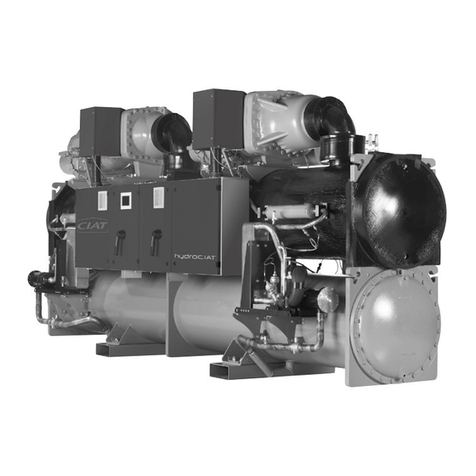

Ⱥɝɪɟɝɚɬɵ ɫɞɜɭɦɹ ɤɨɧɞɟɧɫɚɬɨɪɚɦɢ

•

••

•ȼɈȾȺ + ȼɈȾȺ : ɜɚɪɢɚɧɬ LRT

ȼɨɞɨɨɯɥɚɠɞɚɸɳɢɟ ɯɨɥɨɞɢɥɶɧɵɟ ɦɚɲɢɧɵ CIATCOOLER ɫ

ɞɜɭɦɹ ɤɨɧɞɟɧɫɚɬɨɪɚɦɢ ɫɩɪɨɟɤɬɢɪɨɜɚɧɵ ɬɚɤ ɱɬɨɛɵ

ɩɟɪɟɦɟɳɚɬɶ ɢɭɬɢɥɢɡɢɪɨɜɚɬɶ ɬɟɩɥɨ, ɤɨɬɨɪɨɟ ɨɛɵɱɧɨ ɧɟ

ɢɫɩɨɥɶɡɭɟɬɫɹ ɬɪɚɞɢɰɢɨɧɧɵɦɢ ɯɨɥɨɞɢɥɶɧɵɦɢ ɚɝɪɟɝɚɬɚɦɢ.

ȼɫɬɚɧɞɚɪɬɧɵɯ ɯɨɥɨɞɢɥɶɧɵɯ ɭɫɬɚɧɨɜɤɚɯ, ɪɚɛɨɬɚɸɳɢɯ ɧɚ

ɨɯɥɚɠɞɟɧɢɟ ɤɪɭɝɥɵɣ ɝɨɞ, ɨɬɜɨɞɢɦɨɟ ɨɬ ɨɯɥɚɠɞɚɟɦɨɣ ɫɪɟɞɵ

ɬɟɩɥɨ ɫɧɢɦɚɟɬɫɹ ɫɜɨɞɹɧɨɝɨ ɤɨɧɞɟɧɫɚɬɨɪɚ ɢɨɛɵɱɧɨ

ɜɵɛɪɚɫɵɜɚɟɬɫɹ ɜɚɬɦɨɫɮɟɪɭ ɱɟɪɟɡ ɝɪɚɞɢɪɧɸ ɢɥɢ ɫɭɯɨɣ

ɨɯɥɚɞɢɬɟɥɶ.

Ɍɟɩɥɨ ɤɨɧɞɟɧɫɢɪɭɸɳɟɝɨɫɹ ɝɚɡɚ ɦɨɠɧɚ ɭɬɢɥɢɡɢɪɨɜɚɬɶ ɜ

ɞɪɭɝɨɦ ɤɨɧɞɟɧɫɚɬɨɪɟ ɢɢɫɩɨɥɶɡɨɜɚɬɶ ɞɥɹ ɧɭɠɞ ɨɬɨɩɥɟɧɢɹ ɢ

ɝɨɪɹɱɟɝɨ ɜɨɞɨɫɧɚɛɠɟɧɢɹ.

Ɍɚɤɢɦ ɨɛɪɚɡɨɦ ɢɫɩɨɥɶɡɨɜɚɧɢɟ ɬɟɩɥɚ ɤɨɧɞɟɧɫɢɪɭɸɳɟɝɨɫɹ

ɝɚɡɚ ɫɩɨɫɨɛɫɬɜɭɟɬ ɷɧɟɪɝɨɫɛɟɪɟɠɟɧɢɸ ɜɦɟɫɬɨ ɬɨɝɨ, ɱɬɨɛɵ

ɛɵɬɶ ɛɟɫɩɨɥɟɡɧɨ ɪɚɫɫɟɹɧɧɵɦ ɩɨɫɥɟ ɩɪɨɯɨɠɞɟɧɢɹ ɱɟɪɟɡ

ɜɨɡɞɭɲɧɵɣ ɤɨɧɞɟɧɫɚɬɨɪ.

