5

1. GENERAL DOCUMENTATION

1.1. GENERAL WARNINGS

1.2. PREAMBLE

1.3. TRANSPORT AND HANDLING

•

•

•

•

•

•

•

The present manual is an integral part of the product.

It supplies all of the necessary conditions for correct

installation, use and maintenance of the machine.

The user is obliged to read this manual carefully and

to refer to it always. It must be kept in a known place,

accessible to all authorised operators (installer, user,

maintenance technician).

The blast chiller is intended for professional use.

Therefore only qualified personnel can use it.

The blast chiller is destined to be used only for that

for which it was designed.

The Blast Chiller shall not be installed and utilized in an

explosive environment (presence of explosive powder

or gas)

The manufacturer declines all liability for damage

caused by improper and unreasonable use, such as:

- improper use by untrained personnel.

- modifications or interventions not specifically for the

model.

- use of non-original spare parts or parts not specifically

for the model.

- lack of compliance, even partial, with the instructions

in this manual.

Installation must be carried out by authorised and

specialised staff, respecting the instructions in this

manual. The manufacturer declares and assigns a

Declaration of Conformity to the 2006/42, Machinery

Directive, to the 2014/35/UE Directive and to the

2014/30/UE. Directive to each individual machine

In compliance with directive 97/23/EC, based on the

model the equipment is supplied together with the user

manuals and declarations of conformity of the:

• safety valve;

• liquid receiver;

• liquid separator;

• liquid receiver + separator;

• compressors

• oil separator;

• safety pressure switches.

The joints made by IRINOX S.p.a. comply with the

standard EN14276-2

IMPORTANT NOTE: IRINOX reminds you that all the

machines must undergo periodical inspections in

compliance with national standards in force.

•

Loading and unloading the appliance from the trans-

portation vehicle can be performed with a forklift

truck or pallet mover. The forks must be longer than

half the length of the appliance. The lifting device

must be chosen suitably, based on the dimensions

and mass of the packagedmachine, indicated on the

packaging labels.

All due precautions must be taken to handle the appli-

ance in order not to damage it, respecting the indica-

tions on the packaging.

1.4. UNPACKING

Remove the cardboard, wooden or crate packaging

upon which the blast chiller is placed. Lift the blast

chiller with a suitable means (lift truck), remove the

wooden base and position the machine in the intended

area (see par. 2.2).

After having removed the packaging, make sure that

the blast chiller is intact.

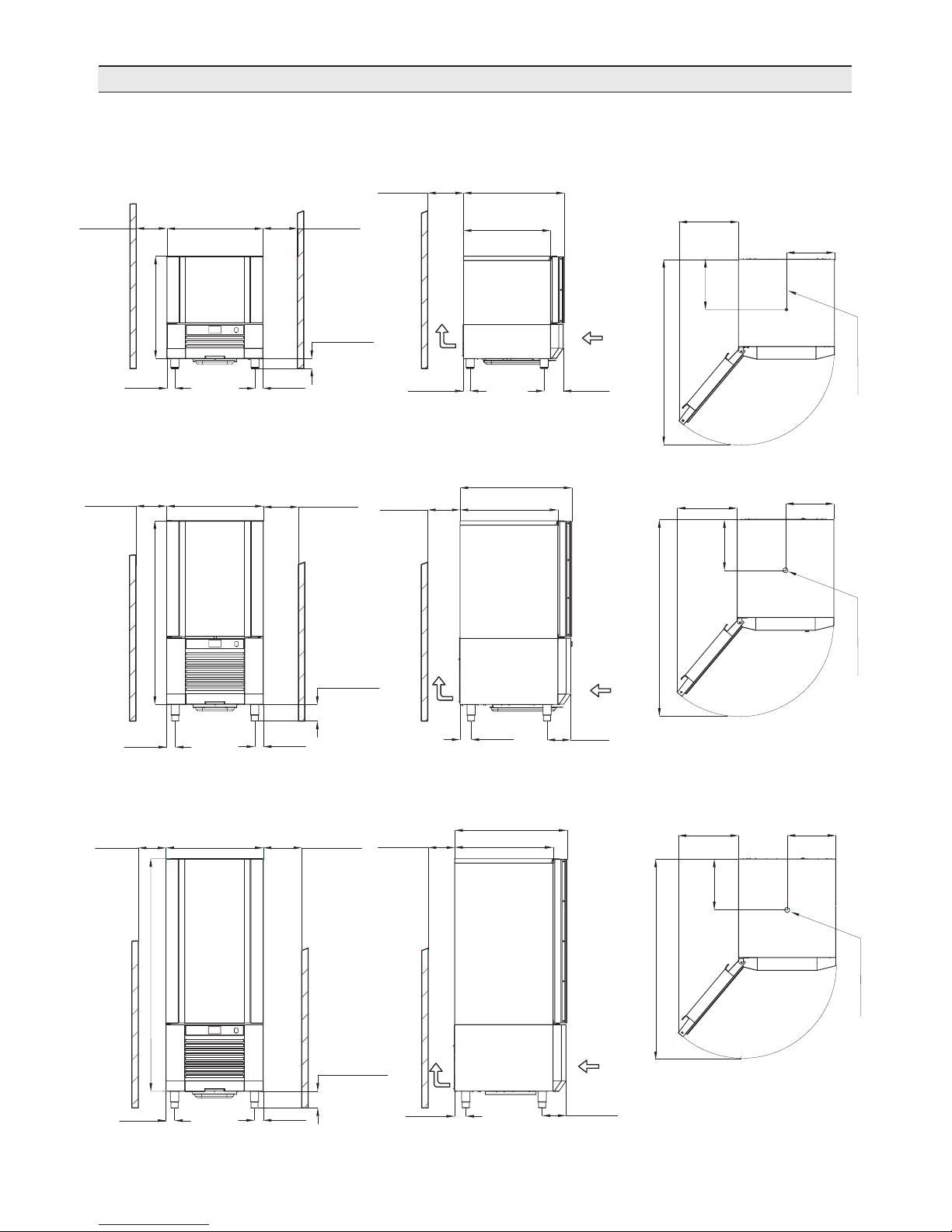

Remove the protective PVC film from all sides (Fig.1).

Use protective gloves to handle the packagin-

gand wooden base.

N.B.: all of the various packaging components must

be disposed of according to the Standards in force in

the Country where the appliance is used. In no case

must anything be dispersed into the environment.

•

•

•

Fig. 1