Contents

1 Overview .................................................................................................................................. 1

2 Installation and Setting........................................................................................................... 2

2.1 Installation of MD380CAN2 ........................................................................................... 2

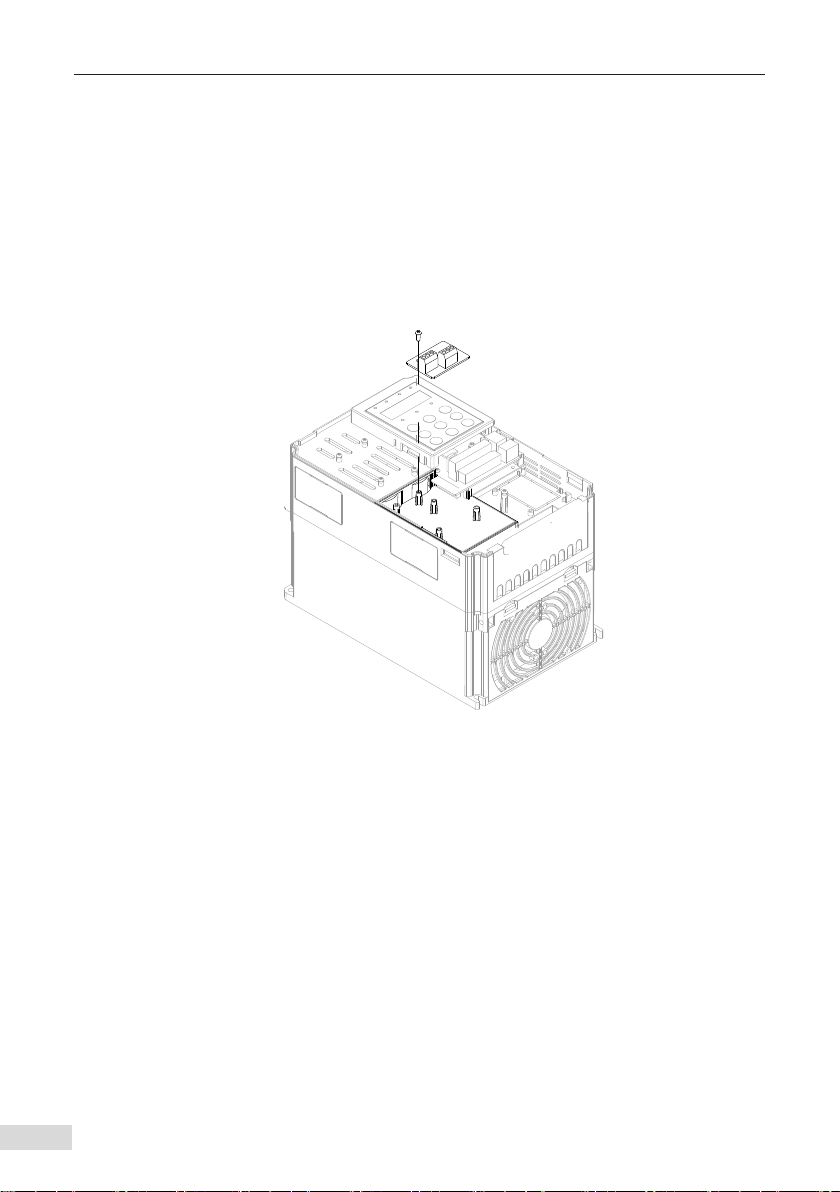

2.2 Hardware Layout ........................................................................................................... 2

2.3 Interface Description ..................................................................................................... 3

