Inficon PEG100 User manual

Operating Manual

Incl. EU Declaration of Conformity

tina14e1-a (2017-12) 1

Penning Gauge

PEG100

2tina14e1-a (2017-12) PEG100.om

In all communications with INFICON, please specify the information on the product

nameplate. For convenient reference copy that information into the space provided

below.

This document applies to products with part numbers

351-000 (PEG100, DN 25 ISO-KF)

351-002 (PEG100, DN 40 CF-F)

The part number (No:) can be taken from the product nameplate.

We reserve the right to make technical changes without prior notice.

All dimensions in mm.

The references to diagrams, e.g. (4/1), consist of the fig. no. and the item no. in

that order.

The Penning Gauge PEG100 has been designed for vacuum measurement of in

the pressure range of 1×10-9 to 1×10-2 mbar.

The Penning Gauge PEG100 is a compact active pressure converter housing a

Penning measurement system as well as the corresponding operating electronics.

They have been developed specifically for integration into vacuum systems and

offer a measurement range from 1×10-9 to 1×10-2 mbar.

The gauge is connected directly to the vacuum system through its DN 25 KF or

DN 40 CF flange.

The electrical connection is provided through a screened 8-pin FCC 68 connector.

Unpack the PEG100 immediately after delivery, even if it is to be installed at a later

date.

Examine the packaging for any external damage. Completely remove all packaging

materials.

Retain the shipping container and the packaging materials in the event of com-

plaints about damage.

Check that the PEG100 is complete and carefully examine the gauges visually.

If any damage is discovered, report it immediately to the forwarding agent and in-

surer. If the damaged part has to be replaced, please get in touch with the orders

department.

Product Identification

Validity

Intended Use

Description

Unpacking and Checking

tina14e1-a (2017-12) PEG100.om 3

Based on a supply voltage of 24 V the PEG100 generates the internal supply vol-

tages required for operation of the integrated Penning measurement system. The

PEG100 supplies a logarithmic representation of the vacuum pressure by way of a

voltage signal which ranges from 0.66 V to 10 V. Moreover, the high tension

generated in the PEG100 can be switched on and off by applying an external con-

trol voltage or by connecting an external switch.

When the gas discharge in the Penning measurement system is ignited, the oper-

ating voltage is raised to 2.8 kV. After successful ignition, this voltage then drops to

1.6 kV thereby increasing the useful service life of the Penning measurement

system.

A status output indicates the two possible conditions of the Penning measurement

system:

1. not ignited (including high tension OFF) and

2. ignited (and pressure > 3×10-9 mbar).

A much improved ignition characteristic in the high vacuum range has been ob-

tained through the special design for the electrodes in the measurement system.

•Penning Gauge

•Replacement cathode plate of titanium

•Replacement ceramics disc

•Operating Manuals

Design and Function

Scope of Delivery

4tina14e1-a (2017-12) PEG100.om

Contents

Product Identification 2

Validity 2

Intended Use 2

Description 2

Unpacking and Checking 2

Design and Function 3

Scope of Delivery 3

1Safety 5

1.1 Symbols Used 5

1.2 Personnel Qualifications 5

1.3 General Safety Instructions 5

1.4 Liability and Warranty 5

2Technical Data 6

3Installation 8

3.1 Vacuum Connection 8

3.2 Electrical Connection 8

3.2.1 Power Supply 10

3.2.2 Switching on the High Tension 10

3.2.3 Measurement Signal Output 10

3.2.4 Status Output 11

3.2.5 Identification 11

4Operation 12

4.1 Operation 12

4.2 Measurement System Status Indication 13

4.3 Degassing 13

4Maintenance 14

5.1 The Electronics Assembly 14

5.2 Cleaning the Sensor 14

5.2.1 Detaching the Electronics Assembly 14

5.2.2 Disassembly of the Sensor 15

5.2.3 Cleaning the Individual Parts 15

5.2.4 Assembly of the Sensor 15

5.2.5 Assembly of the Electronics Assembly 16

6Troubleshooting 16

7Wearing Parts and Original Spare Parts 17

9Returning the Product 18

10 Disposal 18

Appendix 19

A: Output Voltage vs. Pressure 19

B: Examples for Connecting 20

EU Declaration of Conformity 21

For cross-references within this document, the symbol (→XY) is used.

tina14e1-a (2017-12) PEG100.om 5

1 Safety

DANGER

Information on preventing any kind of physical injury.

WARNING

Information on preventing extensive equipment and environmental damage.

Caution

Information on correct handling or use. Disregard can lead to malfunctions or

minor equipment damage.

Notice

Skilled personnel

All work described in this document may only be carried out by persons who have

suitable technical training and the necessary experience or who have been

instructed

•Adhere to the applicable regulations and take the necessary precautions for the

process media used.

Consider possible reactions with the product materials (→6).

•Adhere to the applicable regulations and take the necessary precautions for all

work you are going to do and consider the safety instructions in this document.

•Before beginning to work, find out whether any vacuum components are conta-

minated. Adhere to the relevant regulations and take the necessary precautions

when handling contaminated parts.

Communicate the safety instructions to all other users.

