Innotech SYST-20-475-695 Series User manual

SYST-20-475-695

Corrugated sheeting

Instructions for installation and use

© INNOTECH Arbeitsschutz GmbH. Irrtümer, Druckfehler, technische Änderungen vorbehalten!

© INNOTECH Arbeitsschutz GmbH. Errors and misprints accepted. We reserve the right to make technical changes.

DE – ACHTUNG: Die Verwendung des Innotech-Produktes ist erst zulässig nach-

dem die Gebrauchsanleitung in der jeweiligen Landessprache gelesen wurde.

DE

EN – ATTENTION: Use of the Innotech product is only permitted after the in-

struction manual has been read in the respective national language.

EN

IT – ATTENZIONE: L’utilizzo del prodotto Innotech è permesso solo previa lettura

del manuale di istruzioni nella lingua del paese corrispondente.

IT

FR – ATTENTION : L’utilisation du produit Innotech n’est autorisée qu’après

la lecture du mode d’emploi correspondant dans la langue du pays.

FR

NL – ATTENTIE: Het gebruik van dit Innotech product is pas toegestaan, nadat

degebruikshandleidingindetaalvanhetbetreendelandgelezenwerd.

NL

SV – O B S : Denna Innotech-produkt får inte användas, förrän bruksanvisningen

på respektive lands språk har lästs igenom.

SV

DK – BEMÆRK: Produktet fra Innotech må først anvendes efter at brugsanvis-

ningen på det pågældende lands sprog er læst igennem.

DK

ES – ATENCIÓN: El uso del producto Innotech sólo está permitido después de

que se hayan leído las instrucciones de uso en el idioma del respectivo país.

ES

PT – ATENÇÃO: O uso do produto Innotech apenas é permitido depois de ter lido

as instruções de uso na respectiva língua nacional.

PT

PL – UWAGA: korzystanie z produktu Innotech jest jedynie dozwolone po

przeczytaniupodręcznikawjęzykunarodowym.

PL

RO – ATENŢIE:UtilizareaprodusuluiInnotechesteautorizatăabiadupăceau

fostcititeinstrucţiunileoriginaledeutilizareînlimbaţăriirespective.

RO

SL – POZOR: Uporaba izdelka Innotech je dovoljena šele po tem, ko navodila

preberete v svojem jeziku.

SL

CZ – POZOR:PrácesvýrobkemInnotechjepovolenaažpoprostudovánínávodu

kpoužitívpříslušnémjazycedanéhostátu.

CZ

SK – POZOR:PoužívanievýrobkuInnotechjepovolenéažpotom,keďstesi

prečítalinávodnaobsluhuvjazykupríslušnejkrajiny.

SK

HU – FIGYELEM: Az Innotech termékek használata csak az után engedélyezett,

miután saját nyelvén elolvasta a használati utasítást.

HU

ZH – 注意:只有在阅读了当地语言的使用说明后,才能使用 INNOTECH 公司的产品。

ZH

2

EN

SYST-20-475-695 / Version 170512 / www.innotech.at

Prior to use, the following safety instructions and the current state of the art

must be taken into consideration.

-“SYST” should only be installed by specialised/competent experts familiar with the roof

safety system and in compliance with the current state of the art.

-You must be familiar with these instructions, as well as with the local safety regulations

tosetupandusethesystem.Youmustalsobephysicallyandmentallytandtrained

in the use of PPE (Personal Protective Equipment).

-Medicalconditions(cardiovascularproblems,intakeofmedicines,alcohol)canaect

the safety of the user when working in high places.

-Adhere to the respective accident prevention regulations (e.g. working on roofs) when

installing/using the anchorage device “SYST”.

-Aplanmustbeavailablethatspeciesrescueproceduresforallpossibleemergencies.

-Before starting the work, you must ensure that no objects can fall to the ground from

the work site. The area below the work site (sidewalk, etc.) must be kept clear.

-Thettersmustensurethatthesubstrateissuitableforxingtheanchoragedevice.

If in doubt, consult a structural engineer.

-The anchorage device on the roof is designed for stress in all directions parallel to the

installation surface or at right angles to the anchor.

-If uncertainties arise during installation it is imperative that you contact the manufacturer.

