IV

Table of Contents

Foreword............................................................................................................................................................ I

Important Safeguards and Warnings............................................................................................................. III

1 Product Information...................................................................................................................................... 1

Product Overview ...................................................................................................................................................................... 11.1

Product Features ........................................................................................................................................................................ 21.2

1.2.1 CameraLink Line Scan Camera................................................................................................................................. 2

1.2.2 GigE Line Scan Camera............................................................................................................................................... 2

Typical Networking.................................................................................................................................................................... 21.3

Application Environment........................................................................................................................................................ 31.4

Status Indicator Lights ............................................................................................................................................................. 31.5

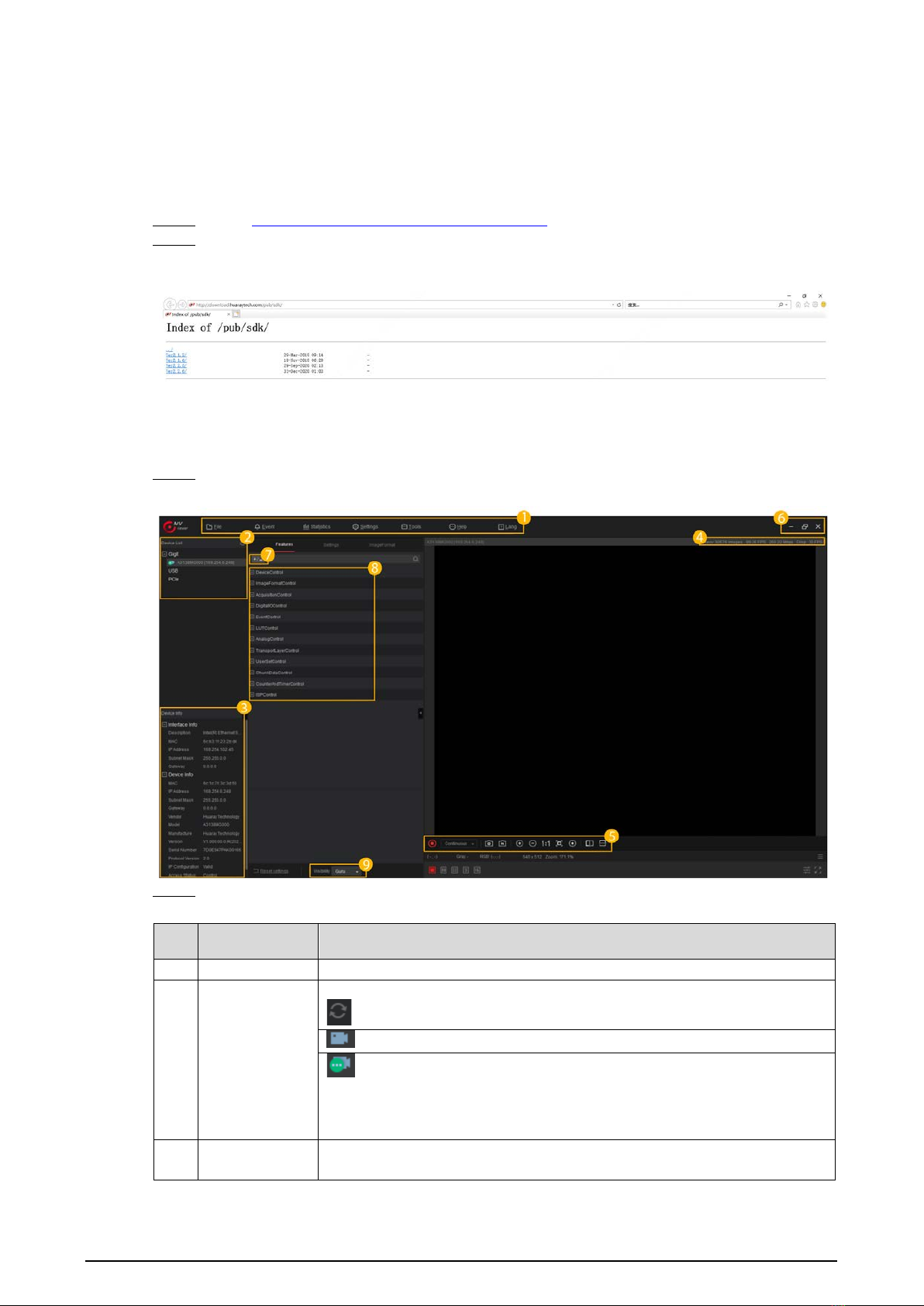

2 MV Viewer Installation and Camera Connection......................................................................................... 4

Downloading and Installing MV Viewer ............................................................................................................................ 42.1

Connecting Camera .................................................................................................................................................................. 42.2

3 Function Parameters ..................................................................................................................................... 7

Line Scan Rate ............................................................................................................................................................................. 73.1

3.1.1 Factors............................................................................................................................................................................... 7

3.1.2 Configuring Line Scan Rate....................................................................................................................................... 7

Frame Timeout ............................................................................................................................................................................ 93.2

Acquisition Mode....................................................................................................................................................................... 93.3

Trigger Mode..............................................................................................................................................................................103.4

3.4.1 Trigger Type...................................................................................................................................................................10

3.4.2 Trigger Source ..............................................................................................................................................................12

Trigger Delay..............................................................................................................................................................................163.5

I/O Control ..................................................................................................................................................................................163.6

3.6.1 Non-isolated Differential Signal ............................................................................................................................17

3.6.2 Non-isolated Single-ended Signal........................................................................................................................17

3.6.3 Isolated Single-ended Signal..................................................................................................................................19

3.6.4 Configuring I/O Output Signal...............................................................................................................................19

I/O Filtering.................................................................................................................................................................................193.7

FPN Correction..........................................................................................................................................................................203.8

Black Level ..................................................................................................................................................................................213.9

Gain.............................................................................................................................................................................................213.10

3.10.1 Analog Gain................................................................................................................................................................21

3.10.2 Digital Gain .................................................................................................................................................................21

White Balance..........................................................................................................................................................................223.11

Gamma ......................................................................................................................................................................................233.12

Transmission Layer Management (TAP Settings).......................................................................................................243.13

3.13.1 CameraLink Line Scan Camera Transmission Layer.....................................................................................24

3.13.2 GigE Line Scan Camera Transmission Layer....................................................................................................25

Testimage (Test Mode).........................................................................................................................................................293.14

Rotary Encoder FAQ ................................................................................................................... 30Appendix 1

External Input Interfaces of Line Scan Camera ........................................................................ 34Appendix 2

Line Scan Camera Models.......................................................................................................... 36Appendix 3

Cybersecurity Recommendations ............................................................................................. 37Appendix 4