22

22

2

CONTENTSCONTENTS

CONTENTSCONTENTS

CONTENTS

GENERAL RECOMMENDGENERAL RECOMMEND

GENERAL RECOMMENDGENERAL RECOMMEND

GENERAL RECOMMENDAA

AA

ATIONSTIONS

TIONSTIONS

TIONS........................................................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................................................

.................................................................................................................................... 33

33

3

SAFETY DIRECTIONS ............................................................................................................................................................................................................................. 3

WARNING ............................................................................................................................................................................................................................................ 3

PRESENTPRESENT

PRESENTPRESENT

PRESENTAA

AA

ATIONTION

TIONTION

TION ....................................................................................................................................................................................................................................................................................................................................

....................................................................................................................................................................................................................................................................................................................................

.................................................................................................................................................................. 44

44

4

WARRANTYWARRANTY

WARRANTYWARRANTY

WARRANTY..................................................................................................................................................................................................................................................................................................................................................

..................................................................................................................................................................................................................................................................................................................................................

......................................................................................................................................................................... 44

44

4

EQUIPMENT SAFETY DEQUIPMENT SAFETY D

EQUIPMENT SAFETY DEQUIPMENT SAFETY D

EQUIPMENT SAFETY DAA

AA

ATT

TT

TAA

AA

A............................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................

.............................................................................................................................................. 55

55

5

INSPECTION AND STINSPECTION AND ST

INSPECTION AND STINSPECTION AND ST

INSPECTION AND STORAORA

ORAORA

ORAGEGE

GEGE

GE ....................................................................................................................................................................................................................................................................................

....................................................................................................................................................................................................................................................................................

.......................................................................................................................................... 66

66

6

CONTENTS OF PCONTENTS OF P

CONTENTS OF PCONTENTS OF P

CONTENTS OF PARCELARCEL

ARCELARCEL

ARCEL ......................................................................................................................................................................................................................................................................................................

......................................................................................................................................................................................................................................................................................................

................................................................................................................................................... 66

66

6

PRODUCT OFFER AND VARIANTSPRODUCT OFFER AND VARIANTS

PRODUCT OFFER AND VARIANTSPRODUCT OFFER AND VARIANTS

PRODUCT OFFER AND VARIANTS ................................................................................................................................................................................................................................................................

................................................................................................................................................................................................................................................................

................................................................................................................................66

66

6

DESCRIPTIONDESCRIPTION

DESCRIPTIONDESCRIPTION

DESCRIPTION........................................................................................................................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................................................................................................................

.................................................................................................................................................................... 77

77

7

CABINET AND FRAME ........................................................................................................................................................................................................................... 7

COMPRESSORS .................................................................................................................................................................................................................................... 7

EVAPORATORS ..................................................................................................................................................................................................................................... 7

CONDENSER BATTERIES ........................................................................................................................................................................................................................ 7

CONDENSER FANS ............................................................................................................................................................................................................................... 7

FAN CONTROLCOMMANDE DES VENTILATEURS ................................................................................................................................................................................... 7

REFRIGERATING CIRCUIT ..................................................................................................................................................................................................................... 7

POWER SUPPLY AND CONTROL BOX ..................................................................................................................................................................................................... 7

TECHNICAL SPECIFICATECHNICAL SPECIFICA

TECHNICAL SPECIFICATECHNICAL SPECIFICA

TECHNICAL SPECIFICATIONSTIONS

TIONSTIONS

TIONS................................................................................................................................................................................................................................................................................

................................................................................................................................................................................................................................................................................

