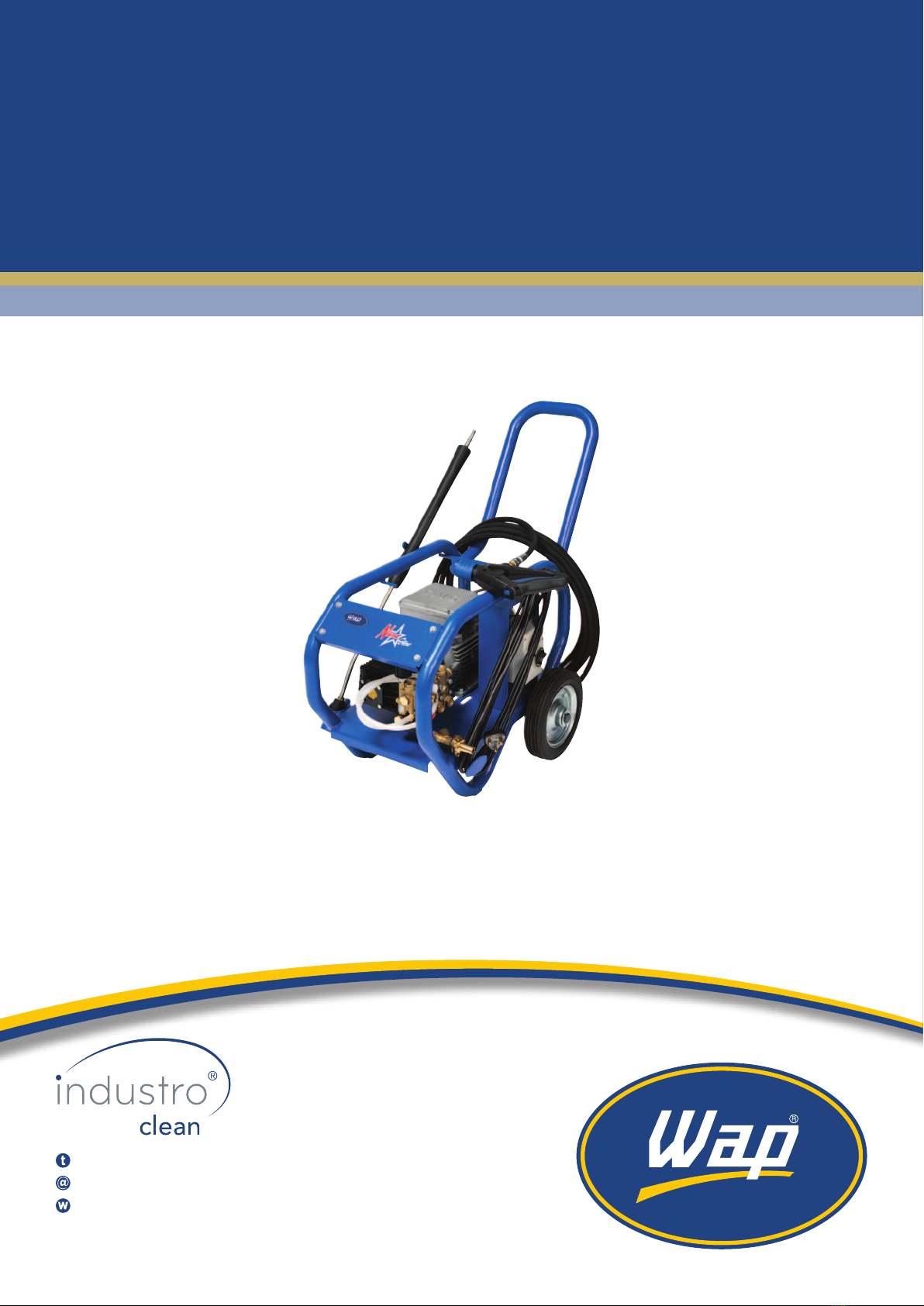

industro clean WAP NOVASTAR HPC 14/130E User manual

We know clean.

Achieve hygiene standards

crucial to your business

+ 27 (0)11 801 4600

info@industroclean.co.za

www.industroclean.co.za

Wap, a flagship brand of Industroclean

OPERATING / INSTRUCTION MANUAL

MODEL: WAP NOVASTAR HPC 14/130E 220V

& WAP NOVASTAR HPC 14/150E 380V

COLD WATER HIGH PRESSURE CLEANER

WAP Pressure Washer Range

Novastar

Mobile High Pressure Washer – Cold Water

The benchmark in mobile pressure washers

This medium duty high pressure cleaner is fully mobile, with all components mounted on a

sturdy steel base frame, protected by a steel impact protection cage. This machine is ideally

suited to industries such as agriculture, building and construction, mining and heavy

engineering.

Key Features

•Sturdy steel chassis with roll cage for maximum component protection, as well as easy loading and offloading

•Two solid, large diameter heavy duty wheels to facilitate convenient transportation, even over rough terrain.