INFICON assumes no liability and the warranty is rendered null and void if the end-

user or third parties

•disregard the information in this document

•use the product in a non-conforming manner

•make any kind of interventions (modifications, alterations etc.) on the product

•use the product with accessories not listed in the corresponding product docu-

mentation.

1.1 Symbols Used

Symbols for residual risks

1.2 Personnel Qualifications

1.3 General Safety

Instructions

1.4 Liability and Warranty

6tina14e1-a (2017-12) PEG100.om

2 Technical Data

Measurement range 1×10-9 to 1×10-2 mbar

Measurement uncertainty in the range from 1×10-8 to 1×10-4 mbar

Deviation from the characteristic ±30 % of the displayed value

Average temperature coefficient of the

output span

<0,5 % / K of the displayed value

Reproducibility <4 % of the displayed value

Measurement principle Cold cathode ionization according to

Penning

Supply voltage 14.5 to 36 V (dc) typ. 24 V (dc),

2 Vss

Power consumption <2 W

Protection IP 40

Flammability UL 94 - V 2

Status displays

Operation (POWER) orange LED

Ready to measure (ignited) READY green LED

Measurement system detachable

Vacuum connection DN 25 KF or DN 40 CF

Degassing temperature see Section 4.3

Internal volume 21 cm3approx.

Materials in contact with the medium stainless steel; CrNi; AL2O3 ceramics;

NiFe; Ni; titanium

Overpressure tolerance 10 bar abs.

(The limits for the flange connections must be observed)

Operating voltage 1.6 kV (current limited to <0,5 mA)

Ignition voltage 2.8 kV (current limited to < 0,5 mA)

Signal output 0 to 10,6 V

Permissible load resistance Ra 10 k

Measurement signal 0,66 to 10,0 V

logarithmic 1.333 V / per decade

Status signal (not ignited) 0.4 V

Input resistance RE: 10 kapprox.

High voltage cut-in with negative logic at

pin 7:

High voltage ON at U <2.5 V

High voltage OFF at U >4 V

or

High voltage cut-in with positive logic at

pin 8:

High voltage ON at U >12 V

High voltage OFF at U <7 V

(for this refer also to figure 3 and section 3.2.2)

Ready to measure High level (13.5 to 35 V, max.

50 mA)

Error (not ignited, HV off) 0 V

For this refer also to section 3.2.4.

General Data

Measurement System

Signal Output

Control Inputs

Status Output

tina14e1-a (2017-12) PEG100.om 7

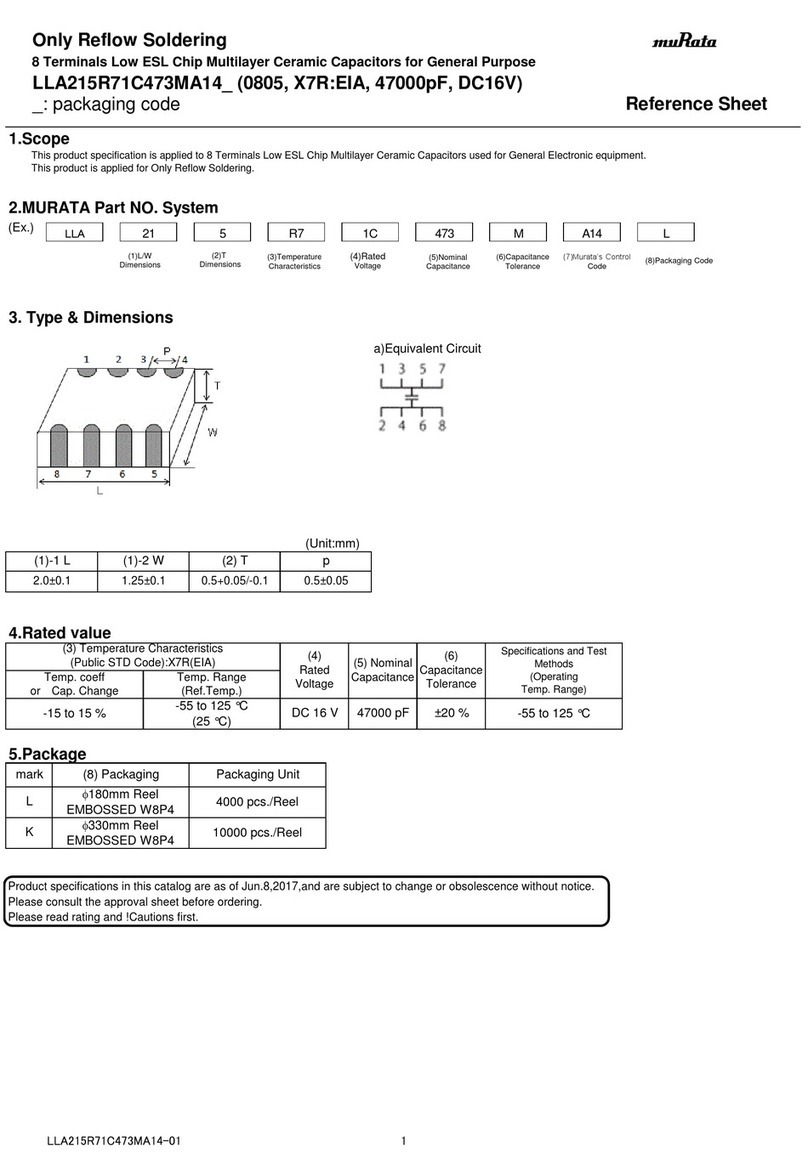

Fig. 1 Dimensional drawing

Weight 500 g approx

Storage temperature range –20 °C to +70 °C

Climatic rating KWF to DIN 40040

Operating temperature range 10 °C to 50 °C

Max. rel. humidity of the ambient air (on 30

days per year, non-condensing)

