intervolt Gen II Maxi Series User manual

WELCOME

Thank you for choosing an interVOLT isolated power conditioner ...

A 24VDC to 24VDC power conditioner is used primarily for connecting auxiliary 24VDC equipment

in a 24VDC wired application. The power conditioner must be sized according to the load

connected in order to ensure good performance, safety and longevity. Listed below are just a few

of the features and benefi ts you have gained in selecting an interVOLT power conditioner.

Intervolt SPCi Series Switchmode power conditioners are designed for high demand power

requirements in transport, telemetry, alternative energy applications and the like. They are

suitable for powering a large range of auxiliary 24VDC equipment including communications,

navigation, monitoring, instrumentation, lighting, refrigeration and much more.

Intervolt SPCi’s incorporate a range of innovative features including an industry fi rst, micro-

processor controlled operator interface for the control and monitoring of the many SPCi

functions. This feature is designed to help trouble-shoot general installation errors and assist in

fault fi nding common problems.

Intervolt SPCi’s are fully protected from typical connection and installation faults by a range of

built-in safety devices. These devices protect the units from reverse connection, short-circuiting,

overloading, high output voltages and high temperatures.

Intervolt SPCi’s are designed to cope with the demands of the harshest applications and will

operate in high temperature, high humidity environments. They are constructed of quality marine

grade materials and when applied and installed correctly are designed to provide many years of

continuous service.

Intervolt SPCi’s are designed and assembled in Australia and comply with relevant Australian and

international standards for electro-magnetic compatibility (EMC). They are supported by a 100%

factory backed 24 month warranty against faulty components and/or workmanship.

1

CONTENTS

OVERVIEW ............................................ 2

SPCi MAXI SERIES GEN II ............................ 2

INSTALLATION ....................................... 3

NOTICE! .............................................. 3

WIRING ............................................... 4

OPERATION ........................................... 7

INITIAL SET-UP ..................................... 7

EXTENDED FEATURES ............................. 9

SCHEMATICS .........................................11

Power conditioner

Standard Installation .................................11

Parallel Installation ................................ 12

Battery Charger

Standard Installation ................................ 13

Auxiliary

External Alarm Output .............................. 14

Remote Switching – manual control ................ 14

Remote Switching – automatic control ............. 15

Remote Switching – with ignition switch control ... 15

OPERATOR INTERFACE ............................ 16

INTRODUCTION ..................................... 16

POWER ICON ........................................ 17

FAN ICON ........................................... 17

TEMP ICON ......................................... 18

INPUT ICON ........................................ 19

OUTPUT ICON ....................................... 20

CHARGE ICON ....................................... 22

OUTPUT LOAD INDICATOR ......................... 23

OUTPUT VOLTS INDICATOR ........................ 23

TROUBLESHOOTING ............................... 24

SPECIFICATIONS .................................... 26

WARRANTY POLICY ................................ 29

INSTALLATION & OPERATION

MANUAL

interVOLT is a registered trademark of Amelec Australia Pty Ltd in Australia and various other countries

including the UK and USA and as such is protected by the relevant laws of the country of registration.

© 2012. All rights reserved. The entire contents of this instruction manual shall remain the property of

Amelec Australia Pty Ltd and should not be reproduced without written permission.

Manual No. MAXISPCi24G2 R1-0

Manufactured by Amelec Australia Pty Ltd

16 Parkinson Lane, O’Connor, WA 6163, Australia

www.intervolt.com

GEN II

MAXI SERIES

ISOLATED

24-24 VDC

Power

Conditioner

2

OVERVIEW

SPCi MAXI SERIES GEN II

The second generation interVOLT SPCi Maxi series isolated power conditioners are the evolution

of the original and renowned SPCi models fi rst released in 2003. The GEN II Series is not just a

cosmetic ‘makeover’ but rather a complete new product from the ground up. The all new design

features complete digital control with a specifi cation second-to-none. Here are just a few of the

new features and benefi ts exclusive to the new range:

– Unique operator interface for control and monitoring

– Galvanically isolated input to output – no common connectivity

– Handy charge mode for charging a 24V auxiliary battery (2 stage)

– High resolution voltage output of less than 0.5% under any load

– Peak effi ciency of 92% (better than 90% under most load conditions)

– Remote operator control to turn unit on/off with signal current only

– Multifunction alarm output for fault and pre-emptive warnings

– Temperature and speed controlled internal cooling fan (Vapo bearing)

– Compact design and can be mounted vertically or horizontally

– Heavy duty termination with separate, removable terminal cover

– 24 months warranty (subject to specifi c terms and conditions)

– High quality assembly featuring marine grade hardware

– Conformally coated printed circuit board assembly (tropicalisation)

This manual contains comprehensive information on the installation, set-up and use of the all

new SPCi isolated power conditioners and is applicable to GEN II models only. Whilst every care

has been taken in the preparation of this manual, Amelec Australia Pty Ltd offers no guarantee,

express or implied, and accepts no liability for any inaccuracies, errors or omissions in its

content. Specifi cations are subject to change without notice.