•Positive displacement piston pump, oil lubricated with three ceramic pistons, suction and pressure valves with

stainless seats.

•Direct drive power transmission between high pressure pump and electric motor.

•Four pole electric motor, revolving at a speed of 1450rpm.

•Automatic unloader/regulator device with a pressure adjustment facility

•Chemical injector, venturi-type for “after-pump” injection of chemicals

WAP Pressure Washer Range

Novastar

Mobile High Pressure Washer – Cold Water

The benchmark in mobile pressure washers

This medium duty high pressure cleaner is fully mobile, with all components mounted on a sturdy

steel base frame, protected by a steel impact protection cage. This machine is ideally suited to

industries such as agriculture, building and construction, mining and heavy engineering.

Key Features

• Sturdy steel chassis with roll cage for maximum component protection, as well as easy loading and

ooading.

• Two solid, large diameter heavy duty wheels to facilitate convenient transportation, even over rough terrain.

• Positive displacement piston pump, oil lubricated with three ceramic pistons, suction and pressure valves

withstainless seats.

• Direct drive power transmission between high pressure pump and electric motor.

• Four pole electric motor, revolving at a speed of 1450rpm.

• Automatic unloader/regulator device with a pressure adjustment facility.

• Chemical injector, venturi-type for “after-pump” injection of chemicals.

WAP Pressure Washer Range

Technical Specifications

Description Unit Novastar 14/130 EC Novastar 14/150 E

Operating pressure bar 125/115/85* 150

Water volume l/hour 840 840

Voltage Hz 220/1/150 330/3/50

Electric Motor kW 3 4

Electric Motor Speed rpm 1450 1450

Dimensions mm 740 x 540 x 970 740 x 540 x 970

Weight kg 85 83

Feed temperature max °C 60 60

*525 volt versions are available on request

Specifications and details are subject to change without prior notice.

Standard Attachments

•Trigger type safety spray lance with 1m long spray

pipe and 25° fan jet nozzle.

•10-meter-long flexible, metal-braided, rubber

coated high pressure hose, with kink protection.

•“Geka” quick coupling for the water supply hose

connection.

WAP Pressure Washer Range

Standard Attachments

• Trigger type safety spray lance with 1m long spray

pipe and 25° fan jet nozzle.

• 10-meter-long flexible, metal-braided, rubber coated

high pressure hose, with kink protection.

• “Geka” quick coupling for the water supply hose

connection.

WAP Pressure Washer Range

Technical Specifications

Description

Unit

Novastar 14/130 EC

Novastar 14/150 E

Operating pressure

bar

125/115/85*

150

Water volume

l/hour

840

840

Voltage

Hz

220/1/150

330/3/50

Electric Motor

kW

3

4

Electric Motor Speed rpm 1450 1450

Dimensions

mm

740 x 540 x 970

740 x 540 x 970

Weight

kg

85

83

Feed temperature max °C 60 60

*525 volt versions are available on request

Specifications and details are subject to change without prior notice.

Standard Attachments

•Trigger type safety spray lance with 1m long spray

pipe and 25° fan jet nozzle.

•10-meter-long flexible, metal-braided, rubber

coated high pressure hose, with kink protection.

•“Geka” quick coupling for the water supply hose

connection.

PAGE NO: 2

TABLE OF CONTENT

1.

INTRODUCTION

3

2.

DESCRIPTION OF PRODUCT

4

3.

TECHNICAL SPECIFICATIONS

5

4.

EQUIPMENT INSTALLATION GUIDELINES

6

4.1.

GENERAL

6

4.2

WATER REQUIREMENTS

7

4.3.

POWER REQUIREMENTS

8

5.

EQUIPMENT OPERATING PROCEDURES

9

5.1.

GENERAL SAFETY GUIDELINES

9

5.2.

PRE START-UP CHECK LIST

10

5.3.

CONTROLS

11

5.3.1.

PRIMARY CONTROL PANEL

11

5.3.2.

SECONDARY CONTROL PANEL

11

5.4.

ACTIVATION OF THE SYSTEM

11

5.4.1.

SELECTION OF OPERATING MODE

11

5.4.2.

PRACTICAL OPERATION

12

5.4.3.

SHUT-DOWN PROCEDURES

12

6.

CHEMICAL APPLICATION

13

7.

RECOMMENDED CHEMICAL PRODUCTS

14

8.

MAINTENANCE / SERVICE REQUIREMENTS

15

9.

HIGH PRESSURE PUMP OIL CHANGE

17

10.

NOZZLE TABLE

18

11.

FAULT IDENTIFICATION / RECTIFICATION

19

12.

REPLACEMENT PART PROCUREMENT PROCEDURE

21

13.

SPARE PARTS – BREAKDOWN

22

13.1.

EXPLODEDVIEW HIGH PRESSURE PUMP

22

13.2.