70 %1) or 95 %2)

1) usable measurement range 10-2 to 10-9 mbar

2) usable measurement range 10-2 to 10-7 mbar

Dimensions [mm], Weight

Ambient Conditions

8tina14e1-a (2017-12) PEG100.om

3 Installation

Please check by referring to the technical data whether or not your gauge is

suitable for your application.

The Penning Gauge PEG100 should preferably be mounted flange down. Inclined

installation is possible but the horizontal orientation must not be exceeded.

Flange up installation is not permissible because under such circumstances con-

densate may collect in the PEG100. This will either adversely affect the measure-

ments, or the sensor itself may possibly be damaged.

The Penning Gauge is equipped with a DN 25 KF or a DN 40 CF connection

flange. The DN 25 KF flange is used to connect the gauge to the mating connec-

tion flange on a vacuum system with the aid of a centering ring and a clamping

ring.

The cathode plate (7/5) also acts as a baffle.

The supply voltage and the high voltage switching signal as well as the measure-

ment voltage signal are carried through the 8-way FCC 68 socket.

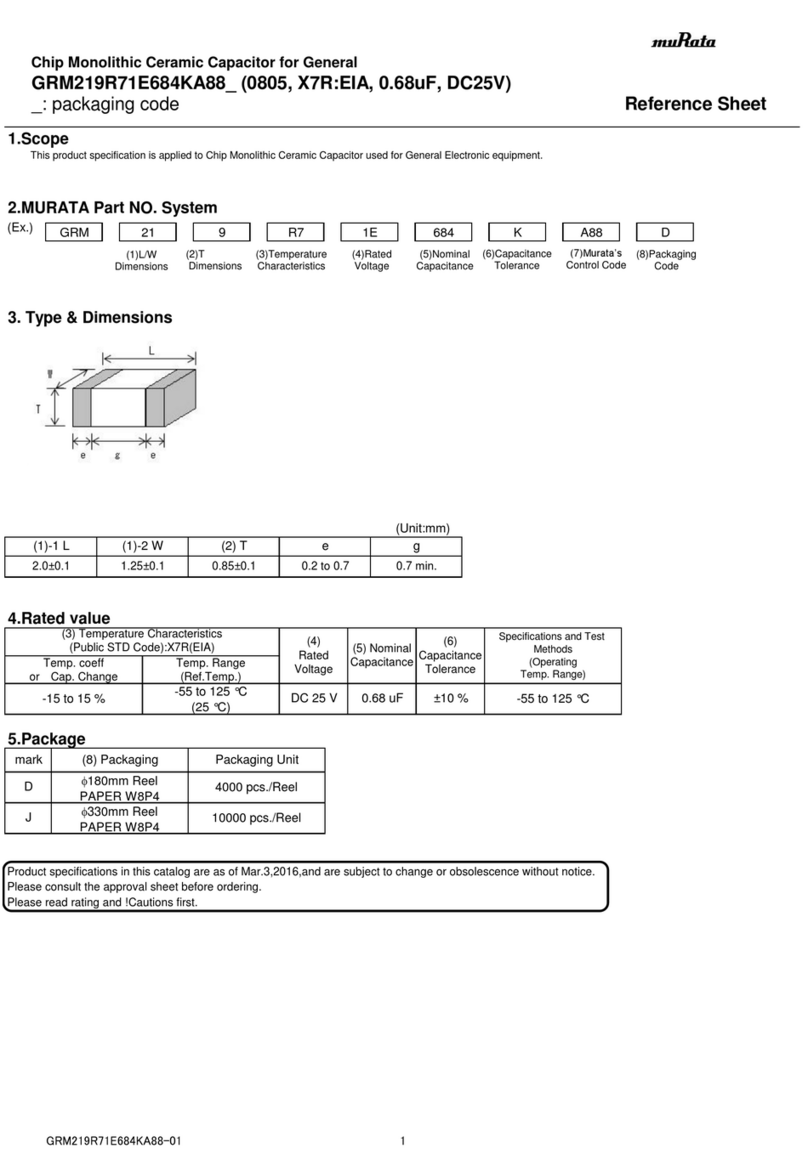

Fig. 2 Connection socket

The pinout is given in Fig. 2.

Pin Signal Designation on

the rear

Pin 1 Supply voltage 14,5 V to 36 V (dc) +24 V (dc)

Pin 2 0 V supply; used as the ground reference for the

supply and control signal voltages

COMMON

Pin 3 Pressure dependent logarithmic signal output SIGN 0 - 10 V

Pin 4 Gauge identification (100 k) IDENT

Pin 5 Signal ground (use only for the pressure signal) SIGN COM

Pin 6 Status (ready to measure) STATUS

Pin 7 High tension "ON / OFF" (control input); Low active HV ON (L)

Pin 8 High tension "ON / OFF" (control input); High active HV ON (H)

Signal ground (Pin 5) and power supply ground (Pin 2) are internally linked. For

this also refer to the block diagram of Fig. 3.

