Ingram Engineering EQ50 User manual

INGRAM ENGINEERING

EQ50

Equalizer

Owner’s Manual

Dec 2016

EQ50 Owner’s Manual

12/2016

2

EQ50 Owner’s Manual

12/2016

3

Table of Contents

INTRODUCTION 5

FRONT PANEL FEATURES 6

EDGE CONNECTOR PIN ASSIGNMENTS 7

SAFETY INSTRUCTIONS 8

INSTRUCTIONS FOR USE 10

1. Installing the EQ50 in a Rack 10

2. Module Warm Up 10

3. EQ In (Bypass Switch) 10

4. Setting Audio Levels 10

5. Low Cut Filter 10

6. See-Saw Filter 11

7. High Cut Filter 13

8. Using Filters in Combination 14

ELECTRICAL SPECIFICATIONS 17

ENVIRONMENTAL SPECIFICATIONS 17

CARE AND MAINTENANCE 18

TROUBLESHOOTING 18

1. Power does not turn on 18

2. Audio Sounds Distorted 18

3. Hum or Buzz is Audible 18

CONTACT INFORMATION 19

WARRANTY INFORMATION 19

EQ50 EQUALIZER RECALL SHEET 22

EQ50 Owner’s Manual

12/2016

4

Table of Figures

Figure 1: Front Panel Features 6

Figure 2: Edge Connector Pin Assignments 7

Figure 3: Low Cut Filter Example Responses 11

Figure 4: See-Saw Filter Example Responses, 400 Hz Pivot Frequency 12

Figure 5: See-Saw Filter Example Responses, 1 kHz Pivot Frequency 12

Figure 6: High Cut Filter Example Responses 13

Figure 7: Filter Plot, Settings for Smoothing a Stereo Mix 14

Figure 8: Filter Plot with Subtle High Frequency Restoration Settings 15

Figure 9: Filter Plot with Compressor Sidechain Filter Settings, Mid-Low Trigger Frequency 15

Figure 10: Filter Plot with Compressor Sidechain Filter Settings, High Trigger Frequency 16

Figure 11: Filter Plot with Presence Boost Settings 16

EQ50 Owner’s Manual

12/2016

5

INTRODUCTION

Welcome, and congratulations on your interest in the EQ50 Equalizer! It has been crafted to

provide extremely high quality audio and a simple user interface that requires minimal effort to

optimize.

The EQ50 contains extremely versatile and musical sounding high pass, low pass and see-

saw filters with a simple and intuitive user interface. Expert circuit design and top quality

components realize an outstanding equalizer that is ideal for individual tracks or for mixing and

mastering stereo signals when the modules are used in pairs.

The unit features differential input and output. Both input and output can operate in differential

or single-ended, unbalanced modes. A high current, cross-coupled active output buffer mimics

the behavior of a transformer, providing constant gain for balanced or unbalanced operation,

when either the positive or negative output signals are grounded. Therefore, the output can

drive differential or single ended output with no extra user configuration needed.

The simple controls and circuit layout belie the finely tuned and expertly engineered design.

Extremely high input common mode rejection capability is realized, even down to critical power

supply frequencies. High qualify film caps, low distortion resistors and excellent quality

integrated active stages realize a high headroom, low noise, and low distortion equalizer with

superb audio quality that is ideal for individual tracks or for mixing and mastering stereo

signals.

.

