Exhaust Requirements MD8 Series Dryers

MD 8 Series dryers are produced under the UL Code 795, Fourth Addition –

Commercial Industrial Gas Heating Equipment. The dryer is also listed under ETL

compliance with the same and has a reference number of J98*10442. All utility hook

ups and exhaust connections should comply with these codes.

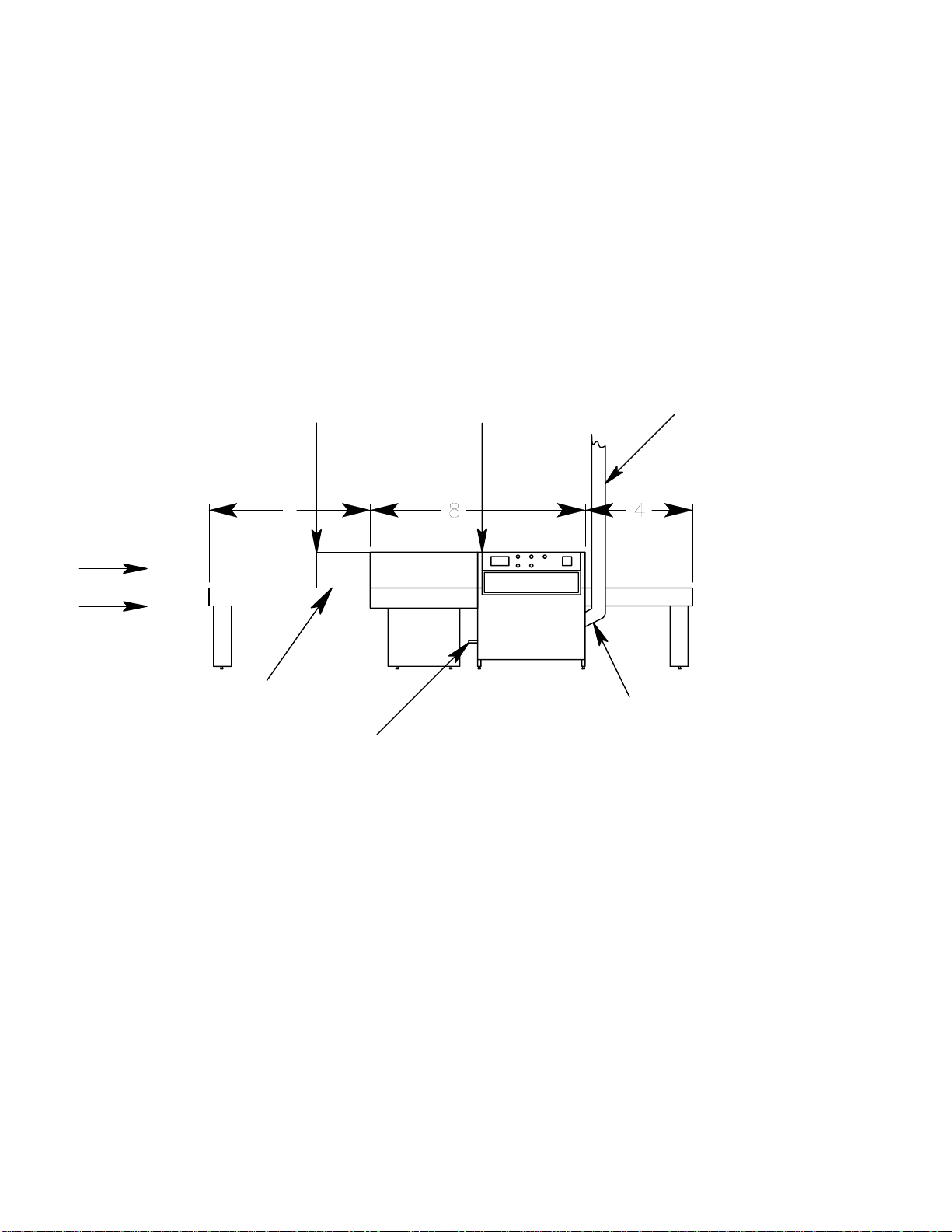

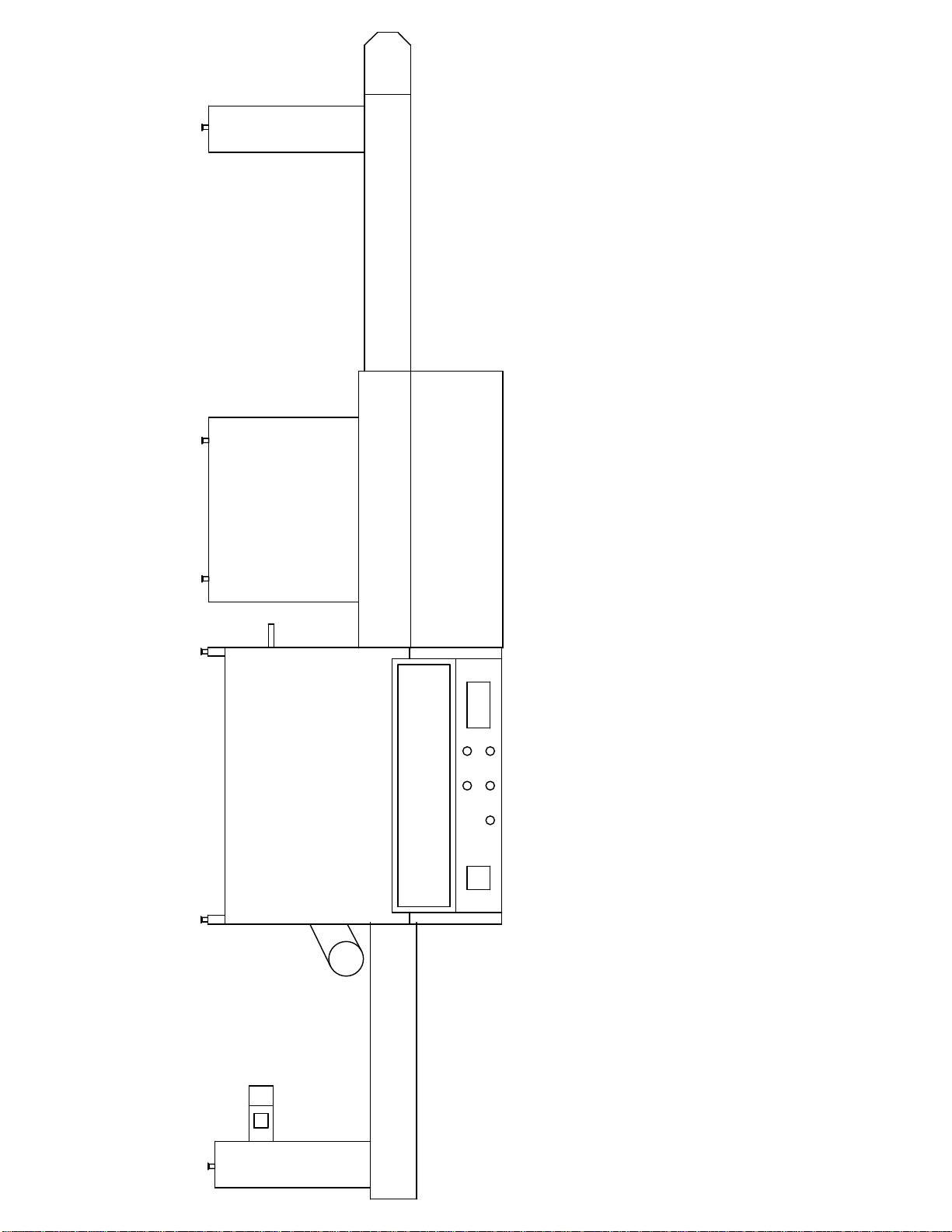

The MD8 is supplied with a 6 inch exhaust duct connection point. Connect 6 inch single

wall or double wall ventilation piping. Please consult your local city and/or state code to

determine which type of ventilation piping is required.

If the ventilation piping travels a distance of over 30 feet from the initial connection

point or if there are more than two 90 degree bends in the total run on the ventilation

piping, a booster blower may be required. It is necessary to maintain 350 - 500

CFM Maximum Exhaust Capacity (12 -17 M3 / Minute Maximum) at connection

point. Exhausting air temperature after 15 ft is approximately 200F. (95C)

90 Dayton Ave Passaic, NJ 07055 USA • PH 973.474.5005 FX 973.473.4485 • www.interchangecorp.com