-Document the professional fastening of the fall protection system to the building with

logsandphotosofeachttingsituation.

-Ensure that stainless steel does not come into any contact with swarf or steel tools,

as this may lead to corrosion.

-All stainless steel bolts must be greased with a suitable lubricant before installation.

(Included: Weicon AntiSeize ASW 10000 or equivalent lubricant)

-You should plan, install and use the anchorage point in such a way that no one can

fall over the edge if the personal protective equipment is used properly.

(See planning documents at www.innotech.at)

-When accessing the roof safety system, you must document the positions of the

anchorage devices by means of diagrams (e.g. top view of the roof).

-The minimum free space required between the roof edge and the ground is calculated as

follows:Manufacturer’sspecicationofthepersonalprotectiveequipmentusedincluding

cabledeectionaccordingtotable+bodyheight+1msafetymargin.

-Fastening on the “SYST” always occurs through the anchorage eye with a carabiner

and must be used with personal protective equipment in accordance with EN 361

(safety harness) and EN 363 (fall arrest system).

1SAFETY INSTRUCTIONS

3

EN

> 1.50 m

SYST-20-475-695 / Version 170512 / www.innotech.at

-If structural alteration work is performed close to the fall protection system following the

nalinspectionofthesafetysystem,youneedtoensurethattheworkwillnotaect

the safety of the installed fall protection system! If in doubt, consult a structural

engineer or contact the manufacturer.

-For horizontal use, only those lanyards may be used that are suited for this purpose

and have been tested for the respective edges (sharp edges, corrugated sheeting,

steel girders, concrete, etc.).

-Thereisahazardwhencombiningindividualelementsofthespeciedunits,sincethe

safe function of one of the elements can be impaired through the combination.

(Followthespecicinstructionsprovidedwitheachelement!)

-Before use, you must visually check the entire safety system (fall protection system and

anchor points (=guide bushes)) for obvious defects (e.g. loose screws, deformations,

abrasion, corrosion, defective roof sealing, etc.). If there are any doubts concerning the safe

function of the safety system, it must be inspected by an expert (written documentation).

-At least once a year, an expert must check the complete fall protection system

including the personal protective equipment used. The inspection by an expert

must be documented in the provided test log.

-After a fall and the resulting strain, you must stop using the fall protection system and

have it checked by an expert (component parts, fastening to the substrate, etc.).

-“SYST” was developed for personal safety and may not be used for other purposes.

Neverattachundenedloadstothesafetysystem.

-Do not use fall protection systems if wind speeds exceed normal parameters.

-Following strong storms, inspect the tin roof (substrate) before continuing to use

the safety system.

-Do not make any changes to the approved anchorage device.

-If used on sloping roofs, roof avalanches (ice, snow) must be avoided by means of

suitable devices to intercept snow.

-If you provide the fall protection system to external contractors, the familiarity with

theinstructionsforinstallationandusemustbeconrmedinwriting.

-If the equipment is sold in other countries, the instructions for installation and use

must be provided in the respective national language!

-For reasons of statics, you must maintain a margin of at least 1.50 m to the end of

the roof deck.

A product that no longer appears to be safe must not be used further,

and must be replaced immediately!

> 1.50 m

1SAFETY INSTRUCTIONS

4

EN

SYST-20-475-695 / Version 170512 / www.innotech.at

2.1. TO BE CHECKED BEFORE EACH USE:

-Before use, the entire fall protection system must be examined for obvious defects.

(E.g. loose threaded/riveted connections; deformation, wear, corrosion;

extreme contamination or other damage, etc.)

- No indications of wear

- No damage

- In addition, use the acceptance log and test log to verify that the entire fall

protection system and protective equipment are suitable for the application.

2.2 ANNUAL INSPECTION:

The “SYST” fall protection system must be subjected at least annually to inspec-

tion by an expert who is familiar with the fall protection system because the user’s

safetydependsontheeectivenessanddurabilityoftheequipment.Depending

on the intensity of use and the environment (e.g. corrosive atmosphere, etc.),

it may be necessary to shorten the inspection intervals. The inspection must be

documented in the test log included with the “SYST” instructions for installation

and use by the expert, and must be stored together with these instructions.