EQ50 Owner’s Manual

12/2016

6

FRONT PANEL FEATURES

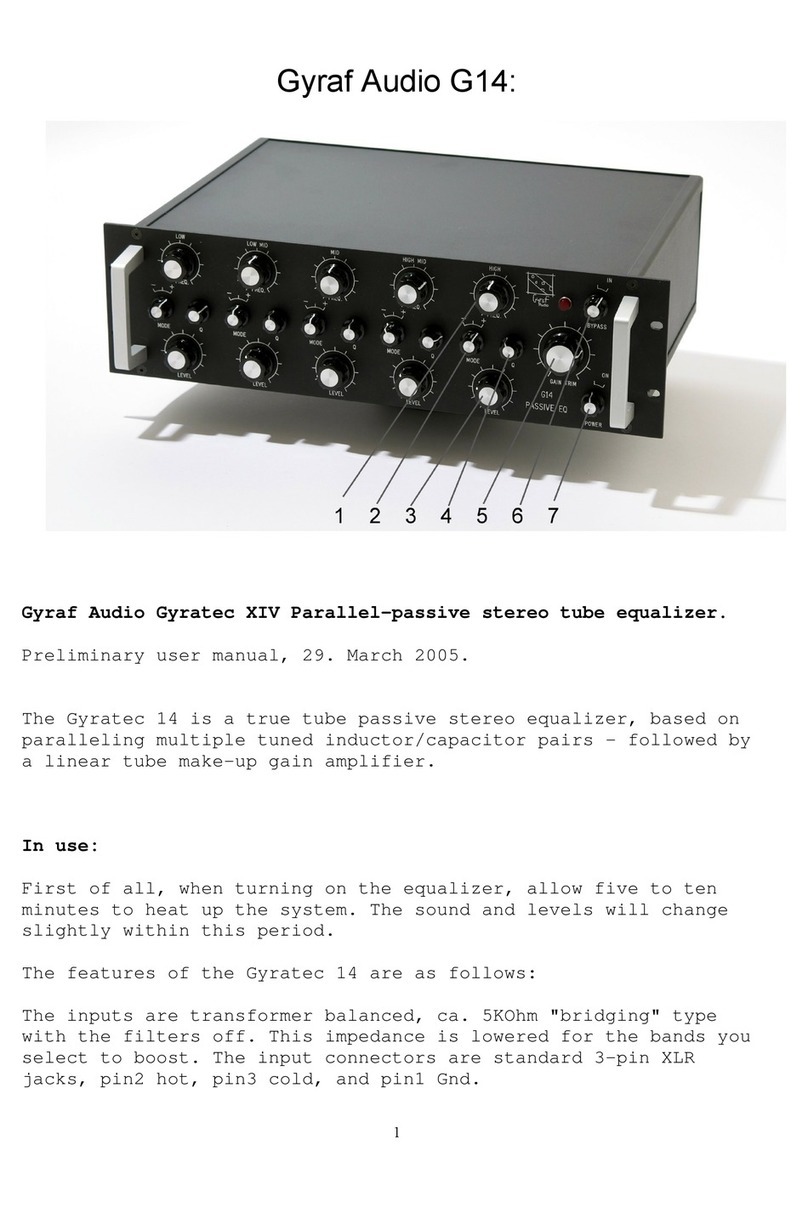

Figure 1: Front Panel Features

Pivot Frequency

Switchable Between

400 Hz and 1 kHz

See-Saw Filter

Simultaneously Adjusts

High / Low Frequencies

High Cut Filter

Sweepable from 5 kHz

to >200 kHz

Low Cut Filter

Sweepable from 20 Hz

to 1 kHz

Hardwire Bypass

Around EQ

Adjusting the Knob

Clockwise Boosts Highs

/ Cuts Lows

Adjusting the Knob

Counter-Clockwise

Boosts Lows / Cuts

Highs1 kHz

EQ50 Owner’s Manual

12/2016

7

EDGE CONNECTOR PIN ASSIGNMENTS

Power, ground and audio signal interface to the EQ50 is through the edge card connector at

the rear of the module. Assignments of the edge card connector pins follow:

Pin 1

Chassis Ground

Pin 2

Output, Balanced, Positive

Pin 3

No Connection

Pin 4

Output, Balanced, Negative

Pin 5

Audio Ground

Pin 6

No Connection

Pin 7

No Connection

Pin 8

Input, Balanced, Negative

Pin 9

No Connection

Pin 10

Input, Balanced, Positive

Pin 11

No Connection

Pin 12

+16V DC

Pin 13

Power Ground

Pin 14

-16V DC

Pin 15

No Connection

Figure 2: Edge Connector Pin Assignments

EQ50 Owner’s Manual

12/2016

8

SAFETY INSTRUCTIONS

1. Read Instructions

All the safety and operation instructions should be read before this product is operated.

2. Retain Instructions

The safety and operating instructions should be kept for future reference.

3. Heed Warnings

All warnings on the product and in these operating instructions should be followed.

