Instrutech Hornet User manual

p/n 000710-116

InstruTech®, Inc.

Hot Cathode Ionization Vacuum Gauge

IGM401 Module

The Hornet™

User Manual

InstruTech, Inc.

1475 S. Fordham St.

Longmont, CO 80503

USA

Phone: +1-303-651-0551

Fax: +1-303-678-1754

www.instrutechinc.com

p/n 000710-116

This User Manual is applicable to the InstruTech® Hornet™ model IGM401 product

manufactured with firmware p/n 1769 versions 108 or higher. For previous versions of IGM401

manufactured prior to the introduction of firmware p/n 1769-108, please go to

http://www.instrutechinc.com/downloads-archived-user-manuals/ to find the version of user manual applicable

to prior versions of IGM401. See section 5.8.5, SERVICE MENU of this manual to determine the firmware

version of your IGM401.

Important User Information There are operational characteristic differences between solid state equipment and

electromechanical equipment. Because of these differences, and because there are a variety of uses for solid state equipment, all

persons that apply this equipment must take every precaution and satisfy themselves that the intended application of this equipment is

safe and used in an acceptable manner.

In no event will InstruTech, Inc. be responsible or liable for indirect or consequential damages that result from the use or application of

this equipment.

Any examples or diagrams included in this manual are provided solely for illustrative purposes. Because of the many variables and

requirements imposed on any particular installation, InstruTech, Inc. cannot assume responsibility or liability for any actual use based on

the examples and diagrams.

No patent liability is assumed by InstruTech, Inc. with respect to use of information circuits, equipment, or software described in this

manual.

Throughout this manual we use notes, notices and apply internationally recognized symbols and safety messages to make you aware of

safety considerations.

Identifies information about practices or circumstances that can cause electrical or physical

hazards which, if precautions are not taken, could result in death or serious injury, property damage, or economic loss.

Identifies information about practices or circumstances that can cause electrical or physical

hazards which, if precautions are not taken, could result in minor or moderate injury, property damage, or economic loss.

Identifies information that is critical for successful application and understanding of the product.

Labels may be located on or inside the device to alert people that dangerous

voltages may be present.

NOTICE

CAUTION

CccWARNING

WARNING

NOTICE

SHOCK HAZARD

CccWARNING

WARNING

Instruction Manual IGM401 Hornet

InstruTech, Inc. Page 1

Copyright © 2011 by InstruTech®, Inc.

All rights reserved. No part of this work may be reproduced or transmitted in any form or by any means, electronic or mechanical,

including photocopying and recording, or by any information storage or retrieval system, except as may be expressly permitted in

writing by InstruTech, Inc.

Printed in the United States of America

Granville-Phillips® and Micro-Ion® are registered trademarks of MKS Instruments, Andover, MA

Conflat® is a registered trademark of Varian, Inc. / Agilent Technologies, Lexington, MA

Teflon® is a registered trademark of E.I. du Pont de Nemours and Company, Wilmington, DE

Swagelok®, Cajon®, VCR® are registered trademarks of the Swagelok Company, Solon, OH.

Hyperterminal® is a registered trademark of Hilgraeve, Inc., Monroe, MI

Instruction Manual IGM401 Hornet

InstruTech, Inc. Page 2

Table of Contents

Introduction / General Information....................................................................................................................41

1.1 Description .................................................................................................................................................4

1.2 Specifications .............................................................................................................................................4

1.3 Dimensions.................................................................................................................................................5

1.4 Part Numbers .............................................................................................................................................5

1.5 Options & Accessories................................................................................................................................5

Important Safety Information.............................................................................................................................62

2.1 Safety Precautions - General......................................................................................................................6

2.2 Safety Precautions - Service and operation ...............................................................................................7

2.3 Electrical Conditions...................................................................................................................................8

2.3.1 Proper Equipment Grounding ............................................................................................................8

2.3.2 Electrical Interface and Control..........................................................................................................8

2.4 Overpressure and use with hazardous gases.............................................................................................9

2.5 Gases other than Nitrogen / air .................................................................................................................9

Installation ........................................................................................................................................................10

3

3.1 Mechanical Installation ............................................................................................................................10

3.2 Electrical Installation ................................................................................................................................11

3.2.1 Grounding.........................................................................................................................................11

3.2.2 Connectors .......................................................................................................................................11

3.2.2.1 Analog Connector pin-out............................................................................................................12

3.2.2.2 RS485 COM / Relay Connector pin-out........................................................................................12

Bakeout.............................................................................................................................................................144

Setup and Operation.........................................................................................................................................155

5.1 Applying power ........................................................................................................................................15

5.2 Emission Current ......................................................................................................................................15

5.3 Overpressure shut down..........................................................................................................................16

5.4 Degas........................................................................................................................................................16

5.5 Filament Material Selection / Venting the Chamber ...............................................................................17

5.6 User Interface Basics................................................................................................................................18

Instruction Manual IGM401 Hornet

InstruTech, Inc. Page 3

5.7 Factory-Set Default Parameters...............................................................................................................19

5.8 Programming............................................................................................................................................20

5.8.1 SETUP DISP .......................................................................................................................................21