The inspection intervals are listed on the rating plate or on the test log.

2.3 ATTENTION! STOP USING THE EQUIPMENT IF:

- Damage or wear to its components is obvious

- Stress has occurred due to a fall

- Damage is determined through regular inspections

- Theproductidenticationisnolongerlegible

If there are any doubts concerning the reliable operation of the safety system,

it must no longer be used until it has been checked by an expert (written

documentation). If necessary, the product must be replaced immediately.

2INSPECTION

!

5

EN

SYST-20-475-695 / Version 170512 / www.innotech.at

Under normal use conditions there is a two year warranty on all components against

manufacturing defects. However, if the fall protection system is used in particularly

corrosive atmospheres, this period may be shortened.

If there is strain (a fall, weight of snow, etc,) the warranty claim is void for those com-

ponents that have been designed to absorb energy, or that may possibly be deformed

and therefore must be replaced.

Attention: for system installation and components planned and installed under

the responsibility of specialised installation companies, INNOTECH assumes

neither responsibility nor warranty in the case of improper installation.

Approved as an anchorage pointonaatorinclinedrooffor end and corner points

as well as intermediate cable brackets (not included) as part of the INNOTECH

horizontal lifeline system in accordance with EN 795:2012 TYP C.

Suitable for the following fall protection systems in accordance with EN 363:2008

• Restraint systems

• Workplace positioning systems

• Fall arrest systems

• Rescue systems

Safeapplicationrequiresthatyouobservethecorrespondingspecicationsprovidedby

the PPE manufacturers.

Approved as an anchorage pointonaatorinclinedrooffor“INNOTECH ABP-10-30”.

• Rope access systems (EN 363:2008)

“SYST”hasbeentestedandcertiedasanendandcornerpointaswellasanintermediate

cable bracket for installation on roofs in accordance with EN 795:2012 TYPE C.

The inspection was executed both statically and dynamically on the original substrate.

THE NOTIFIED AUTHORITY PARTICIPATING IN THE TYPE TEST:

DEKRA EXAM GmbH, Dinnendahlstr. 9, D - 44809 Bochum

3APPLICATION

4WARRANTY

5APPROVAL

6

EN

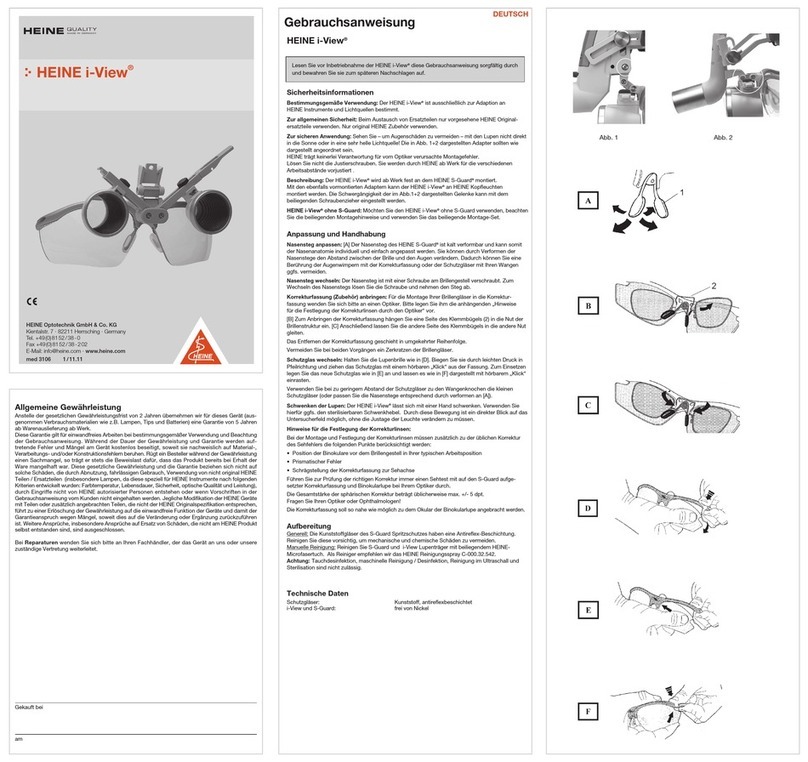

A

B

C

D

E

AIO-SYST-20-475-695

special designed for

02-10-40-20-475-695-Aufkleber-B

Trapezblech

JJJJ-..-...