4. Follow Instructions

All operating and other instructions should be followed.

5. Water and Moisture

This product should not be used near water or in environments with very high humidity

or with condensation.

6. Heat

This product should be situated away from heat sources such as radiators or other

devices that product heat.

7. Power Sources

This product should be connected to a power supply only of the type described in these

operation instructions or as marked on this product.

8. Object and Liquid Entry

Care should be taken so that objects do not fall into and liquids are not spilled into the

inside of this product.

9. Damage Requiring Service

This product should be serviced only by qualified service personnel when:

a. Objects have fallen, or liquid has spilled into the product; or

b. The product has been exposed to rain; or

c. The product does not appear to operate normally or exhibits a marked change in

performance; or

d. The product has been dropped, or its chassis damaged.

EQ50 Owner’s Manual

12/2016

9

10.Servicing

The user should not attempt to service this product beyond those means described in

this operating manual. All other servicing should be referred to the Ingram Engineering

Service Department.

Warning –To reduce the risk of fire or electric shock, do not expose this appliance to

rain or moisture.

EQ50 Owner’s Manual

12/2016

10

INSTRUCTIONS FOR USE

1. Installing the EQ50 in a Rack

RACK POWER MUST BE OFF BEFORE INSTALLING THE EQ50. The module

design is not warrantied for damage that occurs when it is inserted or removed from a

rack with power applied.

2. Module Warm Up

After power up, please allow approximately 2 minutes time for component warm up and

stabilization time before beginning critical listening or recording.

3. EQ In (Bypass Switch)

The EQ In button engages the EQ or switches in a hard-wire bypass of the entire EQ

module. With balanced input and most types of equipment used in conjunction with this

EQ, the EQ has unity gain. Therefore, by alternating between EQ In and EQ Out, the

Bypass Switch is an effective tool to audition the effect of the EQ. An LED indicates

when the EQ is engaged.

4. Setting Audio Levels

Ideal levels for the EQ50 are 0 dBu nominal at mid frequencies. While the EQ50 can

accept audio levels up to +20 dBu when the EQ settings are flat, the see-saw filter has

as much as +20 dB gain when adjusted to its extremes, so it is good practice to set the

EQ50 input levels to 0 dBu. The Low Cut and High Cut filters only attenuate the signal,

so gain added by these filters will not be a factor in setting levels.

5. Low Cut Filter

The Low Cut Filter is a passive filter that provides gentle -6dB / octave cut to

frequencies below that indicated on the knob. The cutoff frequency adjustment range is

very wide, and extends from 20 Hz to 1 kHz. By using a low order -6dB/octave filter,

minimal phase shift of the signal is realized. By providing cutoff frequency as high as 1

kHz, significant attenuation of lowest frequencies can be achieved. The plot below

shows a range of filter responses.

EQ50 Owner’s Manual

12/2016

11

Figure 3: Low Cut Filter Example Responses

6. See-Saw Filter

The See-Saw Filter provides simultaneous cut of one frequency band while boosting

another band. When the adjustment knob is turned fully clockwise, high frequencies are

boosted and low frequencies are cut. When the adjustment knob is turned fully count-

clockwise, low frequencies are boosted and high frequencies are cut. The filter has

approximately linear slope over the entire audio band. Max boost and cut are more

than 16dB, so significant shaping of the audio spectrum can be achieved.

The See-Saw filter has a “pivot” frequency that is selectable as 400 Hz or 1 kHz by

pressing the front panel button. Therefore, frequency band emphasis can be changed

to match the source being equalized. The See-Saw filter has the same linear slope for

each setting. The plots below show a range of filter responses.

EQ50 Owner’s Manual

12/2016

12

Figure 4: See-Saw Filter Example Responses, 400 Hz Pivot Frequency

Figure 5: See-Saw Filter Example Responses, 1 kHz Pivot Frequency

EQ50 Owner’s Manual

12/2016

13

7. High Cut Filter

The High Cut Filter is a passive filter that provides gentle -6dB / octave cut to

frequencies above that indicated on the knob. The cutoff frequency adjustment range is

very wide, and extends from 5 kHz to >200 kHz. By using a low order -6dB/octave filter,

minimal phase shift of the signal is realized. By providing cutoff frequency as low as 5

kHz, significant attenuation of highest frequencies can be achieved. The plot below

shows a range of filter responses.

