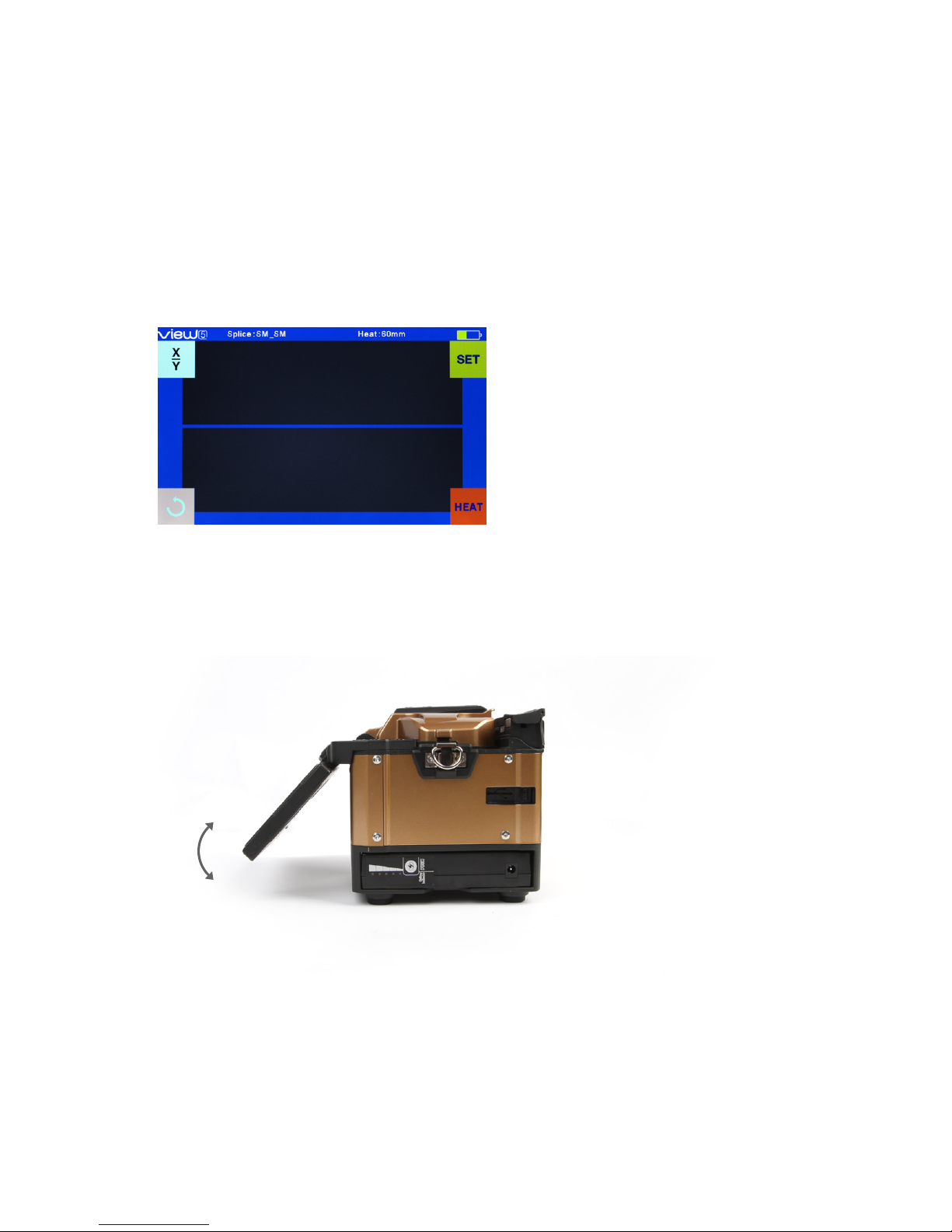

INNO VIEW 5 User manual

Table of contents

Other INNO Welding System manuals

Popular Welding System manuals by other brands

Kühtreiber

Kühtreiber MAKin 320 P HF manual

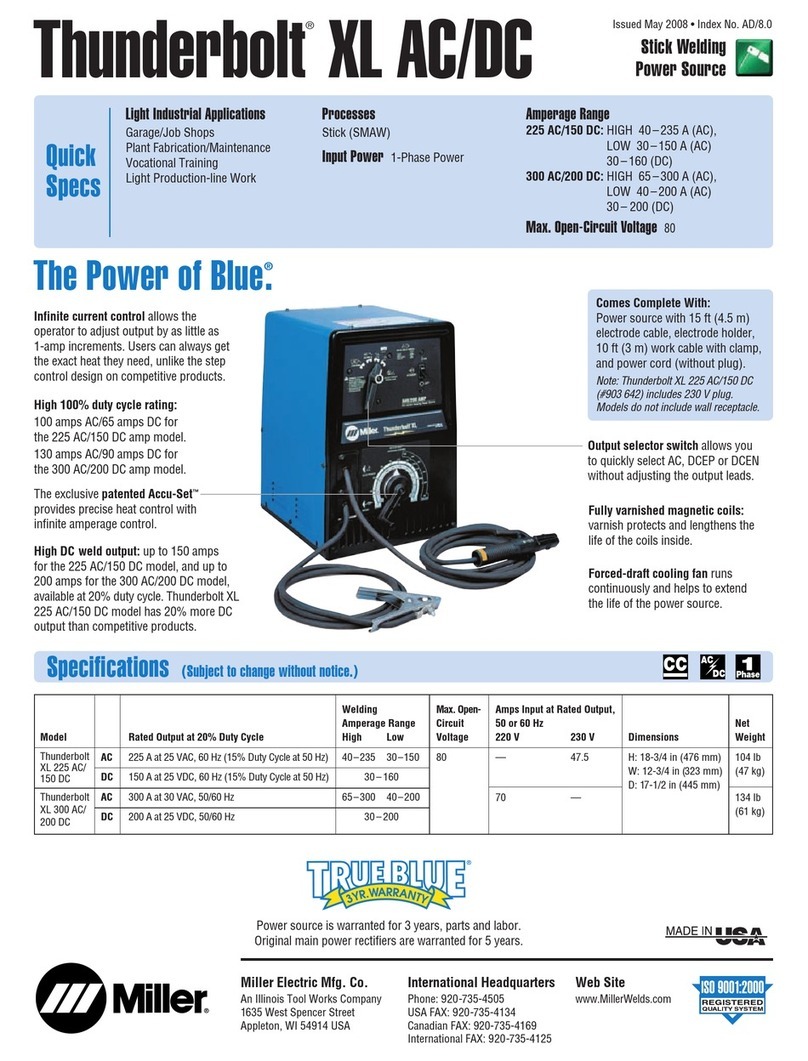

Miller Electric

Miller Electric Thunderbolt XL AC/DC Specifications

Lincoln Electric

