© 2013 Trane RLC-SVX16A-E4

7

Recommended installation components are shown in Figure 1.

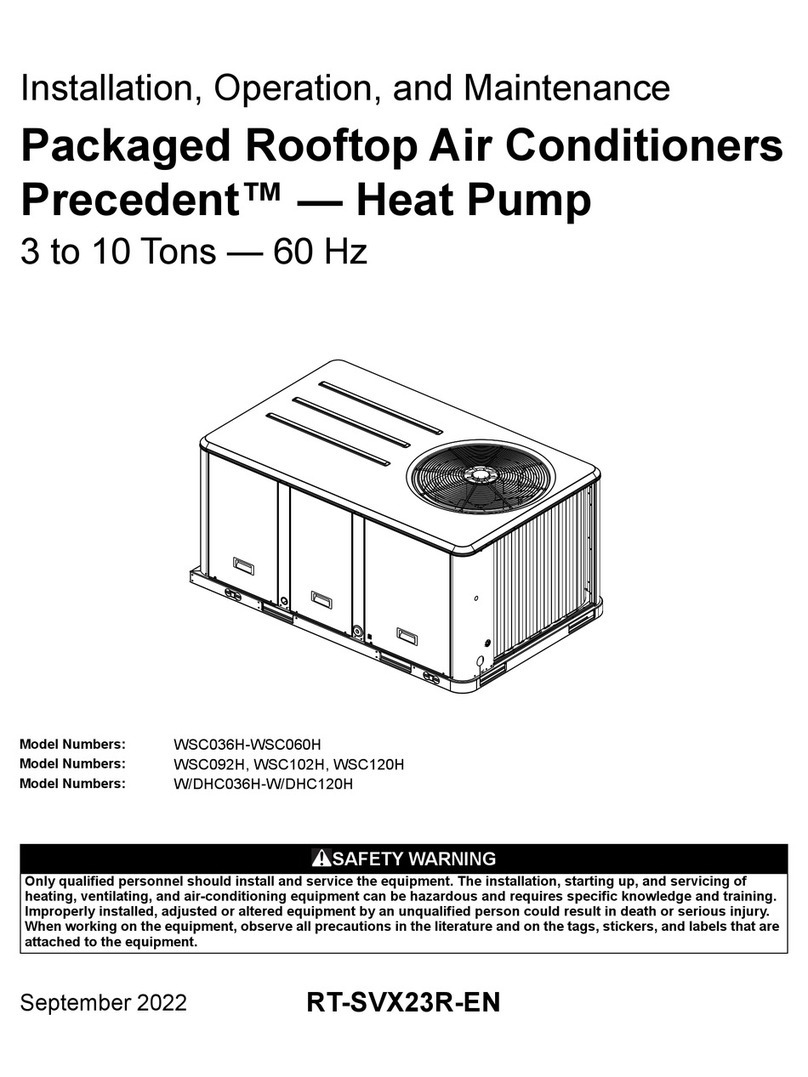

The system may be configured in any of the 3 arrangements shown in Figure 2.The configurations and their

associated elevations, along with the total distance between the remote evaporator and the compressor/condenser

section, play a critical role in determining suction and liquid line sizes. This will also affect field refrigerant and oil

charges. Consequently, there are physical limits which must not be violated if the system is to operate as designed.

Please note the following requirements for field installation:

1. The remote evaporator MUST be matched with its respective outdoor condensing unit.

2. The circuit number on the outdoor condensing unit must match the circuit number on the evaporator If the

circuits are crossed, serious equipment damage

3. Piping between the evaporator and outdoor unit can not exceed 60 meters actual and/or an equivalent length

of 90 meters (includes the equivalent length of all associated field installed fittings, valves, accessories and

straight lengths of interconnecting piping)

4. Horizontal portions of suction lines must be downward sloping toward the compressor with at least 0.4% of

slope.

5. Suction lines must be insulated.

6. Compressor &oil separator heaters must be on at least 24 hours prior to compressor start

The preferred configuration is to have condensing unit at the same level as Evaporator with shortest distance

possible.

Do not use a saw to remove end caps, as this may allow copper chips to contaminate the system. Use a tubing cutter

or heat to remove the end caps.

The outdoor unit and the evaporator are shipped with a 3 bar holding pressure of dry nitrogen. Do not relieve this

pressure until field installation of the refrigerant piping is to be accomplished. This will require the removal of the

temporary pipe caps.

The refrigerant lines must be isolated to prevent line vibration from being transferred to the building. Do not secure the

lines rigidly to the building at any point.

110VAC solenoid liquid valve is recommended upstream electronic expansion valve. Solenoid valve are not provided

by the factory.

Note: Although packaged unit condensers and evaporators are sized to hold complete refrigerant

Suction line Refrigerant piping design

Proper suction line sizing is required to guarantee that oil is returned to the compressor throughout the operating

system. Furthermore, the line must be sized so that the pressure drop does not excessively affect capacity and

efficiency. To accomplish both, it may be necessary to have 2 sizes, 1 for horizontal runs and vertical drops, and

another for the vertical lifts.

Horizontal portions of the suction lines must be horizontal or downward sloping to the compressors. The pitch of the

piping must be at least 12mm per 3meters of run (0.4%). Suction lines must be insulated.

Suction lines should be sized for a maximum of 2 to 3°F (1.1 to 1.7°C) pressure loss.

After commissioning, the suction superheat at compressor shall be measured. Superheat value shall be a minimum of

5K.

Liquid line Refrigerant piping design

Properly sizing the liquid line is critical to a reliable split-system application.

The recommended liquid-line sizing for each RTAC-S model based on its nominal capacity. Using the preselected

tube diameter to uniformly size the liquid line will maintain operating requirements.

Install the liquid line with a slight slope in the direction of flow so that it can be routed with the suction line.

A height limitation exists for liquid lines that include a liquid riser because of the loss of sub cooling that accompanies

the pressure loss in the height of the liquid column.

Again, system designs outside the application envelope of the RTAC-S unit require Trane review.

Install an inverted trap in the liquid line when the evaporator is below the compressor. The apex of the trap should be

at the same height as the top of the condenser coils.

Split systems have larger refrigerant charge than packaged chiller, it is recommended to add a liquid solenoid valve

(not supplied) at DX evaporator inlet, just upstream to the electronic expansion valve.

The solenoid valve, together with electronic expansion valve, will prevent refrigerant migration to the evaporator in

OFF mode

Field installed liquid filter is recommend before solenoid and expansion valve.

Avoid putting lines underground. Route refrigerant lines as short and direct as possible. Only insulate liquid line in

heated area.

RTAC-S operates with one electronic expansion valve per refrigerant circuit. Correct refrigerant distribution

into the coil requires a single distributor per refrigerant / expansion valve.