Figure 6: High Cut Filter Example Responses

EQ50 Owner’s Manual

12/2016

14

8. Using Filters in Combination

The following plots show examples applications of the three filters, used in combination.

Settings are noted for each.

Smooth a stereo mix during mastering: Low Cut frequency = 35 Hz, See-Saw = -0.5,

High Cut frequency = 35 kHz. See-Saw pivot frequency = 400 Hz

Figure 7: Filter Plot, Settings for Smoothing a Stereo Mix

EQ50 Owner’s Manual

12/2016

15

Subtle high frequency restoration: Low Cut frequency = 20 Hz, See-Saw = +0.5,

High Cut frequency = 70 kHz. See-Saw pivot frequency = 1 kHz

Figure 8: Filter Plot with Subtle High Frequency Restoration Settings

Compressor sidechain filter, triggering on mid-lows: Low Cut frequency = 100 Hz,

See-Saw = -2, High Cut frequency = 15 kHz. See-Saw pivot frequency = 1 kHz

Figure 9: Filter Plot with Compressor Sidechain Filter Settings, Mid-Low Trigger Frequency

EQ50 Owner’s Manual

12/2016

16

Compressor sidechain filter, triggering on high frequencies: Low Cut frequency = 1 kHz,

See-Saw = +1, High Cut frequency = 45 kHz. See-Saw pivot frequency = 400 Hz

Figure 10: Filter Plot with Compressor Sidechain Filter Settings, High Trigger Frequency

Presence boost: Low Cut frequency = 35 Hz, See-Saw = +0.75, High Cut frequency

= 35 kHz. See-Saw pivot frequency = 1 kHz

Figure 11: Filter Plot with Presence Boost Settings

EQ50 Owner’s Manual

12/2016

17

ELECTRICAL SPECIFICATIONS

(TA=+25°C unless otherwise noted)

Parameter

Min

Typ

Max

Unit

Comments

Input Impedance

48

k Ω

Differential

Output Impedance

100

Ω

Differential

Gain

0

dBr

EQ Engaged, Diff Input

Max Input Level

+20

dBu

With <0.5% THD

Frequency Response

20

>250k

Hz

±3.0 dB, Equalizer On with Flat

Adjustment

Low Cut Filter

Cutoff Frequency Range

20

1000

Hz

Stopband Slope

-6

dB/Octave

High Cut Filter

Cutoff Frequency Range

5

>200

kHz

Stopband Slope

-6

dB/Octave

See-Saw Filter

Pivot Frequency

400

1k

Hz

Selectable Using Push-Button

Boost / Cut

-15

+15

dB

With Control Fully CW or CCW

Filter Slope

6

dB/Octave

With Max Boost/Cut

THD + Noise

0.002

%

With +20 dBu Input, 1 kHz

Signal, 22 kHz Bandwidth

Noise

-98

dBu

Input Referred

CMRR

90

dB

At 60 Hz

Voltage Supplies

±16

V

Current

±25

mA

ENVIRONMENTAL SPECIFICATIONS

Parameter

Min

Typ

Max

Unit

Comments

Operating Temperature

0

85

°C

Humidity

30

80

%

Non-condensing

EQ50 Owner’s Manual

12/2016

18

CARE AND MAINTENANCE

1. Cleaning

Avoid solvents or chemicals that may dissolve the silkscreen text on the front and back

panels.

TROUBLESHOOTING

1. Power does not turn on

First verify that power is being applied to the module by engaging the EQ In function. It

has a Green LED that illuminates when the EQ is engaged. If this LED does not come

on, verify that the 500-rack has power applied and is switched on. Check the rack AC

fuse.

2. Audio Sounds Distorted

Check the level being applied to the EQ50. 0dBu (-4VU) is the best nominal audio level

to use with the EQ50. The See-Saw filter can realize nearly 20 dB gain when adjusted

to its extremes. If EQ50 input levels exceed 0dBu, it is possible that the audio is being

distorted if extreme See-Saw filter settings are being used.