3.1 Vacuum Connection

3.2 Electrical Connection

tina14e1-a (2017-12) PEG100.om 9

Two examples of how to connect the PEG100 are given in Annex B.

Fig. 3 Block diagram

10 tina14e1-a (2017-12) PEG100.om

DANGER

The Penning Gauge PEG100 may only be connected to supply units

or measuring instruments which meet the requirements of mains

isolated extra-low voltages (PELV) and VDE 0100.

The PEG100 is capable of operating off supply voltages ranging from 14.5 V to

36 V. A supply voltage of 24 V (dc) is recommended.

The power supply must be connected to Pin 1 (+) and Pin 2 (power supply ground).

The high voltage may be switched on either through Pin 7 using negative logic or

Pin 8 using positive logic.

In each case Pin 2 must be used as the reference potential.

Pin 7 switches the high voltage on when

•contact is established with Pin 2 or

•a voltage of less than 2.5 V is present with reference to Pin 2.

Pin 7 switches the high voltage off when

•there is no contact with Pin 2 (open input) or

•a voltage greater than 4 V is present with reference to Pin 2.

Pin 8 switches the high voltage on when

•contact is established with Pin 1 (supply voltage) or

•a voltage greater than 12 V is present with reference to Pin 2.

Pin 8 switches the high voltage off when

•there is no contact with Pin 1 (open input) or

•a voltage of less than 7 V is present with reference to Pin 2.

Operation of the PEG100 in the pressure range above 10-2 mbar will cause the

accumulation of contaminations and will thus reduce service life. For this reason,

the high tension should only be switched on or off when the pressure has dropped

to the 10-2 to 10-3 mbar range.

The high tension may also be switched on or off directly by the output signal pro-

vided by a Pirani Standard Gauge with switching functions (e.g. PSG500-S). Thus

the PEG100 can be switched on or off automatically at a pressure of approximately

5×10-3 mbar.

The PEG100 supplies a defined output signal ranging from 0.66 V to 10 V at Pin 3

with reference to Pin 5 which is signal ground. For this also refer to Table 1 in

Annex A.

Table 1 has been included to clarify the relationship between the output voltage

and the pressure.

The measurement signal provided by the PEG100 depends on the type of gas. The

values stated in Table 1 apply to nitrogen and air. For other gases, corresponding

correction factors must be used which are available from INFICON upon request.

3.2.1 Power Supply

3.2.2 Switching on the High

Tension

3.2.3 Measurement Signal

Output

tina14e1-a (2017-12) PEG100.om 11

When the gauge is ready to measure, this is indicated via the status output.

Status Status signal at Pin 6 (with respect

to Pin 2)

High voltage OFF 0 V

High voltage ON

(not yet ignited)

0 V

High voltage ON

at p < 3×10-9 mbar

0 V

High voltage ON

at p > 3×10-9 mbar

High (13.5 - 32 V, depending at

p > 3×10-9 mbar on the supply vol-

tage (50 mA max.)

When the pressure drops below 3×10-9 mbar, the status signal remains HIGH.

For the purpose of identifying the connected type of gauge and the pressure range,

the PEG100 is equipped with an identification resistor (R = 100 k) between Pin 4

and Pin 2. This resistor may be sensed by connected operating or control units so

that these can automatically adapt.

3.2.4 Status Output

3.2.5 Identification

12

4

O

4.1

O

N

O

T

o

O

peratio

n

O

peration

N

o LED on

O

nly the ora

n

T

he green L

E

o

range LED

n

n

ge LED (6/

1

E

D (6/2) is o

(6/1) is on

F

A

c

o

S

A

R

N

•

•

•

•

•

•

•

1

) is on

n, the

A h

se

n

for

re

m

wh

e

ig. 6 PEG10

0

A

pply the 24 V

o

mes on.

S

witch the hig

h

A

fter successf

u

R

EADY LED (

6

N

ow the gaug

e

Supply volt

a

Measureme

The supply

The high te

Measureme

The supply

The high te

The gas di

s

The pressu

Measureme

DAN

G

h

igh tension w

n

sor in the PE

the PEG100

b

m

oving the ga

u

e

n inadverten

t

0

- front view

supply volta

g

h

tension on v

u

l ignition and

6

/2) will come

e

is ready to

m

a

ge is missin

g

nt signal 0 V

voltage is pr

e

e

nsion has no

t

nt signal 0 V

voltage is pr

e

e

nsion has be

e

s

charge has b

re is over 3×1

nt signal 0.66

G

ER

hich is dange

r

G100. You m

u

b

efore startin

g

u

ge from the

c

t

ly coming in

t

g

e to the PEG

1

i

a the high te

n

at a pressur

e

on.

m

ake measure

g

.

e

sent.

t

been switch

e

e

sent.

e

n switched o

n

een started.