........................................................................................................................................ 88

88

8

REFRIGERANT CHARGE ........................................................................................................................................................................................................................ 8

ÉLECTRIC SPÉCIFICATIONS ................................................................................................................................................................................................................... 8

AERAULIC TECHNICAL SPECIFICATIONS ............................................................................................................................................................................................... 8

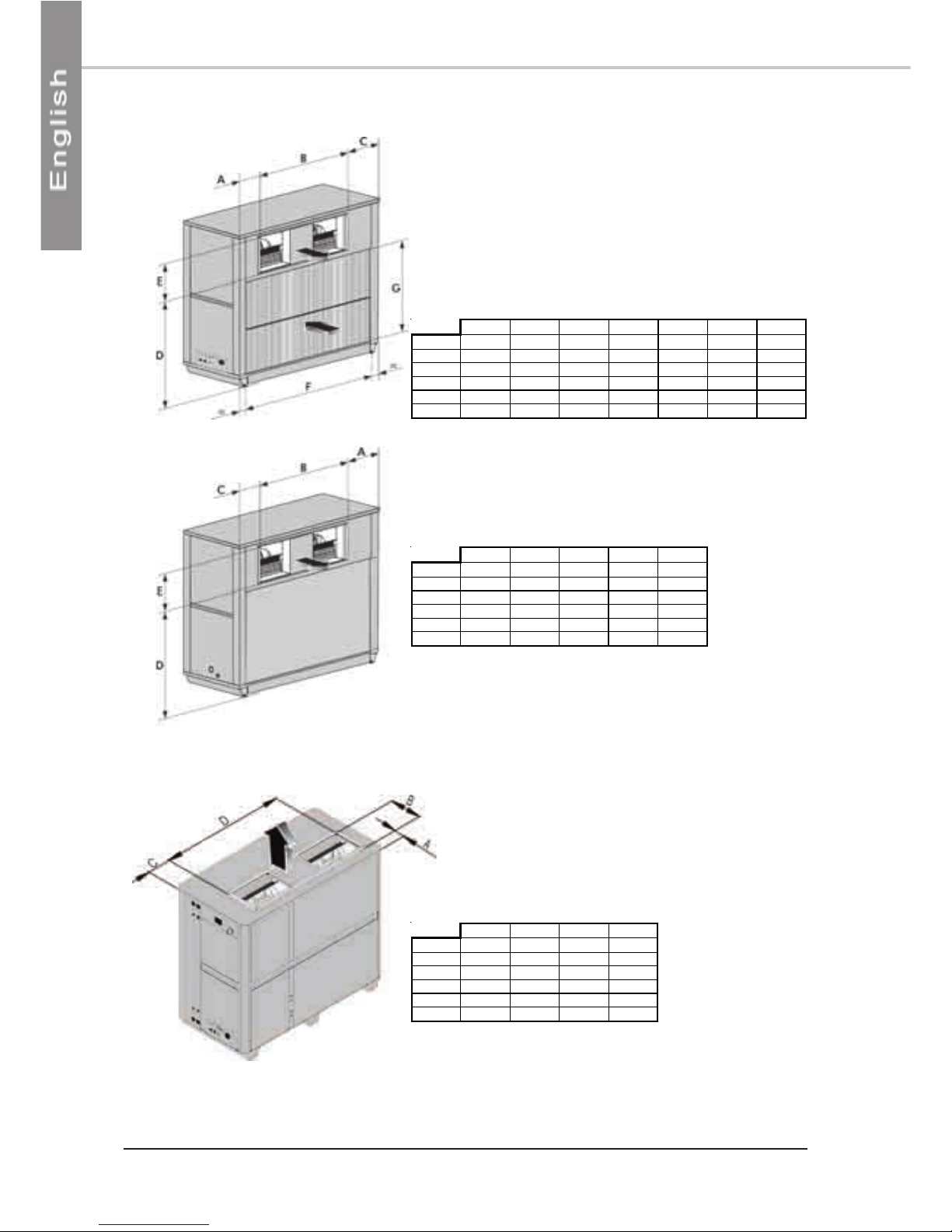

DIMENSIONSDIMENSIONS

DIMENSIONSDIMENSIONS

DIMENSIONS ..........................................................................................................................................................................................................................................................................................................................................

..........................................................................................................................................................................................................................................................................................................................................

