Inmes IF-8500 User manual

Dear Customer,

Thanks for allowing us to share the experience of using an Inmes product.

This manual has been formulated by our technical team specially for you, with the objective of instructing

you on how to use this equipment with safety and productivity.

The IF-8500 CNC Drilling Machine has been developed within the highest technology, to solve your

drilling problems in wood boards, allowing you to get the best value for money additionally to a great finishing

adding more value to the furniture.

Visit our brand website to learn about our new releases and our full product line.

http://www.inmes.com.br

If necessary, contact your distributor to get technical assistance.

Write down the serial number of your equipment below.

Note: INMES Industrial LTDA. Reserves the right to change this manual without previous notice.

INMES Industrial LTDA. –IF-8500 Drilling Machine

2

INDEX

1 –SAFETY INSTRUCTIONS ................................................................................................................. 3

1.1 –Safety Warnings............................................................................................................................. 3

1.2 –Before using the machine............................................................................................................... 3

1.3 –Tools Specifications....................................................................................................................... 4

1.4 –Before every use............................................................................................................................. 5

1.5 –Important information for the reduction of risks of accidents ....................................................... 5

1.6 –Protection ....................................................................................................................................... 6

1.6.1 –Safety Labels............................................................................................................................... 6

1.7 –When finished operating the machine............................................................................................ 9

2 –RECEIVING AND GETTING ACQUAINTED WITH THE IF-8500 CNC DRILLING MACHINE9

2.1 –Receiving the IF-8500 Drilling Machine ....................................................................................... 9

2.2 –Working Area............................................................................................................................... 13

2.3 –Getting Acquainted with the IF-8500 Drilling Machine.............................................................. 14

2.4 –Learning about the Control Panel................................................................................................. 15

2.5 –Learning about the Touch Screen Interface ................................................................................. 16

3 –TECHNICAL SPECIFICATIONS..................................................................................................... 19

4 –INSTALLATION............................................................................................................................... 20

4.1 –Loading and Unloading the Equipment ....................................................................................... 20

4.2 –Characteristics of the Installation Area........................................................................................ 20

4.3 –Electrical Installation.................................................................................................................... 21

4.4 –Installation of the Compressed Air System.................................................................................. 22

4.5 –Installation of the Exhaust System............................................................................................... 23

4.5.1 –Electrical Installation of the Exhaust......................................................................................... 23

4.6 –Software Installation .................................................................................................................... 25

5 –SECURITY SYSTEM........................................................................................................................ 26

5.1 –Movable Protection of the Drilling Set Access............................................................................ 26

5.2 –Emergency Button........................................................................................................................ 26

5.3 –Reset Button................................................................................................................................. 29

6 –OPERATION...................................................................................................................................... 30

6.1 –Turning the Machine on and off................................................................................................... 30

6.2 –Entering the Work Schedule in the Drilling Machine.................................................................. 33

6.4 –Jog Function................................................................................................................................. 42

6.5 –Cycles Function............................................................................................................................ 45

7 –MAINTENANCE............................................................................................................................... 46

7.1 –Cleaning ....................................................................................................................................... 46

7.1.1 –Air Filters Cleaning................................................................................................................... 46

7.1.2 –Axis Y Link Chain Cleaning..................................................................................................... 47

7.1.3 –Axis Z Sensor Cleaning............................................................................................................. 48

7.1.4 –Cleaning the Head Cylinder and Head Lock Plate.................................................................... 48

7.1.5 –Cleaning the Axis X Linear Guide and Gear Rack................................................................... 49

7.2 –Lubrication ................................................................................................................................... 50

7.2.1 –Oil Tank..................................................................................................................................... 50

7.2.2 –Chain Lubrication...................................................................................................................... 51

7.3 –Compressed Air Regulator........................................................................................................... 53

7.4 –Tool Replacement ........................................................................................................................ 53

7.5 –Belt Slack Adjustment.................................................................................................................. 62

7.5.1 –Saw Belt .................................................................................................................................... 62