5.8.2 SETUP UNIT ......................................................................................................................................22

5.8.3 SETUP IG...........................................................................................................................................25

5.8.4 SETUP COMMS .................................................................................................................................27

5.8.5 SERVICE MENU .................................................................................................................................27

5.9 Activating the sensor................................................................................................................................28

Using the gauge with different gases ...............................................................................................................296

Analog Output...................................................................................................................................................307

RS485 serial communications ...........................................................................................................................318

8.1 Device Specific Serial Communication Info..............................................................................................31

8.2 RS485 Command Protocol Summary .......................................................................................................32

Service...............................................................................................................................................................359

9.1 Calibration................................................................................................................................................35

9.2 Troubleshooting - Operation....................................................................................................................35

9.3 Troubleshooting - Error Messages ...........................................................................................................36

9.4 Troubleshooting - Filaments F1 or F2 open .............................................................................................37

9.5 R & D (Research) Diagnostic Display ........................................................................................................38

9.6 Maintenance ............................................................................................................................................40

9.7 Contamination..........................................................................................................................................41

9.8 Sensor Replacement.................................................................................................................................42

Factory Service and Support .............................................................................................................................4310

Warranty ...........................................................................................................................................................4311

Instruction Manual IGM401 Hornet

InstruTech, Inc. Page 4

Introduction / General Information1

1.1 Description

A hot cathode ionization gauge (IG) measures vacuum pressure by ionizing gas atoms and molecules inside the

vacuum region of the gauge transducer and measuring the quantity of ions produced. The measurement of the

resulting ion current is directly proportional to the density of gas inside the gauge transducer therefore

proportional to the pressure. As pressure inside the vacuum system drops, there are fewer ions created and

therefore ion current measured is lower translating to a lower pressure reading.

The InstruTech® IGM401 Hornet™ module provides the basic signal conditioning required to turn a hot cathode

ionization vacuum gauge into a complete measuring instrument. The module provides a log-linear analog

output, RS485 serial communications, and one setpoint relay. In addition, a built-in display provides a

convenient user interface for setup and operation of the vacuum gauge. The measurement range for the

IGM401 hot cathode ionization gauge is 1 x 10-9 to 5 x 10-2 Torr.

1.2 Specifications

measurement range

1 x 10-9 to 5 x 10-2 Torr / 1.3 x 10-9 to 6.7 x 10-2 mbar / 1.3 x 10-7 to 6.7 Pa

accuracy - N2 (typical)

1 x 10-8 to 5 x 10-2 Torr; ± 15% of reading

repeatability - (typical)

± 5% of reading

display

OLED graphical display, 3 digits plus 2 digits exponent, user-selectable Torr, mbar, or Pa

materials exposed to gases

dual filaments: yttria coated iridium or optional tungsten

Ion collector: tungsten Grid: tantalum Others: 316/304 SS, glass, nickel

sensitivity

factory pre-set. Also user adjustable between 2 to 99 using the display

x-ray limit

< 5 x 10-10 Torr, < 6.7 x 10-10 mbar, < 6.7 x 10-8 Pa

emission current

100 µA, 4 mA, or automatic switching between 100 µA and 4 mA

degas

3 W, electron bombardment

overpressure protection

gauge turns off at factory default setting of 5 x 10-2 Torr

internal gauge volume

1.0 in3 (16.4 cm3 )

temperature

operating; 0 to + 40 oC storage; -40 to + 70 oC

bakeout temperature

200 oC (sensor only - electronics removed)

humidity

0 to 95% Relative Humidity, non-condensing

weight

0.6 lb. (0.27 kg) with NW25 KF flange

housing (electronics)

aluminum extrusion

mounting orientation

any

altitude

operating; 8,200 ft. (2,500 m) max storage; 41,000 ft. (12,500 m) max

serial communications

RS485 - ASCII protocol; minimum command interval: 50 ms

analog output

log-linear 0 to 9 Vdc, 1 V/decade

setpoint relay

one single-pole, double-throw (SPDT), 1A at 30 Vdc resistive, or ac non-inductive

status outputs

degas & filament on/off status are determined by display messages,

via open collector transistor or RS485 communication

input signal

degas and filament on/off & emission current are set by continuity to ground

using digital inputs, RS485 or manually using front panel push buttons

filament selection

filament 1 or 2 selectable via front panel push buttons or RS485 commands

input power

20 to 28 Vdc, 30 W protected against power reversal and transient over-voltages

connectors

9-pin D-sub male for analog and 9-pin D-sub female for RS485

CE compliance

EMC Directive 2004/108/EC, EN61326-1, EN55011

Low Voltage Directive 2006/95/EC, EN61010-1

environmental

RoHS compliant

Instruction Manual IGM401 Hornet

InstruTech, Inc. Page 5

1.3 Dimensions

fitting

dimension A

NW16KF

1.45 in. (37mm)

NW25KF

1.45 in. (37mm)

NW40KF

1.45 in. (37mm)

1 1/3 in. Mini CF

1.85 in. (47 mm)

2 3/4 in. Conflat®

1.70 in. (43 mm)