If distortion cannot be attributed to signal levels or filter settings, check the integrity of

the 500-series rack power supply. If these tips do not solve the problem, investigate

other system equipment, then contact Ingram Engineering.

3. Hum or Buzz is Audible

Check the integrity of the system cables. If the 500-Series rack includes a ground lift for

the balanced audio cable, try lifting the ground. Check the integrity of the 500-Series

rack power supply.

EQ50 Owner’s Manual

12/2016

19

CONTACT INFORMATION

Ingram Engineering

PO Box 5870

Atlanta, Ga. 31107, USA

Phone +1 (678) 685-9838

URL: http://ingramengineering.net

Email: information@ingramengineering.net

WARRANTY INFORMATION

Ingram Engineering warrants all materials, workmanship and proper operation of this product

for a period of three years from the original date of purchase. If any defects are found in the

materials or workmanship or if the product fails to function properly during the applicable

warranty period, Ingram Engineering, at its option, will repair or replace the product. This

warranty applies only to equipment sold and delivered by Ingram Engineering or its authorized

dealers. Original purchase receipts showing date and location of purchase must be presented

at the time of submission for warranty work.

Failure to register the product will not void the three year warranty.

Service and repairs of Ingram Engineering products are to be performed only at the factory OR

at an authorized Ingram Engineering Service Center. Unauthorized service, repairs, or

modification will void this warranty. To obtain repairs under warranty, you must have a copy of

your sales receipt from the store where you bought the product. It is necessary to establish

purchase date and thus determine whether or not your Ingram Engineering product is still

under warranty.

To obtain factory service:

Call Ingram Engineering at 678-685-9838 9 AM to 5 PM Monday through Friday (East Coast

Time) to get a Return Authorization (RA). Products returned without an RA number will be

refused.

Pack the product in its original shipping carton. If you do not have the carton, just ask for one

when you get your RA number, and we’ll send a shipping carton to you. Please seal the

product in a plastic bag.

EQ50 Owner’s Manual

12/2016

20

Also include a note explaining exactly how to duplicate the problem, a copy of the sales receipt

showing price and date, and your return street address (no P.O. boxes or route numbers,

please). If we cannot duplicate the problem or establish the starting date of your Limited

Warranty, we may, at our option, charge for service time.

Ship the product in its original shipping carton, freight prepaid to:

Ingram Engineering Service Department

926 Bruce Circle

Atlanta, Ga. 30316 USA

IMPORTANT: Make sure that the RA number is plainly written on the shipping carton.

To obtain service from an Authorized Ingram Engineering Service Center:

Call Ingram Engineering at 678-685-9838, 9 AM to 5 PM Monday through Friday (East Coast

Time) to receive: 1) The name and address of your nearest Authorized Ingram Engineering

Service Center and 2) A return authorization (RA). You must have an RA number before

taking your unit to a service center.

Make sure that you have a copy of your sales receipt from the store where you bought the

product. If you can’t find it, the Authorized Service Center may charge you for repairs even if

your Ingram Engineering product is still covered by the Three Year Limited Warranty.

Make sure the problem can be duplicated. If you bring your Ingram Engineering product to an

Authorized Service Center and they can’t find anything wrong with it, you may be charged a

service fee.

If the Authorized Ingram Engineering Service Center is located in another city, pack the

product in its original shipping carton.

Contact the Authorized Ingram Engineering Service Center to arrange service or bring the

Ingram Engineering product to them.

Ingram Engineering and Authorized Ingram Engineering Service Centers reserve the right to

inspect any products that may be the subject of any warranty claims before repair or

replacement is carried out. Ingram Engineering and Authorized Ingram Engineering Service

Centers may, at their option, require proof of the original date of purchase in the form of a

dated copy of the original dealer’s invoice or sales receipt. Final determination of warranty

coverage lies solely with Ingram Engineering or its Authorized Service Centers.

Ingram Engineering products returned to Ingram Engineering and deemed eligible for repair or

replacement under the terms of this warranty will be repaired or replaced within sixty days of

receipt by Ingram Engineering. Ingram Engineering may use refurbished parts for repair or

Table of contents

Other Ingram Engineering Stereo Equalizer manuals