8 –POSSIBLE PROBLEMS –CAUSES –SOLUTIONS...................................................................... 64

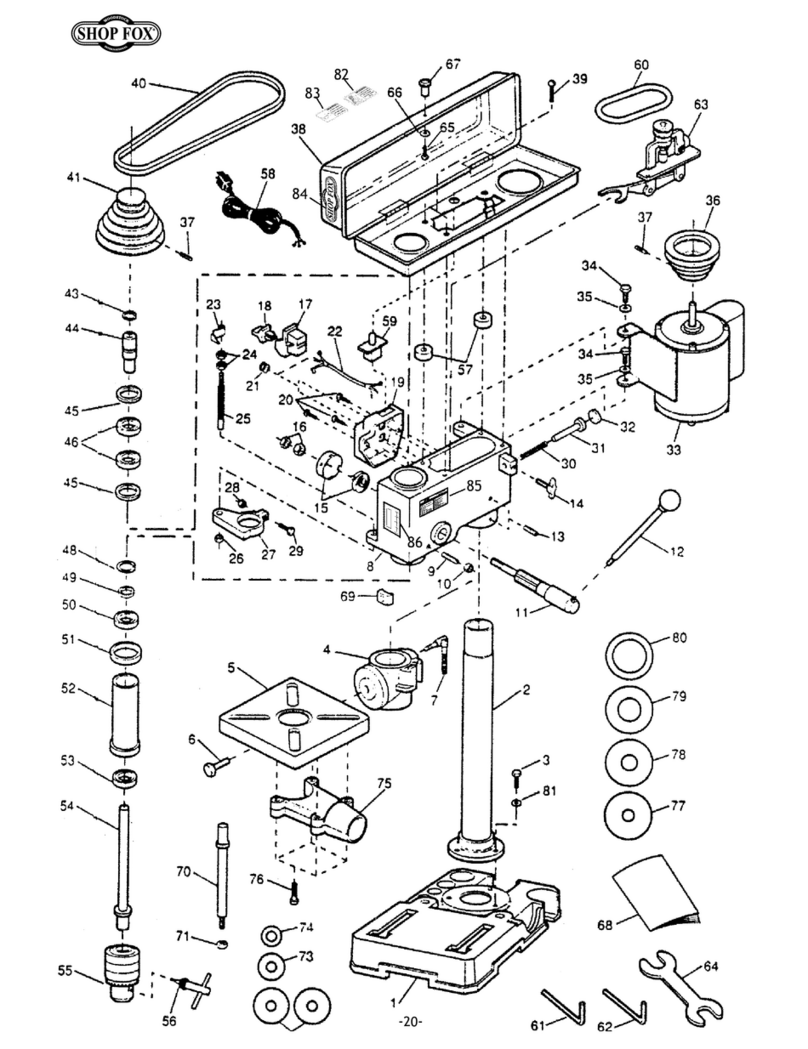

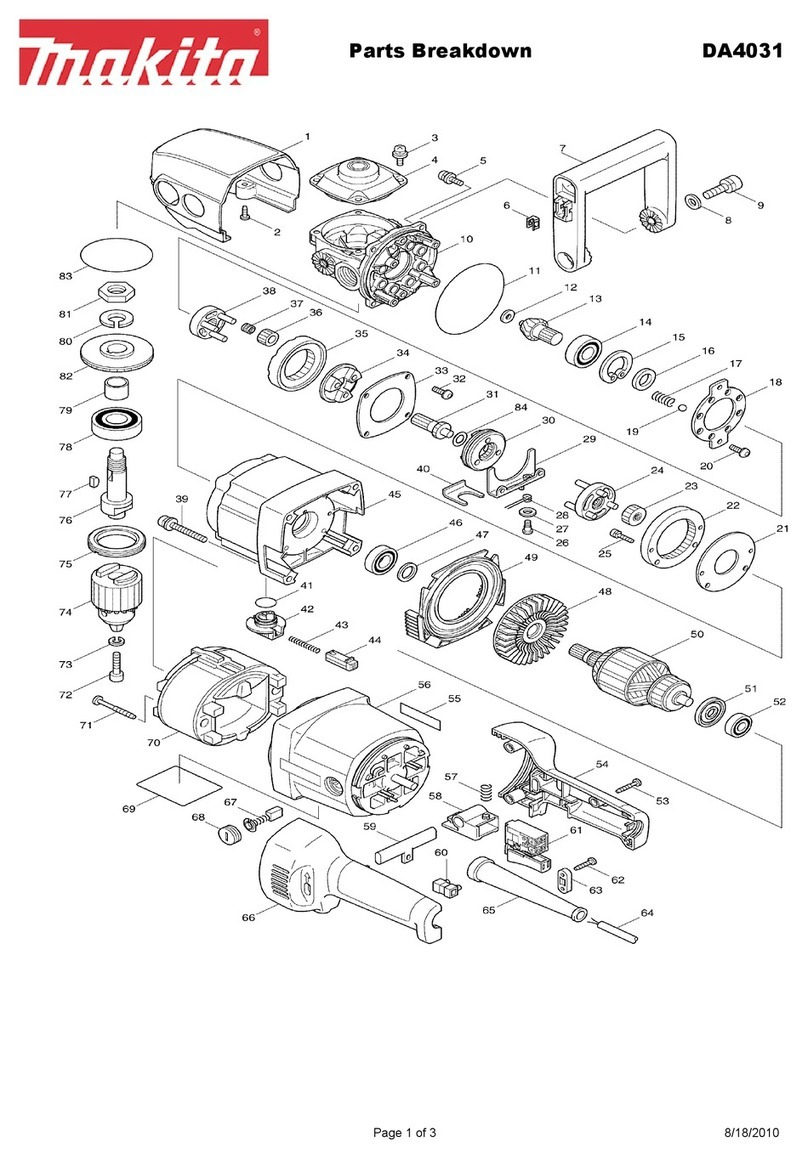

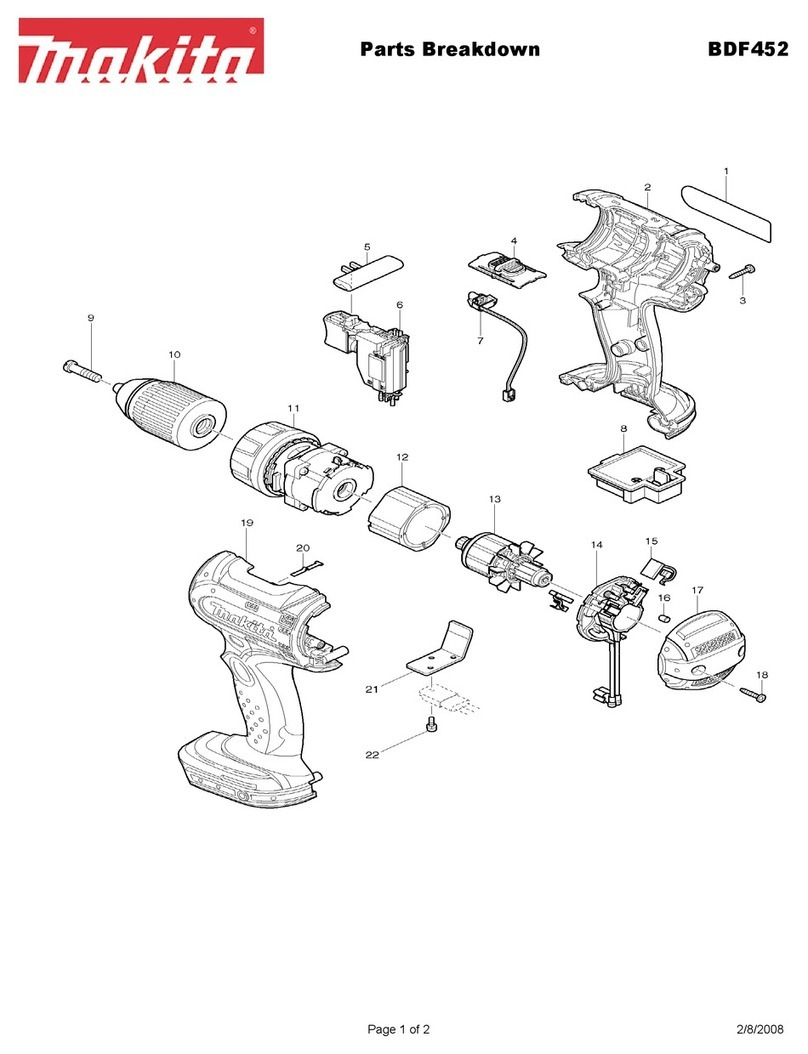

9 –EXPLODED VIEWS.......................................................................................................................... 68

INMES Industrial LTDA. –IF-8500 Drilling Machine

3

1 –SAFETY INSTRUCTIONS

In order to increase the safety of the operator and the durability of your equipment, some caution is re-

quired during its installation and operation.

1.1 –Safety Warnings

Safety information, which, if not complied with, will cause serious risks to the operator’s

life.

Safety information, which, if not complied with, may cause serious risks to the operator’s

life;

Safety information, which, if not complied with, may cause injuries to the operator.

1.2 –Before using the Machine

✓Carefully ready the entire instruction manual before operating the equipment;

✓Keep this manual in a location that is easy for the operator to access;

✓If you are not totally familiarized with how to operate the machine, seek for guidance from a professional;

✓Place the machine so that the working space is suitable to the operator;

✓Do not expose or use the machine in inappropriate sites.

✓Always wear protection glasses;

✓Keep hands away from the moving parts of the machine;

✓Never place your hands or any objects that are not the actual material to be drilled through the openings

where it should be inserted. Not complying with this requirement may cause severe injuries to the operator

and damage to the equipment.

✓Always wait for the moving parts of the machine to stop before any maintenance or adjustment and make

sure that the machine is not connected to the electricity.

✓While you are working, pay full attention to the functioning of the machine. Any lapse of attention may

cause severe injuries.

✓Never connect the Earth cable (green and yellow) to the neutral. Always connect it to a functioning ground

wiring;

✓Never use drills and cutters out of the recommended specifications. Not complying with this requirement

may cause severe damage to the equipment.