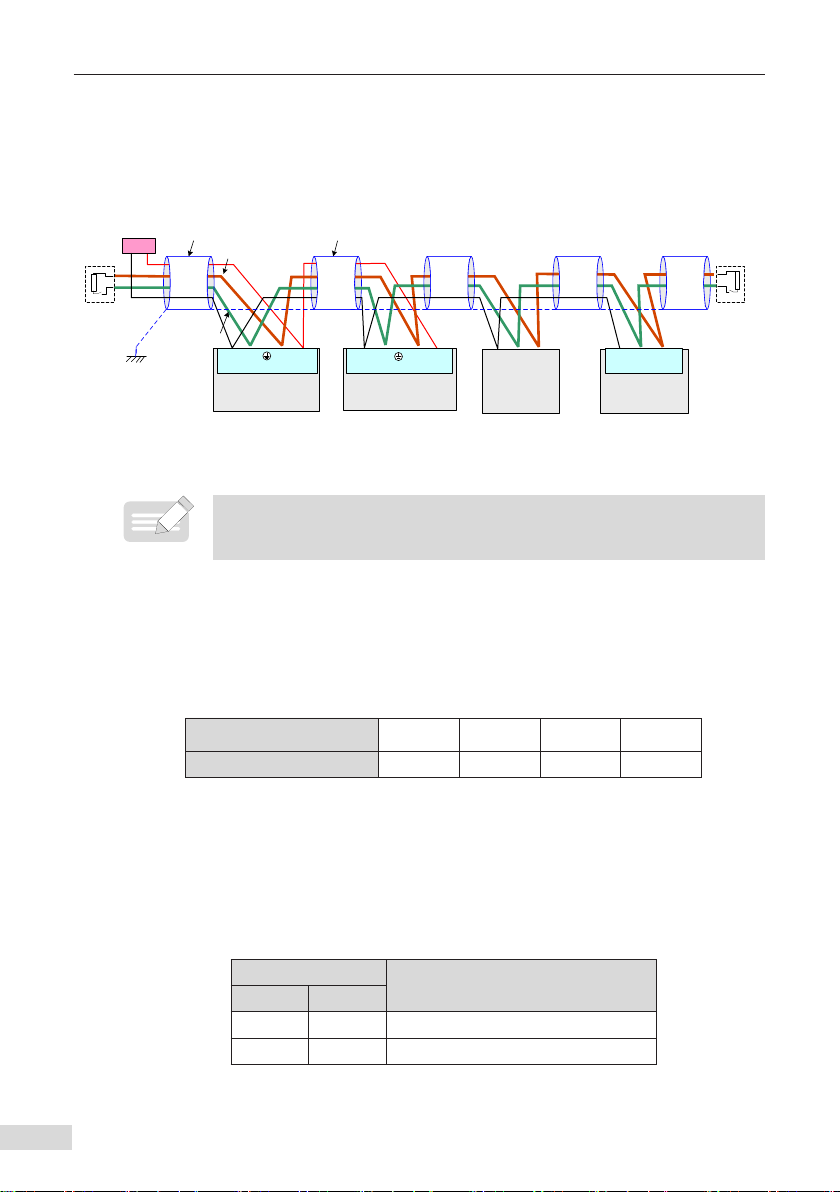

3 Protocol Description of the MD38CAN2................................................................................. 7

3.1 Software Feature ........................................................................................................... 7

3.2 COB-ID ............................................................................................................................ 7

3.3 Parameter Operation of AC Drive.................................................................................. 8

3.4 SDO Read-Write Operations........................................................................................ 10

3.5 PDO AC Drive Operation.............................................................................................. 13

4 Parameters Related to CANopen Communication ............................................................. 15

4.1 CANopen Card Enabling.............................................................................................. 15

4.2 Parameters Related to Communication Control....................................................... 15

4.3 Parameters Related to Communication Monitoring................................................. 16

4.4 Emergency Message and AC Drive Fault Description................................................ 19

5 Simple Diagnosis................................................................................................................... 21

5.1 Brief Introduction ........................................................................................................ 21

5.2 Diagnosis...................................................................................................................... 21

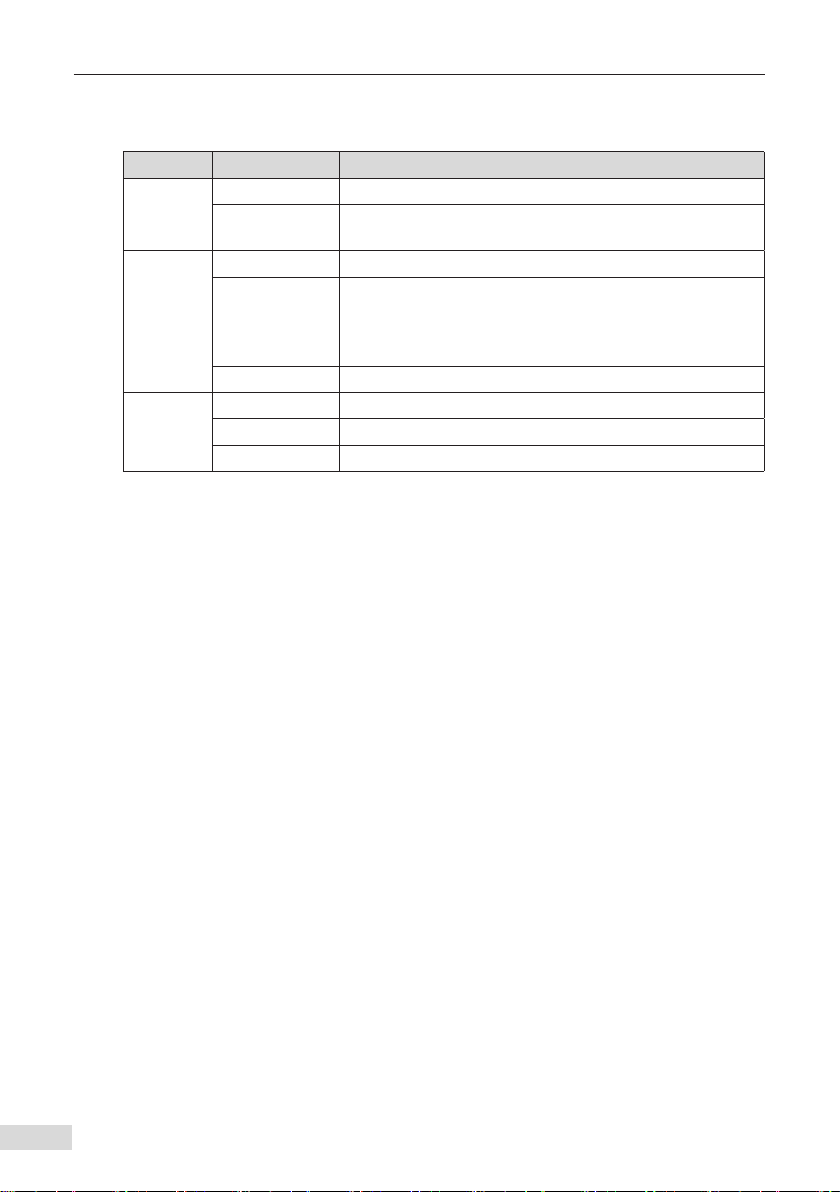

5.3 Troubleshooting .......................................................................................................... 21

6 Overview of the CANopen Protocol ..................................................................................... 22

6.1 Brief Introduction ........................................................................................................ 22

6.2 Object Dictionary......................................................................................................... 22

6.3 Common Communication Objects............................................................................. 23

7 Format Description of CANopen Message........................................................................... 24

7.1 NMT Module Control Message.................................................................................... 24

7.2 NodeGuarding Message .............................................................................................. 24

7.3 Heartbeat Message...................................................................................................... 25

Revision History ....................................................................................................................... 26

Warranty Agreement................................................................................................................ 27