ȼɤɚɱɟɫɬɜɟ ɭɬɢɥɢɡɚɰɢɨɧɧɨɝɨ ɚɩɩɚɪɚɬɚ ɢɫɩɨɥɶɡɭɟɬɫɹ ɜɨɞɹɧɨɣ

ɤɨɧɞɟɧɫɚɬɨɪ, ɚɜɤɚɱɟɫɬɜɟ ɩɪɨɦɟɠɭɬɨɱɧɨɝɨ ɬɟɩɥɨɧɨɫɢɬɟɥɹ –

ɜɨɞɚ. Ɉɧɚ ɨɛɥɚɞɚɟɬ ɯɨɪɨɲɢɦɢ ɬɟɩɥɨɬɟɯɧɢɱɟɫɤɢɦɢ

ɫɜɨɣɫɬɜɚɦɢ, ɱɬɨ ɭɩɪɨɳɚɟɬ ɩɪɢɦɟɧɹɟɦɨɟ ɞɥɹ ɟɟ ɨɛɪɚɛɨɬɤɢ

ɨɛɨɪɭɞɨɜɚɧɢɟ.

•

••

•Ʉɨɧɫɬɪɭɤɰɢɹ :

ȼɨɞɹɧɨɣ ɤɨɧɞɟɧɫɚɬɨɪ + ɜɨɡɞɭɲɧɵɣ ɤɨɧɞɟɧɫɚɬɨɪ.

ɋɠɚɬɵɣ ɝɚɡɨɨɛɪɚɡɧɵɣ ɯɥɚɞɚɝɟɧɬ ɫɧɚɱɚɥɚ ɩɪɨɯɨɞɢɬ ɱɟɪɟɡ

ɜɨɞɹɧɨɣ ɤɨɧɞɟɧɫɚɬɨɪ; ɜɷɬɨɦ ɫɥɭɱɚɟ ɬɟɩɥɨɬɚ ɟɝɨ ɤɨɧɞɟɧɫɚɰɢɢ

ɩɨɥɧɨɫɬɶɸ ɭɬɢɥɢɡɢɪɭɟɬɫɹ. ɉɨɬɟɪɢ ɫɜɹɡɚɧɧɵɟ ɫ

ɩɪɨɦɟɠɭɬɨɱɧɵɦ ɨɯɥɚɠɞɟɧɢɟɦ – ɧɟɡɧɚɱɢɬɟɥɶɧɵ; ɧɚɪɭɠɧɚɹ

ɩɨɜɟɪɯɧɨɫɬɶ ɜɨɞɹɧɨɝɨ ɤɨɧɞɟɧɫɚɬɨɪɚ ɞɨɫɬɚɬɨɱɧɚ ɦɚɥɚ ɩɨ

ɫɪɚɜɧɟɧɢɸ ɫɩɨɜɟɪɯɧɨɫɬɶɸ ɜɨɡɞɭɲɧɨɝɨ ɤɨɧɞɟɧɫɚɬɨɪɚ.

ȼɫɥɭɱɚɟ ɩɪɟɤɪɚɳɟɧɢɹ ɨɬɛɨɪɚ ɬɟɩɥɚ ɨɬ ɜɨɞɹɧɨɝɨ

ɤɨɧɞɟɧɫɚɬɨɪɚ ɢɥɢ ɩɨɫɥɟ ɨɫɬɚɧɨɜɤɢ ɝɢɞɪɚɜɥɢɱɟɫɤɨɝɨ ɧɚɫɨɫɚ ɜ

ɨɛɫɥɭɠɢɜɚɟɦɨɦ ɢɦ ɝɢɞɪɨɤɨɧɬɭɪɟ ɬɟɦɩɟɪɚɬɭɪɚ ɧɟɩɨɞɜɢɠɧɨɣ

ɜɨɞɵ ɦɨɠɟɬ ɩɨɞɧɹɬɶɫɹ ɞɨ 90 °C.

Ɍɟɦɩɟɪɚɬɭɪɚ ɤɢɩɟɧɢɹ, ɧɚɯɨɞɹɳɟɣɫɹ ɩɨɞ ɞɚɜɥɟɧɢɟɦ ɜɨɞɵ

ɜɨɡɪɚɫɬɚɟɬ. ȼɡɚɦɤɧɭɬɨɦ ɝɢɞɨɤɨɧɬɭɪɟ ɧɟɬ ɨɩɚɫɧɨɫɬɢ

ɨɛɪɚɡɨɜɚɧɢɹ ɧɚɤɢɩɢ ɡɚ ɢɫɤɥɸɱɟɧɢɟɦ ɫɥɭɱɚɟɜ, ɬɪɟɛɭɸɳɢɯ ɟɝɨ

ɱɚɫɬɨɣ ɩɨɞɩɢɬɤɢ.