✓It is advisable to work only wood or wood boards such as MDF, MDP or similar. It is not allowed under

any circumstances to work with any other type of material;

✓Make your work safer, making sure that all safety items described in this Instruction Manual are followed

and are functioning normally.

✓Before leaving the work site, be sure that the machine is completed turned off.

✓The machine can only be safely used if the operator thoroughly follows the operation and safety

instructions.

✓It is fundamental to read this manual before using this machine so that you know how the machine Works

and its limitations.

✓Make sure that all safety devices are installed in the machine and that the machine is connected to a dust

extraction system.

✓Leave enough space around the machine and a good lighting in the workshop.

✓When changing the tools or when performing a maintenance job, the machine must always be disconnected

INMES Industrial LTDA. –IF-8500 Drilling Machine

4

from its power supply.

✓Drills, cutters and blades that are not correctly sharpened or are in bad conditions not only decrease the

work quality but also increase the risks of accidents.

✓Always wear appropriate clothes. Loose or torn clothes are very dangerous.

✓Keep children away from the machine and from the workshop.

✓To avoid damages to your hearing, it is recommended that you wear hearing protection while you are close

to the machine.

✓Make sure that all maintenance work is done periodically. Maintenance Works can only be performed with

the machine disconnected from its power supply, disabling any accidentally activation of the machine.

✓Thoroughly read the cleaning instructions for the machine and only clean in when it is disconnected from

electricity.

✓Perform weekly tests of the following electrical components: emergency buttons and test whether the

machine can be operated with the doors open.

✓Always wear hearing protection when operating the machine.

1.3 –Tools Specifications

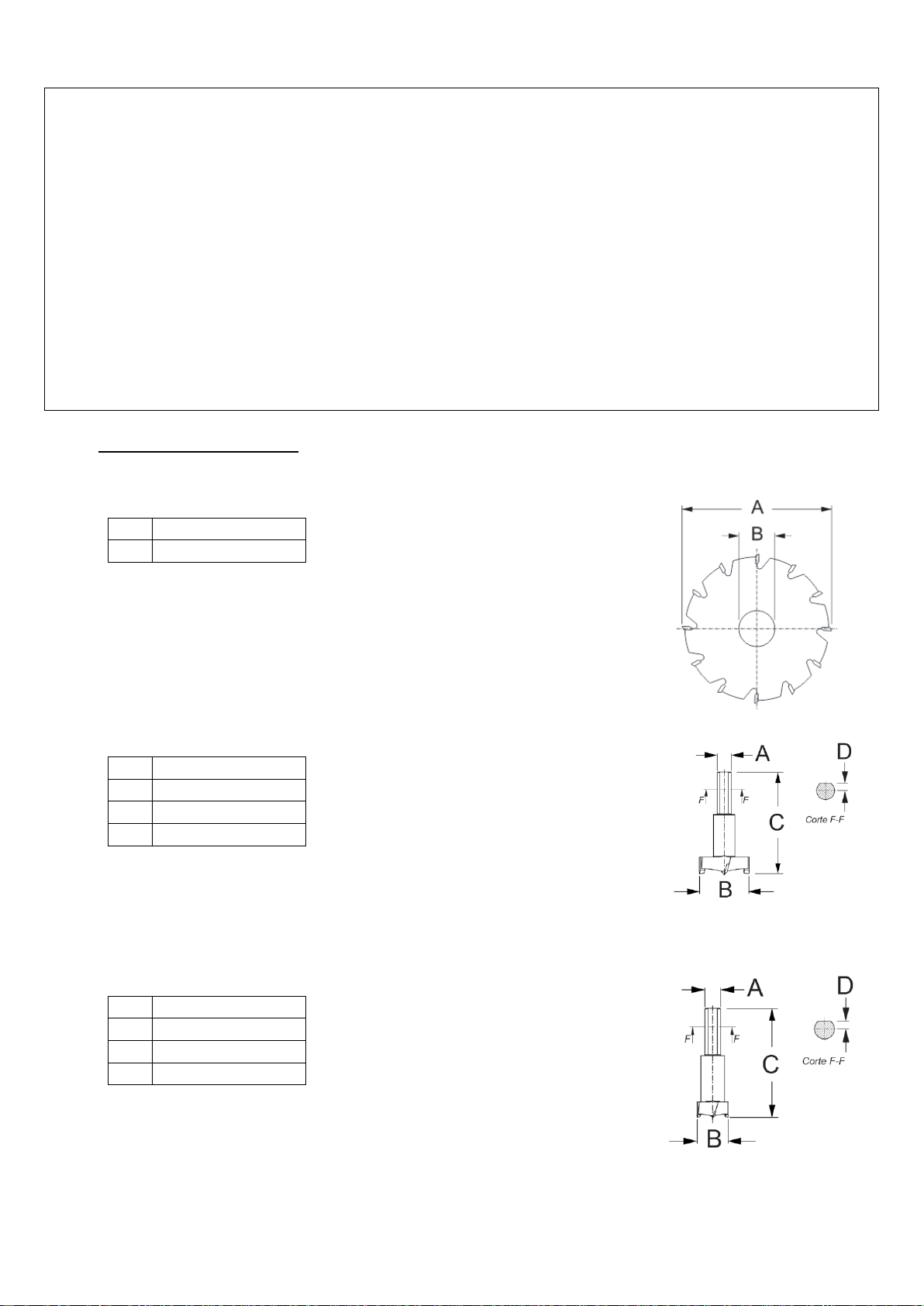

The saw blade must comply with the following specifications:

A

90mm –3 9/16”

B

20mm –13/16”

Rotation limit equal or superior to 3500rpm;

Teeth: 24

To be adequate to the type of material to be cut (wood boards and

similar).

The drill must comply with the following specifications:

A

10mm –3/8”

B

35mm –1 3/8”

C

58mm –2 ¼”

D

4mm –3/16”

Rotation limit equal or superior to 5500rpm;

To be adequate to the type of material to be cut (wood boards and

similar).

The drill must comply with the following specifications:

A

10mm –3/8”

B

15mm –9/16”

C

58mm –2 ¼”

D

4mm –3/16”

Rotation limit equal or superior to 5500rpm;

To be adequate to the type of material to be cut (wood boards and

similar).

INMES Industrial LTDA. –IF-8500 Drilling Machine

5

The drill must comply with the following specifications:

A

10mm –3/8”

B

8mm –5/16”

C

58mm –2 ¼”

D

4mm –3/16”

Rotation limit equal or superior to 5500rpm;

To be adequate to the type of material to be cut (wood boards and

similar).

The drill must comply with the following specifications:

A

10mm –3/8”

B

5mm –3/16”

C

58mm –2 ¼”

D

4mm –3/16”

Rotation limit equal or superior to 5500rpm;

To be adequate to the type of material to be cut (wood boards and

similar).

In the tool head, one of the compartments has a red lid (01) and serves

only for left sided tools, as indicated on the image beside.

1.4 –Before every use

Check for loose or damaged parts.

Remove eventual cutting residues from the machine;

Never use the machine if any original part or protection are missing.