3/4 in. Tube

2.16 in. (55 mm)

1/2 in. VCR

2.58 in. (65 mm)

1.4 Part Numbers

IGM401 Fittings / Flanges

With Yttria

Filaments

With Tungsten

Filaments

Replacement

Sensor - Yttria

Replacement

Sensor - Tungsten

NW16KF

IGM401YBD

IGM401TBD

IG4YB

IG4TB

NW25KF

IGM401YCD

IGM401TCD

IG4YC

IG4TC

NW40KF

IGM401YDD

IGM401TDD

IG4YD

IG4TD

1 1/3 in. Mini-CF/NW16CF Mini-Conflat®

IGM401YED

IGM401TED

IG4YE

IG4TE

2 3/4 in. CF / NW35CF Conflat®

IGM401YFD

IGM401TFD

IG4YF

IG4TF

3/4 in. Tube (3/4 in. O.D. O-ring compression)

IGM401YAD

IGM401TAD

IG4YA

IG4TA

1/2 in. Cajon® 8VCR® female

IGM401YHD

IGM401THD

IG4YH

IG4TH

1.5 Options & Accessories

PS501-A

Compatibility: Powers the IGM401 Hornet™

vacuum gauge module

Power Input: 100 - 240 Vac

Power Plug: North American 115 Vac

Output: 24 Vdc @ 2.5 A (60 W)

Connector: 9-pin D-sub female to mate with and power the

IGM401 module

Cable length: 6 ft. (2 m)

Note: 9-pin D-sub connector backshell can be opened to

enable connections to signals and relays

Instruction Manual IGM401 Hornet

InstruTech, Inc. Page 6

Important Safety Information2

InstruTech has designed and tested this product to provide safe and reliable service, provided it is installed and

operated within the strict safety guidelines provided in this manual.Please read and follow all warnings and

instructions.

To avoid serious injury or death, follow the safety information in this document. Failure to comply with these

safety procedures could result in serious bodily harm, including death, and or property damage.

Failure to comply with these warnings violates the safety standards of installation and intended use of this

instrument. InstruTech, Inc. disclaims all liability for the customer’s failure to comply with these instructions.

Although every attempt has been made to consider most possible installations, InstruTech cannot anticipate

every contingency that arises from various installations, operation, or maintenance of the module. If you have

any questions about the safe installation and use of this product, please contact InstruTech.

This device meets FCC part 15 requirements for an unintentional radiator, class A.

2.1 Safety Precautions - General

Hazardous voltages are present with this product during normal operation. The product should never be

operated with the covers removed unless equivalent protection of the operator from accidental contact with

hazardous internal voltages is provided.

WARNING! There are no operator serviceable parts or adjustments inside the product enclosure; refer

servicing to service trained personnel.

Do not modify this product or substitute any parts without authorization of qualified InstruTech service trained

personnel. Return the product to an InstruTech qualified service and repair center to ensure that all safety

features are maintained. Do not use this product if unauthorized modifications have been made.

WARNING! Source power must be removed from the product prior to performing any servicing.

After servicing this product, ensure that all safety checks are made by a qualified service person. When

replacement parts are required, ensure that the parts are specified by InstruTech, Inc. Substitutions of non-

qualified parts may result in fire, electric shock or other hazards. Use of unauthorized parts or modifications

made to this product will void the warranty.

To reduce the risk of fire or electric shock, do not expose this product to rain or moisture. These products are

not waterproof and careful attention must be paid to not spill any type of liquid onto these products. Do not

use these products if they have been damaged. Immediately contact InstruTech, Inc. to arrange return of the

product if it is damaged.

WARNING

WARNING

WARNING

Instruction Manual IGM401 Hornet

InstruTech, Inc. Page 7

Due to the possibility of corrosion when used in certain environmental conditions, it is possible that the

product’s safety could be compromised over time. It is important that the product be periodically inspected for

sound electrical connections and equipment grounding. Do not use if the equipment grounding or electrical

insulation has been compromised.

2.2 Safety Precautions - Service and operation

Ensure the IGM401 is properly connected to earth ground.

Do not turn on filaments and try to activate the sensor when pressure exceeds 1.00 x 10-3 Torr if the device is

operating at the 4 mA emission current setting.

Do not turn on the filaments and try to activate the sensor when pressure exceeds 5.00 x 10-2 Torr if the device is

operating at the 100 µA emission current setting.

Ensure vacuum level is at or less than 5.00 x 10-5 Torr before attempting to initiate degas.

WARNING! The power supply used in the IGM401 hot cathode gauge module is subject to high voltages

which could cause severe injury or death. In order to prevent electric shock and bodily harm, the user should

wait 5 minutes after power is removed before touching the IGM401 power supply components.

WARNING! When the IGM401 is turned on, 180 V is present at the power supply and other components

such as the ion gauge and the cable. Furthermore, voltages as high as 350 V are present during degas. DO NOT

operate the IGM401 with the IGM401 enclosure removed. Contact with exposed electrical circuits in the

IGM401 could result in death or serious injury.