Lincoln Electric IDEALARC DC 1000 SVM123-A Service manual

Cebora

Cebora MIG Weld 403 S instruction manual

Surtek

Surtek SOLI5140-BV User manual and warranty

Lincoln Electric

Lincoln Electric OUTBACK 145 Operator's manual

ESAB

ESAB ESABMig C420 Service manual

Elektra Beckum

Elektra Beckum MIG/MAG 170 parts manual

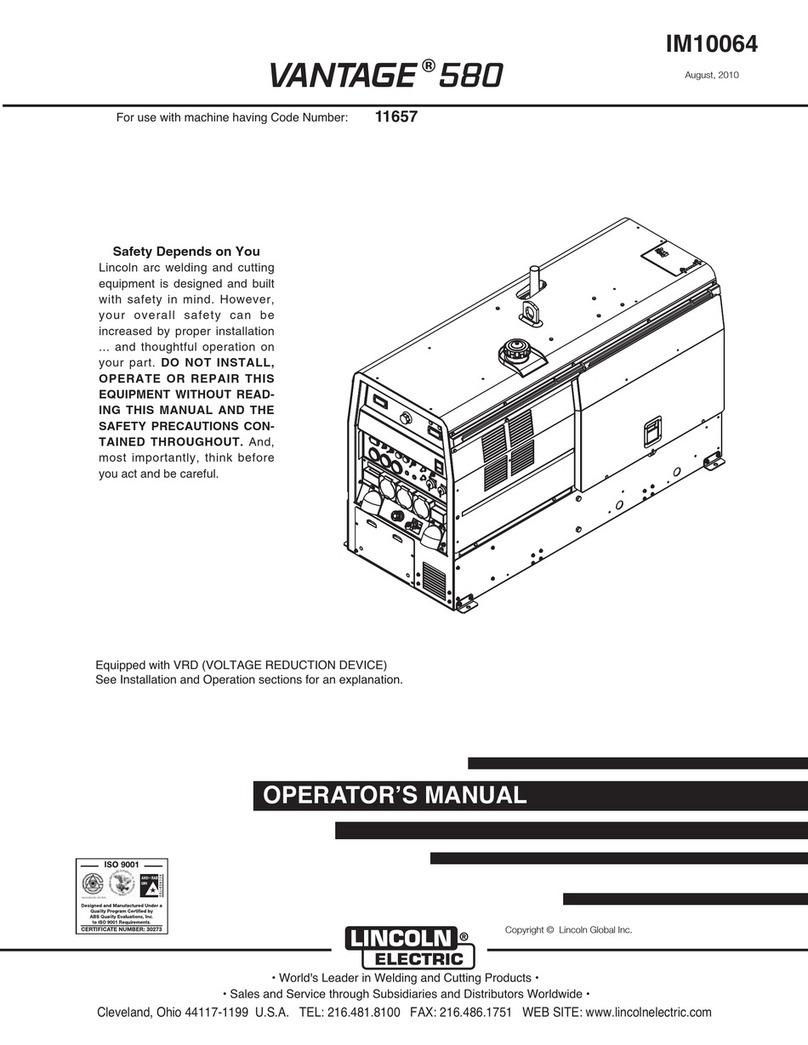