0-9 mbar

V

r

ous when to

u

u

st always s

w

g

any work on

c

onnection fla

n

t

o contact wit

h

Key to

F

1 LE

D

2 LE

D

1

00. The oran

n

sion switchin

g

> 3×10

-9

mb

a

ments.

e

d on.

n

.

tina14

e

u

ched is appli

e

w

itch off the s

u

the gauge (e

v

n

ge) so as to

h

the high ten

s

F

ig. 6:

D

"POWER" (

o

D

"READY" (g

r

n

ge "POWER"

g

input. See

S

a

r the additio

n

e

1-a (2017-12) PEG100.

o

e

d to the

pply voltage

v

en when

avoid injury

s

ion.

o

range)

r

een)

LED (6/1)

S

ection 3.2.2.

n

al green or

o

m

tina14e1-a (2017-12) PEG100.om 13

In the case of the Penning method of measurement one only may draw conclu-

sions as to proper functioning while the gauge is in the measurement mode, i.e.

when the gas discharge is running.

Trouble-free operation ("READY" LED (6/2) is on, status output HIGH) is marked

by the presence of a pressure dependent signal starting at a pressure of about

3×10-9 mbar up to the range limit of 1×10-2 mbar. When the pressure drops

< 3×10-9 mbar this status is also maintained.

When the “READY” LED (6/2) is not on, status output 0 V:

Cause 1: When the high voltage was switched on the pressure was below

p <3×10-9 mbar.

Cause 2: No ignition of the gas discharge, even if the power supply voltage is

present, the high tension has been switched on and a pressure between

about 3×10-9 mbar and 1×10-2 mbar.

WARNING

Before baking out the sensing cell you must detach the electronics

assembly from the sensing cell. The electronics assembly may be

damaged when exceeding a temperature of 70 °C.

Before baking out, you must make sure that an ultra sealing disc

(PEG100, DN 25 KF) or a copper seal (PEG100, DN 40 CF) is used

as the flange seal.

The PEG100 is equipped with all-metal sensing cells so that any outgassing

caused by polymer seals is entirely avoided.

After having detached the electronics (refer to Section 5.2.1) from the sensing cell,

the outgassing rate of the sensing cell may be reduced considerably by baking out,

so that the accuracy of the measurements in the range below 1×10-6 mbar is im-

proved.

When using the gauge chiefly in the UHV range (< 10-8 mbar) it is recommended to

remove the cathode plate. This helps to reduce the surface area of the surfaces

which may release gas.

How to proceed in order to detach the electronics assembly is described in Section

5.2 (cleaning of the sensor).

Permissible bake out temperature:

Sensing cell of the PEG100 (DN 25 KF) 150 °C (with ultra sealing disc)

Sensing cell of the PEG100 (DN 40 CF) 350 °C

4.2 Measurement System

Status Indication

4.3 Degassing

14 tina14e1-a (2017-12) PEG100.om

5 Maintenance

DANGER

DANGER: contaminated parts

Contaminated parts can be detrimental to health and environment.

Before you begin to work, find out whether any parts are contami-

nated. Adhere to the relevant regulations and take the necessary

precautions when handling contaminated parts.

Caution

Caution: vacuum component

Dirt and damages impair the function of the vacuum component.

When handling vacuum components, take appropriate measures to

ensure cleanliness and prevent damages.

Caution

Caution: dirt sensitive area

Touching the product or parts thereof with bare hands increases the

desorption rate.

Always wear clean, lint-free gloves and use clean tools when working

in this area.

The electronics assembly of the PEG100 does not require any maintenance.

DANGER

A high tension which is dangerous when touched is applied to the

sensor in the PEG100. You must always switch off the supply voltage

for the PEG100 before starting any work on the gauge (even when

removing the PEG100 from the connection flange) so as to avoid

injury when inadvertently coming in to contact with the high tension.

In order to detach the electronics assembly and the magnet assembly (7/1) you

must loosen the two cross head screws which can be accessed through two holes

in the rear of the PEG100 by turning these by about 1.5 turns.

Then the electronics assembly and the magnet assembly (7/1) may be pulled off

from the sensor housing.

The magnet assembly (7/1) may drop down during the pulling off pro-

cess.

5.1 The Electronics

Assembly

5.2 Cleaning the Sensor

5.2.1 Detaching the

Electronics Assembly

tina14e1-a (2017-12) PE

G

5.2.2 Dis

a

Sen

s

5.2.3 Cle

a

Par

t

5.2.4 Ass

e

G

100.om

a

ssembly

o

s

o

r

a

ning the I

n

t

s

e

mbly of t

h

o

f the

n

dividual

h

e Senso

r

The se

n

(7/2) an

How to

d

1) Use

2) Use

the

p

3) Det

a

Fig. 7

S

In the c

a

steel w

o

blow cl

e

be rem

o

If possi

b

same s

h

cerami

c

taminat

i

The se

n

describ

e

When i

n

remain

s

Moreov

e

When i

n

(7/2) m

u

n

sor consists

o

d the cathod

e

disassemble:

a pair of twe

e

a pair of plie

r

p

liers to and f

r

a

ch the cera

m

S

ensor

Do not da

m

a

se of severe

o

ol or similar

a

e

an with oil-fr

e

o

ved by blowi

n

b

le, the catho

d

h

ould be don

e

c

s protection

d

i

on.

n

sor is reasse

m

e

d in Section

5

n

serting the a

n

s

between the

e

r, make sur

e

n

serting the c

a

u

st not be be

n

o

f the vacuu

m

e

plate (7/5).