Do not use another gauge to automatically turn off the ion gauge when the ion gauge filament

in use is constructed of tungsten (yttria coated filament is ok). The response time of other gauges may not

allow for timely turn off of the tungsten filament leading to filament damage. Always turn off the IG filament

manually before pressure is to rise above 1.00 x 10-3 Torr.

When using yttria coated filaments, it is highly recommended to periodically alternate operating Filaments 1

and 2. An inactive filament not operating for an extended length of time may result in that filament failing to

establish emission current when it is eventually used. This will be more problematic in dirty applications.

Use an appropriate power source of 20 to 28 Vdc, 30 W min. (InstruTech PS501 power supply is rated 60 W).

Turn off power to the unit before attempting to service the module. Turn off power to the unit before

detaching the electronics from the sensor for sensor replacement or bake-out purposes.

Turn off power to the unit if a cable or plug is damaged or the product is not operating normally according to

this instruction manual.

NOTICE

Instruction Manual IGM401 Hornet

InstruTech, Inc. Page 8

Do not use if the unit has been dropped or the enclosure has been damaged. Contact InstruTech for return

authorization and instructions for returning the product to InstruTech for evaluation.

Use yttria coated filaments with air and inert gases such as N2, argon, etc. Optional tungsten filaments are

available for use with gases not compatible with yttria filaments.

The most common cause of all vacuum gauge failures is contamination of the sensor. Noisy or erratic readings

and total gauge failure are possible indications of gauge contamination. Contamination can generally be

characterized as either:

A) A physical or chemical reaction of process gases with the sensor element. A different gauge may be

considered if neither yttria coated nor tungsten filament sensor materials are compatible with your

application.

B) An accumulation of material on the sensor element. In this case, performing the degas function of the

instrument may resolve the issue.

2.3 Electrical Conditions

WARNING! When high voltage is present in any vacuum system, a life threatening electrical shock hazard

may exist unless all exposed electrical conductors are maintained at earth ground potential. This applies to all

products that come in contact with the gas contained in vacuum chambers. An electrical discharge within a

gaseous environment may couple dangerous high voltage directly to any ungrounded conductor of electricity. A

person could be seriously injured or killed by coming in contact with an exposed, ungrounded electrical

conductor at high voltage potential. This condition applies to all products that may come in contact with the gas

inside the vacuum chamber (vacuum/pressure containment vessel).

2.3.1 Proper Equipment Grounding

WARNING! Hazardous voltages that could seriously injure or cause death are present in many vacuum

processes. Verify that the vacuum connection port on which the ion gauge is mounted is electrically grounded.

Consult a qualified Electrician if you are in doubt about your equipment grounding. Proper grounding of your

equipment is essential for safety as well as intended operation of the equipment. The vacuum gauge transducer

and enclosure of any control module must be connected directly to a good quality equipment earthing

conductor. Use a ground lug on the vacuum connection flange of the pressure measurement device if

necessary.

WARNING! In order to protect personnel from electric shock and bodily harm, shield all conductors

which are subject to potential high voltage electrical discharges in or around the vacuum system.

2.3.2 Electrical Interface and Control

It is the user’s responsibility to ensure that the electrical signals from this product and any connections made to

external devices, for example, relays and solenoids, are used in a safe manner. Always double check the system

set-up before using any signals to automate your process. Perform a hazardous operation analysis of your

Instruction Manual IGM401 Hornet

InstruTech, Inc. Page 9

system design and ensure safeguards and personnel safety measures are taken to prevent injury and property

damage.

2.4 Overpressure and use with hazardous gases

WARNING! Install suitable protective devices that will limit the level of pressure inside your vacuum

chamber to less than what the vacuum chamber system components are capable of withstanding.

In cases where an equipment failure could cause a hazardous condition, always implement fail-safe system

operation. For example, use a pressure relief device in an automatic backfill operation where a malfunction

could result in high internal pressures if the pressure relief device was not installed on the chamber.

The IGM401 is not intended for use at pressures above 20 psia (1000 Torr); DO NOT exceed 35 psig (< 2 ½ bars)

pressure inside the sensor. If your chamber goes to higher pressures, you should install an isolation valve or

pressure relief device to protect the gauge tube from overpressure conditions. With some fittings, actual safe

overpressure conditions may be lower; for example, a quick-connect, O-ring compression fitting may forcibly

release the gauge tube from the vacuum chamber fitting with only a few psi over local uncorrected barometric

(atmospheric) pressure.

CAUTION! If the internal pressure of a vacuum gauge device is allowed to increase above local

uncorrected barometric pressure (atmospheric pressure side), vacuum fittings may release and possible

overpressure conditions may cause leaks that would allow the gas inside the gauge tube to release into the

atmosphere of the surrounding environment. Toxic, pyrophoric and flammable gases are examples of

hazardous gases that if allowed to leak out of the vacuum/pressure containment vessel into the atmospheric

environment, could cause bodily injury and possible damage to equipment. Never expose the gauge tube

internal volume to pressure above local atmospheric pressure when using hazardous gases.

2.5 Gases other than Nitrogen / air

WARNING! Do not attempt to use with gases other than nitrogen (N2) or air without referring to correction

factor data tables.