4

INSTALLATION

WIRING

IMPORTANT! Ensure adequately rated cables are used for the maximum load of the SPCi model

installed. If uncertain, consult your cable supplier quoting the continuous rating of the SPCi and the

length of cable on both input and output. The input current draw is approximately 110% of the output

load (subject to V in and V out references). Under-sizing the cable will result in poor performance,

over-heating, a reduction in longevity and may jeopardise your warranty in the event of a failure.

Disconnect the 24VDC supply at the source before attempting any connection to the input terminals

of the SPCi or equipment to the output.

Install an appropriately rated circuit breaker or fuse (see chart below) as the input protection for the

24VDC supply cable to the SPCi.

EXTERNAL INPUT FUSE REQUIREMENT CHART

SPCi Model No. SPCi Rating Input Fuse

SPCi242410G2 10 Amps cont. 20 Amps

SPCi242420G2 20 Amps cont. 40 Amps

Connect all input wiring to the SPCi ensuring correct polarity. Failure to observe correct polarity will

result in the internal protection circuit blowing the fuse. This circuit protects the SPCi from catastrophic

damage. The internal fuse is not user serviceable. In the event the SPCi is incorrectly reverse polarity

connected, the unit must be returned to vendor for servicing.

The power terminals utilise M5 combination head screws for excellent conductivity. It is recommended

that proper tinned drawn-copper cable lugs are used for termination. An example of this item is

depicted on page 6.

3

NOTICE!

The SPCi must be properly installed in order to comply with environmental operating considerations and

the manufacturer’s warranty terms and conditions.

The SPCi is constructed from marine grade materials and the printed circuit board has been conformally

coated (tropicalised) to protect the SPCi from condensation and humidity. It is NOT however, waterproof.

LOCATION

Select a suitable location where the SPCi can be mounted. Ensure there is adequate ventilation and

that the location is free from excessive moisture, dust, vibration and heat. The SPCi is designed for

installation in a protected environment.

ORIENTATION

The SPCi can be mounted vertically or horizontally. The SPCi should be installed on a hard fl at surface –

do not install on an upholstered or insulated surface. Ensure at least 50mm of clearance all around from

other equipment. There should be no restrictions in the way of the ventilated end cap.

MOUNTING

The SPCi unit should be installed with appropriate fasteners ensuring all anchor holes are utilised. The

mounting hole diameter is 5mm and it is recommended that a fastener with a diameter (major thread) of

no less than 3.5mm be used. Do not overtighten.

WIRING

In order to ensure safety, good performance and long life the SPCi should be wired according to the

method detailed overleaf. Please refer pages 11-15 for schematics of the various wiring circuits available.

INSTALLATION

INSTALLATION

5

INSTALLATION

Once the input supply is terminated the SPCi can be powered up. Upon reconnecting the 24VDC supply

the POWER indicator is illuminated intermittently (pulsing green) indicating the SPCi is operational.

If any other icon is illuminated or the POWER indicator is not illuminated, refer to the troubleshooting

guide on pages 24-25.

The SPCi is now in standby and operating at the factory default output of 26.0VDC. The output can now be

adjusted in one of two ways depending upon the application:

i. For use as a power conditioner – output voltage is selectable between 24.0V and 28.0V in 1V

increments. Please refer to the set-up instructions on pages 7-8 before connecting the output wiring

to the 24V equipment.

ii. For use as a battery charger – output voltage is set to battery charging mode (standard lead acid

battery only). Please refer to the set-up instructions on pages 7-8 before connecting the output wiring

to the 24V battery.

Before connecting the output wiring, ensure the input supply is isolated. Once the output is connected the

SPCi can again be powered up and is now ready for operation.

In addition to the main power terminals there is an auxiliary terminal block located between the input

and output terminals. See over for further information on wiring the auxiliary terminal block.