EXPLODED FLEXI COUPLING FLANGE FOR PUMP

24

13.3.

EXPLODED VIEW CONTROL SET

25

13.4.

CLEANING ATTACHMENTS

28

14.

GUARANTEE

29

15.

NATIONWIDE SALES AND SERVICE NETWORK

30

PAGE NO: 3

REF. 1: INTRODUCTION

Industroclean is the manufacturer and official supplier of WAP mobile and stationary high-

pressure washers and WAP parts washers a in South Africa.

WAP machines are of high quality and are exceptionally reliable.

WAP high-pressure washers are robust and suitable to heavy industry.

Industroclean offers spare parts for WAP pressure washers and parts washers as well as

service and repairs for these machines.

The WAP brand in South Africa has long been associated with products that are characterised

by quality and reliability and has established loyal and satisfied customers for over 40 years.

PAGE NO: 4

REF. 2: DESCRIPTION OF PRODUCT

HIGH PRESSURE CLEANER:

Nilfisk / Wap NovaStar HPC 14/130 E Cold Water High Pressure Cleaner – 220 Volt

Alternatively:

Nilfisk / Wap NovaStar HPC 14/150 E Cold Water High Pressure Cleaner – 380 Volt

This medium duty cleaner is fully mobile, with all components mounted on a sturdy

steel base frame, protected by a steel impact protection cage. The high pressure pump

is electrically driven. Operation of the machine is controlled from the "trigger" type

safety spray lance.

STANDARD ACCESSORIES:

The NovaStar is ready-to-use and supplied complete with:-

•10 m flexible, heat-insulated, metal-braided high pressure hose, with kink-

protection;

•Trigger type safety spray lance with a 800 mm long, straight spray pipe

•30° high pressure nozzle;

•3/4" Water hose coupling;

•5 m heavy duty, rubber protected electric cable.

PAGE NO: 5

FEATURES:

•Sturdy steel chassis with roll cage for maximum component protection, as well as

easy loading and off-loading;

•Two solid rubber, heavy duty wheels to facilitate convenient transportation, even over

rough terrain;

•Direct drive system between pump and engine;

•Chemical injector, - venturi-type for “after-pump” injection of chemicals;

•Positive displacement piston pump, oil lubricated with three ceramic pistons, suction

and pressure valves with stainless seats.

•Excess pressure un-loader valve with integrated by-pass line.

REF. 3: TECHNICAL SPECIFICATIONS

SPECIFICATIONS:NOVASTAR HPC 14/130 E – 220 VOLT

Water volume, variable, max continuous operation ltr/hour 900

Operating pressure, variable max bar/kPa 60 - 130

Voltage V/~/Hz 220/1/50

Electric motor, KW 3

Chemical tanks, capacity ltr External feed

Length x width mm 740 x 540

Height with folded down handle mm 550

Height with unfolded handle mm 970

Weight Kg 85

(Wap reserves the right to alter specifications and scope of supply without prior notice.)

SPECIFICATIONS:NOVASTAR HPC 14/150 E – 380 VOLT

Water volume, variable, max continuous operation ltr/hour 840

Operating pressure, variable max bar/kPa 60 - 150

Voltage V/~/Hz 380/3/50

Electric motor, KW 4

Chemical tanks, capacity ltr External feed

Length x width mm 740 x 540

Height with folded down handle mm 550

Height with unfolded handle mm 970

Weight Kg 83

(Wap reserves the right to alter specifications and scope of supply without prior notice.)

PAGE NO: 6

REF. 4: EQUIPMENT INSTALLATION GUIDELINES

Ref. 4.1. General

The correct positioning of the high pressure cleaner in regards to for example, ease of

access, environmental circumstances, as well as utilities supply is of crucial importance.

When choosing the location for the pressure cleaner, the following criteria should be

taken into account:

•Space requirements!

Is there sufficient space to accommodate the machine with regard to access or

possibility of interference with other plant equipment?

•Equipment obstruction!

Could the machine become an obstruction at any point in the future, in regards to

production or assembly line changes?

What is the likelihood of the machine interfering with vehicle or forklift traffic; or

similarly, being in the way of overhead cranes or other moving plant and equipment?

•General safety!

Is the location safe in respect to possible gas, dust or fibre explosion hazards?

Is the equipment protected against unauthorised usage, abuse, theft, etc?

•Utilities supply!

How convenient is the proposed location in terms of electric power and water mains

supply lines?

•Service access!

Will it be possible to work on the machine, for the purpose of servicing or breakdown

repairs, at any time during normal production shifts?

•Drainage!

Is there a floor drain conveniently close by, to deal with any possible spillage, for

example during servicing, or in the event of a burst water pipe or coupling?

PAGE NO: 7

Ref. 4.2. Water Requirements / Details of Water Connection

The pressure cleaner requires a permanent connection to the water mains supply.