InstruTech gauges and modules are calibrated for direct readout of nitrogen or air. Do not attempt to use with

other gases such as argon (Ar) or carbon dioxide (CO2), unless you have programmed the device for the

appropriate gas or use accurate conversion data for N2 to other gases. Refer to section 6 titled “Using the gauge

with different gases” for a more complete discussion.

WARNING! Do not use this device in an explosive atmosphere or in the presence of flammable gases,

vapors or fumes. Do not use this device to measure the pressure of explosive or combustible gases or gas

mixtures. The sensor filaments operate at incandescent temperatures and could become an ignition source.

This could cause an explosion which could result in serious injury or death.

Instruction Manual IGM401 Hornet

InstruTech, Inc. Page 10

Installation3

3.1 Mechanical Installation

Mount the IGM401 as close as possible to the pressure you want to measure. Long or restricted, small diameter

tubing will create a pressure difference between your process chamber and the gauge. This may cause a delay

in response to pressure changes. Mounting the IGM401 too close to a gas source inlet may also cause

measurement and control instability.

The IGM401 can be mounted in any orientation, however, if possible, mount the gauge with port down to help

minimize the effect of any particles or condensation collecting in the gauge.

Do not mount the IGM401 where it will be subjected to excessive vibration. Vibrations may cause unstable

readings, measurement errors and possible mechanical stress to components in the IGM401.

Shield the IGM401 near ion or electron sources such as an electron beam or in a sputtering system.

For electrical safety purposes the housing of the gauge must be grounded to the vacuum chamber. When using

KF flanges, metal clamps must be used to ensure proper grounding. Do not attempt to modify your flange in

order to use non-metallic-type flange clamps.

Fittings/Flanges - follow the fitting/flange manufacturer's recommendations for installation and use.

Use all metal vacuum fittings with metal seals when operating pressures are expected to be below

1.00 x 10-7 Torr (1.33 x 10-7 mbar, 1.33 x 10-5 Pa).

Instruction Manual IGM401 Hornet

InstruTech, Inc. Page 11

3.2 Electrical Installation

3.2.1 Grounding

Be sure the vacuum gauge and the rest of your vacuum system are properly grounded to protect personnel

from shock and injury. Be aware that some vacuum fittings, especially those with O-rings when not used with

metal clamps, may not produce a good electrical connection between the gauge and the chamber it is

connected to. Use a ground lug on the vacuum connection flange of the pressure measurement device if

necessary.

3.2.2 Connectors

The IGM401 allows for operation of the unit including turning the gauge/filaments on/off, selecting emission

current and turning degas on/off using digital inputs, RS485 communication commands or the front panel push

buttons.

Good, recommended practice is to remove power from any cable prior to connecting or disconnecting it.

The IGM401 is provided with two D-sub connectors used for I/O interface as shown below:

1. 9-pin, D-sub male (DE-9P) connector for Digital I/O and analog output.

2. 9-pin, D-sub female (DE-9S) connector for relay connections and RS485 serial communications.

IGM401 I/O Interface

When using InstruTech’s power Supply PS501A, connect the power supply to the ANALOG connector. If using a

power supply other than InstruTech’s PS501A, connect your power supply to either the RS485 or the ANALOG

connector as shown on the next page.

CAUTION! Do not connect power to both the Analog and the RS485 connectors.

Fabricate a cable according to your interface requirements. For analog signals and digital inputs use the 9-pin,

D-Sub male (DE-9P) connector. For relay connections and serial communications use the 9-pin, D-Sub female

(DE-9S) connector. Refer to the following pages for detailed explanations of the connector pin-outs.

Instruction Manual IGM401 Hornet

InstruTech, Inc. Page 12

3.2.2.1 Analog Connector pin-out

CAUTION! Do not connect power to both the Analog and the RS485 connectors. Apply power only to one

or the other. Applying power to both connectors may cause damage to the gauge and other connected devices.

When using digital inputs to operate the gauge, use the 9-pin D-sub male ANALOG connector described below:

ANALOG I/O 9-Pin D-sub (DE-9P) male connector

PIN NUMBER

PIN DESCRIPTION

1

Sensor on/off input signal. The ion gauge (IG) filament is activated by applying a

continuous ground (relative to pin 2, Power Ground). This will activate the sensor

and will turn on the filament. The IG filament is turned off by removing the ground.

See section 5.9 for other methods of activating the sensor.

2

Power ground & sensor on/off ground.

3

Analog output (log-linear 0 to 9 Vdc, 1 V/decade).

4

Power input (20-28 Vdc at 30 W, minimum). Do not connect power to both the

Analog and the RS485 connectors. Apply power only to one or the other.

5

Degas status output signal. This is an output signal to other external instruments to

confirm degas is on or off.

Signal: Open collector transistor (ground emitter) rated at 40 V max. VCE, 50 mA IC

max. Transistor off = degas off, transistor on = degas on.

6

Degas on/off input signal. Degas is initiated by applying a momentary ground. The

degas cycle will last for 2-10 minutes (based on user setting) even if ground is

removed. The ground must be removed to start cycle again.