NOTE: It is also possible to wire the SPCi’s in parallel to increase the output current rating. For example,

two 20A rated units can be paralleled for a combined total of 40 Amps continuous, three for 60 Amps, etc.

The wiring must be appropriately rated to carry the total load and the output voltage setting of each unit

MUST be the same i.e. 26.0V. The SPCi’s can ONLY be paralleled when used as power conditioners and

NOT when used in battery charging mode. Please refer to pages 11-13 for schematics.

6

INSTALLATION

Auxiliary Terminal Block: The auxiliary terminals are optional and not

required for operation of the SPCi, however they do provide some very

useful functions. Please refer to pages 9-10 for details of the specifi c

control and monitoring functions of the auxiliary circuits.

When connecting any of the optional auxiliary circuits (terminal block)

the wiring used is for low power circuits and should be wired according

to the schematic on pages 14-15. For reference purposes the maximum

current for each of the connections is as follows:

• Terminal A: This is the external alarm output connection and is

limited to 250mA @ input voltage i.e. 24VDC nominal.

• Terminal R: This is the remote control input and is signal current

only. Supply is 8-32VDC via a control switch.

When wiring to the auxiliary terminal block it is recommended that

proper boot-lace or ferrule type crimp connectors are used (see below).

The terminating tunnels in the auxiliary terminal blocks are a cage type

and do not need excessive force to make good contact. Do not over-

tighten the terminal screw.

12m

m

MAX

5.0-6.0mm

COPPER LUG BOOT-LACE FERRULE

4.0mm

diameter

MAX

2.0mm

diameter

MAX

INPUT AUX.

+24V –0V

RA

+24V-0V

OUTPUT

INPUT AUX.

+24V –0V

RA

+24V-0V

OUTPUT

8

Step 2 – Changing Output Setting

Press the SET button again to scroll through the display incrementally to select the desired

setting for your specifi c application as follows:

• For use as a power conditioner the output setting can be adjusted between 24.0V and 28.0V in

1V increments on the OUTPUT VOLTS bar display. It is important to ensure

the equipment connected to the output of the SPCi is correctly rated for the voltage you have

selected.

• For use as a battery charger the CHARGE icon must be selected which changes the output

from a continuous DC regulated supply to a special two stage charging protocol (sample curve

data available upon request). The two stages consist of a boost cycle of 28.8V and a fl oat cycle of

27.2V. These voltages are not adjustable.

Step 3 – Saving Output Setting

Simply release the SET button at the desired point and the output will adjust automatically to

the new setting after a few moments. The OUTPUT icon will pulse rapidly and then disappear

indicating the setting has been successfully saved.

The new setting will be displayed for a further 10 seconds as confi rmation of the new setting. The

selected setting will now be permanently memorised but can be changed at any time if necessary.

NOTE: The factory default settings can be reset at any time. Press and hold the SET button

for 30 seconds until all icons on the operator interface display are illuminated (pulsing).

Release the SET button and the factory default settings will be restored at which point the

illuminated icons will disappear.

OPERATION

7

OPERATION

OPERATION

INITIAL SET-UP

One of the major features of the Gen II SPCi is the ability to adjust

the output voltage when used as a conditioner or alternatively,

select a two stage voltage curve when used as a battery charger

(lead acid only).

As detailed in the wiring section, the output voltage of the SPCi

should ideally be selected before connecting the output supply

to the 24V equipment or battery. The SPCi output can however,

be adjusted at any time providing there is power on the input and

NO load on the output.

The output voltage cannot be adjusted in battery charging mode.

IMPORTANT: A battery should only be connected to the SPCi in

battery charging mode and NOT in power conditioner mode.

Step 1 – Enter Output Set-Up Mode

To adjust the output voltage press and hold the SET button

for 5 seconds until the 5 bars of the OUTPUT VOLTS indicator

and the CHARGE icon are illuminated

intermittently (fl ashing).

At this point release the SET button . The OUTPUT icon

and the factory default voltage setting of 26.0V is displayed on

the OUTPUT VOLTS indicator .

INPUT AUX.

+24V –0V

RA

+24V-0V

OUTPUT

INPUT AUX.

+24V –0V

RA

+24V-0V

OUTPUT

9

OPERATION

EXTENDED FEATURES

The GEN II SPCi has a range of optional features which can be

utilised for control and monitoring purposes.

These functions are enabled through the use of the auxiliary

terminal connections. This is a Euro style terminal block located

between the input and output terminals of the SPCi.