Impurities, dirt and other solid particles contained in the water supply will cause damage

to the sensitive working parts of the positive displacement piston pump.

Therefore, the water supply to the pump should be of drink water (potable) quality. As

an additional precaution, the fitting of a suitable water filter, in-line before the high

pressure pump, is recommended.

Requirements in terms of water supply:

Corresponding to the maximum flow rate of the high pressure pump, the supply should

never be less than 780 / 840 litres per hour, at any time.

The actual supply pressure should never be less than 3 bar and never more than 5 bar,

at any time.

The water supply line should at least have a ¾” or alternatively 1” diameter and must be

equipped with a suitable shut-off valve and hose connection facility.

PLEASE NOTE:

The NovaStar is not supplied with a water supply hose, from tap to machine,

however, a ¾” Geka quick coupling, male and female. forms part of the supply.

We suggest the use of a heavy duty, re-inforced water supply hose, ¾” diameter, with

both hose liners securely fastened with hose clamps.

PAGE NO: 8

Ref. 4.3. Power Requirements / Details of Electrical Connection

The connecting up of the high pressure cleaner must be carried out by a qualified

electrician and in accordance with the Factories, Machinery and Building Work Act, as

amended, and the Machinery and Occupational Safety Act.

It must be confirmed that the rated voltage of the equipment corresponds with the

mains power supply. With this particular machine, the connection should be by means

of a socket and plug arrangement, or alternatively using a suitable isolator.

It is imperative that the power supply to this machine be connected via an Earth

Leakage Circuit Breaker, which cuts off the power supply in the event of an electrical

short circuit.

The NovaStar HPC 14/130 E pressure cleaner requires a 220 Volt, single phase, 50 Hz

power supply with Earth wire protection.

The NovaStar HPC 14/150 E pressure cleaner requires a 380 Volt, 3 phase, 50 Hz

power supply with Earth wire protection.

380 Volt Version 220 Volt Version

Power requirements : 4 kW electric motor 3 kW electric motor

Electrical connection : 380V, 3 Phase, 50 Hz 220V, 1 Phase, 50 Hz

Electric current : 7.8 Amps per phase 19 Amps

•when fitted with a 25055 nozzle

18 Amps (standard version)

•when fitted with a 2506 nozzle

14.7 Amps

•when fitted with a 25065 nozzle

Electric socket : 16 Amps (Cekon) 3 pin socket (20A)

PLEASE NOTE:

The NovaStar HPC 14/150 E is not equipped with an electric plug, due to the

variety of electric sockets in use, in Southern Africa.

PAGE NO: 9

REF. 5: EQUIPMENT OPERATING PROCEDURES

Ref. 5.1. General Safety Guidelines

In the interest of safety at the workplace, this equipment may only

be operated by persons who have been properly instructed in terms

of the correct operating procedures.

Before taking the high pressure cleaner into operation, operating personnel must be

familiarised with the contents of this instruction manual, particularly with regard to any

applicable safety precautions.

During operation the spray lance is subject to substantial recoil forces. With an angled

spray pipe, additional torque effects will be generated. Therefore, it is important to hold

the spray lance firmly in both hands, during operation.

The trigger operated safety spray gun must never be modified, for example to remain in

the open position permanently.

High pressure water jets can be dangerous. Never direct the spray jet at persons,

animals, live electrical equipment or the pump station itself. Keep your hands and legs

clear of the high pressure spray jet, at all times.

The use of high pressure cleaning equipment is subject to the applicable local safety

regulations. In addition to the operating instructions and the compulsory accident

prevention regulations in the country of use, the generally recognised rules for a safe

working environment must also be observed.

Any operating procedures endangering the safety of persons or equipment is

prohibited.

The wearing of protective clothing, i.e. oil skins, shoes with non-slip soles, gloves,

safety glasses or face shield is strongly recommended.

PAGE NO: 10

Ref. 5.2. Pre Start-up Check List

Prior to taking the high pressure cleaner into operation, it is recommended to carry out

a few, basic checks. Not only will this eliminate the wasting of valuable time, trying to

operate the equipment by trial and error, but it will also minimize the possibility of costly

repairs and unnecessary downtime.

Operator Suitability

Is the person intended to operate the system sufficiently trained to do so in accordance

with the instructions, as detailed in this manual ?

Electricity / Water Mains Supplies Check

It is imperative that both utility supplies are checked, i.e. that the water supply valve is

in the open position and that the mains power supply to the machine is established.

Pump Oil Level Check

It is essential to carry out a pump oil level check prior to taking the unit into operation

for the first time and thereafter, at periodic, at least weekly intervals.

Cleaning Attachment Check

Verify that the cleaning attachments,- high pressure hose and spray lance have been

connected properly and made secure.

