INTERSPIRO DIVATOR MKII User manual

Divator MKII Face mask

Instruction manual

Contents

Special points 5

Technical description 6

Face mask 6

Low volume diving visor 6

Breathing valve 7

Breathing valve with positive pressure 7

Usage 8

Preparation 8

Donning 9

Removing the mask 11

Cleaning 12

Daily care: 12

Assembly after cleaning 16

Function test after cleaning 17

Inspection 17

Diving in low water and/or air temperatures 18

1. Breathing valve 18

2. Face mask 19

Repeated dives at air temperatures below +5°C 19

Surface supply (Hose diving) 19

Storage 19

4

5

Special points

The full-face masks are intended only for the use stated in this user

manual. Exceptions can be agreed only in writing.

Servicing, cleaning, maintenance and repairs require precise knowl-

edge and observance of the instructions for use in this manual.

Maintenance and repairs must only be carried out using Original

INTERSPIRO parts. Servicing, maintenance and repairs may only

be carried out by specialist personnel. Inspections must be carried

out at regular intervals by specialists and records of these kept. Care

must also be taken that the replacement intervals for the exhalation-

valve disc and the speech cone are adhered to.

INTERSPIRO offers maintenance contracts which via annual check-

ing, maintenance and, if necessary, repair of your breathing appara-

tus and masks guarantees that they are always in working order.

INTERSPIRO is not responsible for maintenance and repairs car-

ried out by third parties. Nor is it responsible for improper handling

or use. The guarantees and warranties by INTERSPIRO specified in

the conditions of sale are not extended by these “special points”.

6

If it is required to trim the mask to a neutral buoyancy,

weights are available which can be attached to locating lugs

(art. no. 336 190 854) on each side of the visor. See figure.

In addition the visor is closer to the wearer's eyes which

gives the user an increased angle of vision. The low volume

diving visor is suitable for use with any DIVATOR MK II

masks and is available as a retro-fit kit or complete assem-

bly.

LOW VOLUME DIVING VISOR

DIVATOR MK II is fitted with a low volume diving visor. The visor is designed

to minimise the volume of air inside the face mask and so reduce the positive

buoyancy effect. The sides of the visor are mat finished to avoid optical distor-

tions.

Technical description

FACE MASK

The DIVATOR MKII face mask has been tested in accordance with EN 250.EC

Type-examination (Directive93/68/EEC)by SGS Yarsley ICS Ltd,East Grinstead,

West Sussex, RH19 1 ET, UK (Notified body No 0120).

The mask with inner mask is made of rubber and provided with a flat visor. The

mask has holed studs for fitting spectacles. In the connection piece for the breath-

ing valve there is space for a microphone to a diving telephone. (When fitting a

microphone a cover with long screws should be used.)

The rubber head harness has five straps that are tightened and locked by stain-

less steel buckles. The wide and soft sealing edge of the mask is pressed lightly

against the face by the positive pressure and follows the contours of the face

giving an effective seal.

Inhalation and exhalation air will never be mixed because of the separate inha-

lation and exhalation channels. In this way rebreathing of carbon dioxide en-

riched exhaled air is eliminated.

During inhalation air flows from the breathing valve up through the demister

ports over the inside of the visor preventing any condensation from forming, and

on through the non-return valves into the inner mask.

During exhalation the air is expelled to the ambient water through the exhala-

tion valve.

7

BREATHING VALVE

The breathing valve is of the demand type i.e. air is only supplied during inhala-

tion.

Owing to the balanced valve function the breathing resistance can be kept ex-

tremely low, in spite of variations in the secondary pressure which may occur

e.g. in connection with surface supply diving.

In the inhalation channel there is a one way valve to prevent water from pen-

etrating into the valve mechanism where it could freeze and cause the valve cone

to stick in the open position.

Note! The breathing air shall meet the requirements for breathable

air according to EN 132, Annex A.

Note! It is very important that the breathable air is clean and dry.

Note! Do not use oxygen or oxygen enriched air.