1.5 –Important information for the reduction of risks of accidents

✓Broken or damaged drills, cutters and blades must not be used;

✓Before starting to work with the machine, make sure that no objects have been left over it;

✓Adapted or damaged parts must not be used;

✓When any anomaly on the machine is detected, turn it off and disconnect it from electricity and perform the

required maintenance;

✓The machine must not be used if any protection is not working;

✓Only use sharpened drills, cutters and blades and in perfect working conditions;

✓Keep the cutting tools clean;

✓Always keep the working area clean, the dust resulting from work can make the floor slippery;

INMES Industrial LTDA. –IF-8500 Drilling Machine

6

✓The machine must not be used near inflammable liquids, dust, vapor or gases;

✓People under 18 years old are not allowed to operate the machine;

✓Untrained people must be kept away from the machine;

✓The operator must be trained by qualified personnel to operate this equipment;

✓When installed the drill, cutter or blade, check the its mounting and the rotation direction, being careful not

to mount it backwards Fig. 1.2.

Fig. 1.2

✓The existing protections must not be removed. Not complying with these recommendations may

cause serious accidents;

1.6 –Protection

During the operation of the equipment:

✓Do not wear loose clothes, jewelry or ties;

✓Keep your hair away, wear a protection cap if necessary;

✓Always wear hearing protection;

✓Always wear protection glasses;

Always remember: A minor distraction is enough to cause serious accidents;

1.6.1 –Safety Labels

INMES Industrial LTDA. –IF-8500 Drilling Machine

7

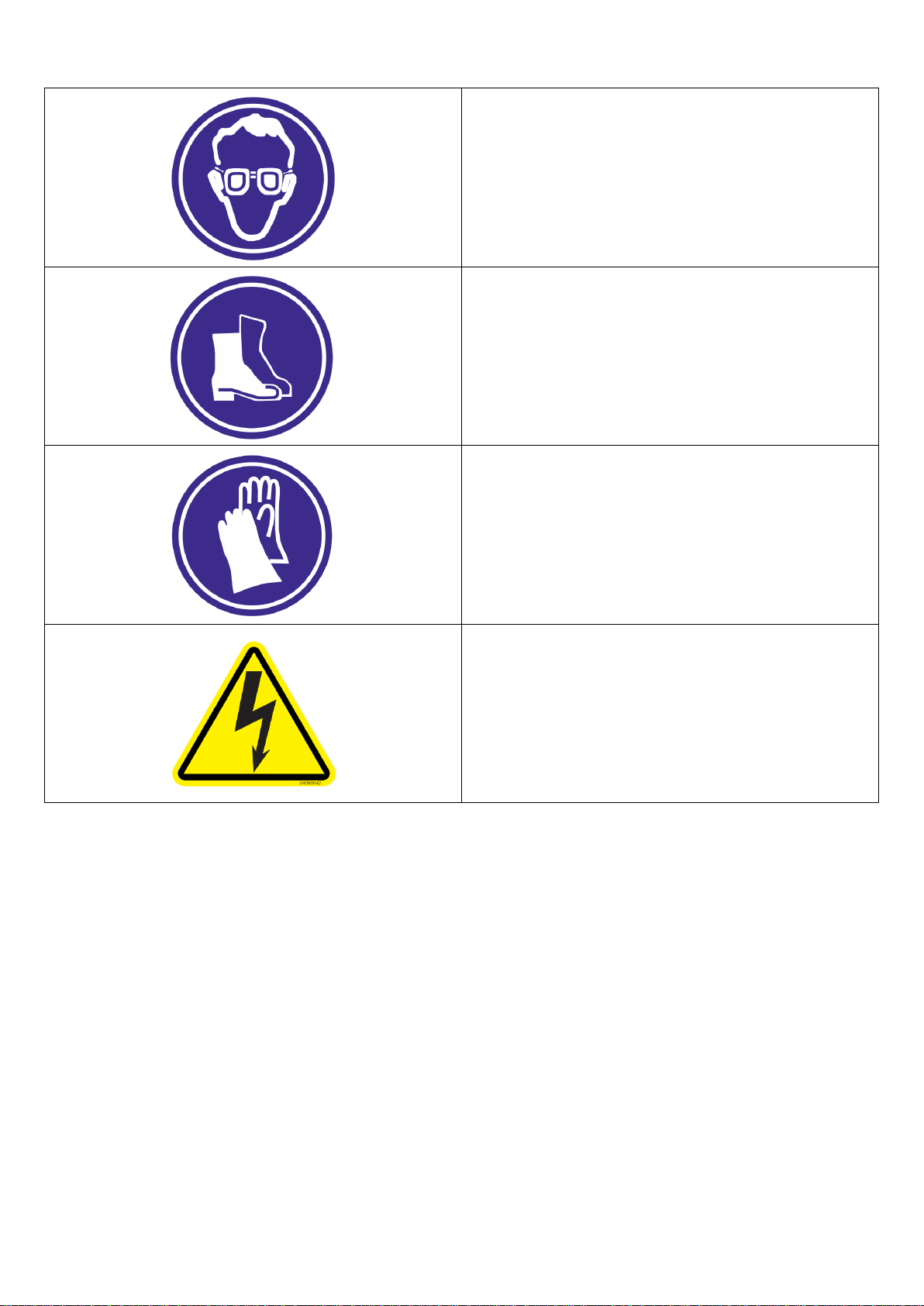

Label

Indication

Indicates the safety rules that must be followed when

operating the machine.

Risk of crushing, keep hands away.

Indicates the use of appropriate clothes.

Indicates the use of hearing protection.

INMES Industrial LTDA. –IF-8500 Drilling Machine

8

Indicates the use of eye protection.

Indicates the use of protection shoes.

Indicates the use of gloves.

Risk of electric shock

INMES Industrial LTDA. –IF-8500 Drilling Machine

9

1.7 –When finished operating the machine

✓Turn the machine off;

✓Turn off the Main Switch of the machine;

✓Turn the circuit breaker off;

✓Clean up the machine and leave it ready for the next operation;

Warning

To request replacement parts, use the parts diagram and the parts list that can be found at the end of this

manual, always referring to the parts codes when ordering.

This manual is extremely useful when replacement parts are needed, therefore, keep it at an appropriate

site. In case you own more than one equipment of the same model, identify it writing the serial number down

on its respective manual on page 2 2.