EN 795:2012

475 - 695

AIO-SYST-20-475-695-SZH

special designed for

02-10-20-20-475-695-SZH-Aufkleber-B

Trapezblech

JJJJ-..-...

EN 795:2012

475 - 695

A

B

C

D

E

SYST-20-475-695 / Version 170512 / www.innotech.at

The basic prerequisite is a corrugated sheeting roof laid in accordance with applicable

standards/rules(sheetmetalthickness≥0.5mmandmadeofaluminium/steel),

a statically bearing substructure, and the use of original fasteners that are suitable

fortheroofprole.Whenusingcoatedsheetmetal,ensurethatthecoatingisnot

damaged in the installation process.

A) Name or logo of the manufacturer/reseller: INNOTECH

B) Type designation: AIO SYST-20-475-695

AIO SYST-20-475-695-SZH

C) Sign stating that the instructions for

use must be complied with:

D) Year of manufacture and manufacturer’s

serial number: JJJJ-..-...

E) Number of the applicable standard: EN 795:2012

6SUBSTRATE FOR ATTACHMENT

7SIGNS & MARKINGS

7

EN

!

1x

2x

4x

1x

1x

8x

8x

8x

25x

A

B

C

D

E

F

SYST-20-475-695 / Version 170512 / www.innotech.at

A. Clamping strips: stainless steel, quality 1.4301

B. Base plate: aluminium, quality 6060

C. Fastening bolts/nuts: stainless steel, quality 1.4301

D. Foam rubber: cellular rubber

E. Rivets: “BULB TITE” with sealing washer (6.3 x 20.2 mm) aluminium/ aluminium

F. Fastening accessories: for AIO components; stainless steel, quality 1.4301

Make sure to use the included “BULB TITE” rivets for installation!

8(AIO SYST)

COMPONENTS

8

EN

!

1x

2x

4x

1x

1x

2x

1x

8

x

8x

8x

25x

A

B

C

D

F

E

G

SYST-20-475-695 / Version 170512 / www.innotech.at

A. Clamping strips: stainless steel, quality 1.4301

B. Base plate: aluminium, quality 6060

C. Fastening bolts/nuts: stainless steel, quality 1.4301

D. Foam rubber: cellular rubber

E. Hex bolt: without shaft, M16 x 160 mm, stainless steel, quality 1.4301

F. Rivets: “BULB TITE” with sealing washer (6.3 x 20.2 mm) aluminium/aluminium

G. Fastening accessories: for the intermediate cable bracket; stainless steel,

quality 1.4301

Make sure to use the included “BULB TITE” rivets for installation!

9(AIO SYST-SZH)

COMPONENTS

9

EN

SYST-20-475-695 / Version 170512 / www.innotech.at

10 (AIO SYST)

SAMPLE APPLICATIONS

10

EN

450 - 670

43

1

5

0

680

195

540

12

ü

ü

SYST-20-475-695 / Version 170512 / www.innotech.at

11 (AIO SYST-SZH)

SAMPLE APPLICATIONS

12 DIMENSIONS

11

EN

1x

2x

1x

13

24

Ø 6,5

1x

SYST-20-475-695 / Version 170512 / www.innotech.at

INSTALLATION TOOLS:

1. APPLYING THE SEALING STRIP:

BOND THE SUPPLIED SEALING STRIPS (4 PCS) ON EACH HOLE CHANNEL

FOUND ON THE UNDERSIDE OF THE CLAMPING PLATE THAT IS PROVIDED

FOR FASTENING.

13 INSTALLATION

13 INSTALLATION

12

EN

~ 2 mm

!

!

SYST-20-475-695 / Version 170512 / www.innotech.at

2. PRE-INSTALLING THE CLAMPING STRIPS:

13 INSTALLATION

13

EN

0,5 mm

> 2 mm

!

!

!

SYST-20-475-695 / Version 170512 / www.innotech.at

ONLY VALID FOR TRAINED, EXPERT,

SPECIALISED COMPANIES!