7

Analog output signal ground (Do not use for sensor on/off ground).

8

Emission current. Applying ground changes emission current from 100 µA to 4 mA.

9

Sensor status. This is an output signal to other external instruments to confirm IG

filament is on or off.

Signal: Open collector transistor (ground emitter) rated at 40 V max. VCE, 50 mA IC

max. Transistor off = IG filament off, transistor on = IG filament on.

Degas Status 5

Input Power 4

Analog Output 3

Power Ground 2

Sensor On/Off 1

9 Sensor Status

8 Emission Range

7 Analog Output Ground

6 Degas On/Off

ANALOG I/O 9-Pin D-sub male (DE-9P) connector

Note - If you are replacing the analog output version of the Granville-Phillips® 354 Micro-Ion® module, simply

plug your existing cable into the IGM401 module 9-pin D-sub connector marked “Analog”. See the following

page if you are using the RS485 (with setpoint Relay) version of the Granville-Phillips® 354 Micro-Ion® module.

1

5

6

9

Instruction Manual IGM401 Hornet

InstruTech, Inc. Page 13

3.2.2.2 RS485 COM / Relay Connector pin-out

CAUTION! Do not connect power to both the Analog and the RS485 connectors. Apply power only to one

or the other. Applying power to both connectors may cause damage to the gauge and other connected devices.

When using the RS485 serial communications mode of operation, use the 9-pin D-sub female (DE-9S) RS485

COM connector as described below. The same connector is also used for ion gauge setpoint relay connections.

RS485 COM / Relay 9-Pin D-sub (DE-9S) female Connector

PIN NUMBER

PIN DESCRIPTION

1

Setpoint relay - Normally Open; referred to as RLY Ion front panel display

2

Power Input (20-28 Vdc at 30 W). Do not connect power to both the Analog

and the RS485 connectors. Apply power only to one or the other.

3

No connection

4

Power ground (Also when using RS485 serial communications, connect this

pin to ground pin of your RS485 converter)

5

Setpoint relay - Normally Closed (RLY Ion front panel display)

6

RS485 DATA A (-) Input/output

7

Setpoint Relay - Common (RLY Ion front panel display)

8

Not used (do not connect)

9

RS485 DATA B (+) Input/output

Setpoint Relay -N.O. 1

Power Input 2

No Connection 3

Power Ground 4

Setpoint Relay -N.C. 5

6 RS-485 Input

DATA A (-)

7 Setpoint Relay

COMMON

8 No Connection

9 RS485 Input

DATA B (+)

RS485 COM / Relay 9-Pin D-sub female (DE-9S) connector

Note - The RS485 version of MKS Instruments / Granville-Phillips® Series 354 Micro-Ion® is provided with a 9-pin

male connector. The InstruTech’s RS485 connector is a 9-pin female connector. If you are replacing an RS485

version of Micro-Ion® and would like to use your existing cable, a 9-pin use a female to male gender changer.

If you are using the InstruTech’s PS501-A power supply and using the RS485 function do not

connect power to pins 2 and 4 of the RS485 COM connector. The will be received via the ANALOG connector.

Use the RS485 COM connector pins for communications and setpoint relay only. If you intend to operate the

IGM401 via RS485 communications only, power may be connected to pins 2 and 4 of the RS485 COM

connector but not the analog connector at the same time. Pin-out assignments are not the same, especially

for the +24 Vdc power and ground (power return) connections for the Analog and RS-485 COM connectors.

5

1

9

6

NOTICE

Instruction Manual IGM401 Hornet

InstruTech, Inc. Page 14

Bakeout 4

If desired, a chamber bake may be performed for new systems or after routine maintenance. The IGM401

sensor can be baked out to 200 oC as long as the sensor fitting uses metal seals. For sensor fittings using

elastomer O-rings, the maximum bakeout temperature is limited to the maximum temperature rating of the

elastomer O-ring. Ensure the temperature of the sensor tube and the vacuum fitting to the sensor is at the

same or above the chamber temperature. The electronic module must be removed from the sensor if the bake-

out temperature is to exceed 70 oC. To bake out the sensor use the following procedure:

1. Turn off power to the IGM401.

2. Disconnect the cable from the IGM401.

3. Use a 3/32 in. size Hex key to remove the #4-40 socket head cap screws (SHCS) as shown below.

4. Detach the metal enclosure and the electronics from the sensor. Gently pull the electronics enclosure away

from the sensor using a gentle rocking motion.

5. The black plastic cap attached to the sensor and the end plate does not have to be removed for bakeout.

6. Perform bake out with the electronics removed.

7. Reattach the electronics enclosure. Reinstall the 4-40 SHCS (4 ea.)

Instruction Manual IGM401 Hornet

InstruTech, Inc. Page 15

Setup and Operation5

5.1 Applying power

Connect power to the IGM401 using the designated pins 4 and 2 of either the 9-pin D-sub ANALOG or the

RS485 COM connector. Do not connect power to both connectors simultaneously.

CAUTION! The +24 Vdc Power and Power Ground pin-out connections are not the same on the ANALOG and

RS485 COM 9-pin D-subminiature connectors of the IGM401. Equipment damage may result if a mating

power/control cable is not wired for the correct power and ground connections. Be certain that you observe the

correct pin-out designation for the connector on the IGM401 that you intend to connect to.