2 –RECEIVING AND GETTING ACQUAINTED WITH THE IF-8500 CNC DRILLING

MACHINE

2.1 –Receiving the IF-8500 Drilling Machine

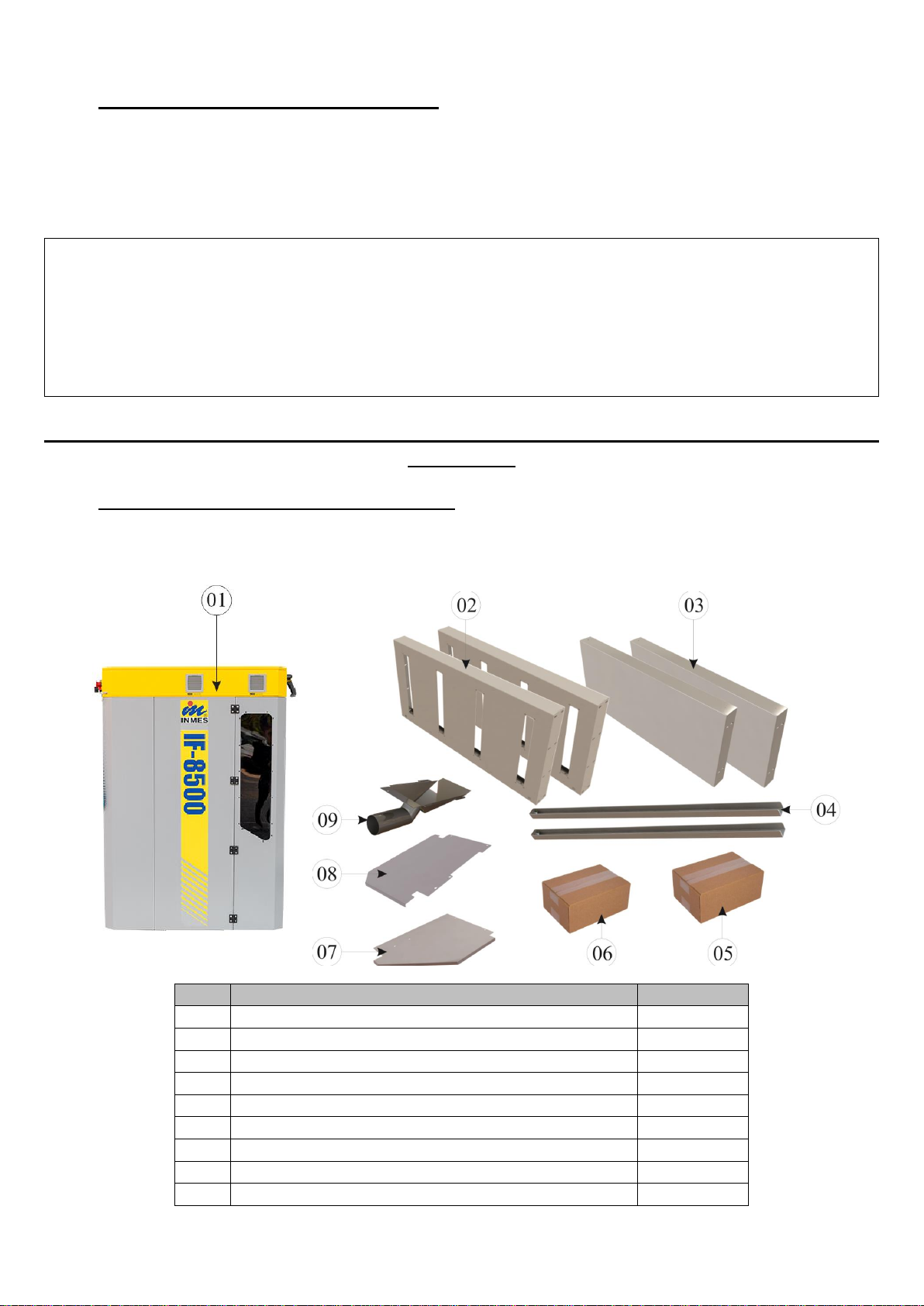

When receiving the machine, please check to make sure all items that go with it are present.

