration

100 ppm CO

25 ppm H2S

Response Time

<10s

<10s

Dimensions

82 x 60 x 27 mm (3.23 " x 2.36 " x 1.07 ")

Weight

85 g ( 3.0 oz.), typical

Ingress protection

IP66 / IP68

Operating Tempc

-40 ° C to +50 ° C (-40° F to +122 ° F)

Operating humidity

5 to 95% relative humidity (RH) noncondensing

Pollution Degree

2

Maximum use

altitude

5000m above sea level

aDepending on operating conditions; the amount of time the unit is in alarm; and the enablement of

unit's confidence indicator.

bApply when the instrument is calibrated using the stated calibration gas and concentration; accuracy

is equal to the stated percentage.

c Operating temperatures below -20° C may cause reduced instrument accuracy and affect display and

alarm performance.

5

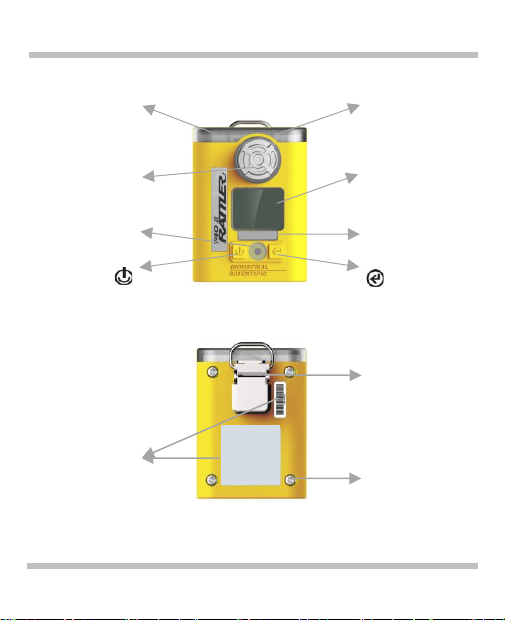

3.2 Hardware Overview

T40 II

Visual alarm indicator

Front

Visual alarm indicator

Sensor port

LCD Screen

Buzzer

On-off/mode button

Gas label

Enter/Edit button

Back

Clip

Serial number and

certificate label

Screw

Hardware overview

6

4. Operation and Instructions

The table below list that Industrial Scientific's minimum frequency recommendations for each program.

These recommendations are based on site data, safe work procedures, industry best practices and

regulatory standards to help ensure worker safety. Users can reduce the frequency of the following

procedures as appropriate according to the safety policy of local government or company, Industrial

Scientific is not responsible for developing security practices and policies.

Procedure

Recommended minimum frequency

Configuration

Before first use, when there is a change in the installed sensor type, and as

otherwise needed.

Calibration

Before first use and 6month interval, depending on use and exposure to

gas and contamination, such as vibration, drop or sensor replacement,

multiple high concentration gas shocks,etc.

Bump test

Prior to each day’s use.

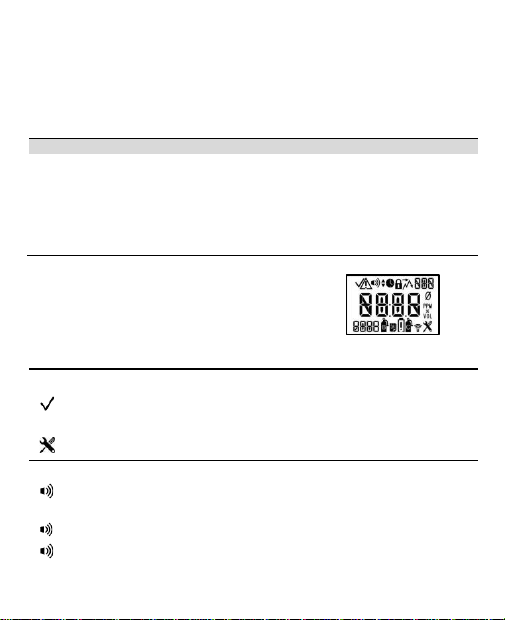

4.1 Display Overview

The visual test screen depicted right shows all the indicators that

can appear on the display screen. Each indicator is stationary and

appears only when relevant to the task being performed.