3. THE “AIO SYST” IS USED AS AN ANCHORAGE POINT FOR END AND

CORNER POINTS AS PART OF THE INNOTECH HORIZONTAL LIFELINE

SYSTEM IN ACCORDANCE WITH EN 795:2012 TYP C:

14 (AIO SYST)

INSTALLATION

14

EN

!

!

!

SYST-20-475-695 / Version 170512 / www.innotech.at

ONLY VALID FOR TRAINED, EXPERT,

SPECIALISED COMPANIES!

4. THE “AIO SYST-SZH” IS USED AS AN ANCHORAGE POINT FOR AN

INTERMEDIATE CABLE BRACKET (NOT INCLUDED) AS PART OF THE INNOTECH

HORIZONTAL LIFELINE SYSTEM IN ACCORDANCE WITH EN 795:2012 TYP C.

THE MAXIMUM SPACING OF THE INTERMEDIATE CABLE BRACKETS IS 12 M.

ATTENTION: DO NOT USE AS END POINT OR CORNER POINT!:

15 (AIO SYST-SZH)

INSTALLATION

15

EN

0,5 mm

> 2 mm

SYST-20-475-695 / Version 170512 / www.innotech.at

15 (AIO SYST-SZH)

INSTALLATION

16

EN

0,5>

>

1

2

>

1

2

4

7

5

-

6

9

5

> 25

0

,

5

>

SYST-20-475-695 / Version 170512 / www.innotech.at

5. POSITIONING ON THE ROOF:

6. INSTALLATION DISTANCES:

16 INSTALLATION ON THE ROOF

17

EN

!

4x

Ø 6,5

1

1

3

2

4

2

3

Ø 6,5

20x

3

12

12

20x

4

12

12

4x

2

1

4

SYST-20-475-695 / Version 170512 / www.innotech.at

7. FASTENING ON THE ROOF, WITH “BULB TITE” RIVETS

(CLAMPING AREA: 1–6.4 mm):

REMOVE ANY DRILLING CHIPS

FROM THE BORES!

16 INSTALLATION ON THE ROOF

18

EN

8 X 20 Nm

!

SYST-20-475-695 / Version 170512 / www.innotech.at

8. TIGHTEN THE BOLTS USING A TORQUE SPANNER (8 x 20 Nm):

9. FINISHED!:

17 INSTALLATION ON THE ROOF

19

EN

SYST-20-475-695 / Version 170512 / www.innotech.at

When installing/using the fall protection system, pay attention to the approved

load directions!

Work/application loads in the direction of the “Z-axis” are not permitted!

18 LOAD DIRECTIONS

19 NOTES

20

EN

SYST-20-475-695 / Version 170512 / www.innotech.at

20 ACCEPTANCE LOG

PROJECT:

PRODUCT:

SERIAL NO.:

CLIENT:

NAME/COMPANY /ADDRESS:

CONTRACTOR:

NAME/COMPANY /ADDRESS:

INSTALLATION:

NAME/COMPANY /ADDRESS:

Client accepts the performances of the contractor. The instructions for installation and

use, clamp log, photo documentation and test sheets have been transferred to the

client (building owner) and have been made available to the user. When accessing

the fall protection system, you must document the positions of the anchorage devices

by means of diagrams (e.g. top view of the roof).

The expert tter familiar with the safety system conrms that the installation

work has been executed properly, in accordance with the state of the art,

and in accordance with the manufacturer’s instructions for installation and

use. The safety specications for reliability are conrmed by the installation

company.

COMMENTS:

Other manuals for SYST-20-475-695 Series

1

This manual suits for next models

2

Table of contents

Other Innotech Rack & Stand manuals

Innotech

Innotech SPAR-11 Series User manual

Innotech

Innotech QUAD-13 User manual

Innotech

Innotech SOPV-NOVO-AIO User manual

Innotech

Innotech QUAD-13 User manual

Innotech

Innotech LOCK-11 User manual

Innotech

Innotech STA-16 User manual

Innotech

Innotech BEF-210-A2 User manual

Innotech

Innotech SAND-01 Instruction manual

Innotech

Innotech SAND-01 User manual

Innotech

Innotech SYST-01-410-610 User manual