Alternatively, you can power the device by connecting InstruTech’s PS501-A power supply to the ANALOG

connector of the IGM401. When you connect power, the display will show “UNIT STATUS OFF”. This indicates

the display is on but the filament is not turned on and the sensor has not been activated yet. Read this user

manual in its entirety before activating the sensor. Refer to section 5.9 titled “Activating the sensor” for further

details.

5.2 Emission Current

Either 4 mA or 100 µA (0.1 mA) emission current are available settings for electron emission current.

1) In clean applications and operating at higher pressure ranges (5.00 x 10-6 Torr to 5.00 x 10-2 Torr) the

100 µA emission current setting is preferred.

2) At lower operating pressures (1.00 x 10-9 Torr to 5.00 x 10-4 Torr) the 4 mA emission current setting

should be used.

3) The emission current can also be set to automatically switch between 4 mA and 100 µA. This results in

optimal and stable pressure readings over the entire measurement range from low to high vacuum. For

example, if an application requires that pressure measurements be performed by the ion gauge from

pressures lower than 5.00 x 10-6 Torr to 5.00 x 10-2 Torr, the user may want to consider using the

automatic emission current switching feature of this instrument. Switching of the emission current may

be programmed to take place at any pressure from 1.00 x 10-6 to 1.00 x 10-4 Torr.

4) When using a diffusion pump or other pumps that use fluids, there is a possibility of the pump oil vapors

entering the IG transducer. These vapors may form an insulator on the internal components of the

transducer which can lead to instability or failure in controlling the emission. In this case, the 4 mA

emission current may provide improved operating lifetime and measurement performance.

Instruction Manual IGM401 Hornet

InstruTech, Inc. Page 16

5.3 Overpressure shut down

The IGM401 is provided with factory set default values for overpressure shut down. The gauge will shut off

automatically should the pressure reach or rise above the pressure shut down values shown below:

Factory set overpressure shut down values

Emission Current

Overpressure Shut

Down (Torr)

Overpressure Shut

Down (mbar)

Overpressure Shut

Down (Pa)

4 mA

1.00 x 10-3

1.33 x 10-3

1.33 x 10-1

100 µA (0.1 mA)

5.00 x 10-2

6.66 x 10-2

6.66

The 100 μA emission current overpressure shut down setting may be adjusted from 1E-05 Torr to 5E-2 Torr.

5.4 Degas

Degas is used to rid the gauge sensor of adsorbed gas. Degas is achieved by applying Electron Bombardment

(EB) to the grid. The intervals at which degas should be applied vary for each application. The low pressure

measurement performance of the transducer will normally improve after each degassing cycle.

Degas can only be applied while the filament is turned on and operating.

Ensure vacuum level is at or less than 5.00 x 10-5 Torr before attempting to initiate degas.

Power during degas is about 3 watts higher than the normal operating power.

Degas will automatically turn off after 2 minutes when using factory default settings. Degas can be

programmed for duration of 2 to 10 minutes.

The IGM401 will continue to measure pressure while degas is in progress.

Degas will automatically turn off if the pressure exceeds 3.00 x 10-4 Torr during the degas cycle.

Degas can be interrupted by turning the IGM401 filament off.

Instruction Manual IGM401 Hornet

InstruTech, Inc. Page 17

5.5 Filament Material Selection / Venting the Chamber

The choice of which type of filament to use in the IGM401 is primarily dependent upon the process and process

gases the ion gauge will be used with. For general vacuum applications, dual yttria coated filaments are offered

for use with air and inert gases such as N2, argon, etc. Optional dual tungsten filaments are available for use

with gases not compatible with yttria filaments.

1) Yttria coated iridium filament

In most general vacuum applications, the yttria coated iridium filament is the best choice.

Yttria coated filaments typically operate at a lower temperature than tungsten filaments and thus have a lower

outgassing rate at UHV and lower chemical reactivity with active gases.

Yttria coated filaments typically have a longer operating life than tungsten filaments in clean applications.

The yttria coated filament can survive occasional accidental start attempts at atmosphere in air, but the overall

life of the filament may be shortened during each occurrence. Good vacuum practice is to use a separate

pressure gauge such as InstruTech’s Stinger™or Super Bee™convection gauge to know when to turn on the ion

gauge filament. The relay outputs of convection gauges can be used to turn on the ion gauge filament.

2) Tungsten filament

Typically a bare tungsten filament is a better choice in those applications where an yttria coated filament is

quickly damaged due to the gas type in use. For example, processes such as ion implantation may only use

tungsten filaments. Be aware that corrosive applications are hard on any filament and filament life will be

shortened while operating in such environments. Tungsten filaments are easily damaged by exposure to

air/oxygen during accidental system vents or if considerable quantities of water vapor are outgassed during

pump-down and bake-out. It is very important to make sure the tungsten filament is turned off before bringing

the chamber up to atmosphere, especially if air is being used to vent the chamber. The use of pure N2gas is

highly recommended to vent or purge your vacuum chamber. Testing has shown that tungsten filaments can

withstand limited high pressure excursions when only N2is present.