PAGE NO: 11

Ref. 5.3. Controls

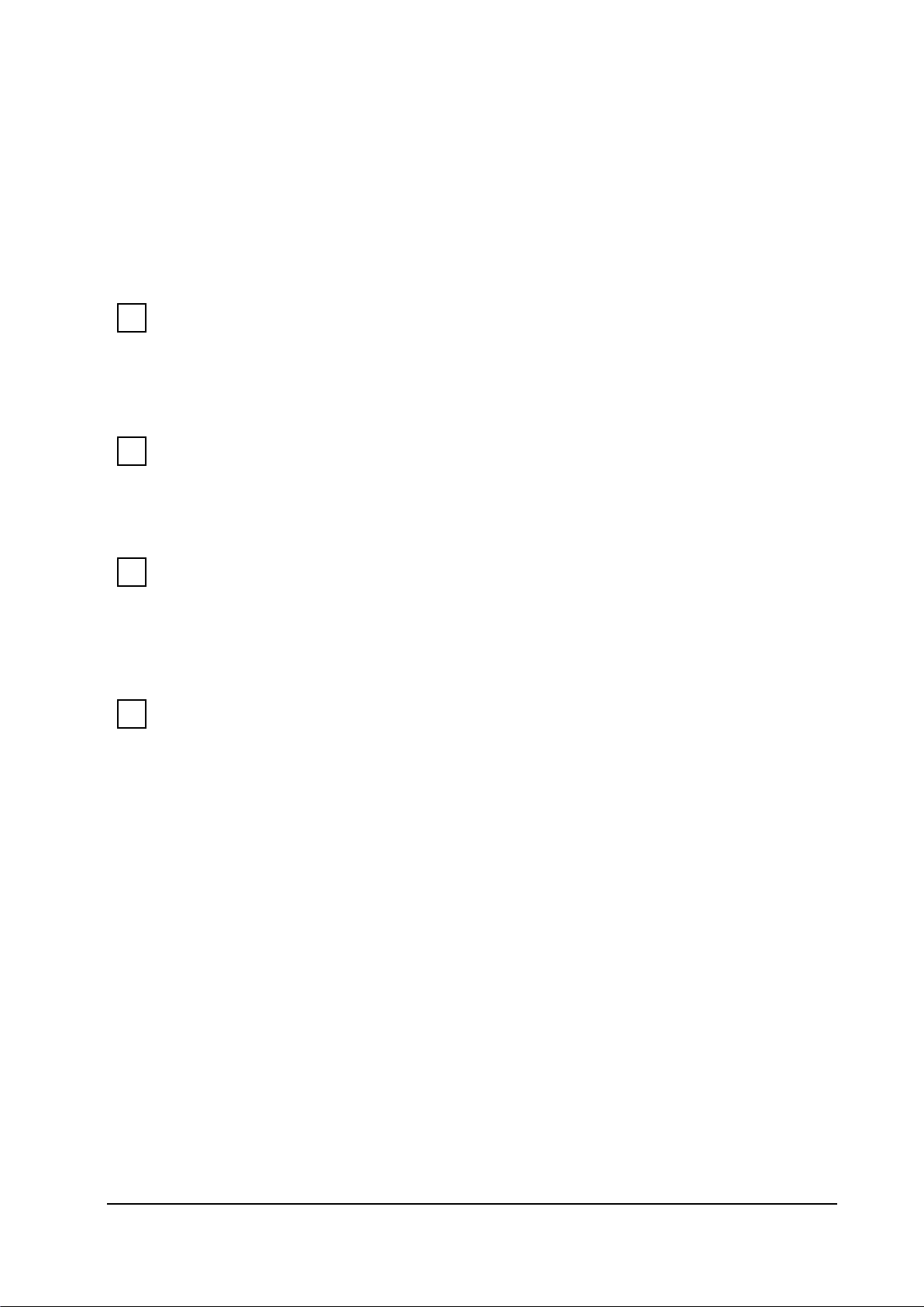

Ref. 5.3.1. Primary controls

The control panel is equipped with the following:

•A two position push button master control switch:

Green button: Machine “On”;

Red button: Machine “Off”;