Breathing valve with positive pressure (for use in contaminated water)

The valve is designed to give a slight positive pressure of approximately 200 Pa

(20 mm water column) in the mask. The positive pressure (safety pressure) is

turned on automatically when the user takes his first breath in the mask. This

ensures that there is no way of forgetting to turn on the positive pressure or that

it could become accidentally turned off.

The positive pressure reduces the risk of water inleakage (which is very impor-

tant when diving in contaminated water) and the positive pressure in the mask is

maintained irrespective of the diver's momentary air consumption. But if water

should still have penetrated, the mask is easily drained by pushing the purge

button of the breathing valve.

When the mask is taken off the black lever on the breathing valve should be

turned in against the valve housing. The breathing valve will then be shut off.

8

Usage

PREPARATION

1. Connect the breathing valve to the

mask by pushing the valve into the

connection piece and by turning it

anti clock-wise so that it grips in

the bayonet coupling.

3. Connect the breathing hose to the

breathing valve and tighten the

union nut by hand.

2. Lock the breathing valve in posi-

tion with the cover which should

be pressed on and the screws tight-

ened by hand. If needed the O-ring

should be lubricated with a thin

layer of lubricant 331 900 269.

9

DONNING

1. Adjust the pressure equalizer pad

to a position which permits easy

breathing through the nose.

2. Pull out the head harness straps as

far as possible and put on the face

mask

3. Tighten the head harness straps

moderately.

Note! Always pull down the head harness as far as possible at the

back of your head and tighten the lower straps first to counteract the

buoyancy of the mask.

10

4. If necessary, pressure equalize by

pressing the breathing valve up-

wards.

4. Check the positive pressure by

holding the breath and inserting

two fingers between the sealing

edge and the face; a strong air flow

should be heard.

4. Inhale deeply to turn on the posi-

tive pressure automatically (alter-

natively press lightly on the purge

button, see figure). Stop breathing

and listen for any leakage. If there

is a fitting leakage check that hair

has not come between the mask and

the face and adjust if necessary the

head harness.

11

REMOVING THE MASK

1. Unlock the buckles and loosen the

head harness.

2. Turn off the positive pressure by

pressing the black lever on the

breathing valve towards the valve

housing. See figure.

3. Remove the mask.

12

CLEANING

Daily care:

1. Immerse the face mask and the breathing valve into clean water.

2. Remove the mask and the breathing valve from the water.

3. Press the purge button and allow the air to flow through the valve until the

valve is dry and loose dirt removed.

Note! Should the breathing valve have been removed from the face

mask the non-return valve may fall off while you rinse it.

After prolonged use or when the apparatus is very dirty the following procedure

should be carried out by a person authorized by INTERSPIRO:

1. Close the cylinder valve and switch

on the positive pressure.

2. Unscrew the medium pressure hose connection.

3. Remove the cover by unscrewing the two screws and pulling the cover off.

4. Turn the breathing valve clock-wise so that it comes away from the bayonet

coupling and pull the valve outwards.

13

5. Dismantle the breathing valve in

the following way:

a) Unscrew the locking ring and re-

move the positive pressure unit

from the valve housing.

b) Seal off the connection nipple and

the inlet channel with rubber plugs.

c) Hold the positive pressure unit and

loosen the diaphragm assembly by

squeezing the thread of the cover.

Separate the components carefully.

14

e) Remove the positive pressure

spring and the guide disc from the

positive pressure unit cover.

d) Remove the sealing disc and the

exhalation diaphragm from the dia-

phragm assembly. Do not disman-

tle the diaphragm assembly any

further.

e) Remove the protective ring from cover if necessary.

Further dismantling of the breathing valve should only be carried out by

an authorized service man.

If sand or dirt has penetrated into the valve the valve insert should be dis-

mantled completely and cleaned by an authorized service man. The setting of

the valve could in this case alter and the valve should therefore be tested with

a test equipment before being put to use again.

15

6. Wash the face mask and the breathing valve dismantled as described above.

Use soap and warm water (maximum 40 °C). Scrub with a brush if necessary.

Instead of soap a detergent can be used.

Note! Strong detergents should be avoided as these may damage rub-

ber and plastic materials.