Venting with air or other oxygen containing gases can damage the tungsten filaments. If you try to turn on an

ion gauge with tungsten filaments while it is sitting on your desk exposed to room air, you will immediately

damage or destroy the filament beyond repair.

Do not use another gauge to automatically turn off the ion gauge when the ion gauge filament

in use is constructed of tungsten (yttria coated filament is ok). The response time of other gauges may not

allow for timely turn off of the tungsten filament leading to filament damage. Always turn off the IG filament

manually before pressure is to rise above 1.00 x 10-3 Torr.

Note - Both types of filaments will suffer eventual damage if operated at high pressures. The type and amount

of damage at high pressure is dependent upon the length of operating time, the pressure and the gas present.

NOTICE

Instruction Manual IGM401 Hornet

InstruTech, Inc. Page 18

5.6 User Interface Basics

The user interface is designed for easy operation and a natural progression of setup parameters. This section

gives a brief explanation of operation for added clarity.

Programming soft-keys

There are four soft-keys located on the front panel, below the display. These keys are used to select and

program the various functions available. During programming of the IGM401, the display will identify what each

function key represents.

To begin programming, press the MENU key. Press the ENTER key to access the parameters and save the new

settings. Press the UP and DOWN key to select the desired menu and change the parameters. Press the MENU

key to return to the previous menu or press repeatedly to return to the main screen. To continue setting

additional parameters, scroll with the UP and DOWN keys until you reach the desired parameter.

This manual suits for next models

1

Table of contents

Other Instrutech Control Unit manuals

Popular Control Unit manuals by other brands

Pickering

Pickering 40-292 user manual

GEM

GEM 740 Installation, operating and maintenance instructions

Bardiani Valvole

Bardiani Valvole BBZPM instruction manual

Grundfos

Grundfos UP-ZV Installation and operating instructions

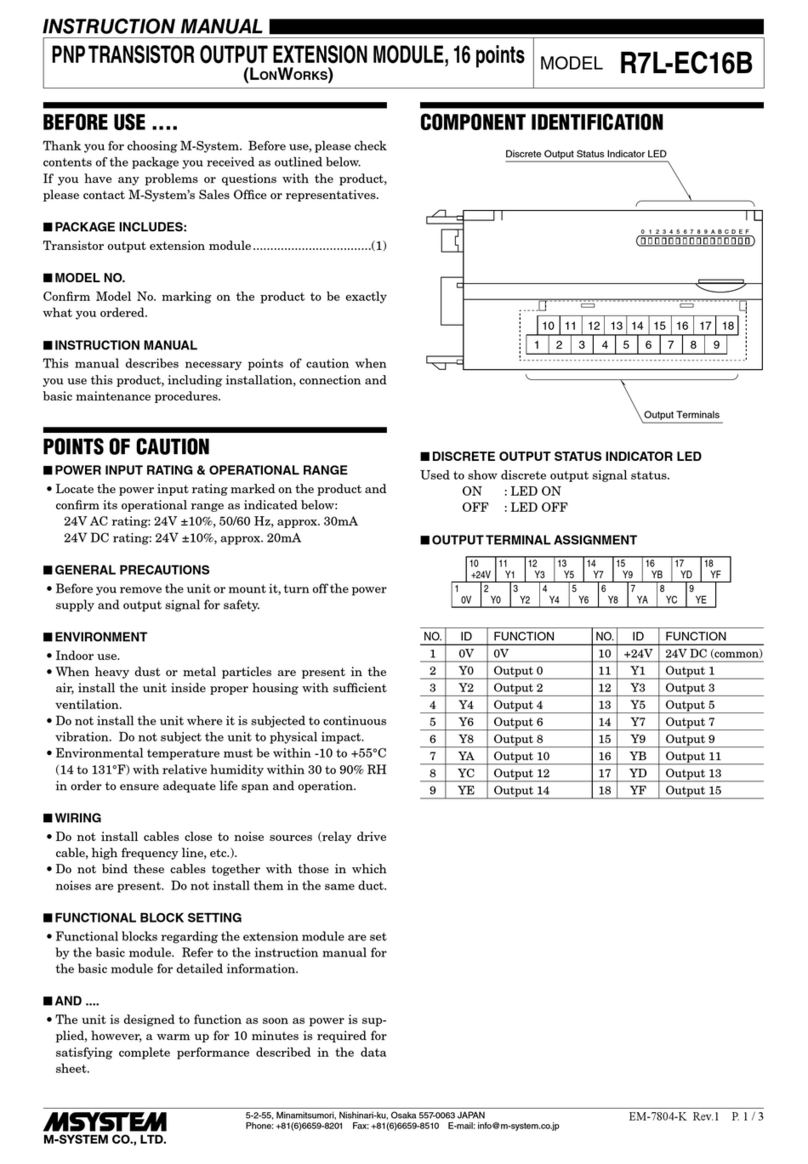

M-system

M-system R7L-EC16B instruction manual

claber

claber Hydro 4 Use and installation manual