Display screens, indicators, and abbreviations

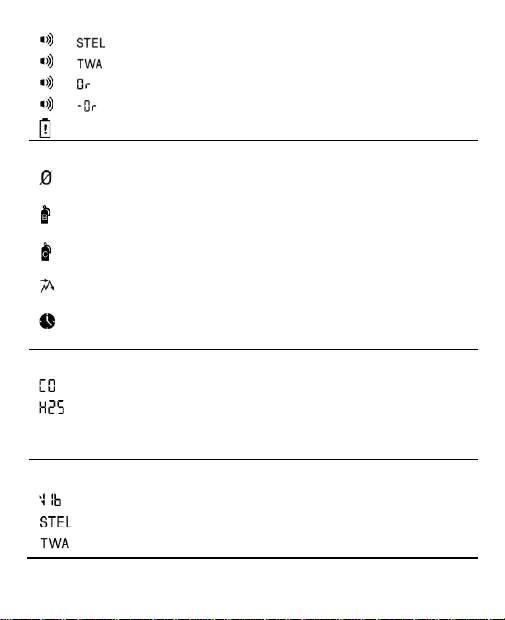

Status indicators

Instrument work normally.

!

Instrument failure.

The unit is in configuration mode.

Alarm indicators

The alarm icon is used in combination with other indicators to communicate a

variety of conditions.

and ▲

High-level gas alarm.

and ▼

Low-level gas alarm.

7

and

STEL alarm.

and

TWA alarm

and

Positive over-range gas alarm.

and

Negative over-range gas alarm.

Low-battery alarm.

Process and time-based indicators

The zero icon is used in combination with other indicators to communicate

sensor zero information.

The bump test icon is used in combination with other indicators to

communicate bump test information.

The calibration icon is used in combination with other indicators to

communicate calibration information.

The peak reading is the highest detected gas reading. Always clear the peak

reading after calibration.

A process is in progress. In configuration mode, indicates a time-based

setting (e.g. bump test response time).

Gas name and unit-of-measure abbreviations

Carbon Monoxide (CO)

Hydrogen Sulfide (H2S or H2S)

PPM

Parts per million is the unit of measure for CO and H2S,PPM is the volume

ratio in describing the gas concentration, 1ppm=10-6 equivalent to 1umol/mol.

Other abbreviations

Vibration alarm enabled.

Short-term exposure limit, default time 15minutes. Display variations: “STEL”

Time-weighted average. default time 8h. Display variations: “TWA”

8

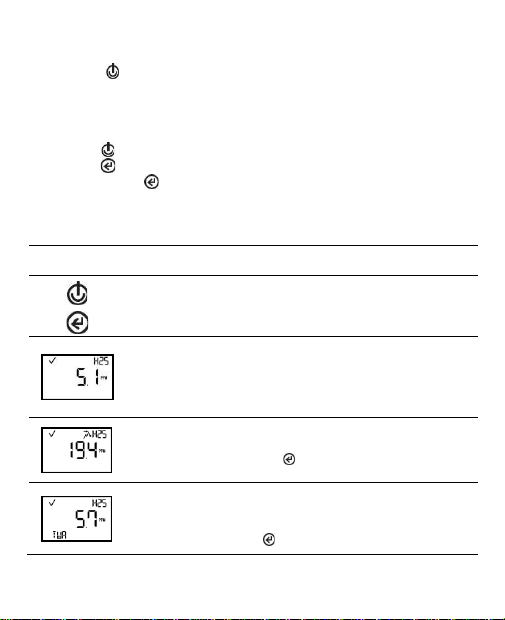

4.2Start-up, Shutdown and Always on

Start-up

Press and hold the for 3 seconds, the instrument starts to power on. After power on, the instrument

automatically enters the visual test, firmware version, 20-second countdown and the second visual test

screen, and is accompanied by warning sound and light test. After a short warm-up, it will automatically

enter the real-time gas monitoring screen.

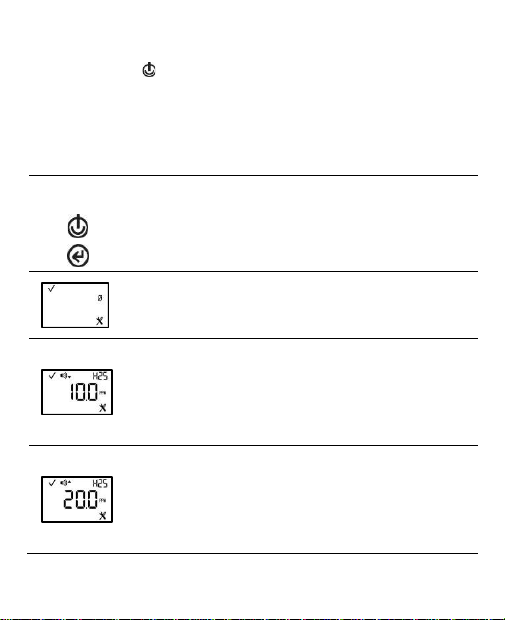

Visual test screen

Version

Countdown

Shutdown and always on

Countdown

Press and hold for five seconds.