S

e

zers to pull t

h

r

s to pull the a

r

o a little.

m

ics disc (7/3)

m

age the seal

contaminatio

n

a

nd then subj

e

e

e pressurize

d

n

g these out

o

d

e plate (7/5)

e

for the anod

e

d

isc (7/3) whic

m

bled in the

r

5

.2.2.

n

ode ring (7/4

wings of the i

e

that the ano

d

a

thode plate (

7

n

t. Therefore i

n

housing, the

S

ee Fig. 7.

h

e cathode pl

a

node ring out

f

rom the curr

e

ing surfaces

o

n

, the inside

o

e

cted to furth

e

d

air or nitrog

e

o

f the housing

.

s

hould be rep

e

ring (7/4) wi

t

h protects the

e

verse order

a

) you must m

a

gnition aid (7

/

d

e ring is lying

7

/5) into the h

n

sert slowly a

n

anode ring (

7

a

te (7/5) out o

from the hou

s

e

nt feed- thro

u

Key to fi

g

1 Mag

n

2 Igniti

o

3 cera

m

4 Ano

d

5 Cath

o

6 Sens

flang

e

o

f the vacuum

o

f the housing

e

r cleaning wi

t

e

n. Any possi

b

.

p

laced by a n

e

t

h the ignition

e

current feed

-

a

s for disass

e

a

ke sure that

a

/

2) and the w

a

g

snug on the

c

ousing the wi

n

nd carefully.

7

/4) with igniti

o

f

the sensor.

s

ing; for this

m

u

gh.

g

. 7:

n

et assembly

o

n aid

m

ics disc

e ring

o

de plate

or housing wi

t

e

flange.

may be clea

n

h alcohol. Fin

b

ly present fla

k

e

w cathode pl

a

aid (7/2) and

-

through agai

n

e

mbly which i

s

a

clearance o

f

a

ll of the hous

i

c

eramics disc

n

gs of the ign

i

15

o

n aid

m

ove

t

h

n

ed with

ally

k

es will

a

te. The

the

n

st con-

s

f

1 mm

i

ng.

.

i

tion aid

16 tina14e1-a (2017-12) PEG100.om

How to proceed:

1) Place the magnet assembly on the sensor.

2) Push the electronics assembly over the magnet assembly and the sensor, and

turn slightly as required until the correct orientation between electronics

assembly and sensor has been found. When the electronics assembly has

been placed as required, the black magnet housing is fully surrounded by the

housing of the PEG100.

3) Retighten the cross head screws at the rear of the gauge.

6 Troubleshooting

Problem Possible cause Correction

No LED is on. Supply voltage is missing.

The "POWER" LED (6/1)

is on, the "READY" LED

(6/2) is not on.

High tension has not been ac-

tivated. Pressure has dropped

below < 3×10-9mbar.

The gas discharge has not

ignited.

Sensing cell not properly con-

nected to the electronics as-

sembly (e.g. after mainte-

nance).

Missing anode ring (e.g. after

maintenance).

The measurement signal

is always greater than

10 V even if the pressure

is much lower than

10-2 mbar.

Short circuit in the sensing

cell.

Clean the sensing

cell. For this refer to

section 5.2.

During pumpdown the

measurement signal re-

mains at some level al-

though the pressure is

dropping.

Contamination within the sen-

sing cell.

Replace the sen-

sing cell.

5.2.5 Assembly of the

Electronics Assembly

tina14e1-a (2017-12) PEG100.om 17

7 Wearing Parts and Original Spare Parts

When ordering spare parts, always indicate:

•all information on the product nameplate

•description and ordering number according to the spare parts list

Ordering number

Replacement kit, consisting of:

Cathode plate of titanium (5 pcs.)

Ceramics disc (5 pcs)

Gauge

351-490

Anode complete with ignition plate 351-499

Sensor (DN 25 KF),

complete with magnet assembly (PEG050)

399-510

Accessories

Ordering number

Connection cable with two FCC 68 plugs, screened 3 m

5 m

10 m

15 m

20 m

30 m

398-500

398-501

398-502

398-503

398-504

398-505

Pirani Standard Gauge PSG500-S (DN 16 ISO-KF)

PSG500-S (DN 16 CF-R)

350-080

350-082

DN 20 / 25 KF clamping ring 211-002

DN 25 KF (Al) centering ring 211-061

Ordering number

Ultra sealing disc (3 pcs.) 211-168

Clamping ring for ultra sealing discs 211-009

For overpressure operation and

degassing:

18 tina14e1-a (2017-12) PEG100.om

9 Returning the Product

WARNING

WARNING: forwarding contaminated products

Products returned to INFICON for service or repair should, if possible,

be free of harmful substances (e.g. radioactive, toxic, caustic or micro-

biological). Otherwise, the type of contamination must be declared.