Lincoln Electric

Lincoln Electric VANTAGE IM10064 user manual

Miller

Miller Big Blue Duo Air Pak 800X owner's manual

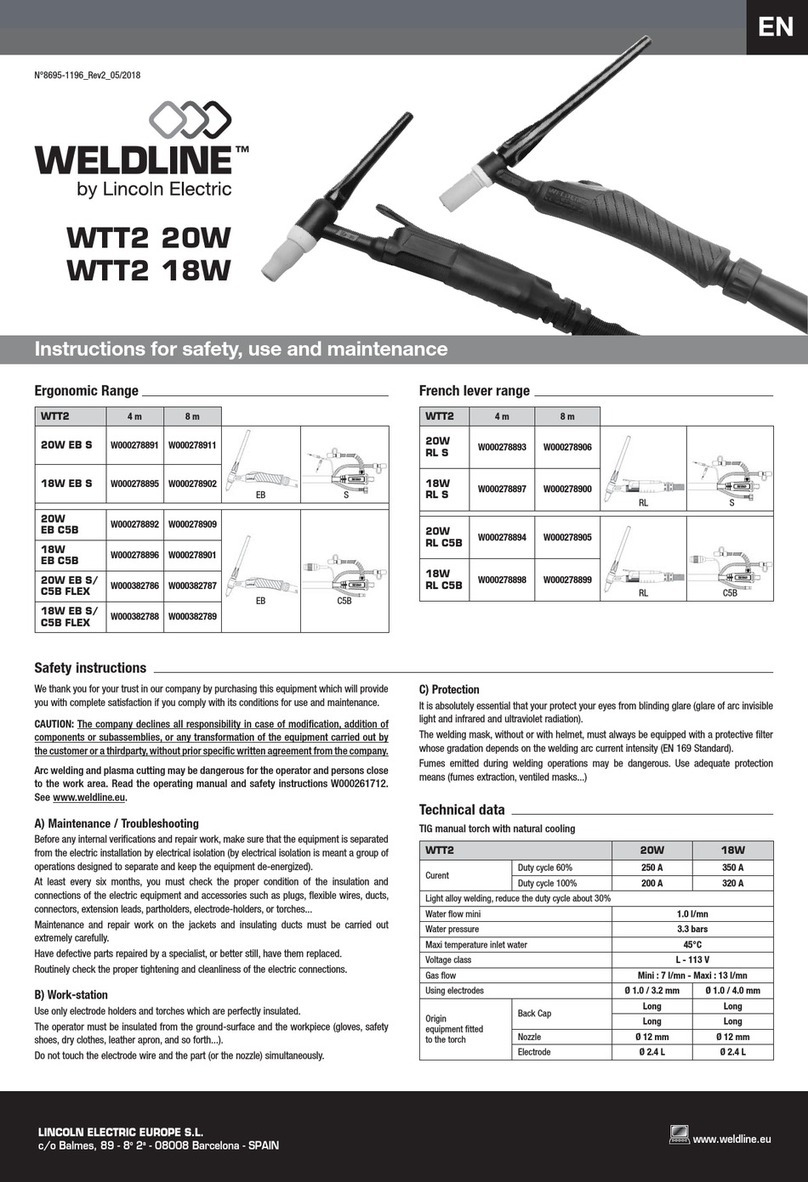

Lincoln Electric

Lincoln Electric WELDLINE WTT2 20W Instructions for safety, use and maintenance

HURNER

HURNER HST 300 Monofuse 2.0 user manual

Oerlikon

Oerlikon CITOCUT 10i Safety instruction for use and maintenance