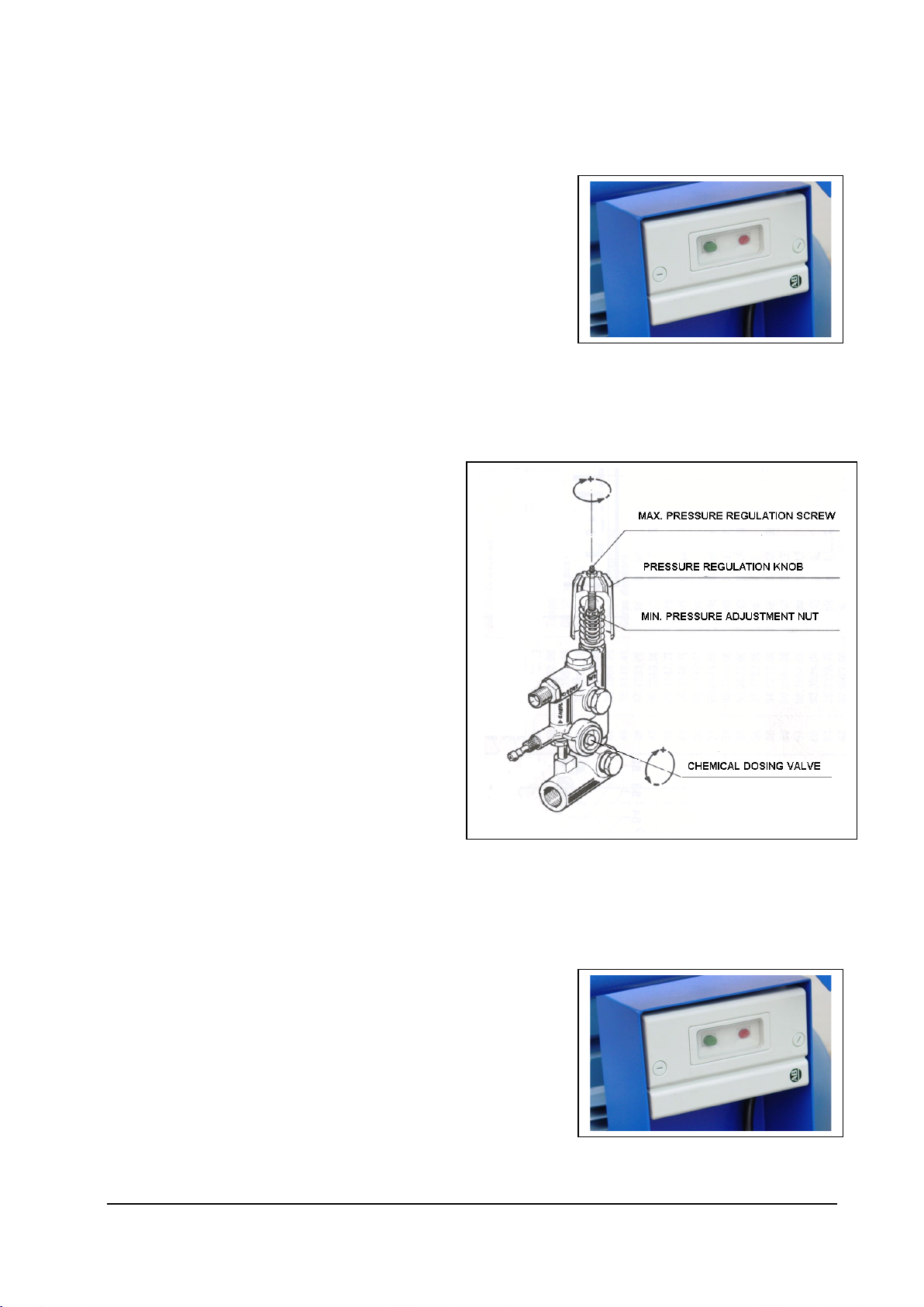

Ref. 5.3.2. Secondary Controls

•Chemical dosing lever;

•Operating pressure adjustment

knob;

•Maximum pressure regulation

screw;

•Minimum pressure adjustment nut;

Ref. 5.4. Activation of the Pressure Cleaner

Ref. 5.4.1. Selection of high pressure operating mode

•Push the green button to activate the machine;

•Pull trigger to commence cleaning;

PAGE NO: 12

Ref. 5.4.2. Practical Operation

Handling the Spray lance:

For optimum cleaning results, maintain an even distance of approximately 5 - 15 cm

between spray nozzle and surface to be cleaned. It is recommended to move the spray

lance at a controlled, steady pace from side to side, - ideally, with the spray lance tilted

at a slight angle to aid the “slicing” effect of the water jet.

During operation, keep the trigger of the pistol in the open position.

Repeated activation and deactivation of the trigger in short intervals is

detrimental to the system and will result in an increased rate of component

wear, at the very least.

Therefore, release the trigger only, if work is to be interrupted for an extended length of

time, or the cleaning task has been completed.

Please note:

Do not operate the machine with faulty cleaning attachments, for example

damaged high pressure hose, leaking spray lance, etc., as this might result in

damage to the high pressure pump aggregate.

In order to obtain the best possible service life from the high pressure hose, it is

essential not to twist the spray lance excessively, nor to pull the hose along sharp

corners.

Ref. 5.4.3. Shut-down Procedure

Step 1:

Upon completion of the cleaning process,

release the trigger of the pistol and return

to the machine.

Step 2:

Press the “red” button which will result in the pump aggregate shutting down.

Step 3:

Release the system pressure by briefly pulling the trigger of the spray-lance.

Step 4:

The high pressure hose and spray-lance can now be disconnected for removal and

safe storage.