After a five-second countdown:

The instrument powers off if;

•the always-on feature is disabled or

•the always-on feature is enabled and the security code is set

to 000.

Enter security code

If this screen is activated, the shutdown process is security-

code protected. To complete shutdown, the user must enter the

correct three-digit code.

Value range: 000 to 999

4.3 Configuration mode

Configuration mode can only be accessed during startup, at the 20 second countdown screen, press

and hold both buttons simultaneously more than 1second to enter configuration mode, select alarm

and warning related options that maximize safety within the air sampling environment.

When the unit is in configuration mode, the following apply:

•The tool icon ( ) displays in the lower right corner of each screen.

•With successive short presses of the on-off button( ), the user can scroll through the

configuration loop.

•The enter button ( ) is used to start the editing process or initiate zero.

•When editing a value, the enter button ( ) increments the value and the on-off-mode

button ( ) saves the value.

9

•When editing a value, once the last value in the range is reached, the display starts again

with the first value.

•When buttons ( ) is pressed and held more than 1 seconds, the unit leaves configuration

mode; it enters operation mode and the home screen is activated.

•Unless otherwise noted, when no button is pressed for 30 seconds, the unit enters operation

mode and the home screen is activated.

•Any changes made in configuration mode are automatically saved to the unit and take effect

immediately.

Configuration instructions

Buttons or

Screen

Button effects or Screen Description

Saves the currently displayed value or activates the next configuration

mode screen.

Increase value or First press activates the value. Continued presses

increment the value; hold to speed the increment pace.

Initiate zero

This screen allows the technician to complete the zero and calibration

processes from configuration mode.

Low gas alarm setpoint

This screen features the status, low alarm, sensor-type, and configuration

icons, with the alarm's current setpoint and unit of measure. Edit the alarm

setpoint based on the following:

Value range = starts at minumum sensor measurement resolution, ends at

the high gas alarm setpoint value.

Value increment = sensor measurement resolution

High gas alarm setpoint

This screen features the status, high alarm, sensor-type, and configuration

icons, with the alarm's current setpoint and unit of measure. Edit the alarm

setpoint based on the following:

Value range = starts at low gas alarm setpoint value, ends at the highest

measurement range value of the sensor.

Value increment = sensor measurement resolution

10

TWA alarm setpoint

This screen features the status, alarm, sensor-type, configuration, and

TWA icons, with the alarm's current setpoint and unit of measure. The

alarm setpoint can be edited.

Value increment = within the sensor measurement resolution

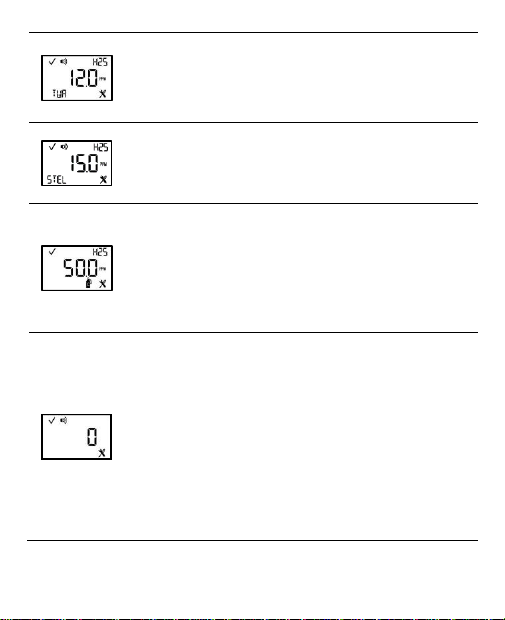

STEL alarm setpoint

This screen features the status, alarm, sensor type, configuration, and

STEL icons, with the current setpoint. The alarm setpoint can be edited.