Item

Description

Quantity

01

IF-8500 Drilling Machine

1

02

Infeed/Outfeed Table

2

03

Infeed/Outfeed Table finishing

2

04

Structure Leaning Support

2

05

Table Assembling Kit Carton Box IF-8500

1

06

Assembling Kit Carton Box IF-8500

1

07

Right Rear Board

1

08

Left Rear Board

1

09

Bottom Dust Collector

1

INMES Industrial LTDA. –IF-8500 Drilling Machine

10

INMES Industrial LTDA. –IF-8500 Drilling Machine

11

❖Items in the assembling kit IF-8500

Item

Description

Quantity

01

Barcode Reader

1

02

Spiral Tube

1

03

Air Outlet for Cleaning

1

04

Articulated Leveler

6

05

Washer 6.35x17.46x1.58mm

18

06

Domed Head Screw Hex. Int. M6x10mm

18

07

Hex. Head Screw Int. M6x30mm

4

08

Tilt Stand Wedge

4

09

Hex. Head Screw Int. M10x40mm

2

10

Hex. Self-Locking Nut M10

2

11

GCad License

1

12

Wi-Fi USB adapter with antenna

1

13

Barcode Reader Support

1

14

Allen Key 2.5mm

1

15

Allen Key 5.0mm

1

16

Saw Blade Replacement Wrench

1

17

Door Handle

1

18

TRUSLIDE ISO VG 220 Oil

1

INMES Industrial LTDA. –IF-8500 Drilling Machine

12

❖Table Assembling Kit Items IF-8500

Item

Description

Quantity

01

Washer 6.35x17.46x1.58mm

4

02

Extension Table Eccentric Shaft

10

03

Bearing Support Bushing

10

04

Extension Table Output Support

2

05

Articulated Leveler

2

06

Hex. Self-Locking Nut M10

10

07

Hex. Nut M12 zinc. DIN 934

2

08

Domed Head Hex. Screw Int. M6x16mm

32

09

Bearing 6300 DDU

30

10

Retractable Shaft Roller

8

INMES Industrial LTDA. –IF-8500 Drilling Machine

13

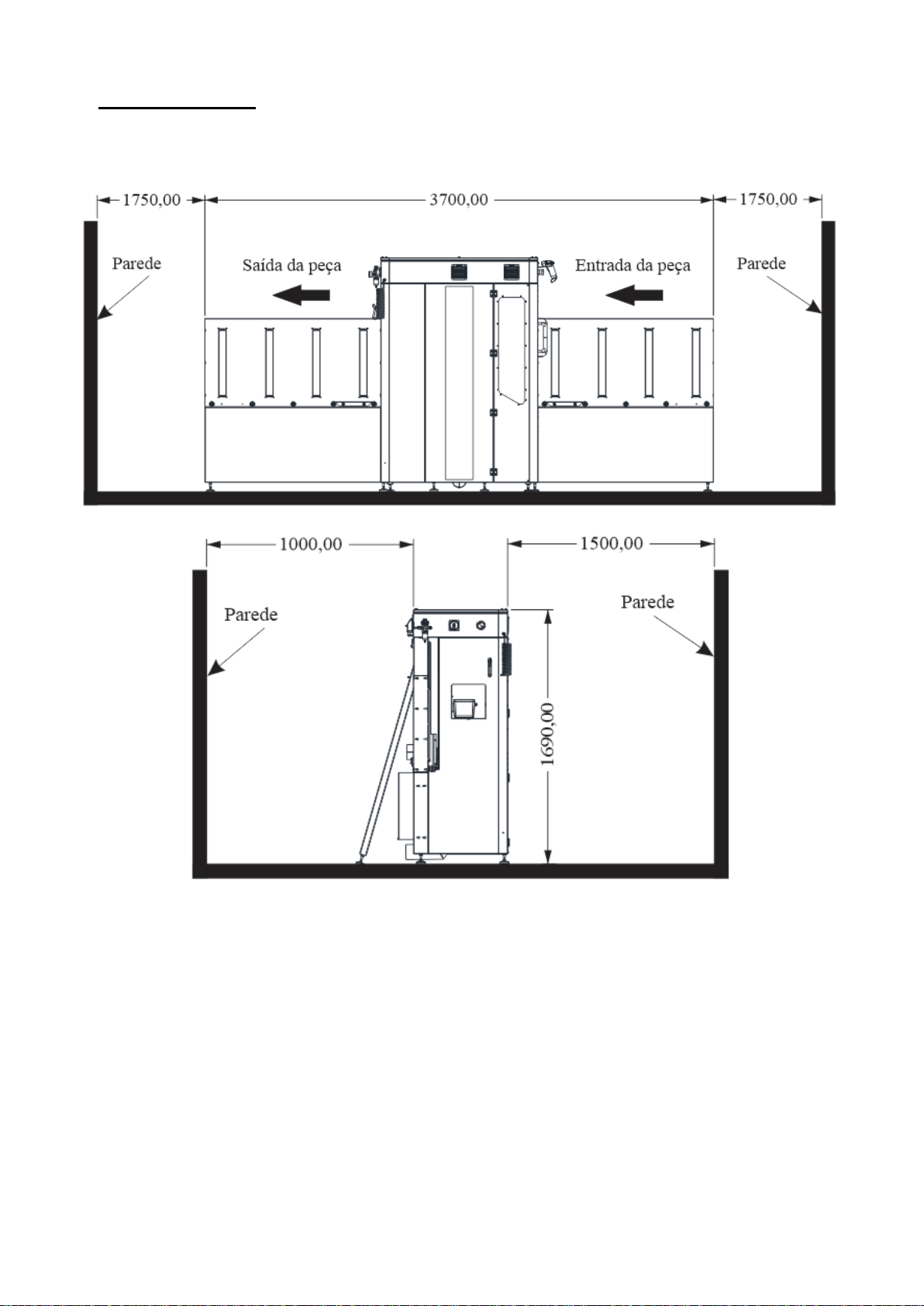

2.2 –Working Area

It is recommended that the working area have at least the dimensions indicated in the image below.

INMES Industrial LTDA. –IF-8500 Drilling Machine

14

2.3 –Getting Acquainted with the IF-8500 Drilling Machine

01 –Outfeed Table;

07 –Air Filter;

02 –Oil Container;

08 –Control Panel;

03 –Air Output for cleaning;

09 –Barcode Reader;

04 –Air Pressure Regulator;

10 –Outfeed Table;

05 –General Switch;

11 –Door;

06 –Emergency Button;

INMES Industrial LTDA. –IF-8500 Drilling Machine

15

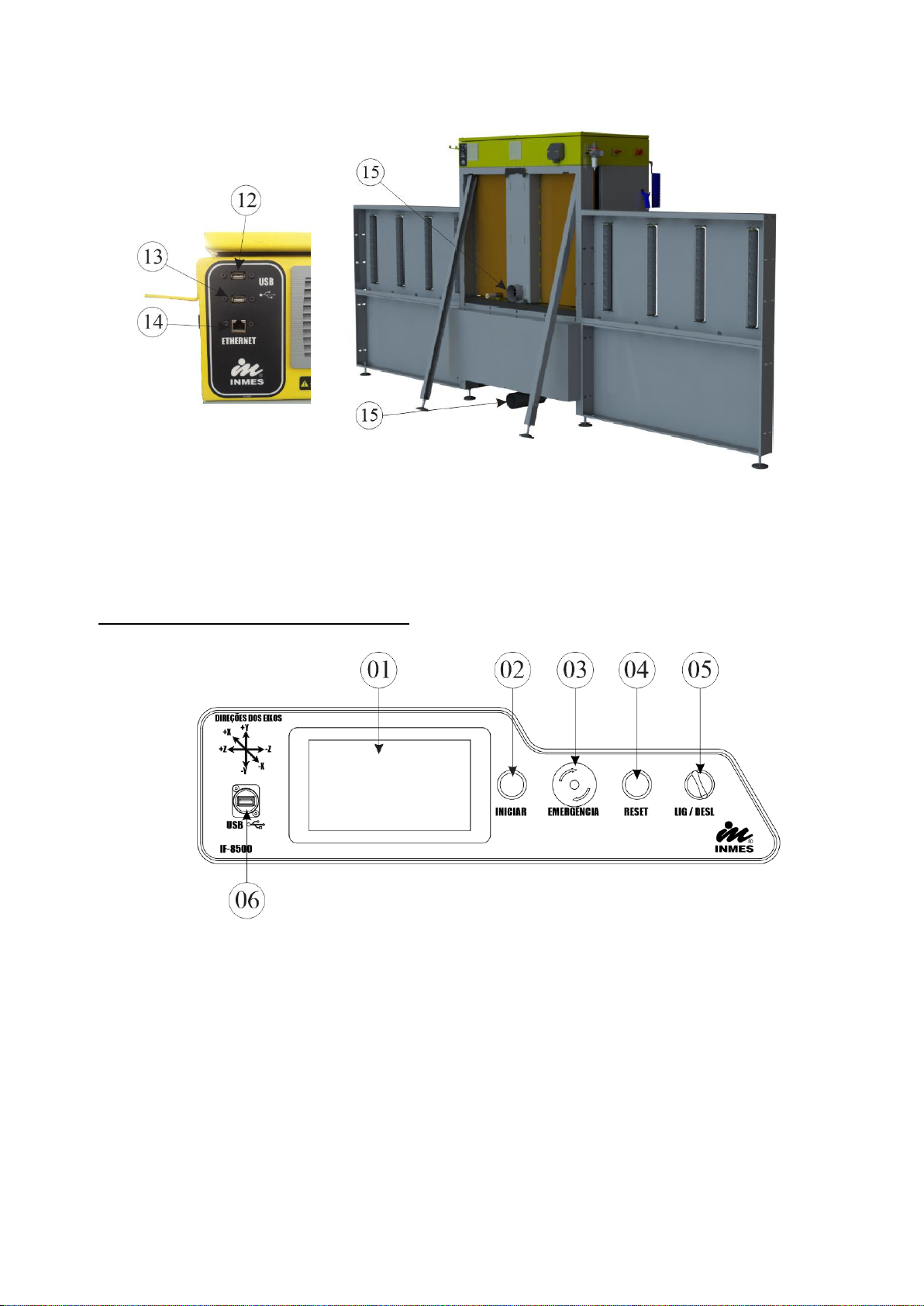

12 –Wi-Fi Antenna USB Port;

13 –Barcode Reader USB Port;

14 –Network Ethernet Port;

15 –Ø4” Dust Collection;

2.4 –Learning about the Control Panel

01 –Touch Screen;

04 –Reset Button;

02 –Start Button;