Ɍɚɤɨɟ ɪɟɲɟɧɢɟ ɬɪɟɛɭɟɬ ɩɨɞɤɥɸɱɟɧɢɹ ɤɝɢɞɪɨɤɨɧɬɭɪɭ

ɠɢɞɤɨɫɬɧɨɝɨ ɪɟɡɟɪɜɭɚɪɚ ɞɥɹ ɬɨɝɨ ɱɬɨɛɵ ɩɪɟɞɨɬɜɪɚɬɢɬɶ

ɩɪɨɬɟɱɤɭ ɯɥɚɞɨɧɨɫɢɬɟɥɹ ɢɡ ɢɡ-ɡɚ ɧɟɭɞɨɜɥɟɬɜɨɪɢɬɟɥɶɧɨɣ

ɪɚɛɨɬɵ ɪɚɫɲɢɪɢɬɟɥɶɧɨɝɨ ɛɚɤɚ.

•

••

•Ƚɢɞɪɨɤɨɧɬɭɪ

ɉɨɞɤɥɸɱɟɧɢɟ ɝɢɞɪɨɤɨɧɬɭɪɚ ɬɟɩɥɨɫɧɚɛɠɟɧɢɹ (ɝɨɪɹɱɚɹ ɜɨɞɚ).

ɇɚ ɝɢɞɪɨɤɨɧɬɭɪɟ ɬɟɩɥɨɫɧɚɛɠɟɧɢɹ ɧɟɨɛɯɨɞɢɦɨ

ɩɪɟɞɭɫɦɨɬɪɟɬɶ ɫɥɟɞɭɸɳɢɟ ɩɪɢɧɚɞɥɟɠɧɨɫɬɢ:

-Ⱦɜɚ ɡɚɩɨɪɧɵɯ ɤɪɚɧɚ ɞɥɹ ɨɬɤɥɸɱɟɧɢɹ ɤɨɧɞɟɧɫɚɬɨɪɚ.

-ɋɬɚɧɞɚɪɬɧɭɸ ɚɪɦɚɬɭɪɭ ɝɢɞɪɚɜɥɢɱɟɫɤɨɝɨ ɤɨɧɬɭɪɚ :

ɜɨɡɞɭɯɨɫɩɭɫɬɧɢɤɢ, ɞɪɟɧɚɠɧɵɟ ɤɪɚɧɵ ɜɧɢɠɧɢɯ ɬɨɱɤɚɯ

ɤɨɧɬɭɪɚ, ɪɚɫɲɢɪɢɬɟɥɶɧɚɹ ɟɦɤɨɫɬɶ …

•ɗɤɫɩɥɭɚɬɚɰɢɹ :

ȼɬɟɩɥɵɣ ɢɩɟɪɟɯɨɞɧɵɣ ɩɟɪɢɨɞ ɝɨɞɚ ɩɪɢ ɬɟɦɩɟɪɚɬɭɪɟ ɫɜɵɲɟ

2 ɨɋɢɩɪɢ ɨɬɫɭɬɫɬɜɢɢ ɧɟɨɛɯɨɞɢɦɨɫɬɢ ɜɝɨɪɹɱɟɣ ɜɨɞɟ

ɜɨɡɦɨɠɧɨ ɢɫɩɨɥɶɡɨɜɚɧɢɟ ɜɟɧɢɥɹɬɨɪɨɜ ɜɨɯɞɭɯɨɨɯɥɚɠɞɚɟɦɨɝɨ

ɤɨɧɞɟɫɚɬɨɪɚ ɜɮɨɪɫɢɪɨɜɚɧɧɨɦ ɪɟɠɢɦɟ, ɩɪɢ ɩɨɦɨɳɢ

ɩɟɪɟɤɥɸɱɚɬɟɥɹ, ɩɨɞɤɥɸɱɟɧɧɨɝɨ ɦɟɠɞɭ ɞɜɭɦɹ ɤɥɟɦɦɚɦɢ ɧɚ

ɤɥɟɦɦɧɨɣ ɤɨɪɨɛɤɟ ɳɢɬɚ ɭɩɪɚɜɥɟɧɢɹ; ɷɬɚ ɦɟɪɚ ɩɨɦɨɠɟɬ

ɫɧɢɡɢɬɶ ɞɚɜɥɟɧɢɟ ɤɨɧɞɟɧɫɚɰɢɢ.