PAGE NO: 13

REF. 6: CHEMICAL APPLICATION

Ref. 6. Chemical Application Procedure under Low Pressure

Chemical application under low pressure is possible in conjunction with the Venturi

based chemical injector and chemical flow actuator nozzle.

Step 1:

To facilitate this, a chemical container with a suitably pre-diluted additive must be

placed next to the pressure cleaner and connected by means of the chemical feeder

hose.

Step 2:

Use the chemical dosing lever to adjust

the mixture, - “up” for more and “down” for less.

Step 3:

Rotate the chemical actuator valve (1) to reduce

the operating pressure sufficiently to activate

the Venturi chemical injector.

Fully opened = low pressure / chemical stage

Fully closed = high pressure / no chemicals

PAGE NO: 14

REF. 7: RECOMMENDED CHEMICAL PRODUCTS

Industroclean chemical products are highly effective, and formulated for use in high pressure

cleaning equipment.

We have a range of chemicals for all industries and unique applications. Please Consult with the

Industroclean team for the most effective chemicals for your cleaning needs.

PAGE NO: 15

REF. 8: MAINTENANCE /SERVICE REQUIREMENTS

The high pressure cleaner, must be checked and serviced regularly to

ensure that the equipment remains in proper working order.

Inspections should be carried out by qualified personnel, i.e. Industroclean

service technicians or personnel trained by Industroclean South Africa.

The frequency of inspections and maintenance work is relative to the number

of operating hours accumulated.

We would like to draw to your attention that Industroclean offers a

maintenance plan. The concept of preventative maintenance is well proven

and in our opinion constitutes the best method of ensuring the satisfactory

performance of the equipment.

WEEKLY INSPECTION OR AT LEAST EVERY 40 HOURS OF OPERATION

•Check oil level of the high pressure pump.

•Check for water leaks in the entire high pressure system.

•Check water filter (if fitted).

•Check spray lance for leaking valve mechanism or faulty O-rings at the couplings.

•Check high pressure hose for leaks or excessive abrasion.

MONTHLY / 2 MONTHLY SERVICE - AT LEAST EVERY 250 - 300 HRS OF

OPERATION

•Change pump oil of high pressure pump.

•Clean out water filter if fitted.

•Carry out functional test of the by-pass valve/pressure regulating block.

•Re-adjust, or replace seal kit if necessary.

•Replace high pressure nozzle if it shows signs of damage or washed out aperture.

•Replace nozzle protection cap, if necessary.

•Check flexi-coupling for damage or wear.

•Replace O-rings of trigger / spray lance couplings.

•Check pistol and replace seal kit, when necessary.

•Inspect chemical supply hose strainer and clean if necessary.

•Clean machine and secondary equipment.

PAGE NO: 16

SIX MONTHLY SERVICE OR AT LEAST EVERY 400 – 500 HRS OF OPERATION

•Change pump oil of high pressure pump.

•Clean out water filter if fitted.

•Carry out functional test of the by-pass valve / pressure regulating block.

•Re-adjust, or replace seal kit if necessary.

•Replace high pressure nozzle if it show signs of damage or washed out aperture.

•Replace nozzle protection cap, if necessary.

•Replace O-rings of trigger / spray lance couplings.

•Check flexi-coupling for damage or wear.

•Check pistol and replace seal kit, when necessary.

•Inspect chemical supply hose strainer and clean if necessary.

•Check pump seals and replace in the event of decreasing operating pressure.

•Check valve seats and replace valve assemblies, as required.

•Clean machine and secondary equipment.

Please note, the service life of pump seals, by-pass valve seal as well as suction and

pressure valves is dependent on the water quality and the type of chemicals used.

(Mineral content, impurities and water hardness)

PAGE NO: 17

REF. 9: HIGH PRESSURE PUMP OIL CHANGE

The oil level of the high pressure pump must be checked periodically and topped-up, as

required.

The high pump is equipped with a sight glass, as well as a dip stick for convenient

measuring.

FIRST OIL CHANGE: 30 – 50 Hours from commissioning

FREQUENCY OF OIL CHANGE: Approximately every 100 operating hours, or

every second month.

RECOMMENDED OIL: WAP HP PUMP OIL

Ref No: 1700000101 (BLUE LABEL)

Supplied in one litre containers.

Motor oils of the SAE 20/30 grade can also

be used, if the above oil is not available.