EINHELL

EINHELL 15.749.75 Original operating instructions

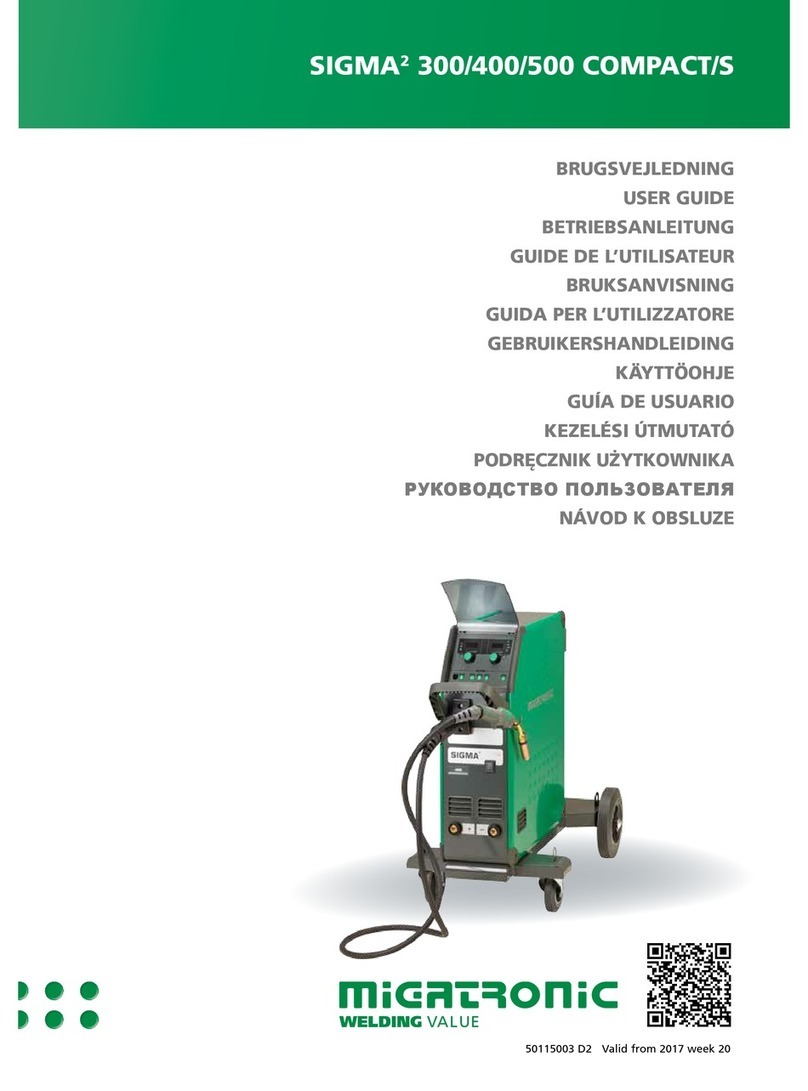

Migatronic

Migatronic SIGMA2 300 COMPACT/S user guide

Weldability Sif

Weldability Sif MIG200E instruction manual

jobmate

jobmate 199-8594-6 Use and care guide

Rothenberger

Rothenberger ROWELD P 125 Instructions for use