..................................................................................................................................................................... 99

99

9

HANDLINGHANDLING

HANDLINGHANDLING

HANDLING..................................................................................................................................................................................................................................................................................................................................................

..................................................................................................................................................................................................................................................................................................................................................

......................................................................................................................................................................... 99

99

9

HANDLINGHANDLING

HANDLINGHANDLING

HANDLING..................................................................................................................................................................................................................................................................................................................................................

..................................................................................................................................................................................................................................................................................................................................................

......................................................................................................................................................................... 99

99

9

WEIGHT ............................................................................................................................................................................................................................................... 9

DUCT OUTLET DIMENSIONSDUCT OUTLET DIMENSIONS

DUCT OUTLET DIMENSIONSDUCT OUTLET DIMENSIONS

DUCT OUTLET DIMENSIONS................................................................................................................................................................................................................................................................................

................................................................................................................................................................................................................................................................................

........................................................................................................................................ 1010

1010

10

STANDARD BLOWING ......................................................................................................................................................................................................................... 10

REAR BLOWING .................................................................................................................................................................................................................................. 10

VERTICAL BLOWING ............................................................................................................................................................................................................................ 10

FLFL

FLFL

FLOW RAOW RA

OW RAOW RA

OW RATE / EXTERNAL STTE / EXTERNAL ST

TE / EXTERNAL STTE / EXTERNAL ST

TE / EXTERNAL STAA

AA

ATIC PRESSURETIC PRESSURE

TIC PRESSURETIC PRESSURE

TIC PRESSURE................................................................................................................................................................................................................................

................................................................................................................................................................................................................................

................................................................................................................ 1111

1111

11

INSTINST

INSTINST

INSTALLAALLA

ALLAALLA

ALLATIONTION

TIONTION

TION ..................................................................................................................................................................................................................................................................................................................................

..................................................................................................................................................................................................................................................................................................................................

................................................................................................................................................................. 1111

1111

11

CLEARANCE ....................................................................................................................................................................................................................................... 11

LOCATING THE UNIT ......................................................................................................................................................................................................................... 11

DE-ICING WATER DRAINAGE (AQCH MODELS ONLY) ......................................................................................................................................................................... 12

ANTI-VIBRATION SPRING-MOUNTED PADS INSTALLATION ................................................................................................................................................................... 12

HYDRAULIC CONNECTIONSHYDRAULIC CONNECTIONS

HYDRAULIC CONNECTIONSHYDRAULIC CONNECTIONS

HYDRAULIC CONNECTIONS ..............................................................................................................................................................................................................................................................................

..............................................................................................................................................................................................................................................................................

....................................................................................................................................... 1212

1212

12

HYDRAULIC CIRCUIT DIAGRAM .......................................................................................................................................................................................................... 13

WIRING DIAGRAM AND LEGENDWIRING DIAGRAM AND LEGEND

WIRING DIAGRAM AND LEGENDWIRING DIAGRAM AND LEGEND

WIRING DIAGRAM AND LEGEND ..............................................................................................................................................................................................................................................................

..............................................................................................................................................................................................................................................................

............................................................................................................................... 1414

1414

14

WIRING DIAGRAM ............................................................................................................................................................................................................................. 14

LEGEND ............................................................................................................................................................................................................................................. 14

POWER SUPPLY ........................................................................................................................................................................................................................ 14

WIRING DIAGRAM KEY DESCRIPTIONS .................................................................................................................................................................................... 15

COOLING ................................................................................................................................................................................................................... 15

FAN MOTOR AND THEIR EQUIPMENT .......................................................................................................................................................................... 15

WATER CIRCUIT ........................................................................................................................................................................................................... 15

CONTROL AND REGULATION ..................................................................................................................................................................................... 16

NOT PROVIDED : ......................................................................................................................................................................................................... 16

RANGE AND SETTINGS OF THEMAL PROTECTION / NOMINAL INTENSITY OF THE CONTACTORS (CLASSE AC3) ...................................................................... 16

PRESSOSTATS SETTING ........................................................................................................................................................................................................... 16

MISCELLANEOUS .................................................................................................................................................................................................................... 16

ELECTRICAL CONNECTIONSELECTRICAL CONNECTIONS

ELECTRICAL CONNECTIONSELECTRICAL CONNECTIONS

ELECTRICAL CONNECTIONS ..............................................................................................................................................................................................................................................................................