ȼɞɪɭɝɢɯ ɫɥɭɱɚɹɯ ɩɪɢ ɬɟɦɩɟɪɚɬɭɪɟ ɧɚɪɭɠɧɨɝɨ ɜɨɡɞɭɯɚ ɧɢɠɟ

2 ɨɋɢɧɟɨɛɯɨɞɢɦɨɫɬɢ ɜɝɨɪɹɱɟɣ ɜɨɞɟ ɧɭɠɧɨ ɩɨɞɞɟɪɠɢɜɚɬɶ

ɞɚɜɥɟɧɢɟ ɤɨɧɞɟɧɫɚɰɢɢ ɧɚ ɬɪɟɛɭɟɦɨɦ ɭɪɨɜɧɟ ɞɥɹ ɬɨɝɨ ɱɬɨɛɵ :

-ɨɛɟɫɩɟɱɢɬɶ ɧɟɨɛɯɨɞɢɦɵɣ ɪɚɫɯɨɞ ɯɥɚɞɚɝɟɧɬɚ ɱɟɪɟɡ

ɪɟɝɭɥɹɬɨɪ ɩɨɬɨɤɚ

-ɩɨɞɝɨɬɚɜɥɢɜɚɬɶ ɝɨɪɹɱɭɸ ɜɨɞɭ ɫɩɨɞɨɝɪɟɜɨɦ ɞɨ ɬɪɟɛɭɟɦɨɣ

ɬɟɦɩɟɪɚɬɭɪɵ

Ⱦɥɹ ɭɞɨɜɥɟɬɜɨɪɟɧɢɹ ɷɬɢɯ ɞɜɭɯ ɭɫɥɨɜɢɣ ɧɟɨɛɯɨɞɢɦɨ

ɭɞɟɪɠɢɜɚɬɶ ɞɚɜɥɟɧɢɟ ɤɨɧɞɟɧɫɚɰɢɢ ɧɚ ɛɨɥɟɟ ɜɵɫɨɤɨɦ ɭɪɨɜɧɟ

ɱɟɦ ɞɚɜɥɟɧɢɟ ɩɨɞɝɨɬɨɜɥɟɧɧɨɣ ɝɨɪɹɱɟɣ ɜɨɞɵ. Ɍɚɤɨɟ ɞɚɜɥɟɧɢɟ

ɤɨɧɞɟɧɫɚɰɢɢ ɩɨɞɞɟɪɠɢɜɚɟɬɫɹ ɩɪɟɫɫɨɫɬɚɬɨɦ ɜɵɫɨɤɨɝɨ

ɞɚɜɥɟɧɢɹ, ɪɚɛɨɬɚɸɳɢɦ ɩɨɫɥɟɞɨɜɚɬɟɥɶɧɨ ɫɜɟɧɬɢɥɹɬɨɪɚɦɢ

ɤɨɧɞɟɧɫɚɬɨɪɚ.

Double condenser units.

•

••

•

WATER + WATER : Version LRT

The CIATCOOLER double condenser water chillers are

designed so as to transfer and recover the calories which are

normally utilized and rejected by the traditional units.

In a standard installation where cooling is required all year,

the calories produced by the units are usually discharged by

the air cooled condenser or by a cooling tower or a dry cooler

via a water cooled condenser.

It is possible to use the condensing gas in another condenser

to contribute to the heating process.'

In this case, the condensing gas participates directly to an

energy saving instead of being cooled without profit in the

discharge condenser.

A water cooled condenser will be used as a recovery

condenser. Water, as intermediary fluid, is easy to carry, the

on-site installation is therefore facilitated.

•

••

•

Design :

Water cooled condenser + air cooled condenser

The discharge gas passing first through the water cooled

condenser, the calories produced by the unit can be totally

recovered. The losses caused by desuperheating are

insignificant, the external surface of a water cooled condenser

being very small compared to the one of an air cooled

condenser.

In the case where the recovery circuit does not evacuate any

of the calories produced and where the circulation pump is

stopped, the circuit stagnant water can rise around 90 °C.

The water circuit being under pressure, the boiling point is

delayed. The water circuit being looped, there is no risk of

scaling, except if the circuit requires a frequent filling.

This solution does necessitate a liquid reservoir in order to

prevent an unpriming of the liquid line, therefore a faulty

supply of the expansion valve.

•

••

•

Hydraulic circuit:

- Heating circuit connection (hot water). It is necessary to

install on the heating circuit:

- 2 stop valves to permit isolation of the water-cooled

condenser.

- The accessories required for all hydraulic circuits : air vents,

drains at low points, expansion vessel...

• Operation :

In summer or mid season, above + 12 °C and when not using

hot water, it is possible to operate the air-cooled condenser

fans in forced run mode by using a switch, connected

between the 2 terminals and positioned on the electrical panel

terminal box; this will maintain a lower condensing pressure.

For the other cases, below +12 °C and with production of hot

water, it is necessary to maintain the condensing pressure at

a correct level to:

- permit a correct supply of the expansion valve

-produce hot water at the desired temperature

To meet these 2 conditions, the condensing pressure will be

kept at a higher value than the hot water outlet temperature.

This condensing pressure will be maintained by HP

pressostats operating in cascade on the condenser fans.