www.initiativeengineering.com

PAGE 9

ESSENTIAL SAFETY REQUIREMENT

Ÿ Install the pump in any shaded place away from direct sunlight.

Ÿ Electrical connecon should be made between Live – Neutral and Not live-Ground.

Ÿ Make sure that any chemicals that are released from the pump or any damaged lines do not causes damages to

system parts.

Ÿ Ensure voltage is within range specified for the pump i.e., 230 ±10% V.

Ÿ Avoid giving supply from the same line as heavy electrical equipment.

Ÿ When working with chemicals, the accident pretension regulaons applicable at the installaon site should be

applied (e.g. wearing protecon clothing's). Observe the chemical manufacturer's safety data sheet and safety

instrucons when handling chemicals.

Ÿ The pump can not be used fin sub-merged condion.

Ÿ The dosing medium must be a liquid, Observe the freezing and boiling point of the dosing media. The

resistance of the parts which comes into contact with the dosing medium, such as the dosing head, PTFE ball

and washer, glass ball, 'O' ring, ball bush, pipe lines, ball seal and sucon filter assembly, NRV body etc. ,

depends on the medium, media temperature and operang pressure. Ensure that the parts come contact with

the dosing medium are resistance to the dosing medium under operang temperature and pressure, see the

data booklet.

Ÿ Before starng work on the pump, the pump must be disconnected from the power supply. The system must

be pressure less.

Ÿ Before switching on the main supply, the tubing cap (both sucon and discharge valve assembly) should be

ghtened to dosing head properly so that the metering liquid can not spray out from the dosing head in

working condion and put operator's in risk. The dosing medium/liquid is pressurized and can be harmful to

health and the environment.

6.Dismantle the sucon and discharge tubing and check whether tubing is blocked, soiled or damaged, replace if

necessary.

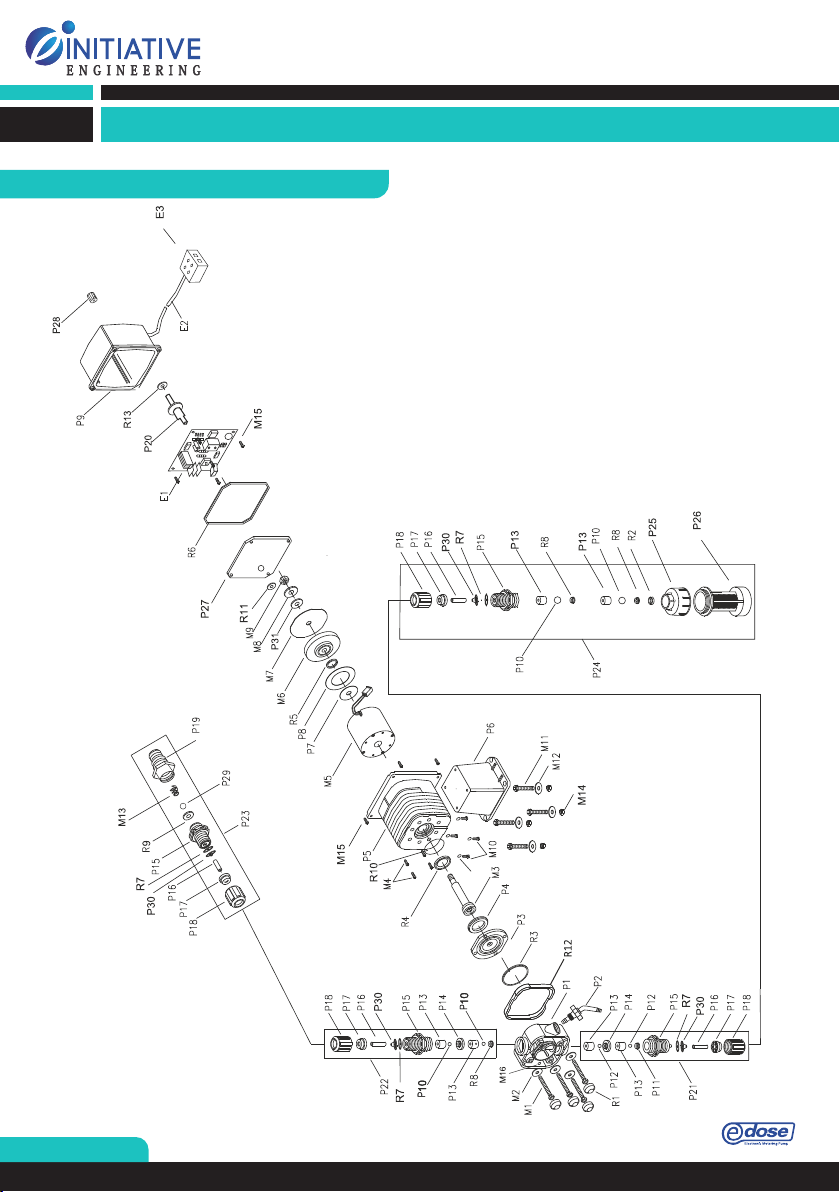

Ÿ Do not operate the pump with a damage/break diaphragm. Operang with damaged diaphragm can lead to

dosing liquid entering pump housing. In case of diaphragm breakage immediately separate the pump from the

power supply. Make sure the pump cannot be put back into the operaon by accident. In case of diaphragm

breakage use the following step to dismantle diaphragm (refer fig. of Edose Dosing Head overview):

1.Make the system pressure less.

2.Empty the dosing head before maintenance and flush it, if necessary.

3.Set the frequency knob to 0%.

4.Switch off mains supply.

5.Take suitable steps to ensure that the returning liquid is safely collected.

7.Dismantle NRV body in sucon and discharge side.