7. Rinse the parts in clean water after cleaning.

8. It is sometimes necessary to disinfect the mask and valve after use.

After cleaning and rinsing leave the parts, except the valve insert, in a 0.1%

solution of chlorhexidine (Hibitan ICI) for one hour. (Chlorhexidine can be

obtained from any chemist. ) Rinse the parts carefully in clean water.

9. Let the parts dry. Temperatures higher than 50ºC must not be used for dry-

ing.

16

ASSEMBLY AFTER CLEANING

1. Check that the rubber parts are supple and without cracks or other defects.

Damaged parts should immediately be replaced. Any repairs to the breathing

valve should always be followed by a function test on the test equipment.

2. All the parts should be completely dry before reassembling.

3. Lubricate the exhalation diaphragm with a thin coating of lubricant

331 900 269. Lubricate the edge of the diaphragm where it seals against

the sealing disc and also the corresponding area of the disc.

If needed the O-rings should be lubricated. Lubricant can also be applied to

the groove for O-ring in order to keep the O-ring in place.

4. Place the guide disc with the positive pressure spring in the cover.

Note! Do not straighten the spring. The slight bend is intended.

5. Push the diaphragm onto the diaphragm assembly, making sure that the

centre is pressed well down on the guide pin.

Note! The sealing edge should lay flat against the valve seat.

6. Assemble the sealing disc and the diaphragm assembly. Check that the

sealing edge of the diaphragm and the edge of the sealing disc are even

and clean.

7. Lubricate if necessary the sealing edge and the sealing area of the sealing

disc with lubricant 331 900 269.

8. Place the diaphragm assembly on top of the positive pressure spring (the

sealing disc has a guide groove for spring). Push the diaphragm assembly

down into the positive pressure cover without twisting it as the spring

tension could be altered.

9. Check that the unit is working correctly by pressing down lightly the guide

pin a few times. The diaphragm assembly should move freely.

10.Place the locking ring on the valve housing and screw the positive pressure

attachment on to the valve.

11. Assemble the breathing valve and the face mask and screw on the cover.

17

FUNCTION TEST AFTER CLEANING

1. Connect the breathing hose to the breathing valve and push the lever to the

off position (i.e. against the valvehousing). Open the cylinder valve. No flow

of air should be heard. A flow indicates a leakage.

2. Turn on the positive pressure briefly. A strong flow of air should be obtained.

If not, the valve has been wrongly assembled and should be adjusted and test

repeated.

3. The automatic positive pressure can be checked by putting on the face mask

and checking that the positive pressure is switched on automatically by the

first inhalation. Turn off the positive pressure and take off the mask before

exhaling. Wipe the sealing skirt of the face mask with disinfectant.

Alternatively the test equipment can be used to test the automatic positive

pressure and other functions. See separate instructions supplied with the test

equipment.

INSPECTION

Inspect the rubber parts, the plastic parts, the non-return valves in the inner

mask and the head harness at regular intervals. A diving apparatus should un-

dergo a complete function test at least once a year, even if it has not been used.

These tests are carried out on a test equipment.

18

Diving in low water and/or air

temperatures

Colder environments always involve greater risk of freezing in a breathing ap-

paratus. We recommend the use of the full-face mask at low temperatures be-

cause it provides better protection for face against cold. It is also physiologically

correct because the inhalation air is warmed and moistened in the nose.

Freezing may cause more serious operating problems but this can be prevented

by following the simple measures described in the following instructions.

Below is a short summary of how the main components of the apparatus may

react at low temperatures.

1. Breathing valve

The breathing valve functions on the demand principle, i.e. air is only supplied

during inhalation. When the diver inhales, air flows from the breathing hose

through the breathing valve and into the diver's lungs. The expansion of the

supplied air means that the breathing valve close to the inlet is cooled to around

-12°C at a water temperature of 0°C. Possible moisture in the inlet section of the

breathing valve will then become ice which could increase the friction between

the moving parts of the valve mechanism so much that the return springs would

not be able to close the valve at the end of each inhalation. In such cases the

diver gets a free flow situation, i.e. there is a continous flow of air through the

breathing valve and mask and out via the exhalation valve.