The Euro style terminal block is a high quality two pole connector

used to terminate separate remote monitoring and control or

auxiliary functions. There are no ferrous components in the

terminal block so there is much less risk of corrosion which results

in poor contact.

Please refer pages 14-15 for schematics of the various wiring

circuits available.

External Alarm Output

This output (terminal A) is used for remote monitoring of the pre-

emptive and shutdown alarms of the SPCi. Subsequently any alarm

condition displayed on the operator interface display of the SPCi can

also be remotely monitored i.e. cooling fan fault, unit overheating,

low input voltage, output overload or short circuit.

Generally the output would be connected to a remote sounder/indicator but can also be used to activate a

relay coil to switch a larger warning device. It is important to note that the maximum power of the Alarm

output is limited to 250mA @ input voltage i.e. 24VDC nominal.

INPUT AUX.

+24V –0V

RA

+24V-0V

OUTPUT

INPUT AUX.

+24V –0V

RA

+24V-0V

OUTPUT

10

OPERATION

Remote Switching Input

The SPCi has a special isolation feature which allows the unit to be remotely turned on/off by using

a simple (N/O) switch to isolate the output. The switch can be in the form of any normally open (N/O)

latching device i.e. toggle, ignition, push-button, etc.

The remote isolation circuit is activated by using the R terminal as the input signal. This circuit is

switched via any 8-32VDC source that is independent of the output side of the SPCi. For example the

feed can be connected directly to the +24VDC input terminal of the SPCi or from a remote source more

conveniently located to the control switch if desired. This control feature can be utilised in different ways

including the following:

• For safety or convenience purposes it is quite often necessary, for example, to isolate all equipment

when the ignition is turned off in a vehicle. In this instance any equipment connected to the 24VDC

output of the SPCi is immediately disconnected when the ignition switch is turned off and the key

removed.

• The SPCi can be used as a fully automatic switching device where there is a requirement to switch

24VDC equipment via a 24VDC source. For example, a fl oat switch or daylight switch can be connected

via the remote input terminal and used to switch the output of the SPCi on or off automatically.

The Remote input requires a trigger voltage of 8-32VDC to activate the internal control circuit. This is

signal current (<5mA) only so the terminal can be wired with extra low power control or data cable.

NOTE: In the event the Remote (R) terminal is connected, the SPCi will memorise the connection, even

if the input supply is disconnected. This is a requirement in order for the function to operate correctly.

Should it be necessary to discontinue the use of this function, a full system reset will need to be

performed. Isolate the 24V input to the SPCi. Remove the wire connected to the Remote (R) terminal.

Re-apply the 24V supply – the POWER Icon does not illuminate. Press and hold the SET button

until the POWER icon illuminates (this will take approximately 1 minute). The SPCi is now operational

and in standby mode again.

12

SCHEMATICS

POWER CONDITIONER

Parallel Installation

Output voltage setting MUST be the same for each unit connected in parallel.

INPUT AUX.

+24V –0V

RA

+24V-0V

OUTPUT INPUT AUX.

+24V –0V

RA

+24V-0V

OUTPUT

+–

+–

12V

12V

FUSE

FUSE

24V nominal

24V DC EQUIPMENT

11

SCHEMATICS

POWER CONDITIONER

Standard Installation

INPUT AUX.

+24V –0V

RA

+24V-0V

OUTPUT

+–

+–

12V

24V DC EQUIPMENT

12V

FUSE

24V nominal

SCHEMATICS

13

SCHEMATICS

BATTERY CHARGER

Standard Installation

INPUT AUX.

+24V –0V

RA

+24V-0V

OUTPUT

+–

+–

12V

12V

FUSE

24V nominal

+

–

+–

12V

12V

14

HEADINGSCHEMATICS

AUXILIARY

External Alarm Output

AUXILIARY

Remote Switching – manual control

INPUT AUX.

+24V –0V

RA

+24V-0V

OUTPUT

RELAY

INDICATOR

BUZZERMUTE SWITCH

(OPTIONAL)

INPUT AUX.

+24V –0V

RA

+24V-0V

OUTPUT

OUTPUT REMOTE SWITCH

16

OPERATOR INTERFACE

INTRODUCTION

The operator interface panel is a new and innovative introduction to the second generation SPCi Maxi

series. This component allows specifi c control functions to aid the installer/operator in addition to

monitoring the status of the unit. The specifi c functions of the operator interface are as follows:

• User selectable voltage output from 24.0V to 28.0V in 1.0V increments to allow for voltage sensitive

equipment or voltage drop over long distances. This is factory set to 26.0V but can be changed at any

time and permanently saved in a non-volatile memory.