05 –On/Off Button;

03 –Emergency Button;

06 –USB Port;

INMES Industrial LTDA. –IF-8500 Drilling Machine

16

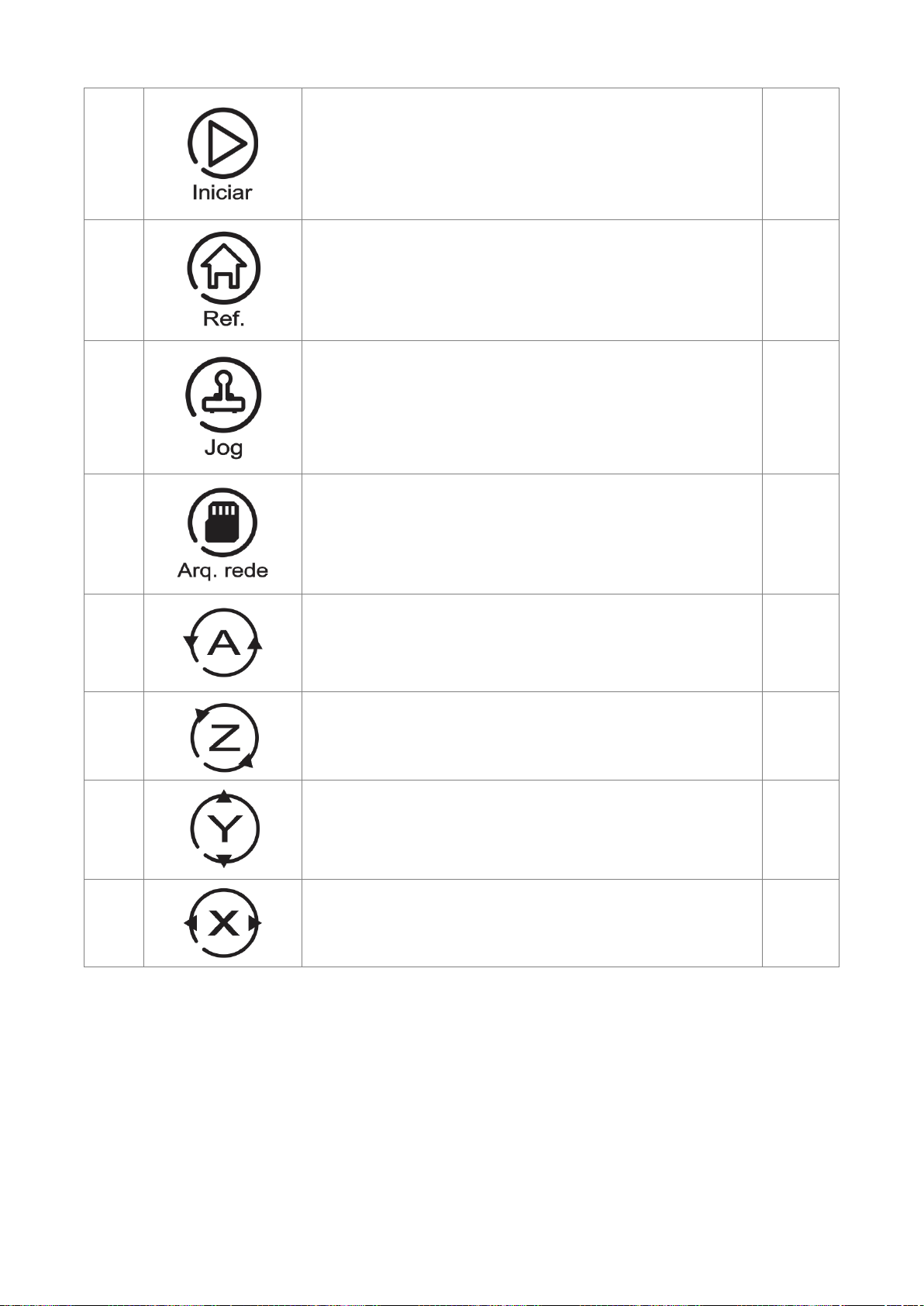

2.5 –Learning about the Touch Screen Interface

Item

Icon

Meaning

Page

01

Machine Limits

58

02

Sistaxis Error

58

03

Execution Error

58

04

Head Lock

58

05

Encoder

58

06

Air Pressure

58

07

Emergency

25

INMES Industrial LTDA. –IF-8500 Drilling Machine

17

08

Inverter

58

09

Cycle

42

10

Shows that the clamp is activated.

-

11

Shows that the tool is activated.

-

12

Shows that the head lock is activated.

-

13

Shows that the door is open.

-

14

Work Plan Name.

-

15

Exit

30

16

Help

-

17

Maintenance

47

18

Work Cycles

42

19

Alarms

28

20

Stop Working

-

INMES Industrial LTDA. –IF-8500 Drilling Machine

18

21

Start Working

-

22

Reference the machine

25

23

Jog –Movement of the machine shafts.

39

24

Search for programs (through the network or USB)