Adhere to the forwarding regulations of all involved countries and for-

warding companies and enclose a completed contamination declara-

tion (Form under www.inficon.com).

Products that are not clearly declared as "free of harmful substances" are de-

contaminated at the expense of the customer.

Products not accompanied by a duly completed declaration of contamination are

returned to the sender at his own expense.

10 Disposal

DANGER

DANGER: contaminated parts

Contaminated parts can be detrimental to health and environment.

Before beginning to work, find out whether any parts are contami-

nated. Adhere to the relevant regulations and take the necessary pre-

cautions when handling contaminated parts.

WARNING

WARNING: substances detrimental to the environment

Products or parts thereof (mechanical and electric components,

operating fluids etc.) can be detrimental to the environment.

Dispose of such substances in accordance with the relevant local

regulations.

After disassembling the product, separate its components according to the

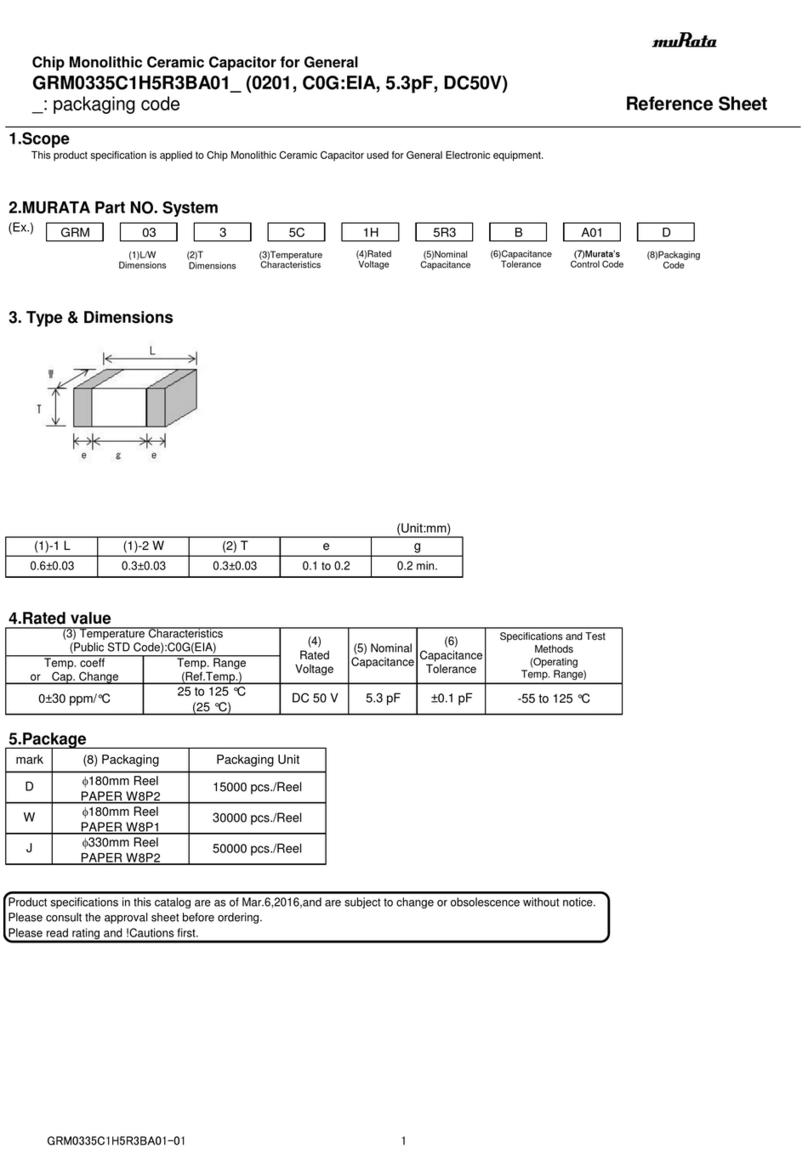

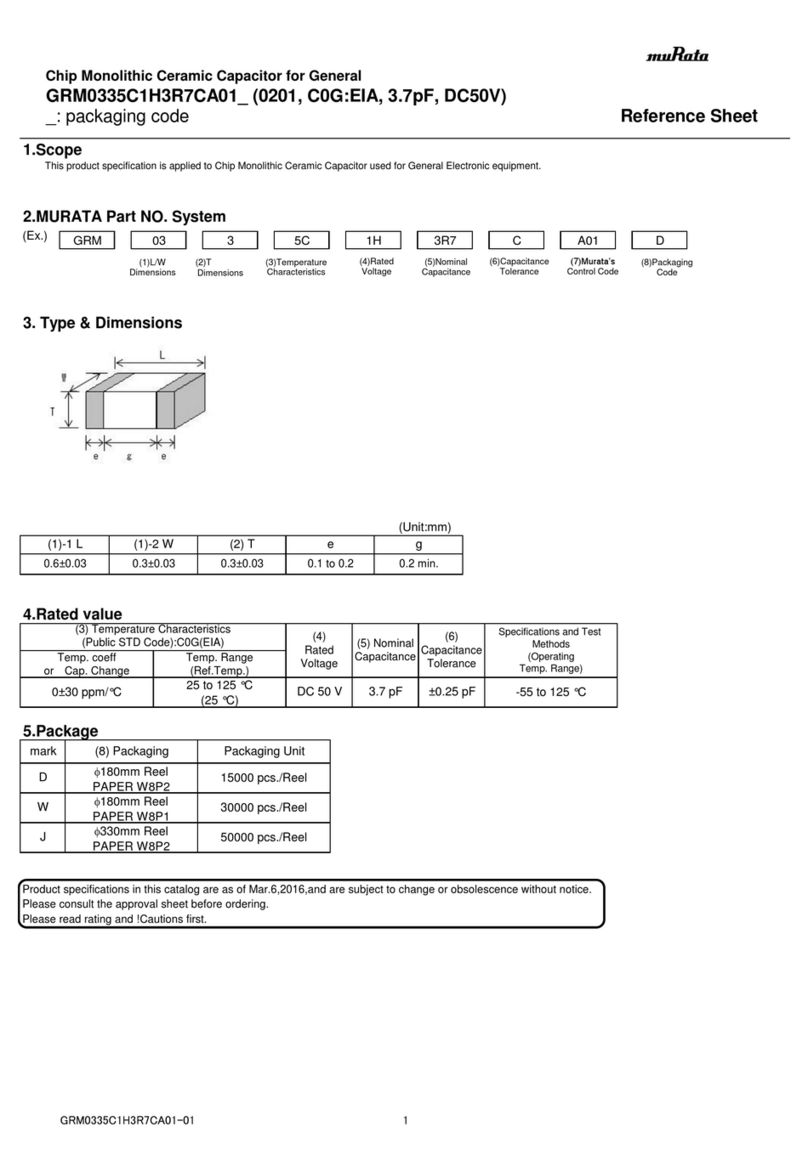

following criteria:

Contaminated components (radioactive, toxic, caustic or biological hazard etc.)

must be decontaminated in accordance with the relevant national regulations,

separated according to their materials, and disposed of.

Such components must be separated according to their materials and recycled.

Separating the components

Contaminated components

Other components

tina14e1-a (2017-12) PEG100.om 19

Appendix

(U = 0.4 V; "not ignited")

U (Out)

[V]

Pressure

[mbar]

U Out)