Value increment: sensor measurement resolution

Calibration gas

This screen features the status, sensor-type, configuration, and calibration

icons, with the current calibration gas setting in the main area.

This setting reflects the concentration of calibration gas that the instrument

expects to read when calibrated; it should be edited to match the cylinder's

gas concentration.

Value range: within the sensor measurement range

Value increment: sensor measurement resolution

Confidence indicator

This screen features the status, alarm, and configuration icons, with the

selected setting value displayed in the main area. The technician can

disable or enable the indicator and choose the indicator type.

When enabled, the unit will emit the selected signal every 90 seconds in

operation mode.

Note: When options 1, 2, or 3 are selected, the expected battery life will be

reduced.

Values:

0 = disabled

1 = audible chirp enabled

2 = LED flash enabled

3 = audible chirp and LED flash enabled

11

Operation-mode bump test

This screen features the status, lock, configuration, and bump test icons,

with the selected setting value displayed in the main area. The technician

can enable or disable this operation mode feature.

When enabled, the instrument operator can bump test the unit from

operation mode.

Values:

0 = disabled ,1 = enabled

Bump test percentage

This screen features the status, configuration, and bump test icons, with

the current setting value displayed in the main area. The technician can set

the percentage of calibration gas to which the unit will respond.

Value range: 50% to 95%

Value increment: 1%

Bump test response-time

This screen features the status, clock, configuration, and bump test icons,

with the current setting in seconds displayed in the main area. A sensor

passes a bump test when it senses the specified percentage of calibration

gas within the specified response time setting.

Value range: 30 to 120 seconds

Value increment: 5 second

Alarm latch

This screen features the status, alarm, lock, and configuration icons, with

the current setting displayed in the main area. The technician can enable

or disable this operation-mode feature.

When disabled, a unit in alarm will turn off its alarm when the gas reading

is no longer at the alarm-producing concentration.

When enabled, a unit in alarm will remain in alarm until it is manually reset.

The instrument operator can reset a latched alarm from gas normal reading

screen by click button.

Values:

0 = disabled ,1 = enabled

12

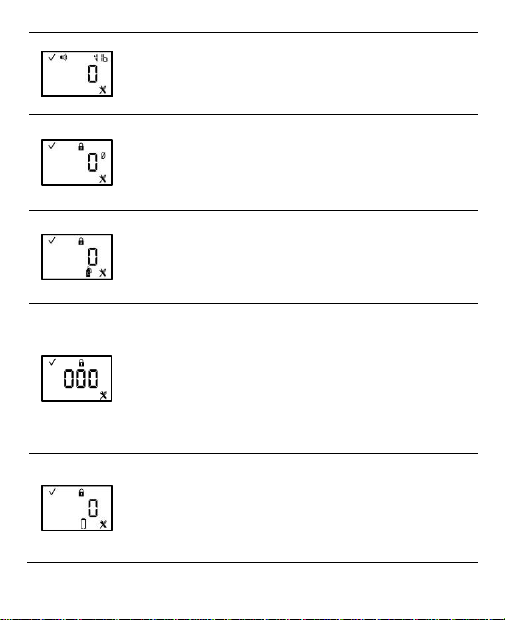

Vibration alarm

This screen features the status, alarm, “VIb”, and configuration icons, with

the selected setting value displayed in the main area. When enabled, the

vibrating alarm will be activated when the unit is in alarm.

Values: 0 = disabled ,1 = enabled

Operation-mode zero

This screen features the status, lock, zero, and configuration icons. The

technician can enable or disable this operation-mode option.

When enabled, the instrument operator can zero the unit from operation

mode.

Values: 0 = disabled ,1 = enabled

Operation-mode calibration

This screen features the status, lock, configuration, and calibration icons.

The technician can enable or disable this operation-mode option.

When enabled, the instrument operator can calibrate the unit from

operation mode.

Values:0 = disabled ,1 = enabled

Security code

This screen features the status, lock, and configuration icons, with the

current security code displayed in the main area. The security code

controls access to a unit's configuration mode and the ability to power off a

unit that is configured for always-on operation.

If the security code is set at 000, entry to configuration mode is not

security-code protected, and an always-on unit can be powered off without

a security code. Any other value will enable the security code.

Value range: 000 to 999

Value increment: 1

Always-on

This screen features the status, lock, configuration, and the battery icon.

The technician can enable or disable this feature.