• A separate output function which can be selected for charging an auxiliary 24V battery connected

to the output. This automatic 2 stage curve features boost and fl oat modes to reliably maintain a

standard lead acid battery.

• A unique output load indicator which displays the load connected to the output (including overload) in

percentage terms. This indicator is a valuable tool and can be displayed at any time at the push of a

button.

• Useful pre-emptive warning of various fault conditions such as overload, over temperature, low input

voltage and low output voltage (battery charging mode only) prior to shutdown. These alarm functions

can be output for remote monitoring.

• Shutdown protection for critical fault conditions such as overload, over temperature, low input

voltage, fan failure and short circuit of output. These alarm functions can be output for remote

monitoring.

• Resetting of factory defaults at the push of a button.

15

HEADINGSCHEMATICS

AUXILIARY

Remote Switching –

automatic control

AUXILIARY

Remote Switching – with

ignition switch control

INPUT AUX.

+24V –0V

RA

+24V-0V

OUTPUT

RELAY

FLOAT SWITCH + TO IGNITION

+ IGNITION SWITCH SUPPLY

INPUT AUX.

+24V –0V

RA

+24V-0V

OUTPUT

17

OPERATOR INTERFACE

POWER ICON

The POWER indicator icon (heart) is illuminated

intermittently (pulsing green) under normal operating

conditions. No other icons or indicators illuminate in this

mode if there are no fault conditions. If a remote control

switch is connected it must be in the ‘on’ position for the

POWER icon to indicate.

FAN ICON

The FAN indicator icon displays a fault condition in relation

to the internal cooling fan of the SPCi. In this condition

the FAN icon is illuminated continuously (steady red) and

the alarm output is activated (to external warning device

if connected). The SPCi will continue to operate in this

condition providing the temperature does not escalate

to shutdown mode. The alarm condition is self-resetting

should the fault condition revert to normal. Cooling

fan failure can be as a result of burn-out, obstruction,

disconnection, etc (see troubleshooting guide)

18

OPERATOR INTERFACE

TEMP ICON

The TEMP indicator icon displays two possible fault

conditions in relation to the operating temperature of the

SPCi, details as follows:

1. Pre-emptive alarm condition.

The TEMP icon is illuminated intermittently (pulsing

red) and the alarm output is activated (to external

warning device if connected). In this condition the SPCi

internal temperature is rising and exceeding factory

preset level. The unit will continue to operate in this

condition providing the temperature does not escalate

to shutdown mode. The alarm condition is self-resetting

should the fault condition revert to normal.

2. Shutdown alarm condition.

The TEMP icon is illuminated continuously (steady red)

and the alarm output is activated (to external warning

device if connected).

In this condition the SPCi internal temperature has risen

above the safe operating level. The unit will shut down

and no output is available until such time as the problem

is rectifi ed. The alarm condition is self-resetting should

the fault condition revert to normal.

20

OPERATOR INTERFACE

OUTPUT ICON

The OUTPUT indicator icon displays fi ve possible fault

conditions in relation to the OUTPUT (24V) voltage supply

to the SPCi, details as follows:

1. Pre-emptive alarm condition.

The OUTPUT icon is illuminated intermittently (pulsing

red) and the alarm output is activated (to external

warning device if connected). In this condition the SPCi

output (24V) is either:

– Over loaded intermittently (>100% but <125% of

continuous rating of SPCi). The unit will continue to

operate in this condition providing the overload does

not escalate to shutdown mode. The alarm condition

is self-resetting should the fault condition revert

to normal. The load bar indicator will also indicate

amber (125%) in this condition.

– Low voltage (charge mode only). In this condition

the SPCi output voltage is falling below factory

preset level. The unit will continue to operate in

this condition providing the voltage does not fall

to shutdown mode. The alarm condition is self-

resetting should the fault condition revert to normal.

19

OPERATOR INTERFACE

INPUT ICON

The INPUT indicator icon displays two possible fault

conditions in relation to the input (24V) voltage supply to the

SPCi, details as follows:

1. Pre-emptive alarm condition.

The INPUT icon is illuminated intermittently (pulsing red)

and the alarm output is activated (to external warning

device if connected). In this condition the SPCi input

voltage is falling below factory preset level. The unit will

continue to operate in this condition providing the voltage

does not fall to shutdown mode. The alarm condition is

self-resetting should the fault condition revert to normal.