..............................................................................................................................................................................................................................................................................

....................................................................................................................................... 1717

1717

17

COMMISSIONINGCOMMISSIONING

COMMISSIONINGCOMMISSIONING

COMMISSIONING ....................................................................................................................................................................................................................................................................................................................

....................................................................................................................................................................................................................................................................................................................

.......................................................................................................................................................... 1919

1919

19

PRE-START CHECK LIST ........................................................................................................................................................................................................................ 19

ELECTRICAL CHECK ................................................................................................................................................................................................................ 19

HYDRAULIC CHECKS .............................................................................................................................................................................................................. 19

VISUAL CHECK ........................................................................................................................................................................................................................ 19

DUCTING .............................................................................................................................................................................................................................. 19

OPERATING CHECK LIST .................................................................................................................................................................................................................... 20

GENERAL ................................................................................................................................................................................................................................ 20

PHASE ROTATION PROTECTION .............................................................................................................................................................................................. 20

ELECTRICAL ............................................................................................................................................................................................................................. 20

SET POINTS ................................................................................................................................................................................................................. 20

OPERATING VOLTAGE: ................................................................................................................................................................................................. 20

CONTROL ................................................................................................................................................................................................................... 20

FAN & DRIVE ........................................................................................................................................................................................................................... 20

COMPRESSOR AND REFRIGERATION SYSTEM ........................................................................................................................................................................... 20

HYDRAULIC CIRCUIT ............................................................................................................................................................................................................... 21

FINAL TFINAL T

FINAL TFINAL T

FINAL TASKSASKS

ASKSASKS

ASKS..........................................................................................................................................................................................................................................................................................................................................

..........................................................................................................................................................................................................................................................................................................................................

..................................................................................................................................................................... 2222

2222

22

IN-IN-

IN-IN-

IN-WARRANTY RETURN MAWARRANTY RETURN MA

WARRANTY RETURN MAWARRANTY RETURN MA

WARRANTY RETURN MATERIAL PROCEDURETERIAL PROCEDURE

TERIAL PROCEDURETERIAL PROCEDURE

TERIAL PROCEDURE ............................................................................................................................................................................................................

............................................................................................................................................................................................................

...................................................................................................... 2222

2222

22

SERVICE AND SPSERVICE AND SP

SERVICE AND SPSERVICE AND SP

SERVICE AND SPARE PARARE PAR

ARE PARARE PAR

ARE PARTS ORDERTS ORDER

TS ORDERTS ORDER

TS ORDER ........................................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................................

............................................................................................................................ 2222

2222

22

FINAL CHECK ......................................................................................................................................................................................................................... 22

MAINTENANCEMAINTENANCE

MAINTENANCEMAINTENANCE

MAINTENANCE................................................................................................................................................................................................................................................................................................................................

................................................................................................................................................................................................................................................................................................................................

................................................................................................................................................................ 2323

2323

23

REGULAR MAINTENANCE ................................................................................................................................................................................................................... 23

REMOVAL OF PANELS ......................................................................................................................................................................................................................... 23

FAN DRIVE SYSTEM .............................................................................................................................................................................................................................. 23

COILS ................................................................................................................................................................................................................................................ 23

ELECTRICAL ........................................................................................................................................................................................................................................ 23

REFRIGERATION ................................................................................................................................................................................................................................. 23

SERVICING CHECKLIST ....................................................................................................................................................................................................................... 24

TROUBLE SHOOTROUBLE SHOO

TROUBLE SHOOTROUBLE SHOO

TROUBLE SHOOTINGTING

TINGTING

TING ........................................................................................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................................................................................

.................................................................................................................................................... 2525

2525

25