When enabled, the entry of the unit's security code (if the security code is

not 000) will be required to complete the shutdown process.

Values:

0 = disabled ,1 = enabled

13

4.4 Operation mode

In the operation mode, the worker can scroll through the operating mode loop by continuously pressing

the on/off button ( ). The zeroing, calibration, and alarm function test procedures can only be

completed if these task settings are enabled for operating mode access。

TWA, STEL (if operating mode access is enabled) and peak readings can also be viewed and cleared.

When the reading summary is cleared, CO and H2S value resets to zero.

In operation mode, the following apply:

•Press to scroll through the operation-mode loop.

•Press to initiate a task or to clear a reading.

•A long press on will reset a latched alarm; it does not disable an enabled latch.

•Except where noted, when no button is pressed for 30 seconds, the home screen is

activated。

Operation instructions

Buttons or

Screen

Button effects or Screen Description

Saves the currently displayed value or activates the next configuration

mode screen.

Increase value or First press activates the value. Continued presses

increment the value; hold to speed the increment pace.

Gas monitoring

This screen (numeric shown) features the check mark and sensor-type

icons, the current gas reading, and unit of measure.

The check mark indicates the unit is operational and there are no sensor

faults.

Peak reading

This screen features the check mark, peak, and sensor-type icons, and the

most recent peak reading, Press clear the reading then the value reset

to 0 .

TWA reading

This screen displays when the TWA reading is enabled in operation-mode.

The screen features the check mark, sensor-type, and TWA icons, and the

current TWA reading. Press clear the reading then the value reset to 0 .

14

STEL reading

This screen displays when the STEL reading is enabled in operation-mode.

The screen features the check mark, sensor-type, and STEL icons, and the

current STEL reading. Press clear the reading then the value reset to 0 .

Initiate bump test

This screen displays when operation-mode bump testing is enabled. The

screen features the check mark and bump test icons.

Initiate zero

This screen displays when operation-mode zeroing is enabled. It features

the check mark and zero icons.

15

4.5 Bump test (or "functional test")

Bump testing is a functional test in which an instrument's installed

sensors are to be briefly exposed to (or “bumped” by) calibration

gases in concentrations that are greater than the sensors’ low-

alarm setpoints. This will cause the instrument to go into low

alarm and will indicate which sensors pass or fail this basic test

for response to gas.

Note:If fails the bump test, please perform a calibration. If failes

the calibration, please contact Industrial Sicentific after-sales

service.

Bump test instructions

Screen

Screen Description

Initiate bump test

From anywhere in the operation-mode loop, press until the initiate bump

test screen is activated.

Press to start the bump test process. Press to cancel the bump test.

Bump test apply gas

Once the bump test is started, the apply-gas screen is activated; the

expected type and concentration of calibration gas are displayed.

This screen remains activated for up to 5 minutes as the unit awaits the

application of calibration gas.

Bump test in progress

Bump test results

If fail the bump test, need to calibrate the instrument.

If pass the bump test, the home screen will be automatically activated.

note

:

Close the cylinder and remove the calibration cup after bump test.

16

4.6 Zeroing

Zeroing adjusts the sensors’ “baseline” readings, which become the

points of comparison for subsequent gas readings. It is a prerequisite

for calibration. During zeroing, the installed sensors are to be

exposed to an air sample from a zero-grade-air cylinder or ambient

air that is known to be clean air. If there are gases in the air sample

that are below the lowest alarm level, the instrument will read them

as zero; its task is to read the air sample as clean air. The user's task

is to ensure the air is clean.

Zeroing instructions

Screen

Screen Description

Initiate zero

From anywhere in the operation-mode loop, press until the initiate-zero

screen is activated.

At the initiate-zero screen, press to start the zero process.

Zero in-progress

While the sensors are zeroed, the zero-in-progress screen is activated.

Note

:

Must be zeroed in fresh air.

Zero results

After the sensors are zeroed, the zero-results screen is activated, and an

audible alert is emitted.

If the result is an "F" for fail, press to reactivate the initiate-zero screen.

Repeat the zero process.

If the result is a "P" for pass, press to display the initiate-calibration

screen. If calibration is not desired, press twice or wait approximately 30

seconds to active home screen.