2. Shutdown alarm condition.

The INPUT icon is illuminated continuously (steady red)

and the alarm output is activated (to external warning

device if connected). In this condition the SPCi input

voltage has fallen below the permissible minimum

operating level. The unit will shut down and no output

is available until such time as the problem is rectifi ed.

The alarm condition is self-resetting should the fault

condition revert to normal.

21

OPERATOR INTERFACE

2. Shutdown alarm condition.

The OUTPUT icon is illuminated continuously

(steady red) and the alarm output is activated.

In this condition the SPCi output is either:

– Over loaded continuously (>125% of continuous

rating of SPCi). The unit will shut down and

no output is available until such time as the

problem is rectifi ed. The alarm condition is

self-resetting should the fault condition revert to

normal.

– Short circuited. The unit will shut down and

no output is available until such time as the

problem is rectifi ed. The alarm condition is

self-resetting should the fault condition revert to

normal.

– Low voltage (charge mode only). In this

condition the SPCi output voltage has fallen

below the permissible minimum operating level.

The unit will shut down and no output is available

until such time as the problem is rectifi ed. The

alarm condition is self-resetting should the fault

condition revert to normal.

22

OPERATOR INTERFACE

CHARGE ICON

In the event the battery charging (24V) mode is

selected (see set-up instructions) the CHARGE icon

is permanently illuminated in addition to the normal

POWER indicator icon. The charging mode is indicated in

two possible states:

– The CHARGE icon is illuminated intermittently

(pulsing amber). In this state the battery charging

output is in boost mode (stage 1) and operating

normally.

– The CHARGE icon is illuminated continuously (steady

amber). In this state the battery charging output is in

fl oat mode (stage 2) and operating normally.

24

TROUBLESHOOTING

INDICATION ICON STATUS CAUSE REMEDY

POWER icon

Illuminated

(pulsing green).

The SPCi is

operating

normally.

N/A. N/A.

POWER icon

not illuminated.

The SPCi is not

in service.

No 24VDC supply available

at input terminals.

Remote isolation control

may be enabled.

Unit has failed due to internal fault.

Check input voltage supply i.e.

connection and/or fuse.

Turn on remote isolation switch or

perform system reset (see page 11).

Return to vendor for servicing.

TEMP icon

illuminated

(pulsing red).

The SPCi is

overheating.

Excessive environmental

temperature.

Ventilated end cap is

blocked or obstructed.

Cooling fan is not operating

(FAN icon illuminated).

Re-locate SPCi to cooler location.

Remove blockage or obstruction to

enable heat to ventilate (exhaust).

See FAN icon fault fi nding

indication (above).

TEMP icon

illuminated

(steady red).

The SPCi has

shutdown due

to overheating.

Excessive environmental

temperature

Ventilated end cap is

blocked or obstructed

Cooling fan is not operating

(FAN icon illuminated)

SPCi has been continually

overloaded to temperature

shutdown point

Re-locate SPCi to cooler location

Remove blockage or obstruction to

enable heat to ventilate (exhaust)

See FAN icon fault fi nding

indication (above).

Rectify overload/short

circuit condition.

23

OPERATOR INTERFACE

OUTPUT LOAD INDICATOR

The OUTPUT LOAD indicator is used to display the value of

the load connected to the 24V output. The indicator consists

of fi ve LED bars from 25 to 125% (four green and one amber).

Push SET button momentarily to display the load in percentage

terms on the output. The percentage is based on the rating

of the SPCi. Continuous load should not exceed 100% of the

maximum rating of the SPCi specifi cation. In normal mode

only the green bars will be illuminated continuously (steady).

If the unit is overloaded the amber bar will be illuminated

continuously (steady) indicating 125% of load in addition to the

OUTPUT warning indicator. The display will indicate for 60

seconds before turning off automatically.

OUTPUT VOLTS INDICATOR

The OUTPUT VOLTS indicator is used to display the user

selected voltage of the SPCi (see set-up instructions). The

indicator consists of 5 LED bars from 24.0V to 28.0V in 1.0V

increments. The fi rst four bars are illuminated green and

the fi fth amber. The factory default setting is 26.0V which will

indicate for 10 seconds when powered up from the 24VDC

supply. If the output voltage setting has been changed the

new setting will be displayed each time the unit is powered

up. The display will indicate for 10 seconds before turning off

automatically.