IT IS IMPERATIVE TO MONITOR PUMP OIL LEVELS

ON A REGULAR BASIS

PAGE NO: 18

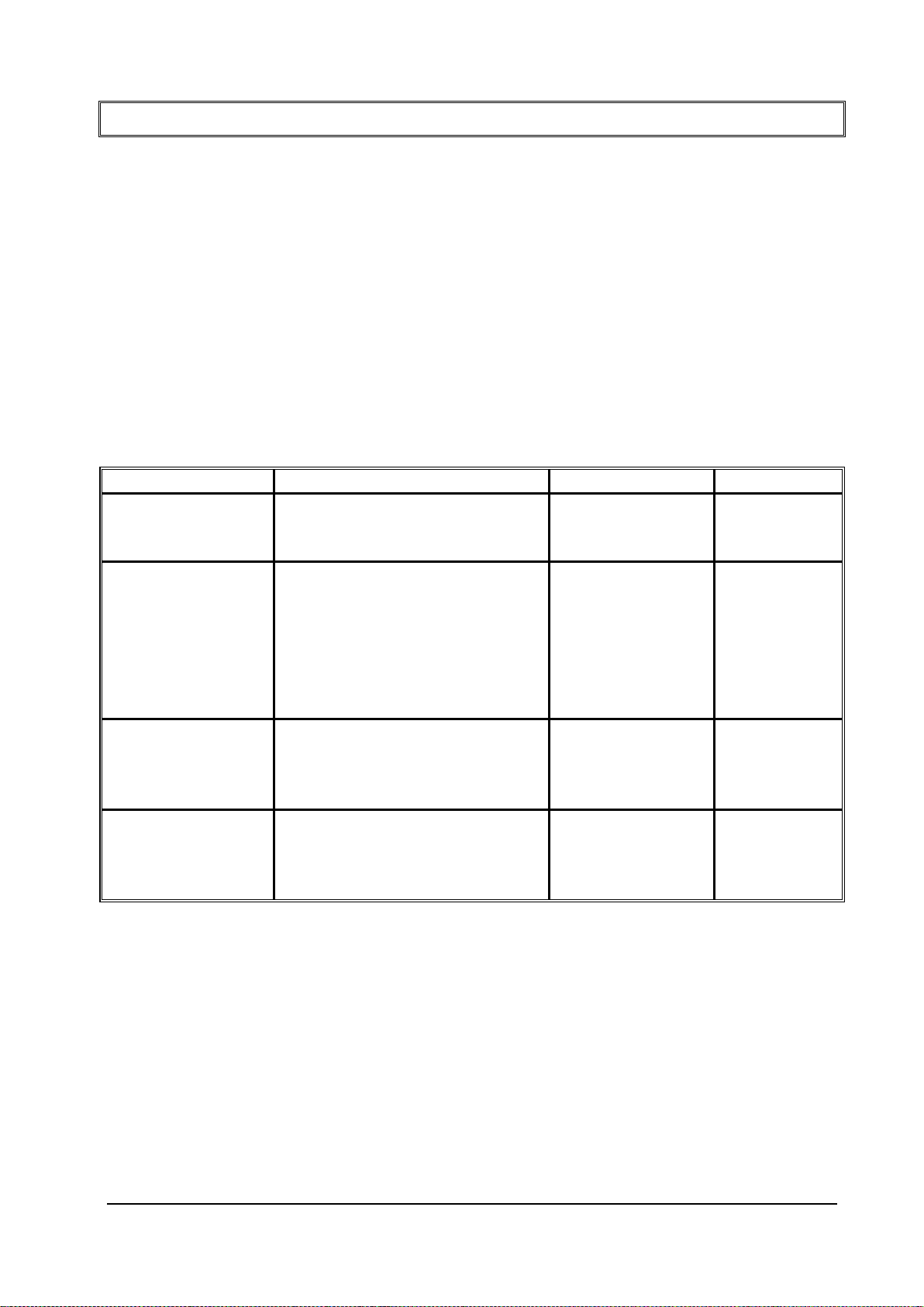

REF. 10: NOZZLE TABLE

It is imperative to use only the stipulated nozzles with this pump module. Incorrect

nozzle sizes will cause the equipment to malfunction, as the operating pressure

depends on the orifice of the nozzle.

The pressure indications stated in the paragraph "Technical Specifications" and in the

table below can vary slightly due to the following reasons:

-manufacturing tolerances of the nozzle,

-voltage and frequency fluctuations of the power supply.

At this stage, the machine is standard equipped with nozzle reference number "2506",

resulting in a 25° spray angle at 115 bar operating pressure.

TYPE OF NOZZLE

PRESSURE

SPRAY ANGLE

15

O

25

O

50

O

BAR

HP NOZZLE

15065 25065

85

optional

1506 2506

115

standard

15055 25055

130

optional

HP NOZZLE

(PENCIL JET)

0006

115 - 120

COMBI NOZZLE

*

61037

*Used only in conjunction with Venturi type low pressure chemical injectors.

This manual suits for next models

1

Table of contents

Popular Pressure Washer manuals by other brands

Briggs & Stratton

Briggs & Stratton 020330-0 Operator's manual

Shark

Shark DG Series Operating instructions and parts manual

Kärcher

Kärcher K 2.97 M manual

Kärcher

Kärcher K 2.21 operating instructions

Nilfisk-ALTO

Nilfisk-ALTO Poseidon PE operating instructions

cecotec

cecotec HYDROBOOST 2500 HOME&CAR instruction manual