To prevent moisture accumulation a non-return valve has been inserted in the

passage between the inlet section of the breathing valve and the mask.

In spite of this moisture may enter the inlet section of the breathing valve in the

following ways.

a) After washing in water if the breathing valve has not been properly dried.

b) The non-return valve is not leaktight.

Check that the breathing valve is functioning properly by turning on and off the

safety pressure. There must be no air flow after the safety pressure has been

turned off. Also check that the non-return valve seals against its seat.

At low outside temperatures there is a risk for ice in the breathing valve if it is

not completely dry. This is especially important as far as the valve insert is con-

cerned. Use dry, clean air, for example from the cylinder pack, to blow dry.

Silicon sprays or other products not approved by us must not be used to keep out

moisture, such products may be harmful to the material or cause allergic reac-

tions.

19

2. Face mask

The face mask has been developed in order to protect the diver's face against

cold and to make it possible to warm and moisten the breathing air on its way

through the nose before it reaches the lungs. The DIVATOR MK II full-face

mask has completely separated inhalation and exhalation channels. This means

that moisture from the diver's exhalation can not pass over to the inlet section of

the breathing valve, neither through the mask channels nor through the valve

mechanism. These features reduce the risk of freezing significantly. However,

the breathing valve must be dry to start with.

Put on the mask before you enter the water. Check that the mask makes a tight

seal against the hood/face. A leaking mask means a continous flow of air with a

cooling effect and increased risk of feezing if the breathing valve is not dry.

Repeated dives at air temperatures below +5°C

To prepare for the next dive shake the mask to remove remaining water.

Put on the mask and push in the purge button and let the air flow through the

valve a few seconds.

Place the mask in a dry place with the visor facing upwards to prevent water or

snow entering.

Shake off water from the reserve air valve and place it away from water or snow.

Surface supply (Hose diving)

When surface supply diving in winter conditions make sure that there is no

water in the hose before the diver enters the water.

Make sure that the diver receives the correct supply pressure so that the mask

does not free flow.

Storage

All parts of rubber or containing rubber components should be stored in a cool,

dry and dark place and in a sealed plastic bag.