25

TROUBLESHOOTING

INDICATION ICON STATUS CAUSE REMEDY

FAN icon

Illuminated

(steady red).

The SPCi cooling

fan has ceased

operating.

Cooling fan has failed.

Cooling fan is obstructed.

Return to vendor for servicing.

Check ventilated end cap for any

visible obstruction and remove/rectify.

INPUT icon

illuminated

(pulsing red).

The SPCi is

sensing low

input voltage.

Input voltage is falling or dipping

towards the factory preset limit. Check input supply voltage.

INPUT icon

illuminated

(steady red).

The SPCi has

shutdown due to

low input voltage.

Input voltage has fallen below

the factory preset limit. Check input supply voltage.

OUTPUT icon

illuminated

(pulsing red).

The SPCi

is being

overloaded.

Output current is exceeding

the continuous load rating.

Output voltage (charge mode

only) is falling or dipping towards

the factory preset limit.

Reduce load on output.

Check condition and/or state of

24V battery connected to output.

OUTPUT icon

illuminated

(steady red).

The SPCi has

shutdown due

to overload or

short circuit.

Output current has exceeded

the maximum load rating.

Output supply is short circuited.

Output voltage (charge mode only)

has fallen below factory preset limit.

Reduce load on output.

Check for short circuits on

output and rectify.

Check condition and/or state of

24V battery connected to output.

OVERLOAD

icon illuminated

(pulsing amber).

The SPCi

is being

overloaded.

Output current is exceeding

the continuous load rating. Reduce load on output.

26

INTERVOLT SPCi GEN II SERIES SPCi242410G2 SPCi242420G2

Continuous Load Rating @ 40°C 10 Amps 20 Amps

Intermittent Load Rating @ 40°C *

(applicable in Power Conditioner mode only)

<125% <125%

Peak Load Rating @ 40°C **

(applicable in Power Conditioner mode only)

125% 125%

Input Voltage Range 20 - 33 VDC initial (will dip to 17V during operation)

Output Voltage – in Power Conditioner Mode User adjustable 24.0V to 28.0V in 1.0V increments

(factory default set at 26.0V).

Output Voltage – In Battery Charging Mode 2 Stage – boost 28.8V, fl oat 27.2V

Standby current draw 85 mA nominal

Power Conversion Effi ciency @ 25°C Typically 91%

Output ripple Less than 20 mV Peak to Peak

Operating Temperature Ideally -25°C to + 50°C

Operating Humidity Ideally less than 90%

Enclosure material 6063-T5 aluminium dye anodised

Enclosure End Caps Injection moulded electrical grade ABS/PC plastic

Diagnostics Custom operator interface (see manual for full description)

SPECIFICATIONS

28

SPECIFICATIONS

W

H

L

MODEL Length Width Height

SPCi242410G2 170mm 110mm 55mm

SPCi242420G2 230mm 110mm 55mm

27

INTERVOLT SPCi GEN II SERIES SPCi242410G2 SPCi242420G2

Transient Voltage Protection Filtering - Purpose designed circuit

Over Load/Short Circuit Protection Shutdown – Current sensing circuit (automatic reset)

Input Under Voltage Protection Shutdown – Voltage sensing circuit (automatic reset)

Over Temperature Protection Shutdown – Temperature sensing circuit (automatic reset)

Negative Disconnect Protection Shutdown – Voltage sensing circuit (automatic reset)

Output Over Voltage Protection*** Internal Fuse – Zener crowbar circuit (not user serviceable)

Input Reverse Polarity Protection Internal Fuse – Diode bypass circuit (not user serviceable)

Termination Screw Terminal – M5 with 304 SS Combination screw

Conformity EMC – IEC 61204-3 and AS/NZS CISPR 11 Group 1, Class B

Certifi cation EMC – Australian C Tick mark and European CE mark

Length Overall 170mm 230mm

Width Overall 110mm 110mm

Height Overall 55mm 55mm

Weight 830 grams 1150 grams

* Based on a 50% duty cycle at 5 minute intervals over and above the continuous load rating.

** Based on a peak surge rating of 5 seconds over and above the continuous load rating.

*** Battery charger mode only

SPECIFICATIONS

29

interVOLT products are warranted for a period of 24 months against faulty materials and/or

workmanship from date of purchase by the end user subject to proof of purchase. In the event proof of

purchase is not provided, and at the discretion of the manufacturer, the warranty shall be 24 months

from manufacturer’s date of sale to the merchant from whom the product was purchased. Intervolt’s 24

month warranty is subject to the following terms and conditions:

The goods must be installed and operated in accordance with the manufacturer’s recommendations and

instructions set out within this booklet.