[V]

Pressure

[mbar]

U (Out)

[V]

Pressure

[mbar]

U (Out)

[V]

Pressure

[mbar]

0,667 1,00E-09 3,4 1,12E-07 6 1,00E-05 8,6 8,91E-04

0,8 1,26E-09 3,5 1,33E-07 6,1 1,19E-05 8,7 1,06E-03

1 1,78E-09 3,6 1,59E-07 6,2 1,41E-05 8,8 1,26E-03

1,1 2,11E-09 3,7 1,88E-07 6,3 1,68E-05 8,9 1,50E-03

1,2 2,51E-09 3,8 2,24E-07 6,4 2,00E-05 9 1,78E-03

1,3 2,99E-09 3,9 2,66E-07 6,5 2,37E-05 9,1 2,11E-03

1,4 3,55E-09 4 3,16E-07 6,6 2,82E-05 9,2 2,51E-03

1,5 4,22E-09 4,1 3,76E-07 6,7 3,35E-05 9,3 2,99E-03

1,6 5,01E-09 4,2 4,47E-07 6,8 3,98E-05 9,4 3,55E-03

1,7 5,96E-09 4,3 5,31E-07 6,9 4,73E-05 9,5 4,22E-03

1,8 7,08E-09 4,4 6,31E-07 7 5,62E-05 9,6 5,01E-03

1,9 8,41E-09 4,5 7,50E-07 7,1 6,68E-05 9,7 5,96E-03

2 1,00E-08 4,6 8,91E-07 7,2 7,94E-05 9,8 7,08E-03

2,1 1,19E-08 4,7 1,06E-06 7,3 9,44E-05 9,9 8,41E-03

2,2 1,41E-08 4,8 1,26E-06 7,4 1,12E-04 10 1,00E-02

2,3 1,68E-08 4,9 1,50E-06 7,5 1,33E-04

2,4 2,00E-08 5 1,78E-06 7,6 1,59E-04

2,5 2,37E-08 5,1 2,11E-06 7,7 1,88E-04

2,6 2,82E-08 5,2 2,51E-06 7,8 2,24E-04

2,7 3,35E-08 5,3 2,99E-06 7,9 2,66E-04

2,8 3,98E-08 5,4 3,55E-06 8 3,16E-04

2,9 4,73E-08 5,5 4,22E-06 8,1 3,76E-04

3 5,62E-08 5,6 5,01E-06 8,2 4,47E-04

3,1 6,68E-08 5,7 5,96E-06 8,3 5,31E-04

3,2 7,94E-08 5,8 7,08E-06 8,4 6,31E-04

3,3 9,44E-08 5,9 8,41E-06 8,5 7,50E-04

A: Output Voltage vs.

Pressure

20 tina14e1-a (2017-12) PEG100.om

Example for connecting the PEG100: Switching the high tension via an external switch or contact

Example for connecting the PEG100: Switching the high tension automatically through a Pirani Standard

Gauge with switching point

B: Examples for

Connecting

Table of contents