20

21

Other manuals for DIVATOR MKII

1

Table of contents

Popular Oxygen Equipment manuals by other brands

Invacare

Invacare Perfecto2 IRC5PO2 user manual

John Bunn

John Bunn JOHN BUNN JB0150-085 instructions

Invacare

Invacare Platinum IRC5LXAW Service manual

DeVilbiss

DeVilbiss 515A Series Instruction guide

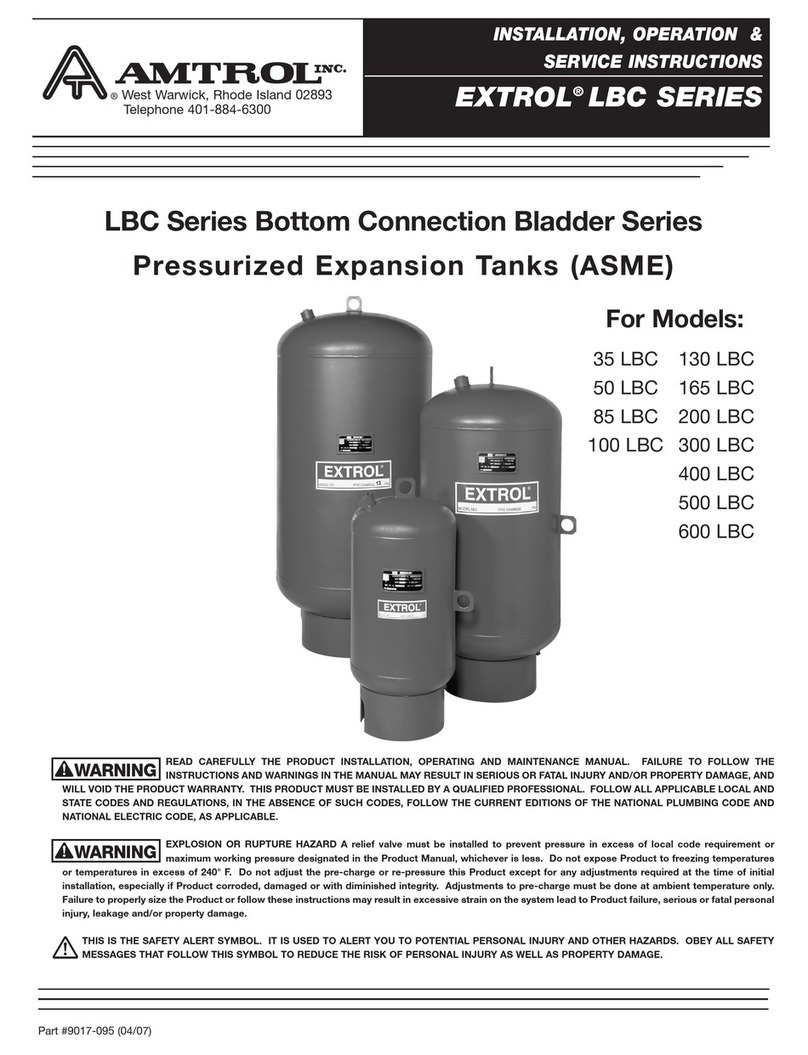

Amtrol

Amtrol EXTROL 100 LBC Installation & operation instruction

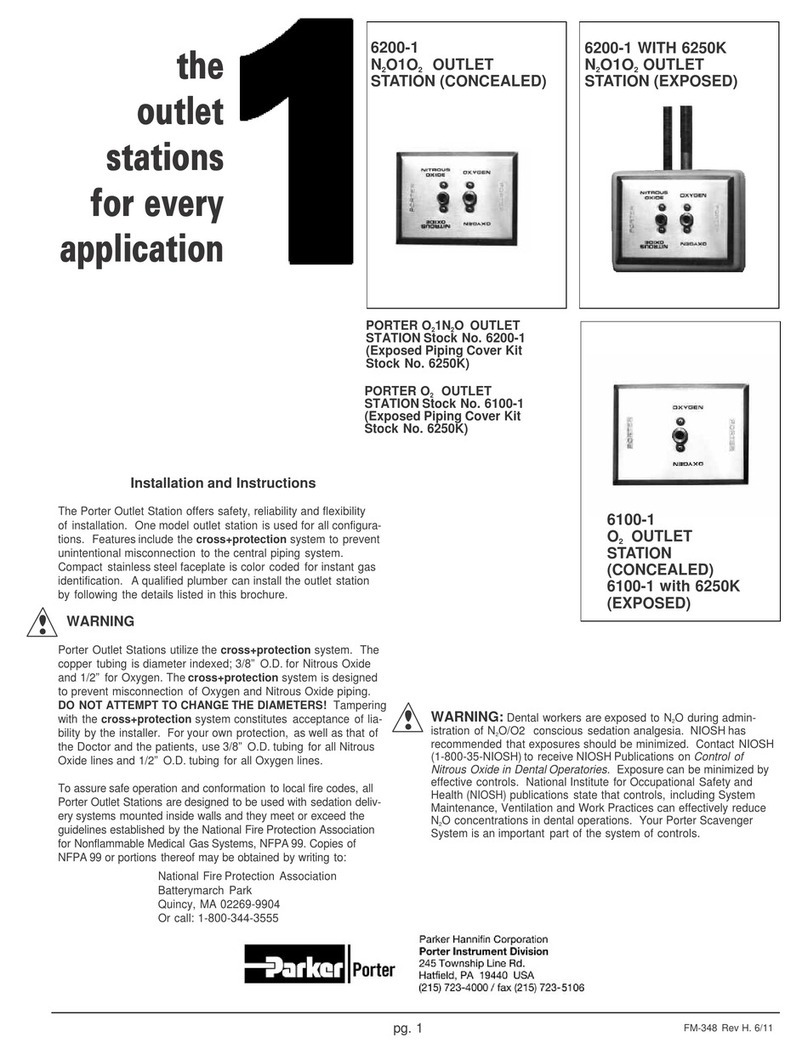

Porter

Porter 6200-1 Installation and instructions