In the event of a claim the goods are to be returned to the original point of purchase with a copy of the

merchant invoice or the relevant merchant invoice number.

In the event of a claim any associated expenses including diagnosis, removal, and/or installation of the

goods is the responsibility of the client including any freight costs.

The warranty shall be void where the goods have been used for a purpose for which they are not

intended, or altered in any way that is detrimental, or opened or tampered with by an unauthorised

party, or damaged by mechanical abuse, or contaminated by water or other substances, or damaged by

incorrect application.

Save and except for the express warranty set out above and to the maximum extent permitted by law,

all conditions and warranties which may at any time be implied by the common law, Trade Practices

Act, Fair Trading Act or any other State or Federal Act are excluded. To the extent that these cannot be

excluded and where the law permits, the manufacturer in respect of any such condition or warranty shall

be limited at their option to the repair or the replacement of the goods or the supply of equivalent goods

or refunding the cost of the goods.

WARRANTY POLICY

Other manuals for Gen II Maxi Series

1

This manual suits for next models

2

Table of contents

Popular AC Power Distribution manuals by other brands

Furman

Furman PL-8 owner's manual

Pacific Power Source

Pacific Power Source AMX Series Operation manual

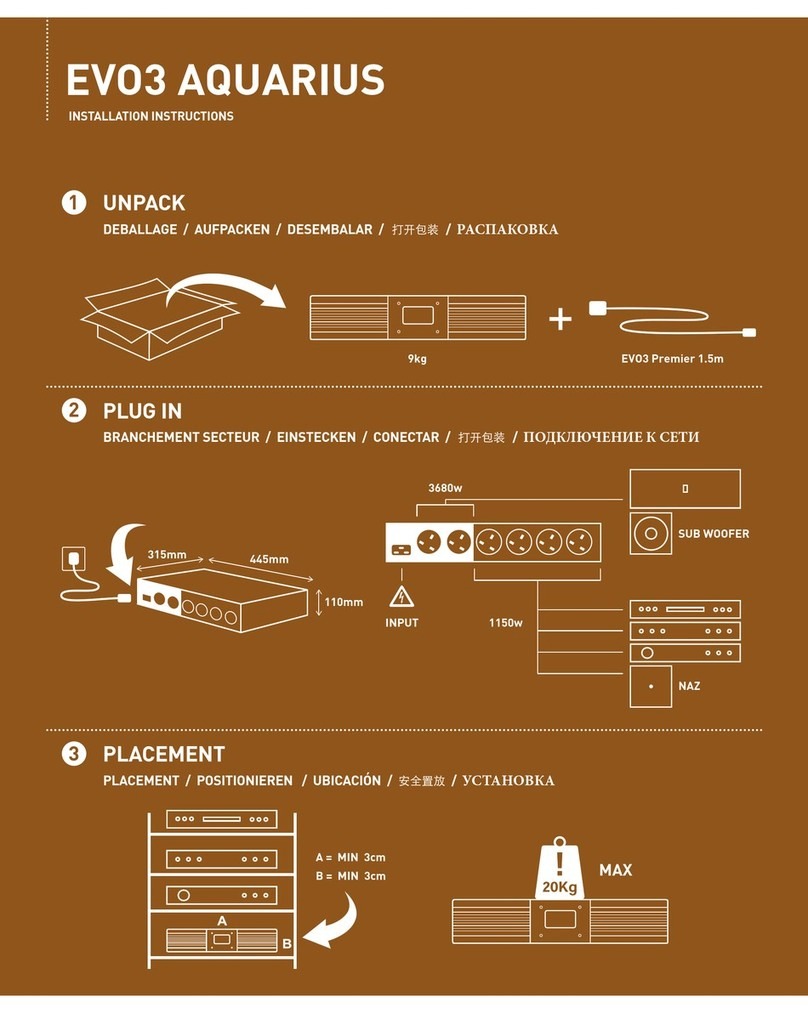

Isotek

Isotek EVO3 AQUARIUS installation instructions

Keysight Technologies

Keysight Technologies AC6801B Operating and service guide

Furman

Furman SPR-16E i owner's manual

PS Audio

PS Audio PerfectWave PowerBase Owner reference guide