17

4.7 Calibration

Regular calibrations promote the accurate measurement of gas

concentration values. During calibration, an instrument’s installed

sensors are to be exposed to their set concentrations of calibration

gases. Based on the sensors’ responses, the instrument will self-

adjust to compensate for declining sensor sensitivity, which naturally

occurs as the installed sensors are used or “consumed”.

Calibration instructions

Screen

Screen Description

Initiate calibration

press button at zero results screen to enter the intiate calibration

screen, then press button to start the calibration.

To cancel the calibration, press button.

Calibration apply gas

Once calibration is started, the apply-gas screen is activated; the expected

type and concentration of calibration gas are displayed.

This screen remains active for up to 5 minutes as the unit awaits the

application of calibration gas.

To cancel calibration, press button.

Calibration in progress

Note

:

Need to open the calibration gas cylinder regulator before

calibration.

Calibration results

If passes calibration, Result screens are alternately activated and displays

the span reserve value.

If fails calibration, the audible, visual, and vibrating alarms turn on. Results

screens are alternately activated; one indicates the fail results and the

other displays the span reserve value.

note

:

Close the cylinder and remove the calibration cup after calibration.

18

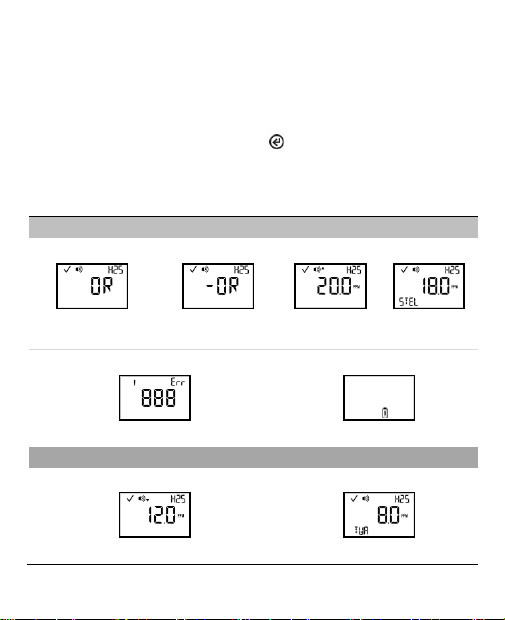

5. Alarms and Notifications

Alarms notify the instrument operator of danger.Warnings notify of a condition that needs attention.

Take seriously all alarms, warnings, and indicators, and respond to each according to company policy.

Alarms

T40 II gas monitors have alarms of two different intensities, high and low. Alarms are persistent: they

turn off when the alarm-causing event is no longer detected, however, if the instrument’s alarm latch is

enabled, an alarm will remain on until the user presses to turn it off.

When all alarm signals are on:

•The high alarm features the red lights, with steady sound. It is fast-paced.

•The low alarm is similar to the high alarm, but it is medium-paced.

Note: Signals (visual, audible, and vibration) vary based on instrument settings.

Alarm Level : High

Gas Present (H2S is shown.)

Gas present, over-

range alarm

Gas present, negative

over-range alarm

Gas present,

high alarm

STEL alarm

System alarm

System alarm

Critical low-battery alarm

Alarm Level: Low

Gas Present

Gas present, low alarm

TWA alarm

19

Notifications

Warnings persist until the event is resolved. In some cases, an

unresolved warning will become more urgent in frequency. For

example, a low-battery warning that is not resolved will change

to alarm status indicating a critical low-battery condition.

Low-battery warning

6. Replace the battery

When the battery has 12 to 72 hours left, T40 II display Low-battery

warning notification and emit 1 beep, visual and vibration alarm every

1minute. The users need contact Industrial Scientific or qualified

person to replace the battery.

1. Using a T10 Torx screwdriver, remove all four screws from the

case bottom; set aside the screws.

2. Lift the battery up from its cradle. Dispose of according to

company policy.

3. Orient the replacement battery so the positive and negative ends align with the "+" and "-" cradle

markings, respectively. Place the new battery into the cradle negative end first. Press down on

the battery to secure it in the cradle.

Note: Use RAMWAY ER14335 battery only.

Use Do not replace battery when an explosive atmosphere is present.

Work on a nonconductive surface in a well-lit area.

Wear grounding straps to prevent electrostatic discharge (ESD), which can cause damage

to the instrument's electronics.

Be sure to turn off the instrument before servicing the unit or replacing the battery.

+

-

Table of contents

Other Industrial Scientific Monitor manuals