31

25

Shows the position of axis A

-

26

Shows the position of axis Z

-

27

Shows the position of axis Y

-

28

Shows the position of axis X

-

INMES Industrial LTDA. –IF-8500 Drilling Machine

19

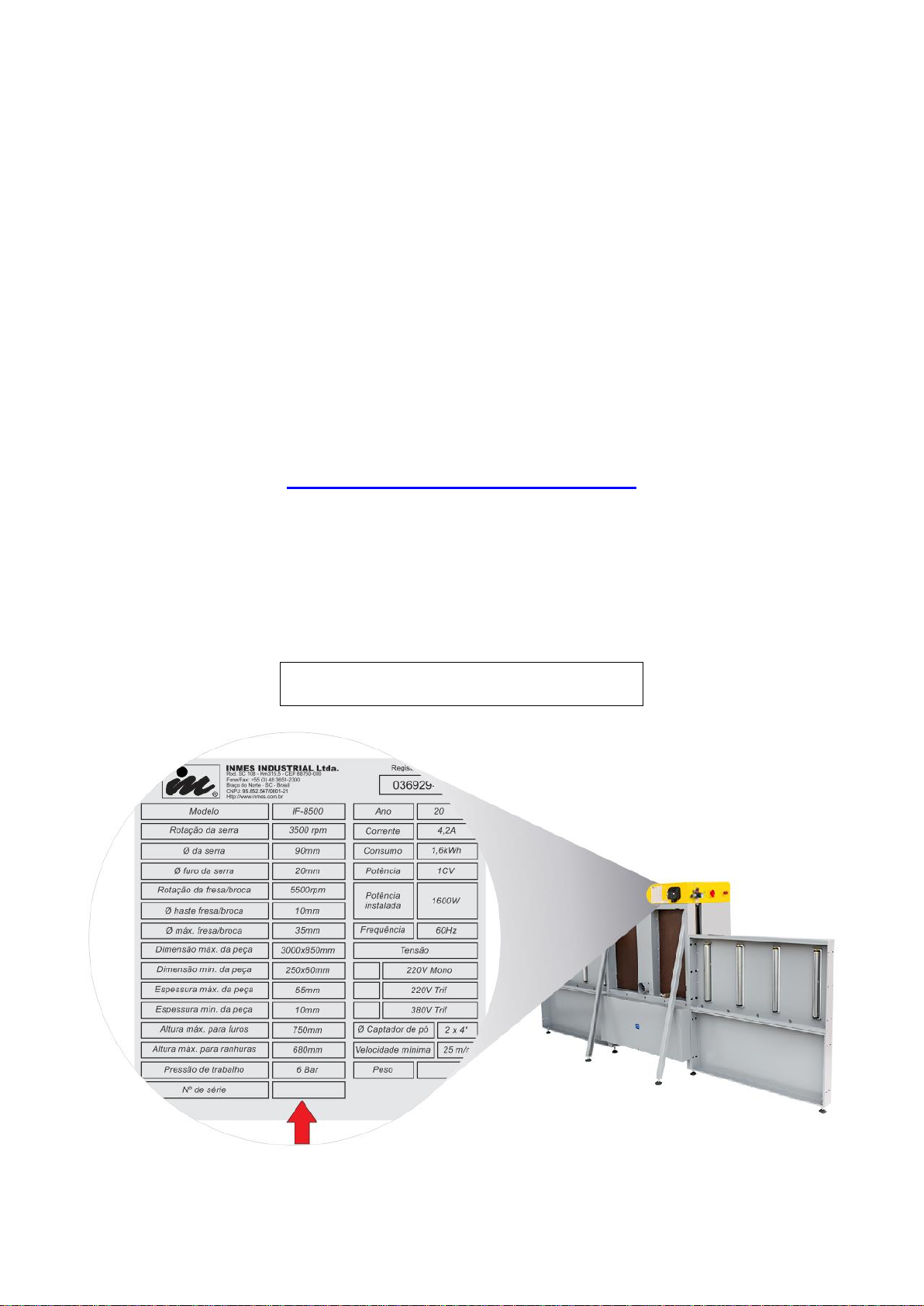

3 –TECHNICAL SPECIFICATIONS

INMES Industrial LTDA. –IF-8500 Drilling Machine

20

4 –INSTALLATION

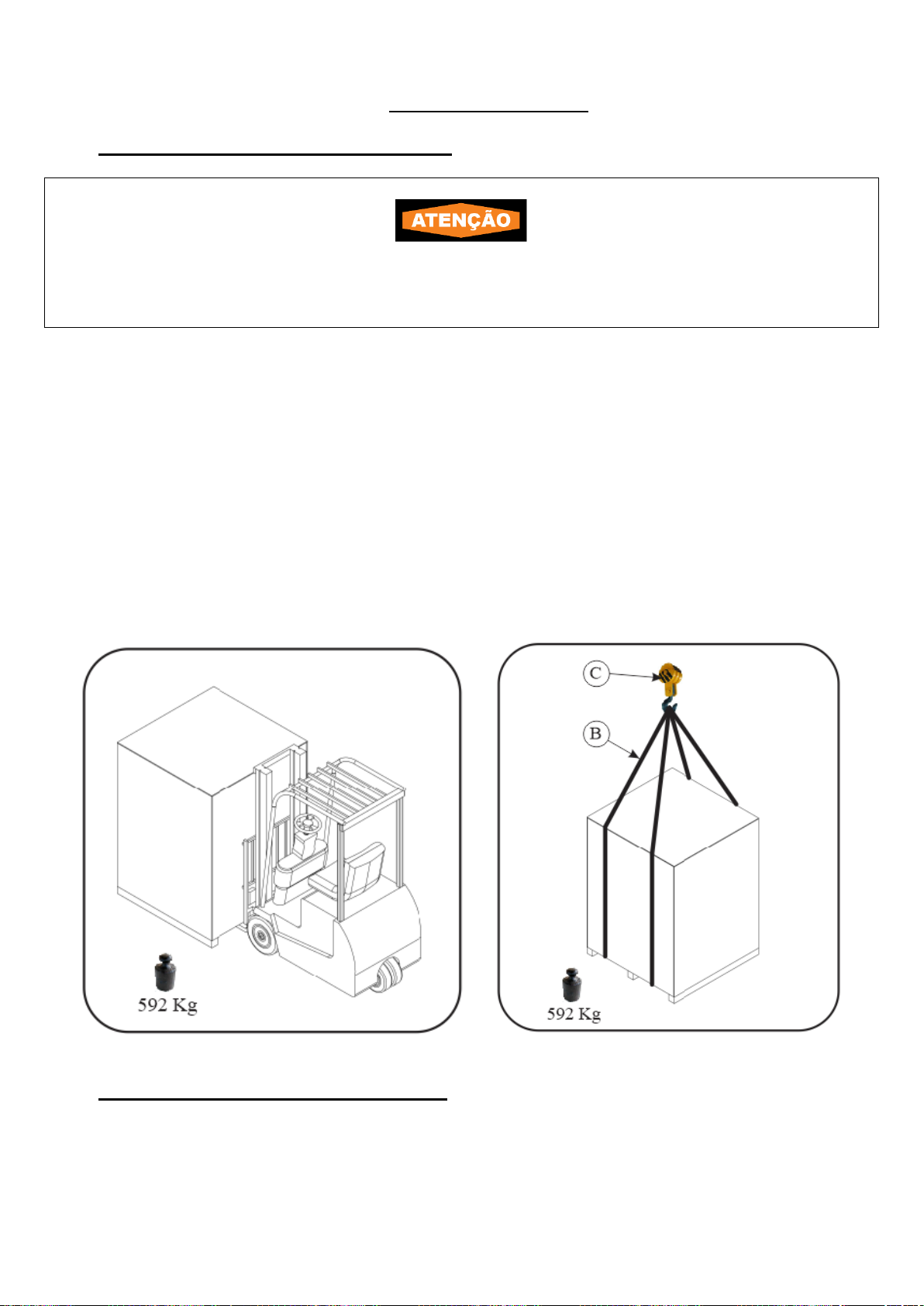

4.1 –Loading and Unloading the Equipment

This equipment should only be transported by persons specially trained to perform this type of

operation.

During loading and unloading of this equipment, avoid mechanical shocks to prevent damage to persons,

objects and the machine itself. Make sure that there are no people around the equipment used to move the machine

while the machine is being moved.

This machine should be lifted by a crane or forklift. Check that the carrying equipment capacity is ade-

quate for the machine weight indicated in Fig.06 and Fig.07.

If transported by forklift proceed as shown in Fig.06.

If a crane is available, proceed as follows:

✓Provide two belts, B Fig.07, of compatible length and capacity.

✓Raise the belts and position them as shown in Fig.07.

✓Adjust the belts at the tip of crane C with the force required to lift the machine.

✓Slowly move the crane so that the belts adjust until the machine is stabilized.

✓Carefully lift the crane without swinging the equipment, then move the machine to its proper place.

Fig.06

Fig.07

4.2 - Characteristics of the Installation Area

The machine should be positioned where it will be installed.

The floor where the machine will be installed should be flat and solid.

Table of contents